Autoquip SRP Setup guide

INSTALLATION, OPERATION

AND SERVICE MANUAL

‘SRP’-‘SRPR’-‘SRPRB’

POWERED TURNTABLE

P.O. Box 1058 •1058 West Industrial Avenue •Guthrie, OK 73044-1058 •888-811-9876

•405-282-5200 •FAX: 405-282-3302 •www.autoquip.com

Item # 830SRP Version 2.0

10/2009

TABLE OF CONTENTS

Identification and Inspection 3

Responsibility of Owners / Users 4

SafetySignalWords 5

SafetyPractices 6

Label Identification 9

Specifications 12

Installation Instructions 15

Operating Instructions 18

Routine Maintenance 20

General Maintenance 21

Replacement Parts List 34

Troubleshooting Analysis 38

Warranty 40

IMPORTANT

Please read and understand this manual prior to installation or operation of this

equipment. Failure to do so could lead to property damage and/or serious personal

injury. If any questions arise, call a local representative or Autoquip Corporation at

888-811-9876 or 405-282-5200.

PLANNED MAINTENANCE PROGRAM

A local Autoquip representative provides a Planned Maintenance Program (PMP) for

this equipment using factory-trained personnel. Call a local representative or Autoquip

Corporation at 1-888-811-9876 or 405-282-5200 for more information.

2

IDENTIFICATION & INSPECTION

IDENTIFICATION

PLEASE HAVE THE MODEL NUMBER AND SERIAL NUMBER of the turntable, when

ordering parts or requesting information or service. This information is on the

nameplate attached to the turntable assembly. Replacement parts are available from a

local Autoquip distributor.

INSPECTION

Immediately upon receipt of the turntable, a visual inspection should be made to

determine that it has not been damaged in transit. Any damage found must be noted on

the delivery receipt. In addition to this preliminary inspection, the turntable should be

carefully inspected for concealed damage. Any concealed damage found that was not

noted on the delivery receipt should be reported in writing to the delivering carrier within

48 hours.

The following is a checklist that will aid you in the inspection of this turntable:

1. Examine entire unit for any signs of mishandling or damage. Pay special

attention to the power unit and PUSH BUTTONS.

2. Using an overhead hoist, remove the turntable platform. Thoroughly examine all

base rollers, bolts and hex nuts. Inspect the base frame and turntable, making

sure they have not been damaged during transit. For units that have the controls

mounted and wired inspect wiring for any signs of damage.

3. After inspection, lag the turntable base securely to the floor or lift platform. Using

the overhead hoist, assemble the turntable on the base, and inspect the turntable

operation.

3

RESPONSIBILTY OF OWNERS/USERS

DEFLECTION

It is the responsibility of the user/purchaser to advise the manufacturer where deflection

may be critical to the application.

INSPECTION & MAINTENANCE

The turntable shall be inspected and maintained in proper working order in accordance

with Autoquip’s Operation & Service Manual and with other applicable safe operating

practices.

REMOVAL FROM SERVICE

Any turntable not in safe operating condition such as, but not limited to, missing rollers,

pins, or fasteners, any bent or cracked structural members, cut or frayed electrical

wires, damaged or malfunctioning controls, detents or manual locks, etc. shall be

removed from service until it is repaired to the original manufacturer’s standards.

REPAIRS

All repairs shall be made by qualified personnel in conformance with Autoquip’s

instructions.

OPERATORS

Only trained personnel and authorized personnel shall be permitted to operate this

turntable.

BEFORE OPERATION

Before using the unit, the operator shall have:

•Read and/or had explained, and understood, the manufacturer’s operating

instructions and safety rules.

•Inspected the turntable for proper operation and condition. Any suspect item

shall be carefully examined and a determination made by a qualified person as to

whether it constitutes a hazard. All items not in conformance with Autoquip’s

specification shall be corrected before further use of the turntable.

DURING OPERATION

The equipment shall only be used in accordance with Autoquip’s Operation & Service

Manual.

•Do not overload the turntable.

•Ensure that all safety devices are operational and in place.

MODIFICATIONS OR ALTERATIONS

Modifications or alterations to industrial turntable shall be made only with written

permission of Autoquip. Autoquip does not foresee and does not anticipate

unauthorized modifications, and these changes or alterations are grounds for voiding all

warranties.

4

SAFETY SIGNAL WORDS

SAFETY ALERTS (Required Reading!)

The following SAFETY ALERTS are intended to create awareness of

owners, operators, and maintenance personnel of the potential safety

hazards and the steps that must be taken to avoid accidents. These same

alerts are inserted throughout this manual to identify specific hazards that

may endanger uninformed personnel. Identification of every conceivable

hazardous situation is impossible. Therefore, all personnel have the

responsibility to diligently exercise safe practices whenever exposed to this

equipment.

____________________________________________________________

DANGER!

Identifies a hazardous situation, which, if not avoided, will result in death or

severe personal injury.

_

____________________________________________________________

WARNING!

Identifies a hazardous situation, which, if not avoided, could result in death

or serious personal injury.

CAUTION!

Identifies a hazardous situation, which, if not avoided, may result in minor

or moderate personal injury.

_____________________________________________________________

NOTICE!

Indicates a potentially hazardous situation, which, if not avoided, may result

in property or equipment damage.

5

SAFETY PRACTICES

Read and understand this manual and all labels prior to

operating or servicing the turntable. All labels are provided

in accordance with ANSI Z535.4.

DANGER!

6

The turntable base MUST be lagged securely to the floor or sufficient

structure, or attached to a lift platform (when applicable) before operating

the turntable. An unsecured base could become unstable and cause the

load to shift unexpectedly resulting in serious personal injury or death.

DANGER!

HIGH VOLTAGE!! Disconnect and/or lock out the electrical supply to the

power unit per OSHA regulations prior to any maintenance being performed.

DANGER!

To avoid personal injury or death, do not use the unit in or around an area

where flammable liquids or vapors may be present.

DANGER!

To avoid personal injury or death, do not use the unit near water. If

electrical parts become wet, electrical shock may occur.

DANGER!

Extending the platform length or width beyond the factory limit could cause

the turntable to tip and the load to shift unexpectedly, resulting in personal

injury or death.

SAFETY PRACTICES

WARNING!

NEVER stand, sit, or ride on the turntable! A rotating work surface may

shift position unexpectedly and cause serious personal injury.

WARNING!

All warning and information decals should be in place as outlined in the

“Label Identification” section. If decals are missing or damaged, they

should be replaced with new decals. Contact Autoquip for replacements.

WARNING!

Do not install the turntable in a pit unless it has beveled-toe guards or other

approved toe protection. A shear point can exist which can cause severe

personal injury.

WARNING!

Load the turntable top as evenly as possible to prevent overloading.

Excessive eccentric loading may overstress the turntable structure and

cause the load to become unstable, possibly resulting in serious personal

injury.

7

SAFETY PRACTICES

WARNING!

To avoid personal injury, stand clear of the unit when the turntable is in

motion.

WARNING!

Familiarize yourself with the operator’s manual before operating this

equipment.

NOTICE

Do not continue to depress the “CW” or “CCW switch if the platform does

not turn or if the platform is jammed. To do so may result in permanent

damage to the motor or speed reducer.

NOTICE

Do not operate the turntable if the torque limiter is out of adjustment.

8

1

TOP OF TURNTABLE

BASE

5

4

Figure 1: Decal Placement Diagram

POWERED Turntable Decals

Item No. Qty Description Part No.

1 3 DECAL, CAPACITY : x,000 POUNDS; (2-1/2” x 11”) 36401586

2 2 DECAL, WARNING-NO RIDERS; (2” x 6”) 36403707

3 2 AUTOQUIP LOGO (3” x 7”) 36403220

4 1 AUTOQUIP Serial Number Nameplate (2” x 8”) 36401560

5 2 WIRE CODE Identification (4” x 4”) 36403343

LABEL IDENTIFICATION

9

LABEL IDENTIFICATION

Note: Labels shown here are not actual size, see Figure 1 for

location of label on Turntable.

Figure 2: Capacity Decal (36401586)

Figure 3: WARNING-NO RIDERS Decal (36403707)

Figure 4: AUTOQUIP LOGO Decal (36403220)

10

LABEL IDENTIFICATION

Note: Labels shown here are not actual size, see Figure 1 for

location of label on Turntable.

Figure 5: Serial Number Nameplate (36401560)

Figure 6: WIRE CODE Identification Decal (36403343)

11

‘SRP’ TURNTABLE --“CHAIN & SPROCKET DRIVE”

Standard

Model Rotating

Capacity

Platform

Dimensions

Base

Dimensions

Lowered

Height

Speed

(RPM)

Shipping

Weight

SRP-36-25 2,500 36 x 36 24 x 24 10 3.50 385

SRP-36-40 4,000 36 x 36 24 x 24 10 3.50 385

SRP-36-60 6,000 36 x 36 24 x 24 10 3.50 385

SRP-42-25 2,500 42 x 42 24 x 24 10 3.50 450

SRP-42-40 4,000 42 x 42 24 x 24 10 3.50 450

SRP-42-60 6,000 42 x 42 24 x 24 10 3.50 450

SRP-4248-25 2,500 42 x 48 24 x 24 10 3.50 485

SRP-4248-40 4,000 42 x 48 24 x 24 10 3.50 485

SRP-4248-60 6,000 42 x 48 24 x 24 10 3.50 485

SRP-48-25 2,500 48 x 48 24 x 24 10 3.50 525

SRP-48-40 4,000 48 x 48 24 x 24 10 3.50 525

SRP-48-60 6,000 48 x 48 24 x 24 10 3.50 525

TURNTABLE SPECIFICATIONS

‘SRPR’ ROUND TURNTABLE -- “CHAIN & SPROCKET DRIVE”

Standard

Model Rotating

Capacity

Platform

Diameter

Base

Dimensions

Lowered

Height

Speed

(RPM)

Shipping

Weight

SRPR-36-25 2,500 36 24 x 24 10 3.50 375

SRPR-36-40 4,000 36 24 x 24 10 3.50 375

SRPR-36-60 6,000 36 24 x 24 10 3.50 375

SRPR-42-25 2,500 42 24 x 24 10 3.50 440

SRPR-42-40 4,000 42 24 x 24 10 3.50 440

SRPR-42-60 6,000 42 24 x 24 10 3.50 440

SRPR-48-25 2,500 48 24 x 24 10 3.50 520

SRPR-48-40 4,000 48 24 x 24 10 3.50 520

SRPR-48-60 6,000 48 24 x 24 10 3.50 520

12

SPECIFICATIONS

‘SRPRB’ TURNTABLE -- “RING BEARING DRIVE”

Standard Model Rotating

Capacity

Platform

Dimensions

Base

Dimensions

Lowered

Height

Speed

(RPM)

Shipping

Weight

SRPRB-36-25 2,500 36 x 36 24 x 24 10 1.00 650

SRPRB-36-40 4,000 36 x 36 24 x 24 10 1.00 680

SRPRB-36-60 6,000 36 x 36 24 x 24 10 1.00 705

SRPRB-42-25 2,500 42 x 42 24 x 24 10 1.00 675

SRPRB-42-40 4,000 42 x 42 24 x 24 10 1.00 705

SRPRB-42-60 6,000 42 x 42 24 x 24 10 1.00 730

SRPRB-42-48-25 2,500 42 x 48 24 x 24 10 1.00 700

SRPRB-42-48-40 4,000 42 x 48 24 x 24 10 1.00 730

SRPRB-42-48-60 6,000 42 x 48 24 x 24 10 1.00 755

SRPRB-48-25 2,500 48 x 48 24 x 24 10 1.00 775

SRPRB-48-40 4,000 48 x 48 24 x 24 10 1.00 1000

SRPRB-48-60 6,000 48 x 48 24 x 24 10 1.00 1025

LOAD CAPACITY

1. The load capacity rating is labeled on the top of the turntable platform.

WARNING!

The Turntable should not be overloaded beyond the established

Capacity as damage and/or personal injury may result.

2. When attaching the turntables to other pieces of equipment such as scissors lifts,

remember that the rated capacity of the turntable must not exceed the rated capacity

of the lift, tilter, etc.

13

SPECIFICATIONS

UNBALANCED LOADING — CHAIN & SPROCKET MODELS:

1. All standard turntable capacities assume that the load on the turntable is

uniformly distributed and that the center of gravity of the load is placed

within 10” of the center pin.

2. Standard turntables are not designed to withstand true edge or axle loading.

If edge or axle loading is anticipated, additional turntable support rollers must be

located at the turntable edges for this design. Contact Autoquip Service Department

for questions on turntable loading.

WARNING!

Load the turntable top as evenly as possible to prevent

overloading. Excessive eccentric loading may overstress the

turntable structure and cause the load to become unstable,

possibly resulting in serious personal injury.

UNBALANCED LOADING — RING BEARING MODELS:

1. Ring bearing turntables are designed to withstand eccentric loading. Do not,

however, exceed the edge load rating stamped on the nameplate.

2. Though the platform is designed to withstand offset loading, ensure that the

turntable base is rigidly attached to its mounting surface to prevent tipping of

the load.

14

INSTALLATION INSTRUCTIONS

FLOOR INSTALLATION

1. Make sure floor is clean and level before starting.

2. Place the turntable in the installation area.

3. If the permanent electrical work is not complete, some means of temporary lines with

an on-off device for the power supply should be set up for testing purposes.

15

CAUTION!

When lifting the turntable, do not attempt to pick it up by the

platform; it is attached in the center only and could be damaged.

Pick up the turntable from under the base frame ONLY using a

strap sling.

4. Make temporary electrical connections. Operate the turntable to ensure that rotation

is in the proper direction.

5. If needed, shim to the desired height. DO NOT “spot” shim. Shim the full length of

the base frame. This will prevent the plate from bending under an exceptionally

heavy load.

DANGER!

HIGH VOLTAGE!! – Disconnect and/or lock out the electrical

supply to the power unit per OSHA regulations prior to any

installation or maintenance being performed.

6. The base plate of the turntable has pre-drilled holes for lagging it securely to the

floor. Mark the holes, drill, and install with anchors. Turntables with oversize

platforms have minimum pull out requirements of 2,000 lbs. for each anchor.

7. Make permanent electrical connections and operate the turntable through a few

cycles.

PIT INSTALLATION -- MODELS WITH BEVEL TOE GUARDS MOUNTED ON

SCISSOR LIFT or MOUNTED TO PIT FLOOR.

WARNING!

Do not install the turntable in a pit unless it has a bevel toe

guard or other approved toe protection. A shear point can exist

which can cause severe injury to the foot.

1. Check the pit dimensions. Length and width should be 2" longer (minimum) and 2”

wider (minimum) than the turntable or lift platform, whichever is greater.

2. Check the conduit chase entrance into the pit. The conduit diameter should be 3".

If the permanent electrical work is not complete, some means of temporary lines with

an on-off device for the motor control should be set up for testing purposes.

3. Make sure the pit floor is clean and level before starting. Lower the Lift and

Turntable into the pit and check for proper height. The turntable should be flush with

the pit angle framing. If needed, shim the LIFT BASE FRAME to the desired height.

DO NOT “spot” shim. Shim the ALL (4) Sides of the Lift base frame. This will

prevent the Lift Base from bending under an exceptionally heavy load.

16

CAUTION!

INSTALLATION INSTRUCTIONS

When lifting the turntable, do not attempt to pick it up by the

platform; it is attached only in the center and could be damaged.

Pick up the turntable from under the base frame ONLY using a

strap sling.

4. Make temporary electrical connections. Operate the turntable to ensure that rotation

is in the proper direction.

INSTALLATION INSTRUCTIONS

PIT INSTALLATION -- continued

DANGER!

HIGH VOLTAGE!! – Disconnect and/or lock out the electrical

supply to the power unit per OSHA regulations prior to any

installation or maintenance being performed.

5. The base frame of the turntable has pre-drilled holes for lagging it securely to the

floor. Mark holes, drill, and install with anchors. Turntables with oversize platforms

have minimum pull out requirements of 2,000 lbs. for each anchor.

6. Make the permanent electrical connections and operate the turntable through a few

cycles.

WARNING!

The turntable base MUST be attached securely to the lift

platform before operating the turntable.

NOTE: Turntables that have platform sizes larger than the lifts to which they are

attached must have toe protection, such as beveled-toe guards.

7. A home position limit switch is mounted to the turntable base and wired to the lift

controller. This will ensure that the turntable (in home position) is positioned

exactly over the pit opening before it is lowered into the pit. Home position for the

turntable allows 1” clearance between each side of the turntable and the pit

curb angle.

8. Lower the lift & turntable combination into the pit and check for proper lowered

height.

9. Make the permanent electrical connections and operate the combination through a

few cycles. Check to ensure that the lift will not lower until the turntable platform is in

home position (for four-sided platform).

CLEAN UP

1. Clean up any debris from the area. A clean installation makes a good impression

and creates a much safer environment!

2. Touch-up paint is available from Autoquip for repair of damaged paint surfaces.

17

OPERATING INSTRUCTIONS

18

WARNING!

All DANGER, WARNING, and CAUTION labels and informational

decals and plates must be intact and in place on the unit.

Contact an Autoquip representative if labels are missing or

damaged. See “Label Identification” section of this manual.

WARNING!

Familiarize yourself with this operator’s manual before

operating this equipment.

WARNING!

NEVER stand, sit or ride on the turntable! Personal injury could

result.

WARNING!

Personnel should always maintain a safe operating distance of

at least 36” away from any side of the turntable, any time the

turntable is operated.

1. Press the “CW” button to cause a clockwise rotation of the turntable. When the

“CW” button is pressed, the coil of the motor starter will close the line contact

permitting electrical power to be applied to the motor. The rotating motor shaft is

mechanically coupled to a gear reducer.

CHAIN AND SPROCKET DESIGN

The gear reducer has an output shaft keyed to a drive sprocket. A drive chain

connects the drive sprocket to a large diameter sprocket attached to the underside

of the turntable platform. As the motor rotates, the output shaft turns and rotates the

platform in the clockwise direction.

OPERATING INSTRUCTIONS

RING BEARING DESIGN

1. The gear reducer output shaft is keyed to a custom-fit gear that meshes with and

drives the drive ring of the ring bearing. The drive ring is bolted to and rotates the

turntable platform in the clockwise direction.

2. Press the “CCW” button to cause a counter-clockwise rotation of the turntable.

Pressing the “CCW” button will cause the reversing motor starter to engage and start

the motor. The platform will rotate counter-clockwise.

3. Normally, the platform will continue to rotate as long as the buttons are pushed.

19

ROUTINE MAINTENANCE

WARNING!

Before maintaining the turntable, read & follow the

recommended safety practices in the Safety Practices section.

Failure to follow these safety practices could result in death or

serious injury.

Powered turntables normally will require very little maintenance. However, a routine

maintenance program could prevent costly replacement of parts and/or downtime.

DYNAMIC INSPECTION (Turntable running)

1. Check any unusual noise when it occurs. Determine the source and correct as

necessary.

2. Check for chain tightness and lubricate every 90 days (chain & sprocket models).

DANGER!

HIGH VOLTAGE!! – Disconnect and/or lock out the electrical

supply to the power unit per OSHA regulations prior to any

installation or maintenance being performed.

ROUTINE STATIC INSPECTION

1. Check for unusual wear on the rollers. Make sure they are free to rotate and that

there is desirable clearance between the rollers and the platform.

2. Check that all platform retention hardware is in place and secure.

3. Check broken or cracked welds.

4. Check that all lag down anchors are in place and secure.

5. Check that the chain connections are secure and that all keepers are in place.

6. Check that all electrical connections and wiring are undamaged and secure.

7. Check the oil level every 90 days in the: gear reducer & air lubricator and add

appropriate oil when needed. Contact Autoquip Service Department for

oil information.

8. Check for unusual wear between worm gear & drive shaft (Ring Bearing Models).

9. Grease Ring Bearing and check oil level in gear reducer every 90 days. Contact

Autoquip Service Department for grease & oil information.

20

GENERAL MAINTENANCE

This manual suits for next models

2

Table of contents

Popular Turntable manuals by other brands

Ortofon

Ortofon AS-212R user guide

tri-art audio

tri-art audio P Series user manual

Dual

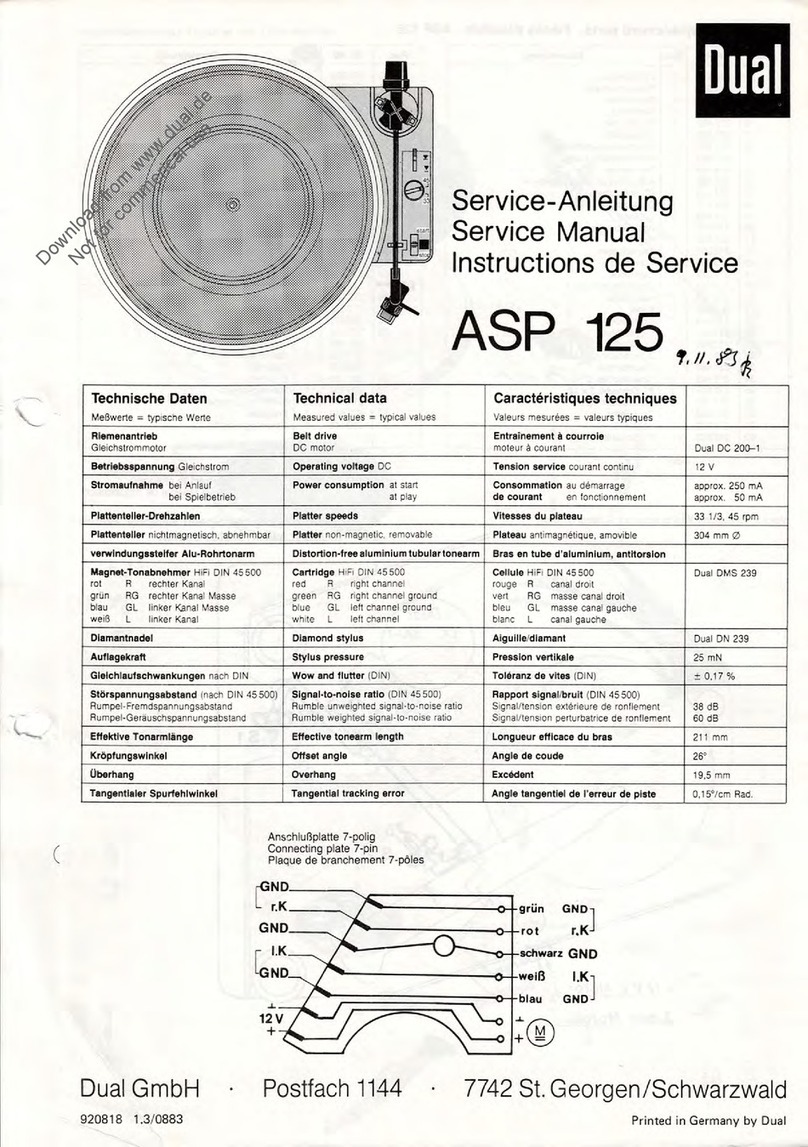

Dual ASP 125 Service manual

Radionette

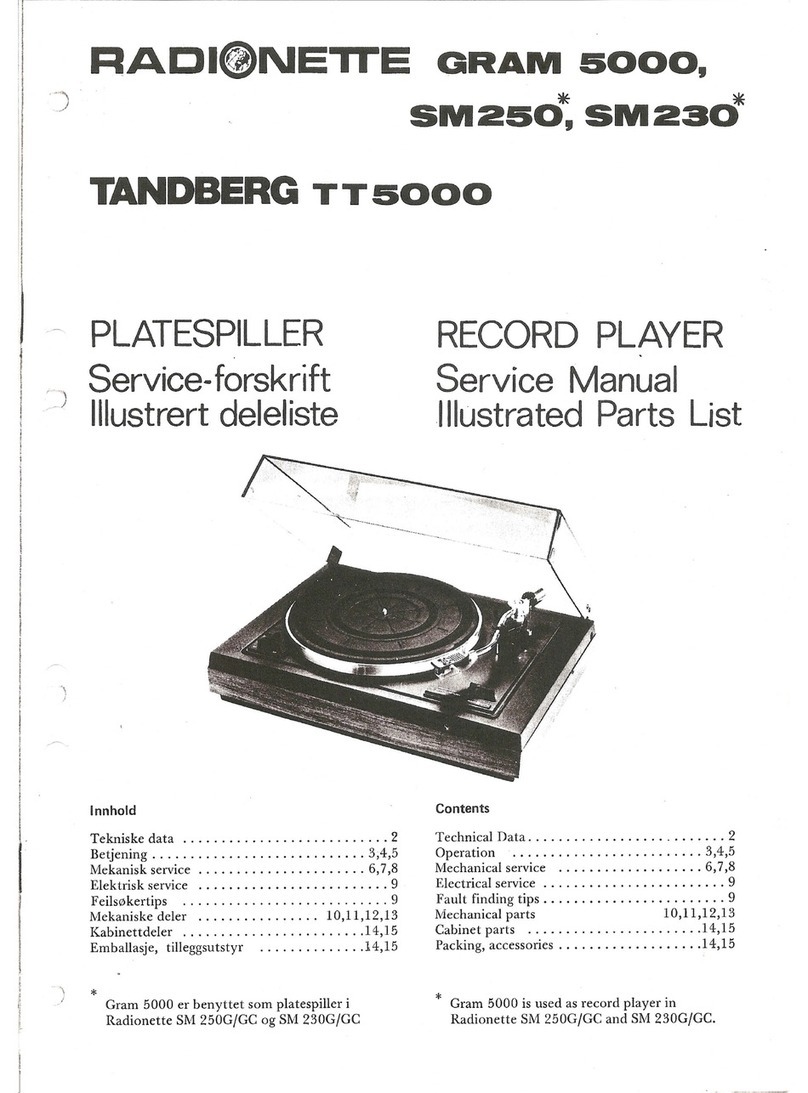

Radionette Tandberg TT 5000 Service manual

Pro-Ject Audio Systems

Pro-Ject Audio Systems Pro-Ject RPM 10 Instructions for use

Audio Technica

Audio Technica AT-LP2D-USB Installation and operation guide