AutoMeter AC-14 User manual

8

1

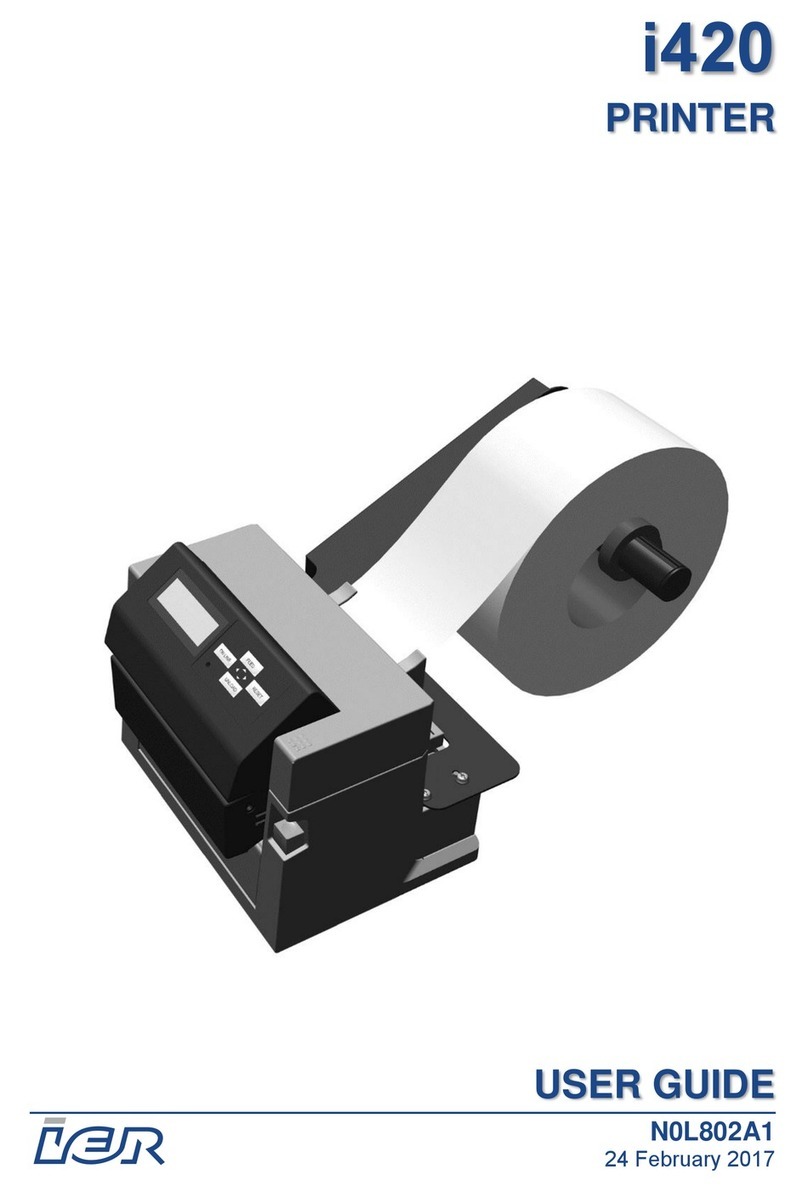

AC-14 Internal Printer

Installation Manual

For use with the Xpress XTC-150 and BVA-2100

The AC-14 Internal printer allows for individual test printouts with

complete test results. Results can also be printed from Auto Meter’s

hand-held testers using an infrared signal.

2650-539X-10

Rev. D

Test Equipment

Auto Meter Products Inc.

413 West Elm Street

Sycamore, IL 60178

Toll Free (866) 883-TEST (8378)

Fax (815)-815-895-6786

www.autometer.com

2

7

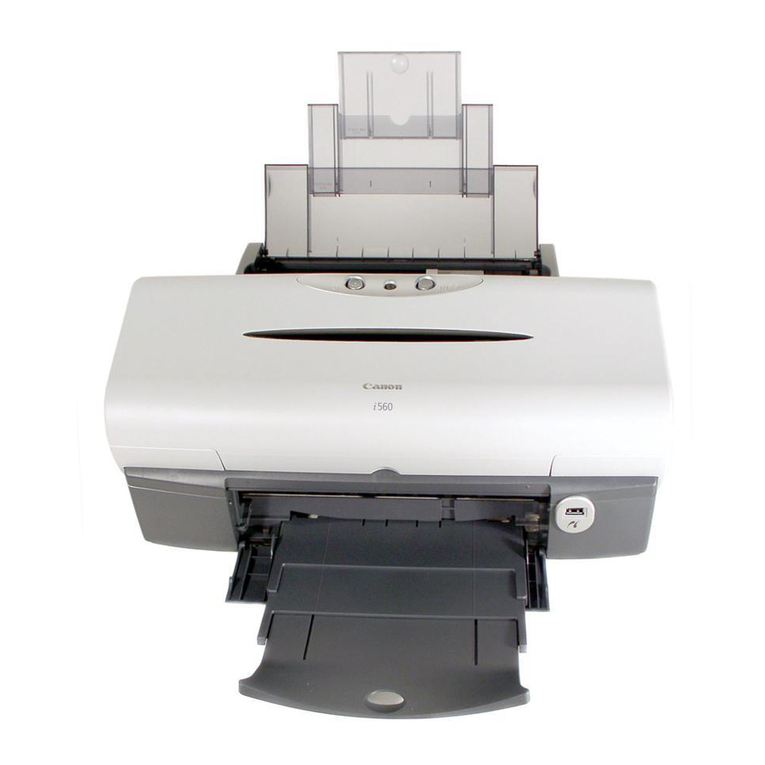

Window for Infrared Receiver

PRINTER INSTALLATION

1. Disconnect any load clamps

from the battery and unplug

the unit from any AC source

before installing the AC-14

printer..

2. Loosen the thumbscrew at

the bottom of the printer

cover plate and remove

entire cover. Save cover if

you think you might want

to use your tester without

a printer. Do not operate

without the printer or cover

plate installed.

3. Carefully pull the printer ribbon cable through the door opening as

shown in the illustration above, but do not disconnect the cable from

the PC board located just behind the front panel.

4. Align the ribbon cable parallel to the printer as shown below.

Note: Next to the PC board the ribbon cable runs in from the

connector. At the printer the ribbon wraps in front as shown.

Do not twist or fold the ribbon cable.

5. Carefully attach the ribbon connector to the pins at the printer. Use

care and do not force. Consider that the pins may not be aligned

Infrared Receiver

This window should be kept clear of obstructions if an Auto Meter hand-

held tester is used to send an infrared signal.

properly.

6. Install the printer making sure the

ribbon is on the outside of the paper

shield and is not crimped at the

door edge. Insert the top tab under

the panel before tightening the

thumbscrew.

Standard 58mm roll thermal paper is

available at your ofce supply

LIMITED WARRANTY

AC-14 1 YEAR FROM DATE OF PURCHASE

The manufacturer warrants to the consumer that this product

will be free from defects in material or workmanship for a

period of one (1) year from the date of original purchase.

Products that fail within this 1 year warranty period will

be repaired or replaced at the manufacturer's option to the

consumer when determined by the manufacturer that the

product failed due to defects in material or workmanship. This

warranty is limited to the repair or replacement of parts and

the necessary labor by the manufacturer to effect the repair or

replacement of the product. In no event shall the manufacturer

be responsible for special, incidental or consequential damages

or costs incurred due to the failure of this product.

Improper use, accident, water damage, abuse, unauthorized

repairs or alterations voids this warranty. The manufacturer

disclaims any liability or consequential damages due to breach

of any written or implied warranty on its test equipment.

WARRANTY AND SERVICE INFORMATION

Warranty claims to the manufacturer's service department

must be transportation prepaid and accompanied with dated

proof of purchase. This warranty applies only to the original

purchaser and is non-transferable. Shipper damage incurred

during return shipments is not covered under this warranty. It

is the responsibility of the shipper (the customer returning the

Test Equipment) to package the tester properly to prevent any

damage during return shipment. Repair costs for such damages

will be charged back to shipper (customer returning the Test

Equipment). Protect the product by shipping in the original

carton. Add plenty of over-pack cushioning such as crumpled

up newspaper.

6

3

PRINTER OPERATION

1. Disconnect clamps from any battery.

2. Loosen the thumbscrew at the bottom

of the printer.

3. Carefully remove the cover.

4. Replace the new paper roll by feeding

it under the roll and over the PC board

as illustrated on the paper shield label. Press the FEED button to

check the advance of the paper. XTC-150 must be turned on.

5. It is best not to disconnect the ribbon cable. However, if the ribbon

cable is disconnected, upon reconnection make sure the top edge

of the ribbon attached to the unit is correctly aligned with the top of

the printer. Do not twist the ribbon cable. Make sure the pins are

aligned properly. Do not force, but make sure the connection is

solid.

6. Reinstall printer by inserting the top tab under the panel and

tightening the thumbscrew. Be careful not to damage the printer

ribbon.

With the BVA-2000 & BVA-2100 you may manually print after each

test. Simply press (PRINT). Results are displayed at the end of each test

or when a review of a previous test is displayed on the LCD.

Xpress XTC is automatically set to print after each test. You can

change the default to manual printing (see XTC printing options).

The results will not print until the test is completed and the results are

displayed. Note: Tear the paper with a downward motion to provide even

separation and avoid jamming of the next printing.

XTC Printing Options:

You have the option to set the printer to print automatically after

each test or only when you press the (PRINT) button.

Example: if the printer automatically prints test results and you

would prefer manual selection make sure battery is disconnected

then do the following: 1. Turn off the AC power

2. Press and hold the print button

3. Turn on the AC power

The option has now been changed. If the reverse is desired

repeat the same procedure.

Changing Paper:

1. Wait until the printer

is completely

nished

printing before

tearing paper off.

If the jam is not obvious,

and all visible papers is

removed, turn wheel on

the right hand side of the

mechanism. The printer

head will move to the

right making it easier

to detect and remove a

jamed paper.

TO PREVENT FUTURE PAPER JAMS

2. Always tear the

paper in a downward

motion. Never to the

right against the end.

REMOVING JAMED PAPER

For Technical support

see back cover for con-

tact information.

Standard 58mm roll

paper is found at most

ofcsupply.

4

5

1. If paper is still in the

printer, cut at paper roll.

2. Pull paper out from

front. Pulling paper from

the back could tear paper

and leave jammed section

inside. If there is no paper

to pull and the paper will

not advance by pressing

the feed button, proceed

to step 2.

3. Removing paper roll

from the bracket will make

disassembly easier.

CHECKING FOR PAPER JAM

6. If a jam is obvious,

carefully remove it.

This jam is usually

due to tearing paper to

the right causing it to

buckle and keep the

head from passing or

returning.

5. Turn PC Board

over and look in

left side of printer

mechanism for paper

jam.

Note: print head is usually where

the jam occures

4. Using a Philips

screwdriver, remove

all four screws from

back of PC Board.

REMOVING PAPER JAM

Other AutoMeter Printer manuals