AUTOSCALER AW25C User manual

1

Table of Contents

Tabletop Model (AW25C/AW30C)

Tabletop Model (AW25C/AW30C) Direcons for Use ............................. Pg 3

Warranty .................................................................................................. Pg 2

Features ................................................................................................... Pg 4

Responsibilies ........................................................................................ Pg 4

Special Precauons .................................................................................. Pg 4

Infecon Control ...................................................................................... Pg 5

Introducon ............................................................................................. Pg 6

Electronic Generator and Water System ................................................. Pg 6

Handpiece Assembly ................................................................................ Pg 7

Electrical Requirements ........................................................................... Pg 7

Installing the Handpiece Assembly .......................................................... Pg 8

Installaon and Operaon ....................................................................... Pg 8

Shut Down Procedure ............................................................................ Pg 10

Troubleshoong..................................................................................... Pg 10

Scaling Techniques ................................................................................. Pg 11

Ultrasonic Scaler Inserts......................................................................... Pg 26

Build-In Model (AW25BI/AW30BI)

Build-In Model (AW25BI/AW30BI) Direcons for Use ........................... Pg 12

Warranty .................................................................................................. Pg 2

Features ................................................................................................. Pg 13

Build-In Model Installaon Guide .......................................................... Pg 14

Responsibilies ...................................................................................... Pg 17

Daily Procedures .................................................................................... Pg 17

Special Precauons ................................................................................ Pg 17

Infecon Control .................................................................................... Pg 18

Introducon ........................................................................................... Pg 18

Electronic Generator and Water System ............................................... Pg 19

Handpiece Assembly .............................................................................. Pg 19

Electrical Requirements ......................................................................... Pg 20

Installaon and Operaon ..................................................................... Pg 20

Shut Down Procedure ............................................................................ Pg 22

Troubleshoong..................................................................................... Pg 22

Scaling Techniques ................................................................................. Pg 23

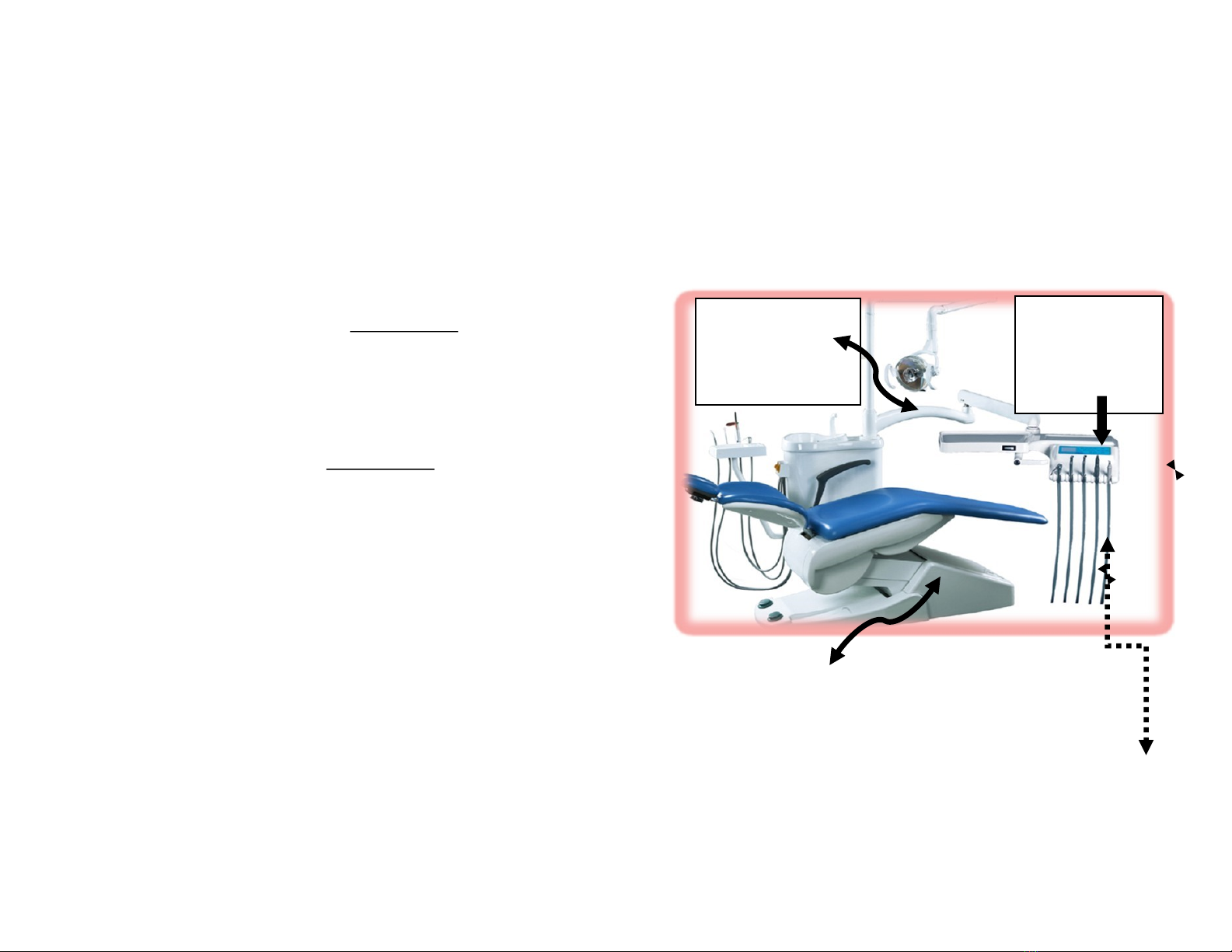

Brief Layout of the Build-In Style AUTOSCALER® ................................... Pg 24

Ultrasonic Scaler Inserts......................................................................... Pg 26

2

AUTOSCALER® WARRANTY INFORMATION

For All Models

Proof of purchase such as a copy of ORIGINAL BILL OF SALE must be

submied to obtain warranty service. Warranty DOES NOT include

Shipping and Handling charges in either direcon.

South East Instruments, LLC (hereaer SEI) subject to the terms and

condions herein below expressly set forth in Paragraphs "1" through "4"

HEREBY WARRANTS that it will repair the AUTOSCALER® Ultrasonic

Scaler which proves defecve by reason of improper workmanship and or

materials.

1. SIX YEAR Parts and Labor coverage on circuit boards, and TWO YEAR

Parts and Labor coverage on all other components of the

AUTOSCALER®.

2. ORIGINAL PURCHASER: This warranty is limited to the original

purchaser of the unit. When requesng warranty service, SEI needs a

RETAIL sales receipt to VALIDATE sales/installaon date.

3. PROPER DELIVERY: The unit must be shipped, Freight Prepaid, or

delivered to SEI to render the services provided hereunder in either

its original package, or a similar package aording an equal degree of

protecon. Warranty does not include shipping and handling back to

the customer.

4. UNAUTHORIZED REPAIR, ABUSE, ETC.: The unit must not have been

previously altered, repaired or serviced by anyone other than SEI or a

qualied technician. To render such service, the serial number on the

unit must not have been altered or removed. The unit must not have

been subjected to accident, misuse, abuse, or operated contrary to

the operang instrucons. Handpiece assembly is not warranted if

subjected to abuse from excessive pulling/stretching, debris and/or

chemical accumulaon from water supplies. Water system is not

warranted by failure due to debris, and/or chemical deposits from

water supplies or added medicinal soluons. Foot switch is not

warranted by failure due to tampering, or operaon/storage in a wet

environment.

EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, NO OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WARRANTIES OF

MERCHANTABILITY, AND FITNESS FOR A PARTICULAR PURPOSE, SHALL AP-

PLY TO THIS EQUIPMENT. DAMAGES ARE LIMITED STRICTLY TO REPAIR OR

REPLACEMENT OF PARTS. UNDER NO CIRCUMSTANCES SHALL SEI BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE USE

OF THE EQUIPMENT, AND SEI NEITHER ASSUMES NOR AUTHORIZES ANY

REPRESENTATIVE, OR OTHER PERSON TO ASSUME FOR IT ANY OBLIGATION

FOR LIABILITY OTHER THAN SUCH AS IS EXPRESSLY SET FORTH HEREIN.

3

®

DIRECTIONS FOR USE

For Tabletop Models

AW25C and AW30C

ULTRASONIC SCALER/PROPHYLAXIS UNIT

AUTOSCALER® DIRECTIONS FOR USE

ALL RIGHTS RESERVED

Form #QP272-G, Rev. September 2020

Documents Aected: AW25C, AW30C; FM119, MP104

THE AUTOSCALER® ULTRASONIC SCALER IS A PRESCRIPTION DEVICE AND IS

INTENDED FOR USE ONLY BY LICENSED DENTAL PRACTITIONERS.

FEDERAL LAW RESTRICTS THE DEVICE TO SALE BY OR ON THE ORDER OF A

LICENSED PRACTITIONER.

4

FEATURES

The AUTOSCALER® is designed for Dental Prophylaxis Treatment when

used with the appropriate Cavitron® brand – Series: “P”, “SLIMLINE”™,

“FSI”™ or “TFI”™ 25,000Hz series inserts*. If you have purchased the

AUTOSCALER® 30,000Hz model you must use 30,000Hz frequency

inserts. Inserts are not interchangeable. The AUTOSCALER® is

acceptable for use in scaling and cleaning surfaces of teeth in

conjuncon with other prophylacc measures.

AUTOSCALER® is a registered trademark of South East Instruments,

LLC.

Recommendaons by the manufacturer contained within this

instrucon booklet are recommendaons only. Other opons may be

available or mandated by the professional or regulang agencies.

RESPONSIBILITIES

It is the responsibility of the dental professional using this device to be

fully trained in the proper use of ultrasonic scalers. The operator must

be observant of possible changes in performance during a procedure

and immediately disconnue use of this product, and determine the

cause of such changes in performance before connuing dental

procedures. Performance varies slightly between manufacturers of

ultrasonic scalers, so the operator must become familiar with the

operang parameters, and adjustments of this parcular device.

Performance varies between Ultrasonic Inserts due to the style insert,

model insert, and from the age and/or modicaons of the insert.

SPECIAL PRECAUTIONS

The exible Water Input Hose is subject to deterioraon by

aging, chemicals in the water supply, excessive exing, and

pressure uctuaons. As an added precauon, the water supply

should be turned OFF at the end of the day. REMEMBER to turn

the water back ON prior to use the next day.

The AUTOSCALER® should NOT be used for restorave dental

procedures involving the CONDENSATION OF AMALGAM.

*Cavitron®, SLIMLINE™, FSI™, and TFI™ are registered trade marks of Dentsply Sirona

5

The AUTOSCALER® should NOT be used on or near anyone ed

with a CARDIAC PACEMAKER.

Do not remove the cover from the unit. There are NO user

serviceable parts inside. Allow only qualied technicians to service

your AUTOSCALER®.

DO NOT AUTOCLAVE the detachable HANDPIECE assembly. A

Federally approved non-immersion WATER BASED cold

sterilizaon soluon may be used on the detachable handpiece

assembly. However, DO NOT get sterilizaon soluons on the

electrical contacts of the Handpiece CONNECTOR as this will cause

oxidaon, and a poor electrical connecon. DRY ALL SURFACES

with clean air or clean paper towels.

If your unit is le ON, and the footswitch is accidentally depressed

while unaended, this will permanently damage your unit. Be sure

nothing is touching the operatory air foot switch when not in use.

INFECTION CONTROL

Manufacturer recommends that all operators of this ultrasonic

unit wear at least one pair of surgical rubber gloves, and for extra

prevenon wear double pairs of gloves to isolate the operator

from infecon, and cross contaminaon of other paents.

It is recommended that complete eye and face protecon be used

during the use of this unit to prevent saliva spray from being

inhaled, and from entering the operator’s eyes.

Operator should be careful not to puncture the skin with any

insert p containing saliva from paents. Insert ps should be

sterilized aer each paent according to the insert manufacturer’s

instrucons.

DO NOT AUTOCLAVE the detachable HANDPIECE assembly. A

Federally approved non-immersion WATER BASED cold

sterilizaon soluon may be used on the detachable handpiece

assembly. However, DO NOT get sterilizaon soluons on the

electrical contacts of the Handpiece CONNECTOR as this will cause

oxidaon, and a poor electrical connecon. DRY ALL SURFACES

with clean air or clean paper towels.

Manufacturer recommends the use of a disposable handpiece

sleeve/barrier that keeps contaminaon from geng on the

handpiece assembly. Dispose of sleeve/barrier aer each paent.

Ask your local dealer for HIGH SPEED LONG sleeve/barrier.

6

INTRODUCTION

Your South East Instruments AUTOSCALER® Ultrasonic Scaler is a

precision engineered instrument, constructed with the nest of

materials, and requiring no special maintenance. By taking the

following precauons your unit will give you many years of service.

1. Do not place unit on or near any source of heat.

2. Clean the outer surfaces of the AUTOSCALER® with a Federally

approved non-immersion WATER BASED cold sterilizaon soluon.

Dry immediately with clean air or clean paper towels.

3. Unit should be located where a normal amount of air will circulate

freely around the case when in use.

4. The handpiece and Quick Connector are very strong but care

should be taken NOT TO PULL with excessive force.

Basically, the unit consists of three major components: the electronic

generator, the water system, and the handpiece assembly.

ELECTRONIC GENERATOR AND WATER SYSTEM

The electronic generator produces the frequency and the power to

acvate a wide variety of interchangeable Cavitron® insert ps. The

water system provides precise control over the water lavage ow

which serves to wash debris from the work area, and to cool the

laminaons of the insert p. The following controls are found on the

front panel of your AUTOSCALER®:

Toggle Switch : To turn unit On and O.

Indicator L.E.D. Lamp (above the switch) which lights when the

Toggle Switch is set to the ON-I posion, indicang the unit is

ready for operaon.

Power Control Knob: The Linear Power Control knob adjusts the

output power to the insert p. The blue

shaded area is for use when using

Cavitron® SLIMLINE™, FSI™ or modied

Periodontal inserts. It is recommended

the Power not be set higher than 12:00

even if no mist appears at the p.

Slimline inserts do not easily mist

the water, and are very fragile at higher

power sengs. FOLLOW INSERT

MANUFACTURER'S COMPLETE

INSTRUCTIONS.

7

Water Control Knob: For adjusng the ow of water to the

handpiece and insert p. To obtain the necessary water ow of at

least (18cc - 30cc/+/minute) turn the WATER KNOB clockwise.

HIGHER water ow to the RIGHT, and LOWER water ow to the

LEFT.

Handpiece Panel Receptacle: Accepts the male side of the

Handpiece connector with lock ring.

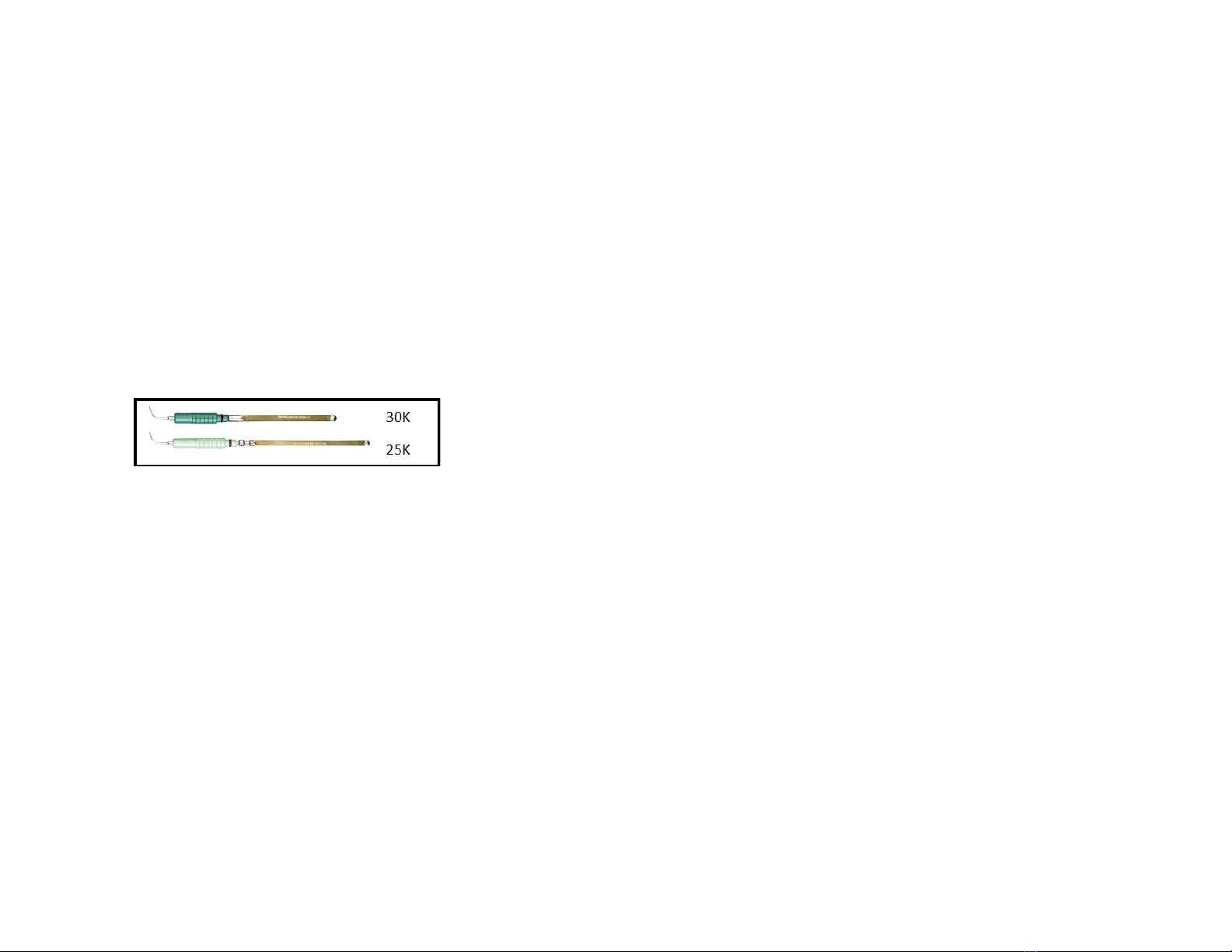

HANDPIECE ASSEMBLY

The handpiece assembly is used to accept Cavitron® interchangeable

insert ps. It is connected to the AUTOSCALER® front panel by a Quick

Connector. The open end of the handpiece will accept all Cavitron®

brand: "P", "TFI™", “SLIMLINE™” or “FSI™” style 25,000Hz (25K)

inserts. If you ordered a 30,000Hz (30K) model AUTOSCALER®, you

must use the shorter (30K) frequency insert ps.

30K ps measure (Shorter style approx. 6.25 inches long)

25K ps measure (Longer style approx. 7.25 inches long)

(25K) inserts will NOT work in your 30K unit.

(30K) inserts will NOT work in your 25K unit.

Inserts are extremely FRAGILE. If one is dropped, bent, or scratched it

WILL NOT cavitate (i.e. will not funcon) or funcon by operang at a

higher than normal temperature, and should be replaced immediately.

Insert ps should be rounely replaced according to insert

manufacturer's recommendaons.

ELECTRICAL REQUIREMENTS

A GROUNDED wall receptacle is required supplying a voltage range

of 110-125 volts 50/60 Hz A.C. If a 3 to 2 prong adapter is used, the

ground wire MUST be connected to the base plate screw. Have an

electrician test your outlet for correct wiring polarity and a safe

ground. Do not assume the ground is complete. If you plug the

AUTOSCALER® in a GFI (Ground Fault Interrupt ) outlet it may trip the

socket due to the high sensivity of the socket. If this occurs plug the

AUTOSCALER® into a non-GFI socket.

*Cavitron®, SLIMLINE™, FSI™, and TFI™ are registered trade marks of Dentsply Sirona

8

INSTALLING THE HANDPIECE ASSEMBLY

1. Align the electrical contacts of the MALE connector with the same on

the FEMALE panel connector.

2. Gently insert the connector. It should slide in with very lile eort. If

the connector does not align, DO NOT force it. Turn the CONNECTOR

BODY in either direcon unl the connector correctly aligns and goes

in.

3. Once the connector has been completely inserted, screw the OUTSIDE

LOCK RING to the RIGHT with light nger pressure unl it stops. DO

NOT over ghten the lock ring, be careful not to cross thread the lock

ring.

4. To remove the connector, unscrew the lock ring to the le, and gently

pull outward grasping the enre connector body.

INSTALLATION AND OPERATION

DO NOT use your AUTOSCALER® unl all of the following steps have been

completed.

1. Upon receipt of your unit carefully unpack it and see that the Toggle

Switch is in the OFF-O posion.

2. The Water Control Knob should be in the HIGH posion by turning

the water control knob all the way to the RIGHT.

3. Set the Power Knob all the way to the LEFT in the LOW posion.

4. Plug the male Water Quick Release Valve water connector into the

Dental operatory or have a plumber install a SHUT OFF style FEMALE

connector. A minimum of (20 P.S.I.) water input pressure and a

maximum of (60 P.S.I.) is needed from the operatory for proper oper-

aon of the AUTOSCALER®. It is recommended that water line ltra-

on be used to remove larger parcles before entering the scaler.

5. Plug the power cord into the wall (see electrical requirements). Press

the toggle switch to the ON-I posion. The L.E.D. light above the

switch should be ON (“I” posion).

6. Select an insert. Moisten the rubber O-RING before inserng into

the handpiece. While holding the handpiece UPRIGHT place the

insert in the open end of the handpiece and with a gentle PRESS and

TURN moon, snap the insert in fully. DO NOT force the insert.

7. Manufacturer recommends the use of a disposable handpiece

sleeve/barrier be used over the handpiece assembly. Place the

sleeve/barrier over the handpiece. While holding the sleeve/

barrier in place, puncture the insert through the plasc at the open

end of the handpiece, and snap the insert in fully. Dispose of

sleeve/barrier aer each paent.

8. Due to atmospheric exposure and exposure to sterilizaon soluons

the O-RING on the insert p may become swollen, brile, or crack,

and require replacement.

9

9. Hold the handpiece in a VERTICAL upright posion and step on the

foot switch. Within 10-15 seconds water should come out of

10. Inserts and handpiece will burn in 45-60 seconds in the absence of

water. A (18cc—30cc/+/min) ow is the normal ow range, and

necessary at all mes. NEVER touch the Cavitang/Vibrang end of the

insert p to any esh such as the cheek, tongue, or gums unless

performing special periodontal procedures. This will cause a FRICTION

BURN to the paent. Always keep the insert in moon, do not rest the

handle or insert on the lips during a procedure. The insert p should

touch primarily the calculus on the tooth surface and NOT the enamel

of the tooth surface.

11. Allow the air bubbles to escape for about 10-20 seconds. Turn the

POWER KNOB to the RIGHT in the Medium posion and the insert p

should Cavitate/Vibrate with a strong mist. Turn the water knob to

the right if there is no mist or weak misng.

12. The applicaon of the power knob is for controlling the Output Power

to the insert p in a smooth linear acon. The operator can select the

EXACT power needed for cleaning. Set power knob LOW (Le Direcon)

to MEDIUM (Center) for cooler handpiece/insert temperature.

13. The high power seng is for applicaons where an excessive amount

of calculus is built up. The Low power seng can be used for

periodontal Subgingival cureage and root planing procedures. Most

scaling should be done only on the LOW to MEDIUM power seng.

14. If SLIMLINE™, FSI™ or Modied Periodontal inserts are used set the

POWER Knob in the BLUE shaded area. This power level is designed to

be used with these fragile specialty inserts. Inserts may give a drip and

mist combinaon, this is normal for these inserts. This is actually

preferred by most Periodontal professionals due to the water drip

being ultrasonically acvated within 0.5mm of the p assisng in killing

plaque.

UNIT IS NOW READY FOR USE

the open end of the handpiece IF NOT, QUICKLY

turn WATER KNOB clockwise to get water ow,

some air will escape at the same me. This step is

IMPORTANT because trapped air will cause HOT

SPOTS (usually noted by a loud screeching sound)

which can aect the performance of the

AUTOSCALER® or permanently damage the

handpiece assembly.

10

SHUT DOWN PROCEDURE

1. IMPORTANT: At the end of the work day turn o the water supply to

the AUTOSCALER® by disconnecng the QUICK RELEASE VALVE water

connector or shung o the main operatory water supply. This will

prevent water damage to your oce by aging or unseen defects in

water lines that could rupture under connuous pressure.

2. Purge water from the AUTOSCALER® water hose and plumbing system

at the end of the day.

• Connect the QUICK RELEASE VALVE water connector to an air

source.

• Turn the Power Knob to the Le to the lowest seng and the

Water Knob to the Right to the highest seng.

• Press the Toggle switch to the ON-I posion

• Hold the handpiece assembly over a basin and step on the

footswitch and run the scaler just unl all water is expelled via

the handpiece assembly.

3. Press the Toggle Switch to the OFF-O posion. The light should be o.

4. Reconnect the QUICK RELEASE VALVE water connector to the water

supply.

5. REMEMBER to reconnect (turn on) the water the next day before

usage.

TROUBLESHOOTING

If the unit does not funcon, proceed with the following:

1. If the power L.E.D. light above the switch is not lit, replace the FUSE

on the rear panel with a "LITTLE FUSE" 2 amp Fast Blow style. If the

fuse opens again DO NOT aempt to replace the fuse as this indicates

a serious condion that must be examined by the factory. Call for

service (800) 648-9445.

2. Check the plug. Is it all the way in the receptacle?

3. Try another insert. Make sure it is the correct frequency, 25K or 30K,

depending on your model. Each model has a frequency (25K or 30K)

label on the cover and the frequency is also indicated on the serial

number plate located on the back of the device. The most common

mistake when purchasing a new unit is selecng the wrong

frequency insert.

4. If water ow is insucient, check water pressure at the operatory for

minimum of 20 P.S.I. The Insert Water slot could be clogged with

debris. Try another insert. See if the QUICK RELEASE VALVE water

connector is locked fully in place.

5. If the handpiece handle or insert operates HOT: REDUCE POWER

LEVEL and INCREASE WATER FLOW.

11

6. NEVER touch the Cavitang/Vibrang end of the insert p to any

FLESH such as the cheek, tongue, or gums unless performing special

periodontal procedures, this will cause a fricon burn to the paent.

Always keep the insert in moon. Do not rest the handle or insert on

the lips during a procedure. The insert p should touch PRIMARILY the

calculus on the tooth surface, and NOT the enamel of the tooth

surface.

7. If the AUTOSCALER® stops funconing or is intermient when the

handpiece cord is moved, this means a wire in the handpiece cord is

broken and must be immediately repaired or replaced. DO NOT

connue to press the foot switch as there is a possibility the internal

circuit safety fuse may blow and require replacement by a qualied

technician.

8. If handpiece service is needed: Turn the unit OFF. Carefully unscrew

the outer lock ring of the handpiece assembly to the LEFT and gently

unplug the handpiece from the front panel. You can call your dealer

for assistance or SEI at (800) 648-9445 for further instrucon.

9. If a humming or high pitch sound is noted from the console during

roune use, this is a normal circuit resonance which will change as the

POWER control knob is adjusted up and down, and will not aect the

performance of your AUTOSCALER®.

10. Slimline™ and FSI™ inserts are extremely thin and FRAGILE. During

normal use the water may not mist like standard inserts (i.e. like a

TFI#10 curee p); however, the cleaning acon is just a eecve. It is

recommended the Power knob be set in the LOW posion (Blue area)

to assure best performance.

Call your dealer or customer service at South East Instruments for

further instrucons at (800) 648-9445 to help you with quesons and

what to do next.

SCALING TECHNIQUES

Scaling techniques are at the opon of the professional using this

instrument.

1. Excessive pressure is not necessary with the AUTOSCALER®. Use a

gentle, rapid moon with small overlapping strokes, being certain that

the insert is at a 15 degree angle to the tooth surface.

2. If paent Hypersensivity is noted, you should lighten pressure on the

handpiece, Reduce the Power Level or move from the sensive tooth

to another and return to the tooth later. If sensivity persists, switch

to a hand instrument.

12

®

DIRECTIONS FOR USE

For Build-In Retrot Models

AW25BI and AW30BI

ULTRASONIC SCALER/PROPHYLAXIS UNIT

AUTOSCALER® DIRECTIONS FOR USE

ALL RIGHTS RESERVED

Form #QP272-G, Rev. September 2020

Documents Aected: AW25BI, AW30BI; FM124, MP105

THE AUTOSCALER® ULTRASONIC SCALER IS A PRESCRIPTION DEVICE AND IS

INTENDED FOR USE ONLY BY LICENSED DENTAL PRACTITIONERS.

FEDERAL LAW RESTRICTS THE DEVICE TO SALE BY OR ON THE ORDER OF A

LICENSED PRACTITIONER.

13

FEATURES

The AUTOSCALER® is designed for Dental Prophylaxis Treatment when

used with the appropriate Cavitron® brand – Series: “P”, “SLIMLINE”™,

“FSI”™ or “TFI”™ 25,000Hz series inserts*. If you have purchased the

AUTOSCALER® 30,000Hz model you must use the 30,000Hz frequency

inserts. Inserts are not interchangeable. The AUTOSCALER® is acceptable

for use in scaling and cleaning surfaces of teeth in conjuncon with other

prophylacc measures.

This Build-In style AUTOSCALER® unit is NOT intended for user/owner

install. It requires a technician familiar with dental operatory Air and

Water circuitry. This product needs installaon of the following for

proper operaon:

1. The Handpiece Assembly. Roung of 18 gauge wires through the

dental operatory to the AUTOSCALER® console.

2. Water delivery/control for the unit. The AUTOSCALER® does not come

equipped with any water control devices/controllers, however proper

water ow is mandatory for the operaon of this product. See oper-

ang instrucons later in this booklet for proper operang parameters.

3. Power Control Pot. Roung of (2) 18 gauge wires through the dental

operatory to the AUTOSCALER® console.

4. An independent Air Source to acvate the AUTOSCALER® supplied by

the dental operatory (i.e. independent air/water block with auto

holder). The air supply must relieve to zero pressure aer each

depression of the main air rheostat.

AUTOSCALER® is a trade mark of South East Instruments, LLC.

Recommendaons by the manufacturer contained within this instrucon

booklet are suggesons only. Other opons may be available or mandated

by the professional or regulang agencies.

The source of the air signal, water supply, and installaon are not the

responsibility of South East Instruments, LLC. Any damage to the

AUTOSCALER®, PATIENTS or DENTAL OPERATORY resulng from improper

installaon or conguraon is the sole responsibility of the installing dealer

or technician. The AUTOSCALER® BUILD-IN Models AW25BI or AW30BI are

sold as component devices that require further installaon by a party

appointed by the end user. If the installing technician or end user is in doubt

as to correct installaon procedures they should stop immediately and call

South East Instruments, LLC for further instrucons at (800) 648-9445 before

aempng to proceed with the installaon.

*Cavitron®, SLIMLINE™, FSI™, and TFI™ are registered trade marks of Dentsply Sirona

14

BUILD-IN MODEL INSTALLATION GUIDE

This GUIDE is to assist the technician. Most dental chairs ulize similar

conguraons. It is the responsibility of the technician to properly

install and conrm proper funcon with the parcular chair

manufacturer conguraon.

DO NOT aempt to install this device without an independent air/

water block with automac handpiece holder. The technician must

be familiar with dental chair air water logic to correctly install this

device. Most installaons convert the exisng 3rd or 4th air/water

high or low speed drill block for this purpose.

There MUST be (4) 18

GAUGE wires running from

the juncon box,

THROUGH THE ARM to the

tray for handpiece and power

control connecons.

The handpiece and

(POWER CONTROL)

are mounted on the (tray).

An (AUTOMATIC

HOLDER) must be used

for the Autoscaler®

handpiece.

The AUTOSCALER® (CONSOLE) is mounted under the chair or

(JUNCTION BOX). NOTE: If the AUTOSCALER® receives an air signal

from another source (i.e. high speed or low speed drill) it can damage

the device and the handpiece assembly.

WATER FLOW to the handpiece is received from the air/water block (NEEDLE

VALVE). When the main air rheostat is pressed, an air signal is sent to the

AUTOSCALER® console to (cavitate the insert) and the air/water block opens to

release water ow to the handpiece. Quickly adjust the water knob to get

water owing.

15

If no water is present:

The handpiece will become overheated and damage the

handpiece within 45-60 seconds.

Do not acvate the AUTOSCALER® without an insert in the

handpiece. This can cause the internal coil to overheat and

damage the handpiece.

Connecons on the console are:

Front Panel - Connector for handpiece and power control wires.

Black and Red wires are for the HANDPIECE. There is NO

POLARITY for the handpiece wires.

2 Yellow wires are for the POWER CONTROL. There is NO

POLARITY for the power control wires.

ALL WIRES MUST BE 18 GAUGE. THINNER WIRE WILL RESULT IN

THE WIRE HEATING AND LOSS OF POWER and/or TUNING.

Rear Panel - Air input line yellow 1/16” to receive the

independent acvaon signal (20 to 60 PSI Range) from the

dedicated air/water block (chip/drive air). BE SURE when the

AUTOSCALER® handpiece is picked up from the automac

holder, no other air handpieces are acvated. Verify that when

a high or low speed drill is removed from the automac holder

the AUTOSCALER® does not receive an air signal and acvate. If

so, it will permanently damage the AUTOSCALER®. Only ONE

handpiece should acvate at a me when picked from the

holder.

Rear Panel - AC power plug on rear panel.

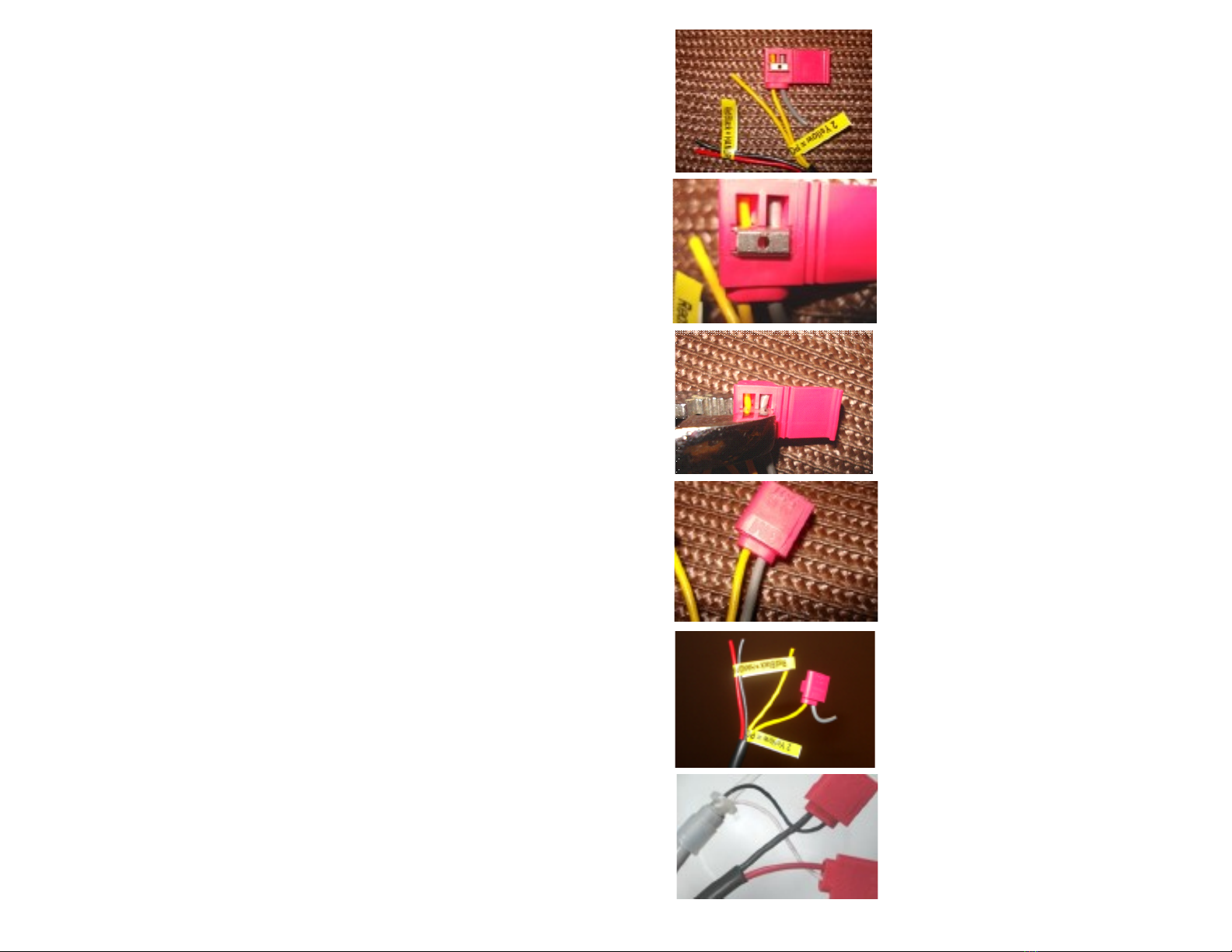

Enclosed: (10) Scotchlok 557 wire connectors to complete your wire

connecons. Only 8 are needed and two are spares. Tools needed

are pliers to compress and secure the Scotchlok 557 connector. The

example on the following page shows one connecon for the power

control yellow wires connecng to the exisng wires from the

dental unit arm.

The exisng wires in the dental chair arm MUST be 18 gauge in

order not to overheat the wires and cause tuning and/or power

issues.

16

Example shows hookup of one of the 4

wires on the console side in the juncon

box. Insert one yellow wire into the

connector and one of the wires from the

chair arm.

Make sure both wires are inserted fully.

Take your pliers and pinch the metal

clamp fully unl it clicks and is at with

the plasc.

Fold over the plasc lid unl it locks. Repeat

process for other connecons. If the

Scotchlok 557 connector fails to complete

the connecon, the technician MUST

SOLDER the wires and apply a UL or CSA

approved heat shrink. DO NOT twist, tape or

use wire nuts for the connecons.

On the tray side repeat the same

method for the handpiece and power

control wires.

The handpiece wires are thinner and

care should be noted that the wires are

fully inserted and align straight in the

metal clamp blades to make a secure

connecon.

Power Control Wires

Handpiece Wires

Wires

Inserted Fully

Metal Clamp

17

RESPONSIBILITIES

It is the responsibility of the dental professional using this device to be

fully trained in the proper use of ultrasonic scalers. The operator must

be observant of possible changes in performance during a procedure

and immediately disconnue use of this product and determine the

cause of such changes in performance before connuing dental

procedures. Performance varies slightly between manufacturers of

ultrasonic scalers, so the operator must become familiar with the

operang parameters, and adjustments of this parcular device.

Performance varies between Ultrasonic Inserts due to the style insert,

model insert, and from the age and/or modicaons of the insert.

DAILY PROCEDURES

At the end of the work day shut o ALL operatory Air and Water

supplies. This will prevent water damage to your oce by aging or

unseen defects in water lines that could rupture under connuous

pressure.

REMEMBER to turn back on the next day before usage.

SPECIAL PRECAUTIONS

As an added precauon, the water supply should be turned OFF at

the end of the day. REMEMBER to turn the water back ON prior to

use the next day.

The AUTOSCALER® should NOT be used for restorave dental

procedures involving the CONDENSATION OF AMALGAM.

The AUTOSCALER® should NOT be used on or near anyone ed

with a CARDIAC PACEMAKER.

Do not remove the cover from the unit. There are NO user

serviceable parts inside. Allow only qualied technicians to service

your AUTOSCALER®.

Do not remove the internal air restrictor. This is a safety device

and must not be removed.

DO NOT AUTOCLAVE the HANDPIECE assembly. A Federally

approved non-immersion WATER BASED cold sterilizaon soluon

may be used on the handpiece assembly. DRY ALL SURFACES with

clean air or clean paper towels.

If your unit is le ON, and the footswitch is accidentally depressed

while unaended, this will permanently damage your unit. Be sure

nothing is touching the operatory air foot switch when not in use.

18

INFECTION CONTROL

Manufacturer recommends that all operators of this ultrasonic

unit wear at least one pair of surgical rubber gloves, and for extra

prevenon wear double pairs of gloves to isolate the operator

from infecon, and cross contaminaon of other paents.

It is recommended that complete eye and face protecon be used

during the use of this unit to prevent saliva spray from being

inhaled, and from entering the operator’s eyes.

Operator should be careful not to puncture the skin with any

insert p containing saliva from paents. Insert ps should be

sterilized aer each paent according to the insert manufacturer’s

instrucons.

DO NOT Autoclave the handpiece assembly. Federally approved

non-immersion WATER BASED cold sterilizaon soluons may be

used on the handpiece assembly. DRY ALL SURFACES with clean air

or clean paper towels.

Manufacturer recommends the use of a disposable handpiece

sleeve/barrier that keeps contaminaon from geng on the

handpiece assembly. Dispose of sleeve/barrier aer each paent.

Ask your local dealer for HIGH SPEED LONG sleeve/barrier.

INTRODUCTION

Your South East Instruments AUTOSCALER® Ultrasonic Scaler BUILD-IN

UNIT, is a precision engineered instrument, constructed with the nest

of materials. By taking the following precauons your unit will give you

many years of service.

The AUTOSCALER® BUILD-IN unit is NOT a table top user installaon

product. It must be installed by a qualied technician knowledgeable

in Dental Operatory Air circuitry and Water systems.

1. Do not place unit on or near any source of heat.

2. Unit should be located where a normal amount of air will circulate

freely around the case when in use.

3. The handpiece is very strong but care should be taken NOT TO

PULL with excessive force.

19

Basically, the unit consists of two major components, the Electronic

Generator and the Handpiece Assembly (Water Source is also NECESSARY

but not supplied with this model). The Water Supply is used from the

Dental operatory, and must be applied/congured by a qualied technician.

ELECTRONIC GENERATOR AND WATER SYSTEM

The electronic generator produces the frequency and the power to acvate a

wide variety of interchangeable INSERT TIPS. A Water System/SUPPLY MUST BE

ATTACHED to your unit to provide precise control over the water ow which

serves to wash debris from the work area, and to cool the laminaons of the

insert p. The following is a brief descripon of controls needed for the proper

operaon of your AUTOSCALER®:

The AIR SOURCE (20 PSIG) minimum is required, and (must be

installed by a qualied technician) providing an independent supply of

air to your AUTOSCALER® unit.

POWER CONTROL KNOB: The linear Power Control knob adjusts the

output power to the insert p (must be installed by a qualied technician).

WATER CONTROL (supplied by the dental operatory, and is not part

of the AUTOSCALER® unit) is for adjusng the ow of water to the

handpiece, and insert p. To obtain the NECESSARY water ow of at

least (18cc - 30cc/+/minute) - i.e. a very strong mist, it may require more

than ONE or MORE complete rotaons of the knob in either direcon.

Depending on the water regulator supplied in your operatory the following

applies: HIGHER water ow to the RIGHT, and LOWER water ow to the

LEFT. Some water regulators adjust the opposite (more ow to le and less to

the right). Become familiar with your controls rst before performing any

dental procedures on paents.

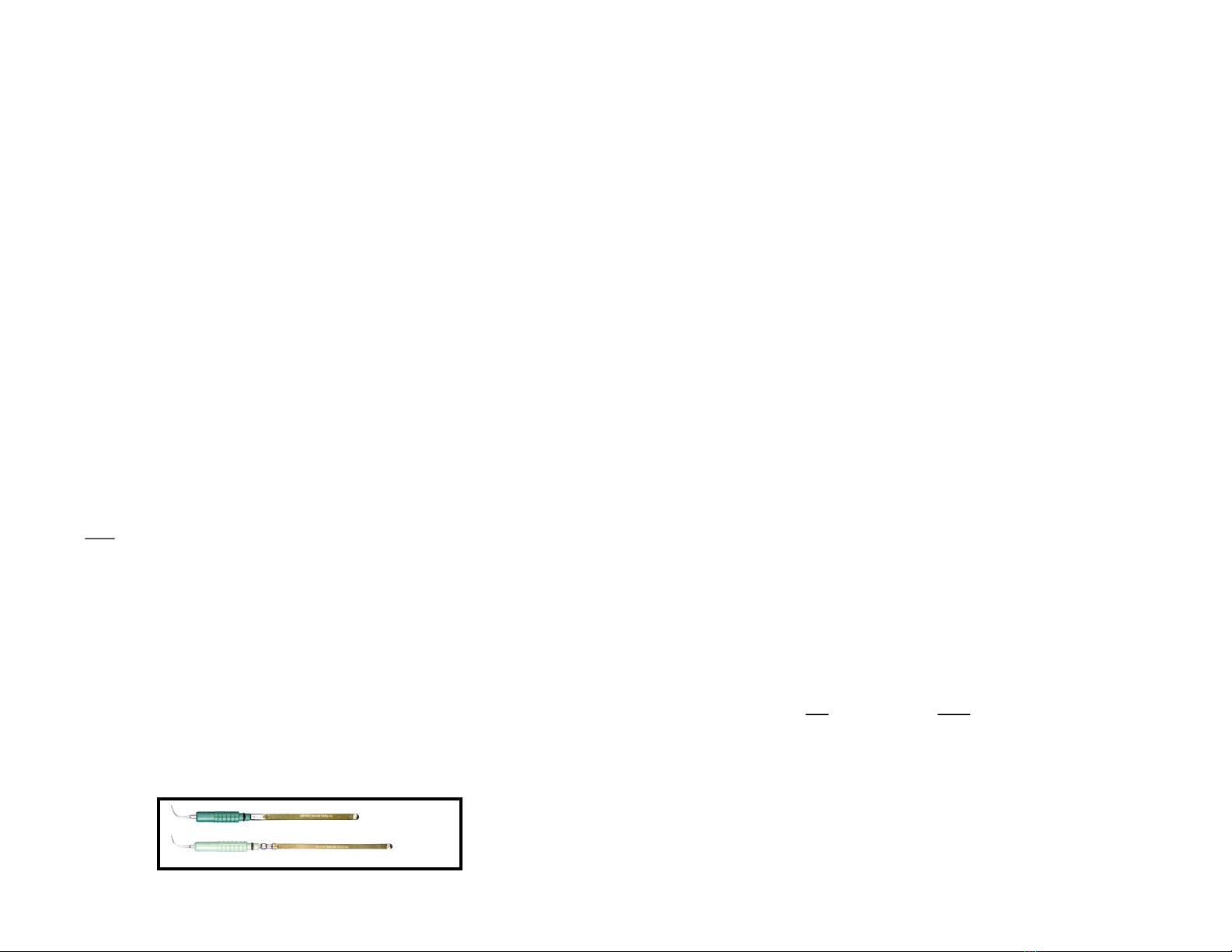

HANDPIECE ASSEMBLY

The handpiece assembly is used to accept Cavitron® interchangeable

insert ps. It is connected to the AUTOSCALER® through specially

routed wires in your operatory (INSTALLED BY QUALIFIED TECHNICIAN

ONLY). The open end of the handpiece will accept all Cavitron® brand:

"P", "TFI™", “SLIMLINE™” or “FSI™” style 25,000Hz (25K) inserts. If you

ordered a 30,000Hz (30K) model AUTOSCALER® you must use the

shorter (30K) frequency insert ps.

30K ps measure (Shorter style approx. 6.25 inches long)

25K ps measure (Longer style approx. 7.25 inches long)

*Cavitron®, SLIMLINE™, FSI™, and TFI™ are registered trade marks of Dentsply Sirona

30K

25K

20

(25K) inserts will NOT work in your 30K unit.

(30K) inserts will NOT work in your 25K unit.

Inserts are extremely FRAGILE . If one is dropped, bent, or scratched it

WILL NOT cavitate (i.e. will not funcon) or funcon by operang at a

higher than normal temperature and should be replaced immediately.

Insert ps should be rounely replaced according to insert

manufacturer's recommendaons.

ELECTRICAL REQUIREMENTS

A GROUNDED electrical receptacle is required supplying 120-130

volts 50/60 Hz A.C. If a 3 to 2 prong adapter is used, the ground wire

MUST be connected to the base plate screw. Have an electrician test

your outlet for correct wiring polarity and a safe ground. DO NOT plug

the AUTOSCALER® in a GFI (Ground Fault Interrupt ) outlet.

HANDPIECE—POWER CONTROL POT INSTALLATION

Two 18 gauge wires must be routed between the AUTOSCALER®

console and the handpiece assembly. Thinner wire may result in

poor tuning/operaon or non funcon.

Two 18 gauge wires must be routed between the AUTOSCALER®

unit and the Power Control Pot. A minimum of ½ wa rang @ 5K

ohms is required if substung the power control pot with

another brand/style.

INSTALLATION AND OPERATION

1. The Water Control Knob should be in the HIGH posion. It is

normal for the Knob to turn past the High posion several

rotaons which will increase water ow substanally.

Depending on the water regulator supplied in your operatory the

following applies: HIGHER water ow to the RIGHT and LOWER

water ow to the LEFT. Some water regulators adjust the opposite

(more ow to le and less to the right). Become familiar with your

controls rst before performing any dental procedures on

paents.

2. Your unit is equipped with a AIR SWITCH ACTIVATOR. The air

supply must be aached to the rear of the unit, and a minimum

of ( 20 PSIG ) is necessary to acvate the switch. DO NOT

REMOVE THE INTERNAL AIR RESTRICTOR FITTING. The restrictor

relieves the air input line if accidentally charged from another air

21

source without a purge cycle. The scaler air line will bleed o to

zero pressure protecng the AUTOSCALER®.

3. Plug the power cord into the wall (see electrical requirements).

4. Select an insert. Moisten the rubber O-RING before inserng into

the handpiece. While holding the handpiece, UPRIGHT, place the

insert in the open end of the handpiece, and with a gentle PRESS

and TURN moon, snap the insert in fully. DO NOT force the insert.

5. Manufacturer recommends the use of a disposable handpiece

sleeve/barrier be used over the handpiece assembly. Place the

sleeve/barrier over the handpiece. While holding the sleeve/

barrier in place, puncture the insert through the plasc at the

open end of the handpiece, and snap the insert in fully. Dispose of

sleeve/barrier aer each paent.

6. Due to atmospheric exposure, and exposure to sterilizaon

soluons, the O-RING on the insert p may become swollen,

brile, or crack, and require replacement.

7. Set the POWER KNOB all the way to the LEFT in the LOW posion

8. Hold the handpiece in a VERTICAL upright posion, and step on

the foot switch. Within 10-15 seconds water should come out of

9. Inserts and handpiece will burn in 45-60 seconds in the absence

of water. A (18cc—30cc/+/min) ow is the normal ow range, and

necessary at all mes. NEVER touch the Cavitang/Vibrang end

of the insert p to any esh such as the cheek, tongue, or gums

unless performing special periodontal procedures. This will cause a

FRICTION BURN to the paent. Always keep the insert in moon.

Do not rest the handle or insert on the lips during a procedure.

The insert p should touch primarily the calculus on the tooth

surface, and NOT the enamel of the tooth surface.

10. Allow the air bubbles to escape for about 10-20 seconds. Turn the

POWER KNOB to the RIGHT in the Medium posion, and the

insert p should Cavitate/Vibrate with a strong mist. Turn the

water knob to the right if there is no mist or weak misng.

the open end of the handpiece IF NOT, QUICKLY

turn WATER KNOB clockwise 1-2 rotaons to get

water ow. Some air will escape at the same

me. This step is IMPORTANT because trapped

air will cause HOT SPOTS (usually noted by a

loud screeching sound) which can aect the

performance of the AUTOSCALER® or

permanently damage the handpiece assembly.

22

11. The applicaon of the power knob is for controlling the Output

Power to the insert p in a smooth linear acon. The operator can

select the EXACT power needed for cleaning. Set power knob LOW

(Le Direcon) to MEDIUM (Center) for cooler handpiece/insert

temperature.

12. The high power seng is for applicaons where an excessive

amount of calculus is built up. The Low power seng can be used

for periodontal Subgingival cureage and root planing

procedures. Most scaling should be done only on the LOW to

MEDIUM power seng.

13. If SLIMLINE™, FSI™ or Modied Periodontal inserts are used, set

the POWER Knob in the BLUE shaded area. This power level is

designed to be used with these fragile specialty inserts. Inserts

may give a drip and mist combinaon, this is normal for these

inserts. This is actually preferred by most Periodontal

professionals due to the water drip being ultrasonically acvated

within 0.5mm of the p assisng in killing plaque.

UNIT IS NOW READY FOR USE

SHUT DOWN PROCEDURE

Be sure to shut o Air and Water supply to the scaler when

unaended. The installing service technician will indicate to the

operator which controls perform this acon.

TROUBLESHOOTING

If the unit does not funcon, proceed with the following:

1. Check the plug. Is it all the way in the receptacle?

2. Try another insert. Make sure it is the correct frequency 25K or

30K depending on your model. Each model has a frequency (25K or

30K) label on the cover and the frequency is also indicated on the

serial number plate located on the boom of the device. The most

common mistake when purchasing a new unit is selecng the

wrong frequency insert.

3. If water ow is insucient, check water pressure at the operatory for

minimum of 20 P.S.I. The Insert Water slot could be clogged with

debris. Try another insert.

4. If the handpiece handle or insert operates HOT: REDUCE POWER

LEVEL and INCREASE WATER FLOW. Depending on the water

regulator supplied in your operatory the following applies: HIGHER

water ow to the RIGHT, and LOWER water ow to the LEFT. Some

water regulators adjust the opposite (more ow to le and less to the

23

right). Become familiar with your controls rst before performing any

dental procedures on paents.

5. NEVER touch the Cavitang/Vibrang end of the insert p to any

FLESH such as the cheek, tongue, or gums unless performing special

periodontal procedures. This will cause a fricon burn to the paent.

Always keep the insert in moon. Do not rest the handle or insert on

the lips during a procedure. The insert p should touch PRIMARILY the

calculus on the tooth surface, and NOT the enamel of the tooth

surface.

6. If the AUTOSCALER® stops funconing or is intermient when the

handpiece cord is moved, this means a wire in the handpiece cord is

broken and must be immediately repaired or replaced. DO NOT

connue to press the foot switch as there is a possibility the internal

circuit safety fuse may blow and require replacement by a qualied

technician.

7. If a humming or high pitch sound is noted from the console during

roune use, this is a normal circuit resonance which will change as the

POWER control knob is adjusted up and down, and will not aect the

performance of your AUTOSCALER®.

8. Slimline™ and FSI™ inserts are extremely thin and FRAGILE. During

normal use the water may not mist like standard inserts (i.e. like a

TFI#10 curee p). However, the cleaning acon is just as eecve. It

is recommended the Power knob be set in the LOW posion (Blue

area) to assure best performance.

Call your dealer or customer service at South East Instruments for

further instrucons at (800) 648-9445 to help you with quesons and

what to do next.

SCALING TECHNIQUES

Scaling techniques are at the opon of the professional using this

instrument.

1. Excessive pressure is not necessary with the AUTOSCALER®. Use a

gentle, rapid moon with small overlapping strokes, being certain that

the insert is at a 15 degree angle to the tooth surface.

2. If paent Hypersensivity is noted, you should lighten pressure on the

handpiece, Reduce the Power Level, or move from the sensive tooth

to another, and return to the tooth later. If sensivity persists, switch

to a hand instrument.

24

Front view 25K and 30K

Rear view

Circuit board 20mm-4.0 amp

Fuse Fast Blow

AC power AGC 2.0 amp Fuse

Fast Blow

BRIEF LAYOUT OF THE BUILD-IN STYLE AUTOSCALER®

25

Connect the AC POWER CORD to supply. GROUND conductor MUST BE

Used.

Connect Handpiece leads, and Power Control pot leads according to

drawing FRONT VIEW. There is NO POLARITY for Handpiece leads or

Power Control Pot leads. IT IS SUGGESTED THE 15’ EXTENSION WIRES

(not supplied) CONNECTED TO THE AUTOSCALER® CONSOLE BE

SOLDERED TOGETHER, AND INSULATED WITH A “UL or CSA”

APPROVED SHRINK TUBING Hand twisng and taping of wire

connecons is NOT recommended. It may aect the performance and

safety of the installaon.

When installing the AUTOSCALER® build-in unit, the AIR SOURCE used

to acvate the scaler MUST be independent of all other operatory

equipment, and the supply line pressure must relieve to ZERO PSI aer

each acvaon. The AUTOSCALER® unit may be damaged by acvaon

while other equipment is in use if the air signal is not turned OFF to

the scaler, and line pressure fully relieved when not in use.

The AUTOSCALER® is internally ed from the factory with a pressure

relief valve (restrictor) and must not be removed. This restrictor helps

relieve line pressure aer each acvaon.

IMPORTANT: The AUTOSCALER® unit has been calibrated

ancipang approximately 15’ Fieen feet of 18 GAUGE wire will be

used in the installaon. DO NOT use any wire thinner than 18 GAUGE.

This will change the tuning (i.e. insert will not vibrate properly) of the

AUTOSCALER® and/or not funcon.

26

ULTRASONIC SCALER INSERTS

DIRECTIONS FOR USE FOR OPTIMAL FUNCTION.

Sterilize before each use in accordance with the insert

manufacturer’s instrucons

Federal Law restricts the device to sale by or on the order of a

licensed praconer

3 month warranty

INSERT DEVICE DESCRIPTION

Ultrasonic inserts are accessory inserts designed for use with

magnetostricve scaler units, (see specicaons) that generate a

frequency of either 25KHz or 30KHz. A range of p designs are available to

suit dierent clinical condions. Finger-grips are either plasc or metal

and the water channel is either of internal or external design. These

inserts are designed to be used in magnetostricve ultrasonic scalers only

by professionally trained operators, such as Densts or Dental Hygienists,

to perform general supra and subgingival scaling procedures.

Internal water channel with plasc nger-grip

External water channel with metal nger-grip

Tip Design Applicaon

DF#3 Beaver Tail/Flat

DF#10 Universal Curee

Heavy to moderate supragingival deposits

on buccal and lingual surfaces.

Heavy to moderate supragingival deposits,

light to moderate subgingival deposit on all

surfaces.

DF#100 Periodontal Style Light to moderate supragingival deposits

especially interproximally.

Tip Design Applicaon

DF#10 Universal Curee Heavy to moderate supragingival deposits,

light to moderate subgingival deposit on all

surfaces.

DF#100 Periodontal Style Light to moderate supragingival deposits

especially interproximally.

27

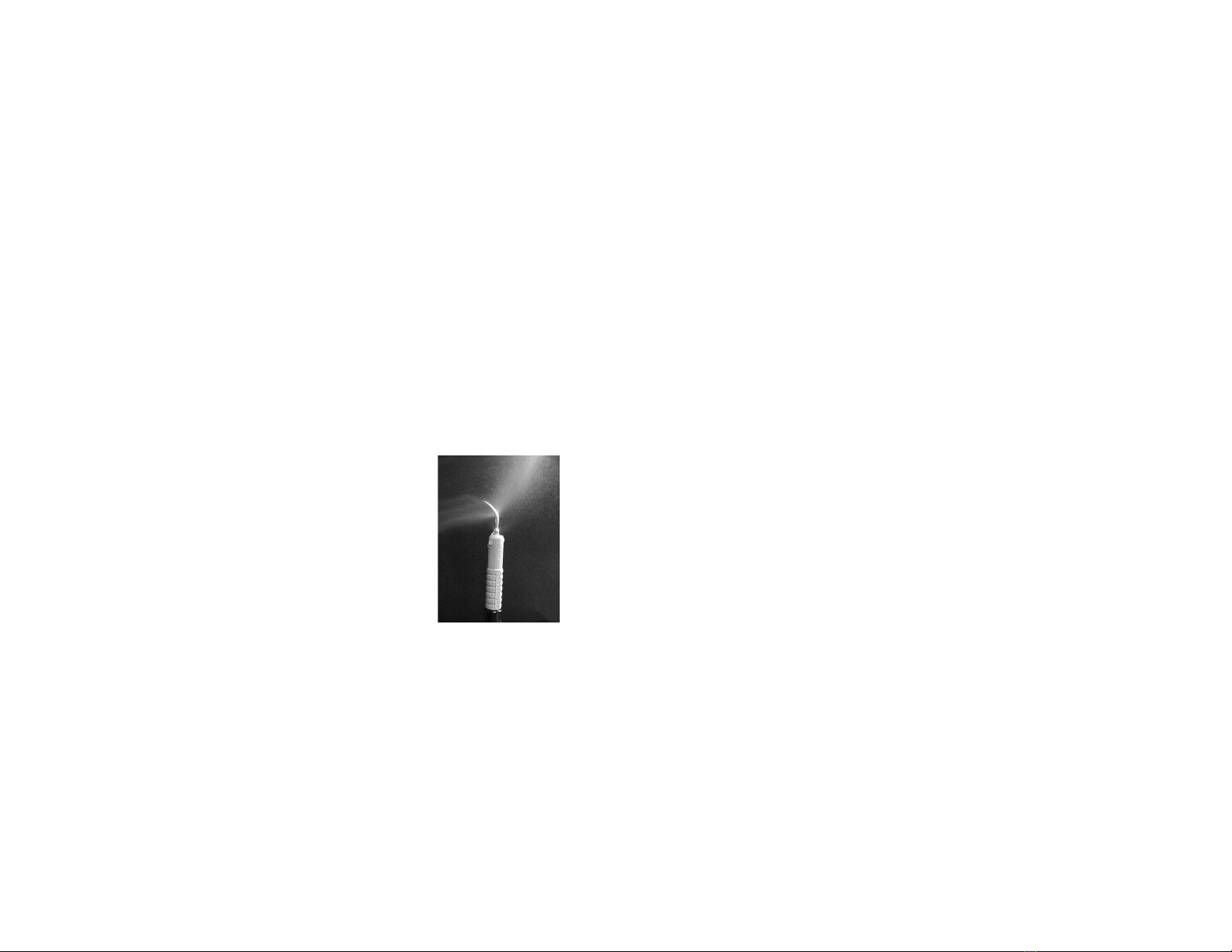

WATER FLOW

An adequate water ow seng, indicated by a small spray or rapid drips,

should be selected for the power seng used to prevent overheang of

the insert p during funcon, and to prevent possible injury.

INSTRUCTIONS FOR USE

Ensure that the insert is suitable for the frequency (25K or 30K) of the

scaler unit. Always sterilize inserts prior to each use in accordance with

the insert manufacturer’s instrucons. Always use a light, smooth, gentle

touch with a well-posioned stable intraoral or extraoral fulcrum. The

lateral surfaces of the insert are normally used for clinical procedures. In

the event that this insert is dropped or damaged or becomes bent, discard

the insert and replace with a new insert. Inserts with high usage, which

exceed the warranty period, should be discarded to avoid in-use breakage

and possible injury.

Inserts should not be used for condensaon of amalgam.

Care must be exercised to avoid iatrogenic results from the use of

ultrasonics in the presence of dental restoraons. Note that the p end or

other sharp aspect of an insert can scratch or otherwise modify the

surface of gold or amalgam restoraons. Thin porcelain veneers and

composite margins can be cracked or crazed by acvated ultrasonic ps.

Normal wear of the p occurs during funcon. When approximately 2 mm

of the p has worn the insert may lose up to 50% eciency, and should be

discarded. Contact with composite restoraons will cause more rapid

arion of ultrasonic inserts.

O-RINGS

Before placing inserts into the handpiece performing the following steps

will increase O-ring life.

1. Fill enre handpiece with water

2. Lubricate O-ring (black or green material) with water

3. Gently twist the insert down into the handpiece unl fully seated

UNIT POWER SETTINGS

1. DP#100, & DF#100 inserts should be used with minimum power

seng only on the unit.

2. DF#10, DF#1000 & DP#10 inserts should be used on low - medium

power seng.

3. DF#3 inserts may be used on medium - high power seng

As a rule the power seng on the unit should always be set at the

minimum and increased only as dictated by clinical requirements.

28

INSERT STERILIZATION

Sterilize inserts before each use in accordance with the insert

manufacturer’s instrucons.

SPECIFICATIONS

These inserts are designed for 25K or 30K magnetostricve scaler

handpieces with:

Internal diameter of 7.3 mm.

Internal length of no less than 125 mm.

INSERTS LIMITED WARRANTY

If, in normal use, any insert is found to be defecve in material or

workmanship within a period of ninety (90) days from the date of

original purchase it will be replaced or the purchase price will be

refunded.

The limited warranty stated herein is the sole and exclusive warranty

to the insert and SEI hereby disclaims any and all other warranes,

expressed or implied, including without limitaon, any statutory

warranes or any warranes of merchantability, tness for use or

tness for any parcular purpose. SEI shall not be responsible for any

inconvenience loss, injury, or direct, indirect, tort, exemplary, punive,

special incidental or consequenal damage arising from the possession

or use of the insert. In no event will SEI's liability exceed the purchase

price of the insert.

Tampering, abuse, misuse, neglect, alteraon, accidental damage,

failure to follow manufacturer's instrucons, improper disinfecon or

sterilizaon procedures, bending, re-grinding or re-shaping, or lack of

reasonable care with respect to the insert will void this warranty. Use

of the insert by anyone other than a licensed dental praconer or

qualied hygienist will void this warranty.

A warranty claim must be accompanied by a dated sales receipt or

other appropriate documentaon showing the date of purchase. In the

event of a warranty claim, it is the responsibility of the user to return

the defecve insert(s) to original purchaser.

This manual suits for next models

1

Table of contents

Popular Media Converter manuals by other brands

Idis

Idis DE-1104 Operation manual

D&H

D&H DH05C manual

Cross Technologies

Cross Technologies 2015-7075 instruction manual

Sierra Video

Sierra Video SV-SM-8 user manual

Comtech EF Data

Comtech EF Data MN/LBC4000.IOM Installation and operation manual

Baumer

Baumer Hubner Berlin HOG 16 + DSL.E Installation and operating instructions

Lika

Lika Posicontrol IF55 LIN CB Series Mounting instructions

CHD Elektroservis

CHD Elektroservis SY2-KBD installation manual

Transition Networks

Transition Networks CGFEB10xx-12x user guide

Linetek

Linetek HD1TO1LR1 user manual

Digital Barriers

Digital Barriers TVI D1000 user manual

Kiloview

Kiloview S2 quick start guide