1. We recommend fitting the cartridge with the tonearm in position. However it is possible to fit the cartridge

before suspending the tonearm. Great care needs to be taken when installing the cartridge as the Well

Tempered Lab bears no responsibility for cartridge damage.

2. Install the cartridge to the manufacturer's specifications. The LTD features a head shell that requires no

tracking alignment adjustment. We strongly recommend it remains firmly fixed in the correct position as

supplied.

3. The Well Tempered Lab LTD Tonearm has an effective length of 10.5î (267 mm). The head-shell is fixed ex-

factory in the optimum position. There is no provision for over-hang adjustment. Some alignment protractors

may well disagree. However, The Well Tempered Lab stands by their convictions.

Important: There is absolutely no reason to torque head-shell / cartridge mounting hardware to excess.

Cartridge mounting hardware only requires firm but gentle tightening. Heavy handed torquing of mounting

hardware can result in movement of the LTD head-shell (refer to www.welltemperedlab.net on tracking

geometry).

4. There is an optional finger lift provided which can be attached to the cartridge fixing screw, adjacent to the

right hand side of the plinth.

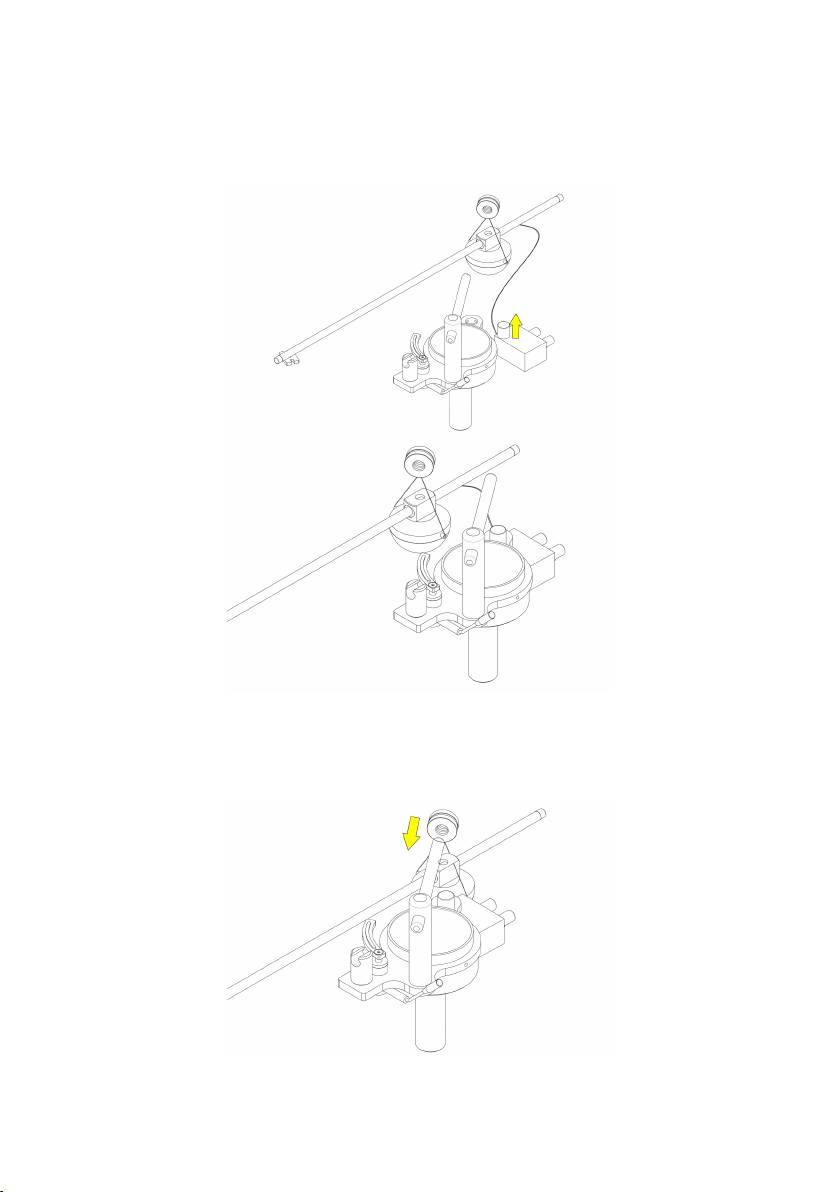

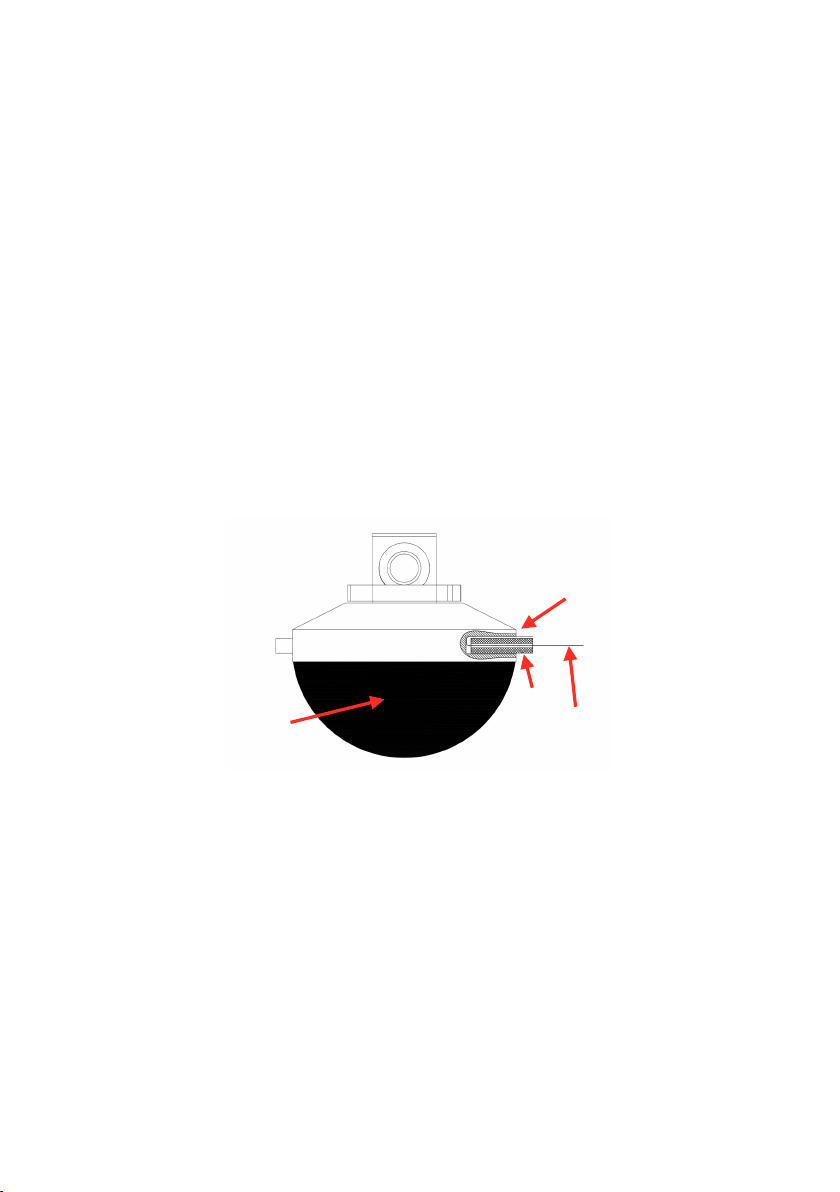

5. Apply enough damping fluid so as that no more than one third of the golf ball is submerged in fluid.

6. To set tracking force, two counterweights are supplied to enable correct tracking force to be applied to

cartridges of various weights. We recommend choice of counterweight (s) that allow correct tracking force to be

obtained with weight (s) as close to the tonearm lead out cable as practicable. This is not critical but care needs

to be taken as to not damage tone-arm lead out cable when attaching counterweights to tone-arm.

7. Adjust tonearm for correct VTA by raising or lowering bearing cup (Part no. 7) in base plate (Part no. 1) and

tightening set screws when correct VTA is obtained.

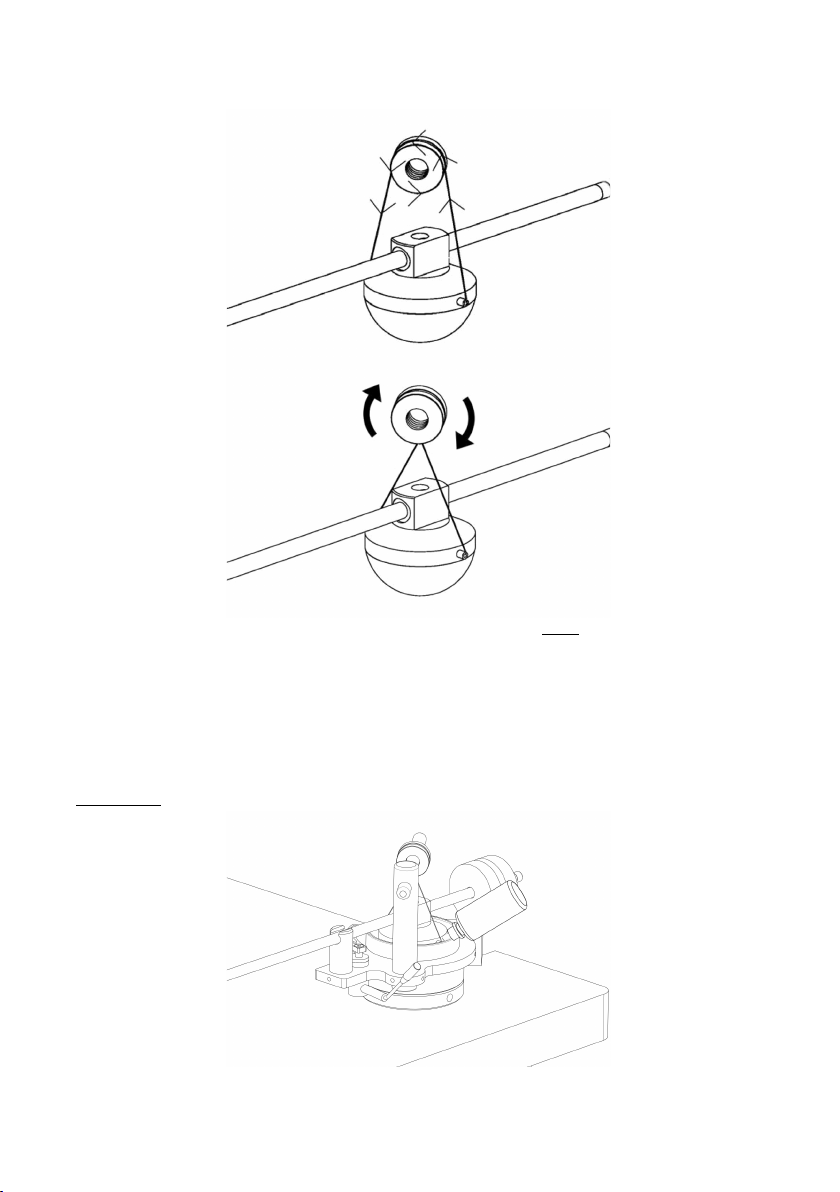

8. Correct Azimuth can be obtained by gently rotating the azimuth adjustment collar to allow the cartridge to

track parallel to the record surface. This can be achieved whilst the record is rotating and requires only minor

correction in both directions to achieve the correct result.

9. Due to the viscosity of the damping fluid adjustments in both tracking force and azimuth require the tonearm

to momentarily settle to affect the correct results.

Effective Mass: 10 g

Net Weight: 0.80 kg (800 g)

Cartridge fixing centres: 12.7 mm

Max Height above mounting surface: 140 mm

Max Depth below mounting surface: 45 mm

Max Radial clearance for Counterweights: 98 mm

Available in both:

Nominal: 9 inch (228.6 mm) version.

Nominal: 10 3/4 inch (273.05 mm) version.