7 8

DELETE: Delete the present test data, the value of Test No. will

deduct 1 after every time pressing this key.

SELECT: Enter the operating menu on the screen.

CLEAR: Set zero for scale of microscope during measurement,

only needs to set zero one time after power on the machine.

Select the test scale:

2

Press “

“MEASURING SCALE” by using up and down keys, press “OK”

and

SELECT” to enter the menu as below, move the cursor to

move the cursor to “MEASURING SCALE” by using up and

down keys, press “OK” to confirm and back to initial interface.

Set dwell time:

3

Press “SELECT” to enter the menu as below, move the cursor to

“DWELLING TIME” by using up and down keys, press “OK” and

move the cursor to “MEASURING SCALE” by us/ing “+/-” keys,

press “OK” to confirm and back to initial interface.

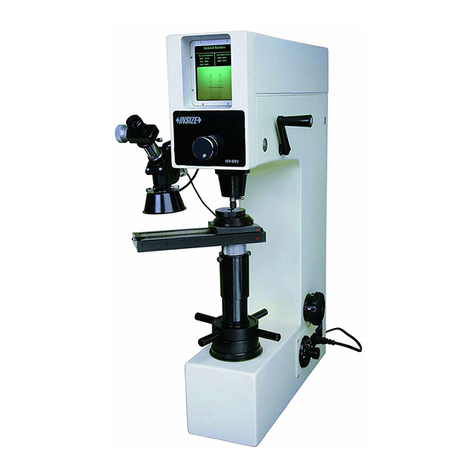

Install the indenter:

4

Select right indenter according to the measuring scale, insert it to

the mount hole and lock the screw.

Start to test:

5

Turn the turret and make the indenter in front with a click sound,

make the workpiece stable. Press “CLR-F” to zero the test force,

slowly lift the stage and the test force on screen keep changing

until there is a promotion tone, now the test force is about 27kgf

(when test force less than or equal to 250kgf) or 90kgf

, the machine will start to loading the main

test force.

(when test

force larger than 250kgf)

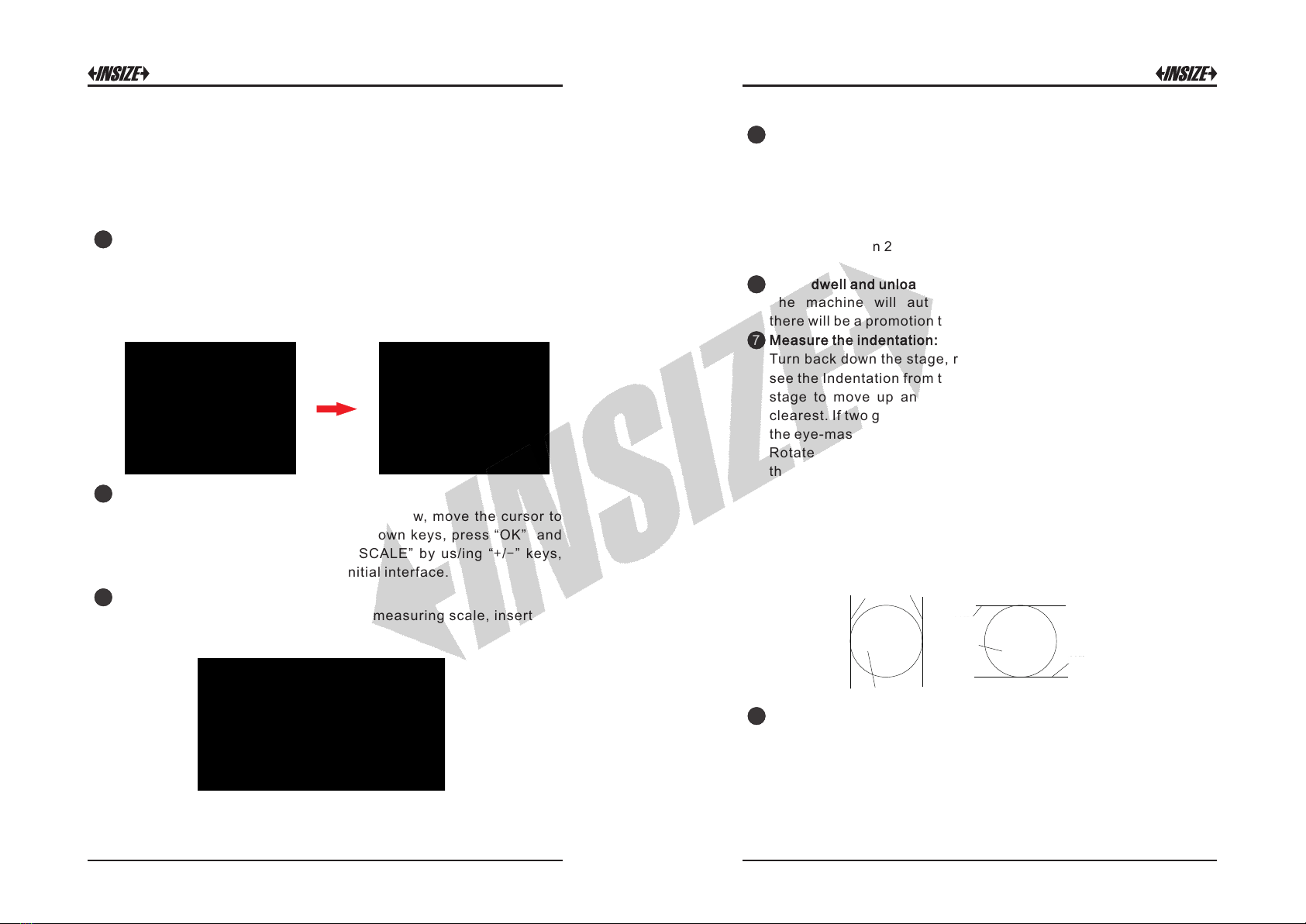

Load, dwell and unload:

6

The machine will automatically loading, dwell and unloading,

there will be a promotion tone after unload.

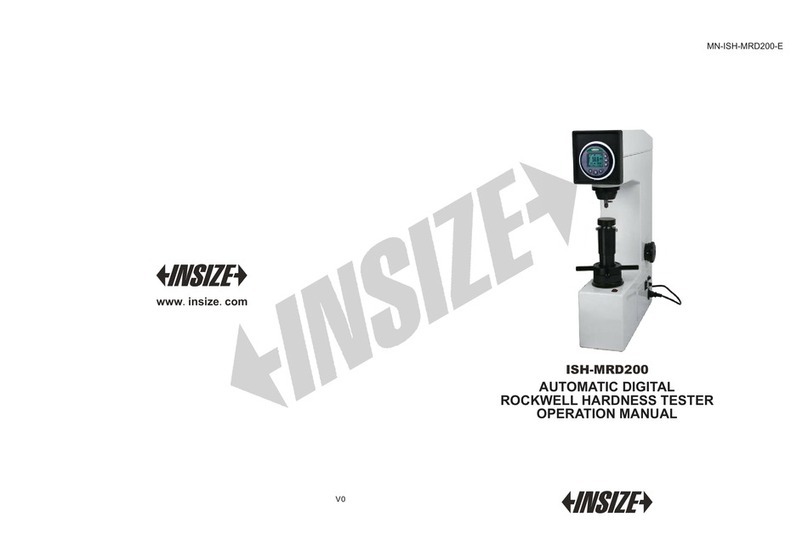

Measure the indentation:

7

Read the hardness value:

6

The hardness value will be shown on screen after two times

measurements, press “PRINT” key to print the results.

8

Note: The first measurement will not be counted, normally we test

5 times to get the average value for a workpiece.

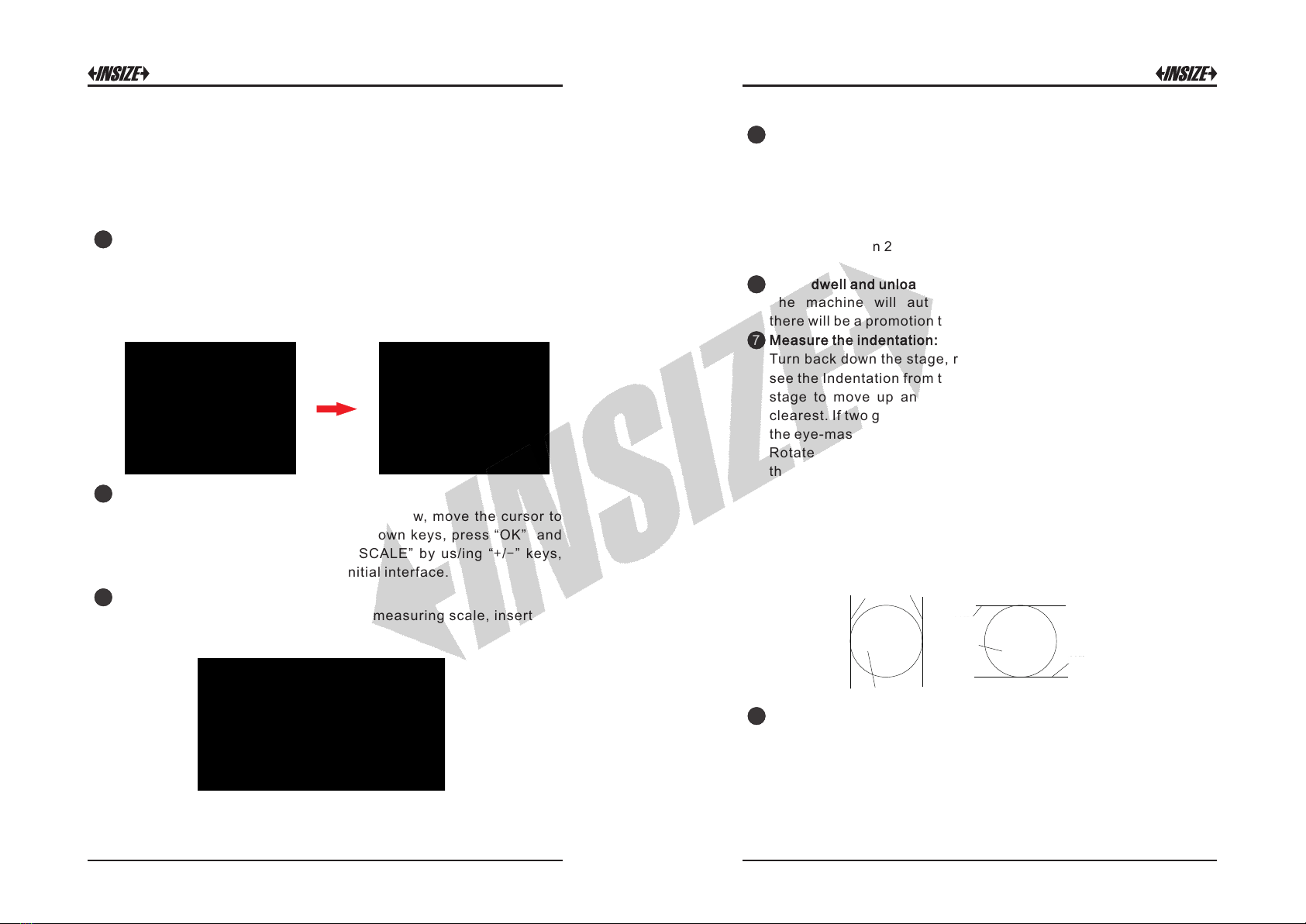

Turn back down the stage, rotate the objective to front direction to

see the Indentation from the vision field of the eyepiece. Adjust the

stage to move up and down till the image of the Indentation is

clearest. If two graduated lines seem vague in the eyepiece, adjust

the eye-mask till the graduated lines are clearest.

Rotate the f to move

the graduated line of eyepiece, enable two graduated lines

closely. When the two lines are align, press “CLEAR” Key, at this

time, the value on the main screen is zero

Now separate the two lines in two side of the indentation and press

measuring button to get the first diameter, then turn the eyepiece

90° to measure the diameter again

ine adjustment and scale moving handwheel

.

.

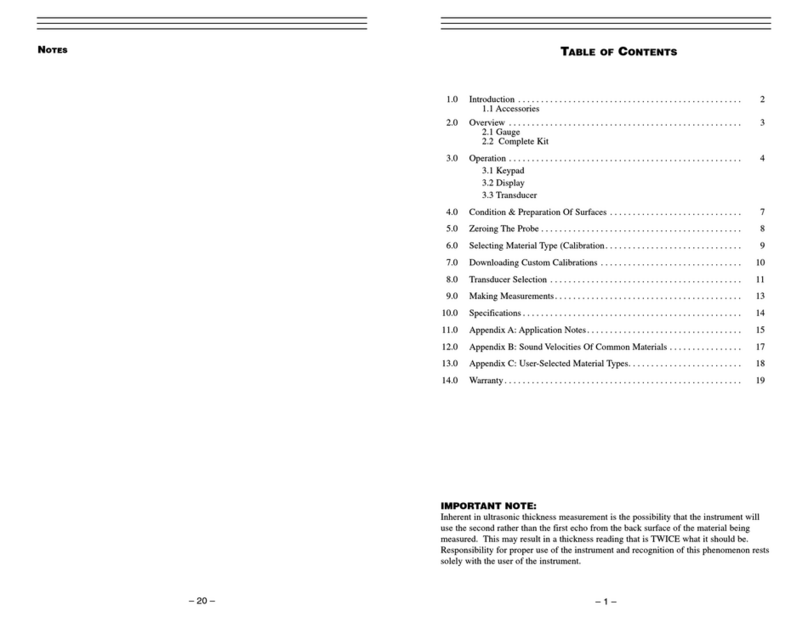

left line right line

indentation

left line

right line

indentation