autosen AS002 User manual

Operating instructions

Magnetic-inductive flow meter

autosen AS002, AS003

AS004

80237868 / 00 02 / 2016

UK

2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������4

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������5

4 Function���������������������������������������������������������������������������������������������������������������5

4�1 Processing of the measured signals��������������������������������������������������������������6

4�2 Direction of flow ���������������������������������������������������������������������������������������������6

4�2�1 Determination of the direction of flow (Fdir)������������������������������������������6

4�2�2 Detection of the direction of flow (dir�F) ������������������������������������������������7

4�3 Consumed quantity monitoring (ImP) ������������������������������������������������������������7

4�3�1 Display and counting method of the quantity meter �����������������������������8

4�3�2 Consumed quantity monitoring via pulse output�����������������������������������8

4�3�3 Consumed quantity monitoring via preset counter �������������������������������9

4�4 Switching function����������������������������������������������������������������������������������������10

4�5 Analogue function ����������������������������������������������������������������������������������������10

4�6 Measured value damping (dAP) ������������������������������������������������������������������13

4�7 Start-up delay (dSt) �������������������������������������������������������������������������������������13

4�8 Low flow cut-off (LFC)����������������������������������������������������������������������������������15

4�9 IO-Link ���������������������������������������������������������������������������������������������������������15

5 Mounting������������������������������������������������������������������������������������������������������������16

5�1 Recommended mounting position ���������������������������������������������������������������16

5�2 Not recommended installation position��������������������������������������������������������17

5�3 Installation in pipes ��������������������������������������������������������������������������������������17

5�4 Grounding����������������������������������������������������������������������������������������������������18

6 Electrical connection������������������������������������������������������������������������������������������18

7 Operating and display elements ������������������������������������������������������������������������20

8 Menu������������������������������������������������������������������������������������������������������������������22

9 Set-up ����������������������������������������������������������������������������������������������������������������24

10 Parameter setting ��������������������������������������������������������������������������������������������24

10�1 Parameter setting in general ���������������������������������������������������������������������25

10�1�1 Change to the menu "Extended functions"���������������������������������������25

10�1�2 Locking / Unlocking ��������������������������������������������������������������������������26

10�1�3 Timeout���������������������������������������������������������������������������������������������26

3

UK

10�2 Settings for volumetric flow monitoring������������������������������������������������������26

10�2�1 Limit monitoring volumetric flow (OUT1) ������������������������������������������26

10�2�2 Limit monitoring volumetric flow (OUT2) ������������������������������������������26

10�2�3 Analogue output flow rate (OUT2) ����������������������������������������������������26

10�2�4 Detection of the direction of flow (OUT1 or OUT2)���������������������������26

10�3 Settings for consumed quantity monitoring �����������������������������������������������27

10�3�1 Quantity monitoring by pulse output (OUT1) ������������������������������������27

10�3�2 Quantity monitoring by preset counter (OUT1)���������������������������������27

10�3�3 Pulse value ���������������������������������������������������������������������������������������27

10�3�4 Manual counter reset������������������������������������������������������������������������27

10�3�5 Time-controlled counter reset �����������������������������������������������������������28

10�3�6 Deactivation of the counter reset������������������������������������������������������28

10�3�7 Counter reset using an external signal ���������������������������������������������28

10�4 Settings for temperature monitoring ����������������������������������������������������������28

10�4�1 Limit monitoring temperature (OUT2)�����������������������������������������������28

10�4�2 Analogue output temperature (OUT2) ����������������������������������������������28

10�5 User settings (optional)������������������������������������������������������������������������������28

10�5�1 Standard unit of measurement for volumetric flow ���������������������������28

10�5�2 Standard display�������������������������������������������������������������������������������29

10�5�3 Output logic ��������������������������������������������������������������������������������������29

10�5�4 Start-up delay �����������������������������������������������������������������������������������29

10�5�5 Measured value damping �����������������������������������������������������������������29

10�5�6 Error behaviour of the outputs ����������������������������������������������������������29

10�5�7 Low flow cut-off���������������������������������������������������������������������������������30

10�5�8 Counting method of the totaliser�������������������������������������������������������30

10�5�9 Direction of flow ��������������������������������������������������������������������������������30

10�6 Service functions ���������������������������������������������������������������������������������������30

10�6�1 Read min/max values �����������������������������������������������������������������������30

10�6�2 Restoring the factory settings �����������������������������������������������������������30

11 Operation ���������������������������������������������������������������������������������������������������������31

11�1 Reading the process value ������������������������������������������������������������������������31

11�2 Changing the process value display in the RUN mode������������������������������31

11�3 Reading the set parameters�����������������������������������������������������������������������31

12 Troubleshooting �����������������������������������������������������������������������������������������������31

13 Technical data��������������������������������������������������������������������������������������������������33

14 Factory setting ������������������������������������������������������������������������������������������������34

4

1 Preliminary note

►Instructions

> Reaction, result

[…] Designation of keys, buttons or indications

→Cross-reference

Important note

Non-compliance may result in malfunction or interference�

Information

Supplementary note�

2 Safety instructions

• Please read this document prior to set-up of the unit� Ensure that the product is

suitable for your application without any restrictions�

• If the operating instructions or the technical data are not adhered to, personal

injury and/or damage to property can occur�

• Improper or non-intended use may lead to malfunctions of the unit or to un-

wanted effects in your application� That is why installation, electrical connec-

tion, set-up, operation and maintenance of the unit must only be carried out by

qualified personnel authorised by the machine operator�

• In order to guarantee the correct condition of the device for the operating time it

is necessary to use the device only for media to which the wetted materials are

sufficientlyresistant(→Technicaldata).

• The responsibility whether the measurement devices are suitable for the

respective application lies with the operator� The manufacturer assumes no

liability for consequences of misuse by the operator� Improper installation and

use of the devices result in a loss of the warranty claims�

• For medium temperatures above 50

°C (122 °F) some parts of the housing

can heat up to over 65 °C (149 °F)� Moreover, during installation or in case of a

fault (e�g� housing damage) media under high pressure or hot media can leak

from the system� To avoid personal injury, take the following measures:

►Install the units according to the applicable rules and regulations�

►Ensure that the system is free of pressure during installation�

5

UK

►Protect the housing against contact with flammable substances and uninten-

tional contact� To do so, equip the units with suitable protection (e�g� protective

cover)�

►Do not press the pushbuttons manually� instead use another object (e�g�

ballpoint pen)�

3 Functions and features

The unit monitors liquid media� It detects the 3 process categories volumetric flow,

consumed quantity, medium temperature�

Pressure Equipment Directive (PED)

The units comply with the Pressure Equipment Directive and are designed and

manufactured for group 2 fluids in accordance with the sound engineering prac-

tice�

Application area

Conductive liquids with the following properties:

• Conductivity:≥20µS/cm

• Viscosity: < 70 mm2/s at 40 °C; < 70 cSt at 104 °F

4 Function

• The unit detects the flow based on the magnetic-inductive volumetric flow

measuring principle�

• The unit also detects the medium temperature�

• It features an IO-Link interface�

• The unit displays the current process value�

6

4.1 Processing of the measured signals

The unit generates 2 output signals according to the parameter settings:

OUT1/IO-Link: 4 selection options Parameter setting

- Switching signal for volumetric flow quantity limit →10.2.1

- Pulse signal for quantity meter →10.3.1

- Switching signal for preset counter →10.3.2

- Switching signal for direction of flow →10.2.4

OUT2: 6 selection options Parameter setting

- Switching signal for volumetric flow quantity limit →10.2.2

- Switching signal for temperature limit →10.4.1

- Analogue signal for volumetric flow quantity →10.2.3

- Analogue signal for temperature →10.4.2

- Switching signal for direction of flow →10.2.4

- Input for external counter reset signal (InD) →10.3.7

4.2 Direction of flow

In addition to the flow velocity and the volumetric flow quantity, the unit also de-

tects the direction of flow�

4.2.1 Determination of the direction of flow (Fdir)

An arrow with the text "flow direction" on the unit indicates the positive flow direc-

tion.Theflowdirectioncanbeinversed(→10.5.9).

►Use the supplied label to mark the changed flow direction (new positive

direction of flow)�

Flow... Process value display

corresponds to the marked flow direction + (positive)

against the marked flow direction - (negative)

7

UK

4.2.2 Detection of the direction of flow (dir.F)

Whendir.Fisactivated(→10.2.4),thedirectionofflowisindicatedbyaswitching

signal�

The output is switched on until the set minimum volumetric flow quantity in nega-

tive direction of flow (- LFC) is not reached (1)�

Afterwards the following applies:

- The output switches ON when + LFC is exceeded (2)�

- The output switches OFF when - LFC is not reached (3)�

+ LFC

+ Q

- Q

- LFC

1

0

1 2 3

+ Q : Flow in positive direction of flow

- Q : Flow in negative direction of flow

+ LFC: Minimum volumetric flow quantity in positive direction of flow

- LFC : Minimum volumetric flow quantity in negative direction of flow

Positive direction of flow = marked direction of flow,

with the factory setting marked by the arrow on the unit or after change via Fdir

markedbytheattachedlabel(→4.2.1).

4.3 Consumed quantity monitoring (ImP)

The unit has an internal quantity meter (totaliser)� It continuously totals the

consumed quantity after the last reset� Pulse signals or a switching signal can be

used to monitor the consumed quantity�

→10.3.1Quantitymonitoringbypulseoutput(OUT1)

→10.3.2Quantitymonitoringbypresetcounter(OUT1)

8

4.3.1 Display and counting method of the quantity meter

Meter reading:

• Thecurrentmetercountcanbeindicated(→11.2).

• In addition the value before the last reset is saved� This value can also be

displayed(→11.2).

The meter saves the totalled volumetric flow quantity every 10 minutes�

After a power failure this value is available as the current meter reading� If a

time-controlled reset is set, the elapsed time of the set reset interval is also

saved� So the possible data loss can be maximum 10 minutes�

Counter reset:

• There are different ways to reset the quantity meter�

→10.3.4Manualcounterreset

→10.3.5Time-controlledcounterreset

→10.3.7Counterresetusinganexternalsignal

• If the quantity meter is not reset using one of the above-mentioned processes,

an automatic reset will be made when the maximum volumetric flow quantity

that can be displayed is exceeded (overflow)�

Taking into consideration the direction of flow:

• The quantity meter takes account of the flow direction for totalisation� The fol-

lowingcountingmethodscanbedefinedviatheparameter[FPro](→10.5.8):

[FPro] Counting method

0+ Negative flow values (against the marked direction of flow) are not taken

into consideration for totalling�

– + Negative flow values are subtracted from the consumed quantity�

4.3.2 Consumed quantity monitoring via pulse output

Output 1 indicates a pulse signal when the set volumetric flow quantity has been

reached(pulsevalue→10.3.3).

Depending on the setting of the counting method [FPro] totalling of the volumetric

flow quantity takes into account the flow in negative direction of flow (– +) or does

nottakeitintoaccount(0+)→4.3.1.

9

UK

ImpFPro = – +

Imp

FPro = 0 +

+ Q

t

t

- Q

V

+ Q = volumetric flow quantity in positive direction

- Q = volumetric flow quantity in negative direction

V = volumetric flow quantity absolute (= sum of negative and positive flow)

4.3.3 Consumed quantity monitoring via preset counter

2 kinds of monitoring are possible which can be set via the parameter [rTo]�

[rTo] Output Counter reset

OFF

(→10.3.6)

OUT1 switches when the volumetric

flow quantity set with [ImPS] has

been reached�

The preset counter is only reset

- whenamanualresetismade(→

10�3�4) or

- when the maximum display range

has been exceeded�

1, 2,��� h

1, 2,��� d

1, 2,��� w

(→10.3.5)

OUT1 switches when the volumetric

flow quantity set with [ImPS] is

reached within the set time�

The preset counter is reset auto-

matically when the time has elapsed

and counting starts again�

10

4.4 Switching function

OUTx changes its switching status if it is above or below the set switching limits

(flow or temperature)� Hysteresis or window function can be selected� Example of

volumetric flow monitoring:

Hysteresis function Window function

SP

rP

SP = set point

rP = reset point

HY = hysteresis

Hno = hysteresis NO (normally open)

Hnc = hysteresis NC (normally closed)

SP = upper limit

rP = lower limit

FE = window

Fno = window NO (normally open)

Fnc = window NC (normally closed)

When the hysteresis function is set, the set point [SP] is defined first and

then the reset point [rP] which must have a lower value� If only the set point

is changed, the reset point remains constant�

When set to the window function, the upper limit [SP] and the lower limit

[rP] have a fixed hysteresis of 0�5 % of the final value of the measuring

range� This keeps the switching status of the output stable if the flow rate

varies slightly�

4.5 Analogue function

• The unit provides an analogue signal that is proportional to the volumetric flow

quantity and the medium temperature�

• The analogue signal can be provided as current or voltage signal�

• Within the measuring range the analogue signal is 4���20 mA (current output) or

0���10 V (voltage output)�

11

UK

• If the measured value is outside the measuring range or in the event of an

internal error, the current or voltage signals indicated in Figure 1, Table 2 are

provided�

• The measuring range is scalable:

[ASP2] determines at which measured value the output signal is 4 mA or 0 V�

[AEP2] determines at which measured value the output signal is 22 mA or

10 V�

Minimum distance between [ASP2] and [AEP2] = 20 % of the final value

of the measuring range�

MAW Initial value of the measuring range For non-scaled measuring range

(= factory setting)

MEW Final value of the measuring range

ASP2 Analogue start point For scaled measuring range

AEP2 Analogue end point

Table 1: Definitions

12

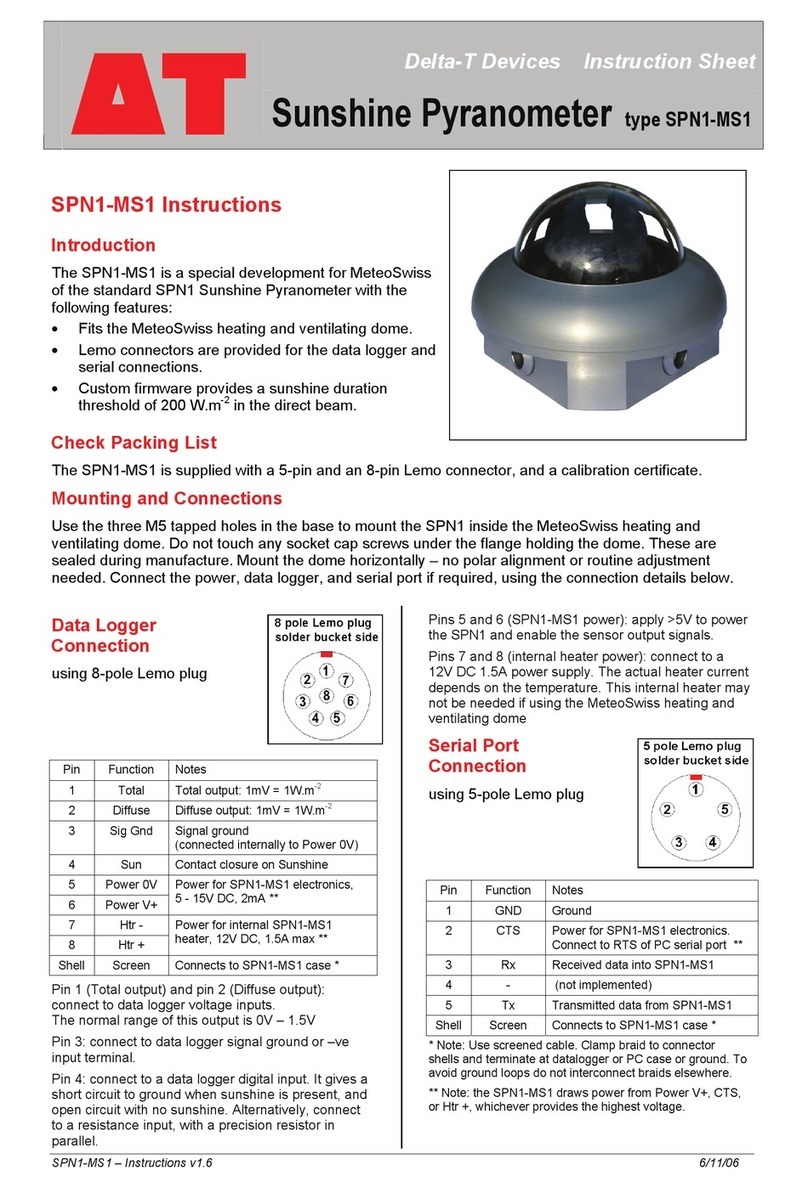

MEWMAW AEPASP

-120Q [% MEW]

[°C]T -40 -20 80 100 110

-130

-50

[°F]-40 -4 176 212 230-58

120

1000 130

4

3,50FOU=OFF

20

21,5

22

[mA]

0

10

11,5

12FOU=On

[V]

1

2

5

4

6

5*

6*

3

cr.UL UL OL cr.OL

Figure 1: Characteristics of the analogue output according to the standard IEC 60947-5-7�

Q: Flow (a negative flow value means flow against the marked flow direction)

T: Temperature

UL: Below the display range

OL: Above the display range

cr�UL: Below the detection zone (error)

cr�OL: Above the detection zone (error)

FOU=On: Default setting at which the analogue signal goes to the upper final value in

case of an error�*

FOU=OFF: Default setting at which the analogue signal goes to the lower final value in

case of an error�*

*Thetypeoferrorisdisplayed:cr.UL,cr.OL,Err(→12).

1

Analogue signal (voltage or current)

2

Measured value (flow or temperature)

3

Detection zone

4

Display range

5

Measuring range

5*

Analogue signal in the measuring range

with factory setting

6

Scaled measuring range

6*

Analogue signal for scaled measuring

range

13

UK

4.6 Measured value damping (dAP)

The damping time allows to set after how many seconds the output signal has

reached 63 % of the final value if the flow value changes suddenly� The set damp-

ing time stabilises the outputs, the display and the process value transfer via the

IO-Linkinterface.Thesignals[UL]and[OL](→12Troubleshooting)aredefined

under consideration of the damping time�

4.7 Start-up delay (dSt)

The start-up delay [dST] influences the switching outputs of the volumetric

flow monitoring�

If the start-up delay is active ([dSt] > [0]), note: As soon as the volumetric flow

exceedstheLFCvalue(→4.8),thefollowingprocessesarecarriedout:

> The start-up delay is activated�

> The outputs switch as programmed: ON for NO function, OFF for NC function�

After the start of the start-up delay there are 3 options:

1� The volumetric flow increases quickly and reaches the set point / good range

within [dST]�

> Outputs remain active�

2� The volumetric flow increases slowly and does not reach the set point /good

range within [dSt] > Outputs are reset�

3� Volumetric flow quantity falls below [LFC] within [dST]�

> Outputs are reset at once; [dSt] is stopped�

14

Example: dSt for hysteresis function

Condition Reaction

1 Volumetric flow quantity Q reaches LFC dST starts, output becomes active

2 dST elapsed, Q reached SP Output remains active

3 Q below SP but above rP Output remains active

4 Q below rP Output is reset

5 Q reaches again LFC dST starts, output becomes active

6 dST elapsed, Q has not reached SP Output is reset

7 Q reaches SP Output becomes active

15

UK

Example: dSt for window function

Condition Reaction

1 Volumetric flow quantity Q reaches LFC dST starts, output becomes active

2 dST elapsed, Q reached good range Output remains active

3 Q above SP (leaves good range) Output is reset

4 Q again below SP Output becomes active again

5 Q below rP (leaves good range) Output is reset again

6 Q reaches again LFC dST starts, output becomes active

7 dST elapsed, Q has not reached good

range

Output is reset

8 Q reaches good range Output becomes active

4.8 Low flow cut-off (LFC)

With the function Low Flow cut-off small volumetric flow quantities can be sup-

pressed(→10.5.7).FlowsbelowtheLFCvalueareevaluatedbythesensoras

standstill (Q = 0)�

4.9 IO-Link

This unit has an IO-Link communication interface which enables direct access to

process and diagnostic data� In addition it is possible to set the parameters of the

unit during operation� Operation of the unit via IO-Link interface requires an IO-

Link capable module (IO-Link master)�

With a PC, suitable IO-Link software and an IO-Link adapter cable communication

is possible when the system is not in operation�

16

For the IODDs necessary for the configuration of the unit, detailed information

about process data structure, diagnostic information and parameter addresses

visit www�autosen�com�

5 Mounting

►Ensure that the system is free of pressure during installation�

►Ensure that no media can leak at the mounting location during installa-

tion�

The unit can be installed independently of the orientation if the following is

ensured:

- No air bubbles can form in the pipe system�

- The pipes are always completely filled�

5.1 Recommended mounting position

►Install the unit so that the measuring pipe is always completely filled�

►Arrange for inlet and outlet pipe lengths�

S

F F

S

5 x D 2 x D

S = disturbance (e�g� shut-off / control device, pump, bends)

D = pipe diameter

F = direction of flow

17

UK

►Install in front of or in a rising pipe�

F

F

5.2 Not recommended installation position

• Directly behind shut-off / control devices�

• On the suction side of a pump�

• At the highest point of the pipe system�

• Directly in front of a falling pipe�

• In a falling pipe�

• Directly in front of the spout of the pipe�

5.3 Installation in pipes

The units with a G thread can be installed in the pipes using adapters�

Information about the available mounting accessories at www�autosen�com�

1� Grease the threads of the process connection, adapter and sensor� Use a

lubricating paste which is suitable and approved for the application�

18

2� Screw the adapter (B) into the pipe (A)�

3� Place the seals (C) and install the unit according to the marked flow direction�

4� Screw the adapter (B) with the threads (D) until it is hand-tight�

5� Tighten the two adapters in opposite direction (tightening torque: 30 Nm)�

After installation air bubbles in the system can affect the measurement�

►Corrective measures: Rinse the system after installation for ventilation (rinsing

quantity > 3 l/min; 1 gpm)�

In case of horizontal installation:

As a result of design requirements a small quantity of the medium always

remains in the measuring channel after switching off the pump�

5.4 Grounding

If installed in an ungrounded pipe system (e�g� plastic pipes), the unit must

be grounded (functional earth)�

6 Electrical connection

The unit must be connected by a qualified electrician�

The national and international regulations for the installation of electrical

equipment must be adhered to�

Voltage supply according to EN 50178, SELV, PELV�

►Disconnect power�

►Connect the unit as follows:

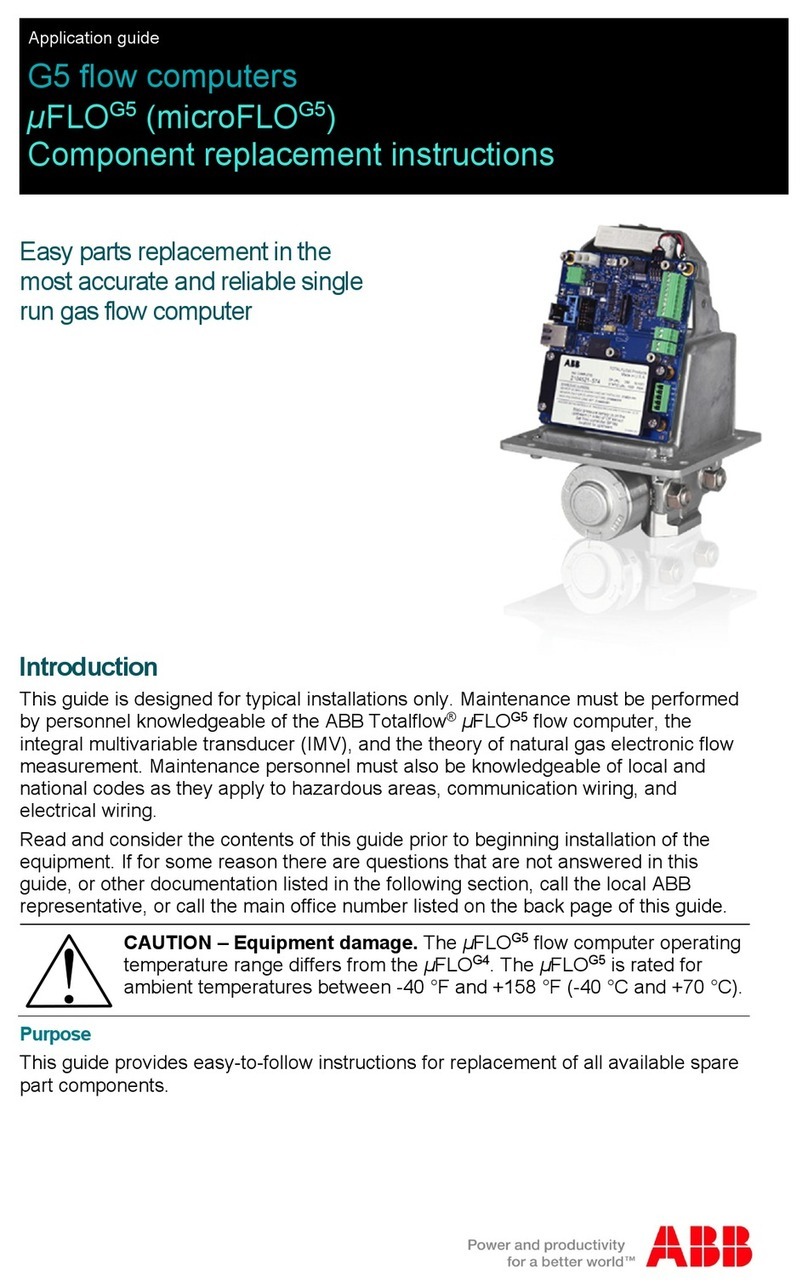

43

2 1

BK: black

BN: brown

BU: blue

WH: white

BN

WH

BK

BU

4

1

3

2OUT2

L+

L

OUT1

Colours to DIN EN 60947-5-2

19

UK

Sample circuits:

2 x positive switching 2 x negative switching

L

L+

3 BU

4 BK

2 WH

1 BN

L

L+

3 BU

4 BK

2 WH

1 BN

1 x positive switching / 1 x analogue 1 x negative switching / 1 x analogue

L+

L

3 BU

4 BK

2 WH

1 BN

L+

L

3 BU

4 BK

2 WH

1 BN

Pin 1 L+

Pin 3 L-

Pin 4

(OUT1)

•Switching signal: limits for volumetric flow

•Pulse signal: 1 pulse every time the defined volumetric flow quantity is reached

•Switching signal: quantity meter reached preset value

•Switching signal for direction of flow

•IO-Link

Pin 2

(OUT2/

InD)

•Switching signal: limits for volumetric flow

•Switching signal: limits for temperature

•Analogue signal for volumetric flow quantity

•Analogue signal for temperature

•Switching signal for direction of flow

•Input for external counter reset signal (InD)

20

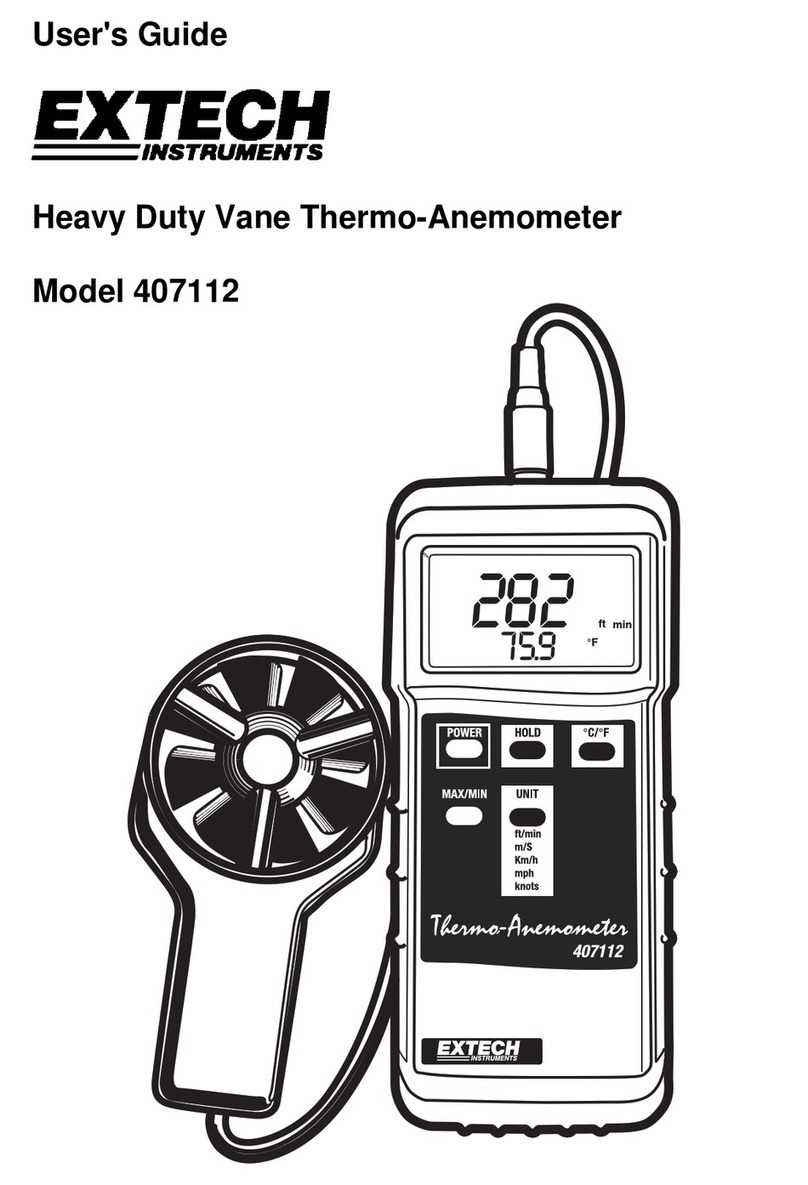

7 Operating and display elements

Mode /

Enter

Set

123 4 56

SP2

7

9

SP1

8

10

11

1-6: Indikator-LEDs für Prozesswertanzeige

LED Process value display Unit

1Current flow volume per minute l/min

2Current flow volume per hour m3/h

3Current consumed quantity (= meter

reading) since the last reset

Totaliser *

l

4m3

4 + 6 m3x 103

3

Consumed quantity (= meter reading)

before the last reset

l

4m3

4 + 6 m3x 103

5 Current medium temperature °C

LED is lit; LED flashes

* The consumed quantity is automatically displayed in the unit of measurement providing

the highest accuracy�

This manual suits for next models

2

Table of contents

Other autosen Measuring Instrument manuals