4

The Reference Tonearm series is a prime example

of how the Danish design philosophy and Japanese

precision can produce a truly exceptional product.

Since 1953, Ortofon has been designing tonearms with the goal of

combining craftsmanship and technology, and the Reference Tonearm

series is the culmination of decades of experience and expertise in the

field of audio engineering. It improves upon the great build of our original

legacy AS-212 and AS-309 models, combining exquisite design, precision

manufacturing, and attention to detail, resulting in a beautifully designed

tonearm that delivers outstanding performance.

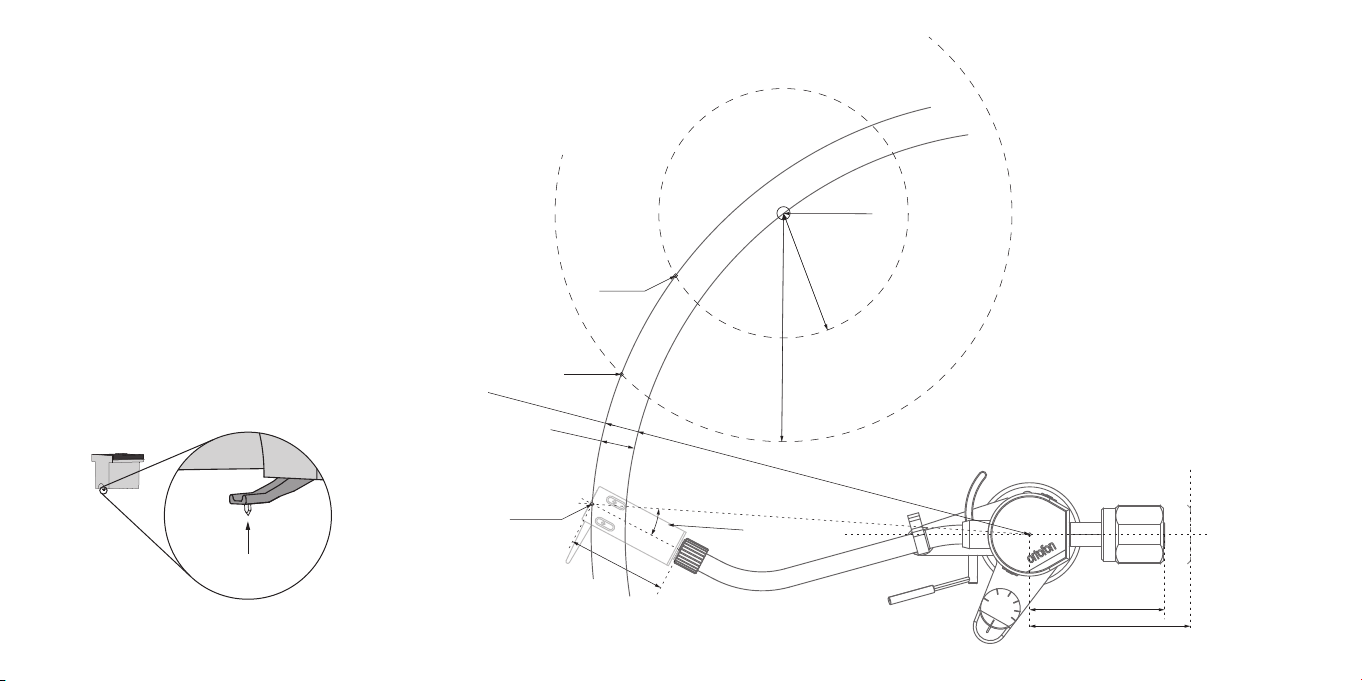

The classic and beautiful S-shaped tonearm tube is crafted from high-

grade aluminum alloy, offering an optimal combination of rigidity and mass.

The Reference tonearms are intuitive and easy, featuring improved high-

grade bearings, a universal brass connector, and a high-strength alloy that

enhances rigidity. The internal wiring uses Flexible Copper Wire to allow

the arm to move freely without affecting its movement. Its beautiful design

and compatibility with a wide range of cartridges and turntables make it an

attractive option for any vinyl lover.

About the included counterweights

The tonearm comes with two types of counterweights: a standard weight

and a heavy weight, which can be utilized according to the cartridge’s

weight to allow mounting a wide range of cartridges.

For the AS-212R/309R, the standard weight is used for cartridges on

headshell with a total weight of 18 to 26 g, and the heavy weight is for

cartridges on headshell weighing 26 to 38 g.

Introduction

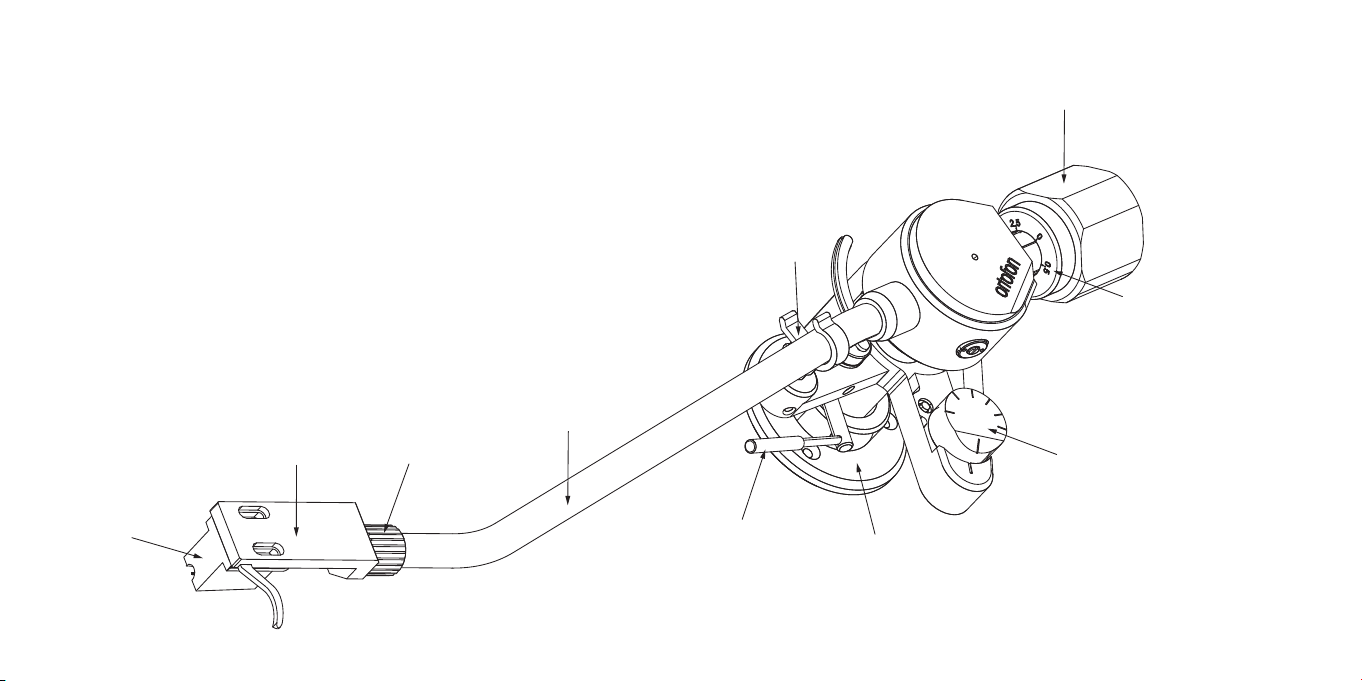

Headshell

(Not included) Universal

connector Arm tube

Cartridge

(Not included)

Arm lift

Tonearm base

Anti-skating

Tracking force scale

Counterweight

Arm rest