8 37

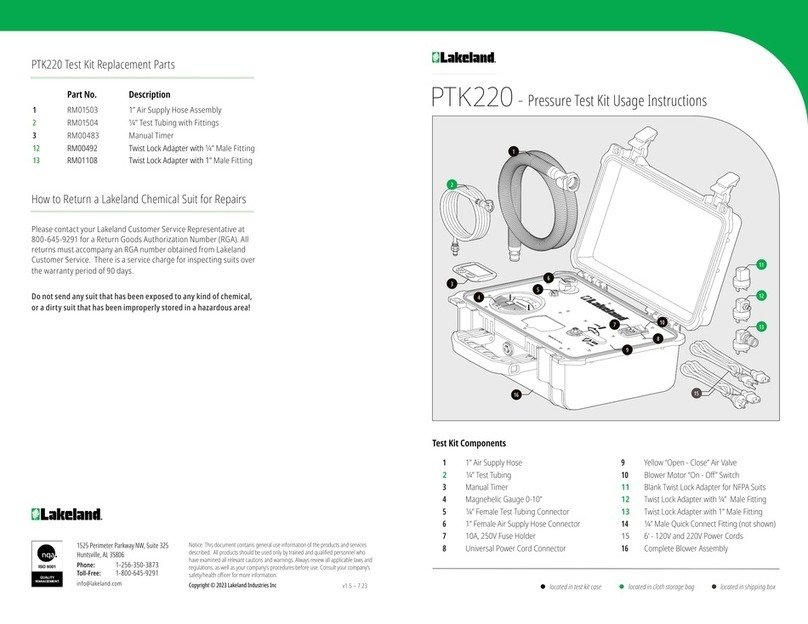

The following may be needed in fleet operations. The manual will assume NO in

all cases. If you select YES, you will be asked to input the information or perform

certain checks as requested in each test.

CONFIGURING THE BVA-2100/RYD (Cont.)

To require vehicle ID numbers select

YES. The manual will assume NO.

To require technician numbers select

YES. The manual will assume NO.

To require visual checks select YES.

The manual will assume NO. The visual

checks, when required for a particular test,

will request CHECKS before continuing

such as:

To require a battery serial number before

each battery test select YES. The manual

will assume NO. If YES is selected then

before each battery test the tester will

prompt for a 14 digit alpha-numeric serial

number. This serial number will be printed

near the bottom of the printout along with

the warranty code.

To require battery date code select

YES. The manual will assume NO.

Select MARGINAL BATTERY to allow

the test result to be MARGINAL

BATTERY when a battery is close to

being bad or select GOOD OR BAD

ONLY to not allow marginal as a test

result.

--CONFIGURATION--

>REQUIRE VEHICLE

ID NUMBERS? YES

USE +/-

'Y' TO SELECT

--CONFIGURATION--

>REQUIRE TECHNICIAN

NUMBERS? YES

USE +/-

'Y' TO SELECT

--CONFIGURATION--

>REQUIRE VISUAL

CHECKS? YES

USE +/-

'Y' TO SELECT

--CONFIGURATION--

>REQUIRE BATTERY

NUMBERS? NO

USE +/-

'Y' TO SELECT.

--CONFIGURATION--

>USE TEST RESULTS:

MARGINAL BATTERY.

USE +/-

'Y' TO SELECT.

--CONFIGURATION--

>REQUIRE BATTERY

DATE CODES? NO

USE +/-

'Y' TO SELECT.

When inputting numbers when required in each test, there will be a set of 0000. Use

the (UP) or (Down) key to select the desired number for the rst zero then press

(ENTER) to advance to the next 02000.

INSPECT BELT CONDITION – TENSION

INSPECT CABLES AND ALTERNATOR OUTPUT

INSPECT BATTERY FOR DIRT, LEAKS OR CRACKS

INSPECT POSTS AND CONNECTIONS

The date code has a letter for the

month (A to M) and 01/00 for the day

and the year. You have to increment

each of these to the desired date that

will print out in the standard 00/00

format.

Charging

Cables

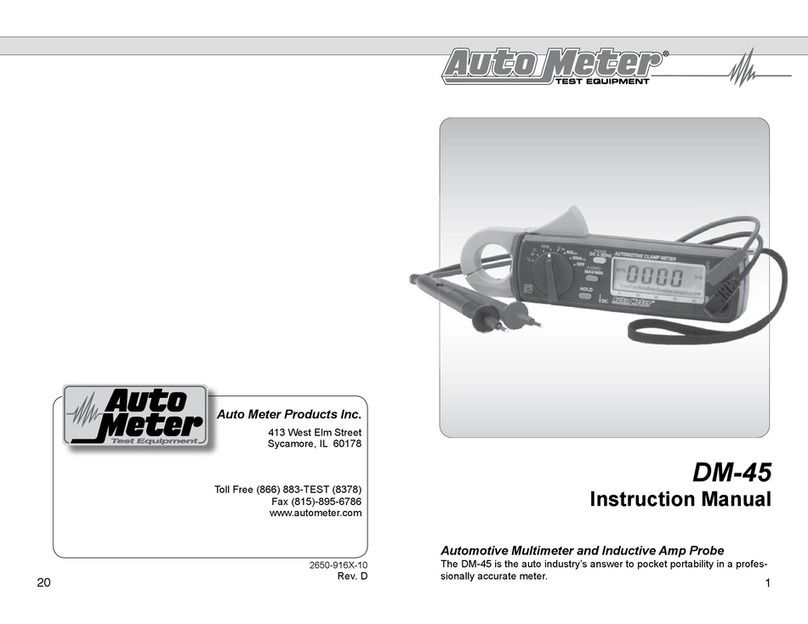

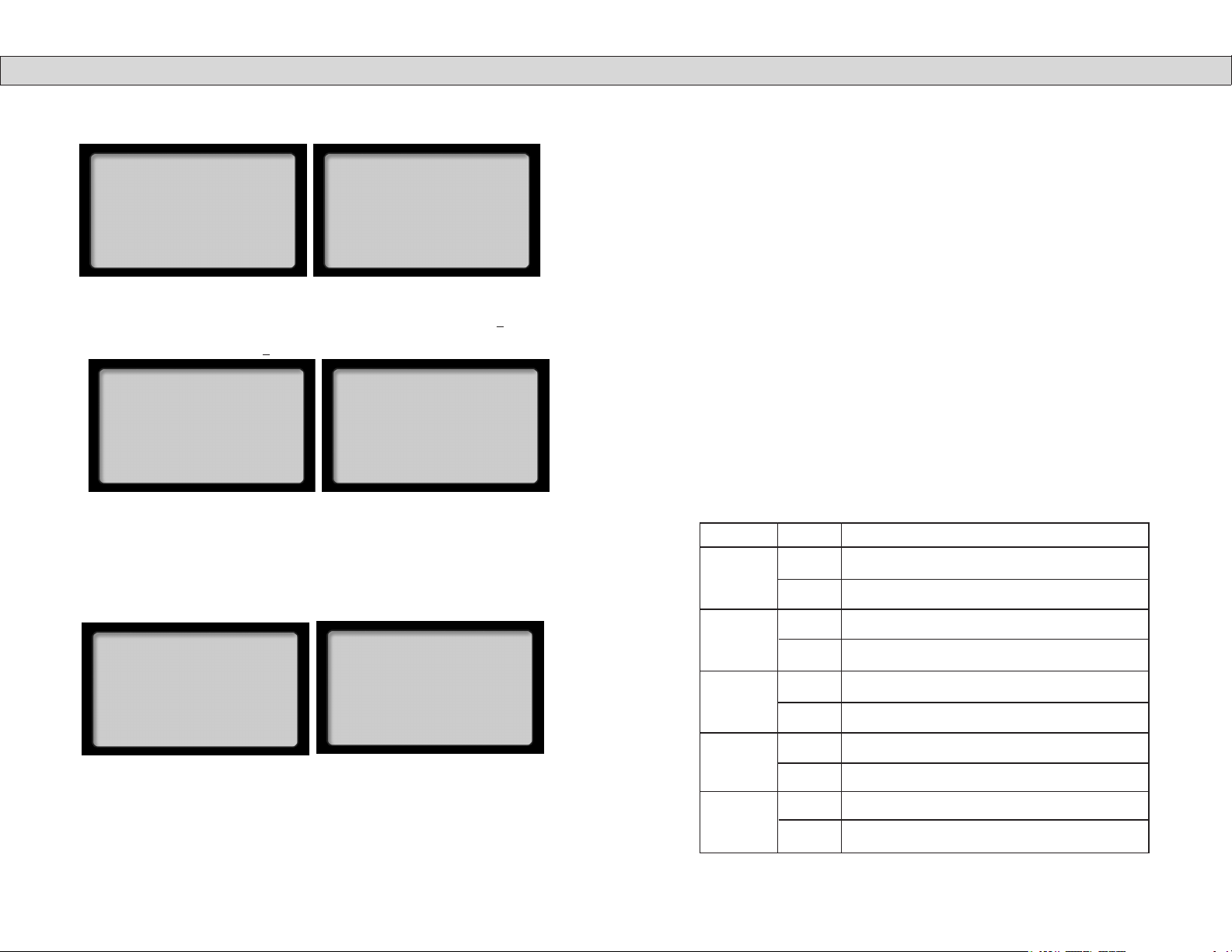

TEST SYSTEM PASS/FAIL

12 Volt Maximum drop at rated alternator output is 0.5 Volts

Maximum drop at rated alternator output is 1.0 Volts

Maximum drop at 500 Amps is 0.5 Volts

Maximum drop at 250 Amps is 1.0 Volts

Maximum drop at 80 Amps is 1.0 Volts

Maximum drop at 40 Amps is 2.0 Volts

Reports the drops at the entered current

Reports the drops at the entered current

24 Volt

12 Volt

24 Volt

12 Volt

24 Volt

12 Volt

24 Volt

Main

Starting

Cables

Magnetic

Circuit

Straight

Drive

Maximum drop at 300 Amps is 1.0 Volts

Maximum drop at 225 Amps is 2.0 Volts

12 Volt

24 Volt

Magnetic

Circuit

Gear

Reduction

Generic

Voltage

Drop Test

DEFINITIONS - SYSTEM SPECIFICATIONS

VOLTAGE DROP TESTS

The specications for those tests are listed below.

The minimum system voltage to run a test is 12.25 Volts for a 12 Volt

system and 24.5 Volts for a 24 Volt system.

During each battery test the BVA-2100/RYD uses various results that are

displayed after each test. The denition of those results are as follows:

• % Charge = an approximate amount of charge the battery is

currently holding. This is based upon the batteries voltage.

• Est. CCA = is the approximate CCA of the fully charged battery.

• GOOD BATTERY = a battery that is good and is charged.

• GOOD NEEDS CHARGE = a battery that is good but is low on

charge.

• MARGINAL BATTERY = a battery that has passed the load

test but the estimated CCA is getting low or the battery is

approaching its end of life.

• CHARGE and RETEST = a battery with insufcient charge to

provide accurate test results.

• BAD BATTERY = a battery that is bad and should be replaced.

A bad battery is a battery that failed the load test or had an

estimated CCA below about 70% of the rated value.

BATTERY TEST