of

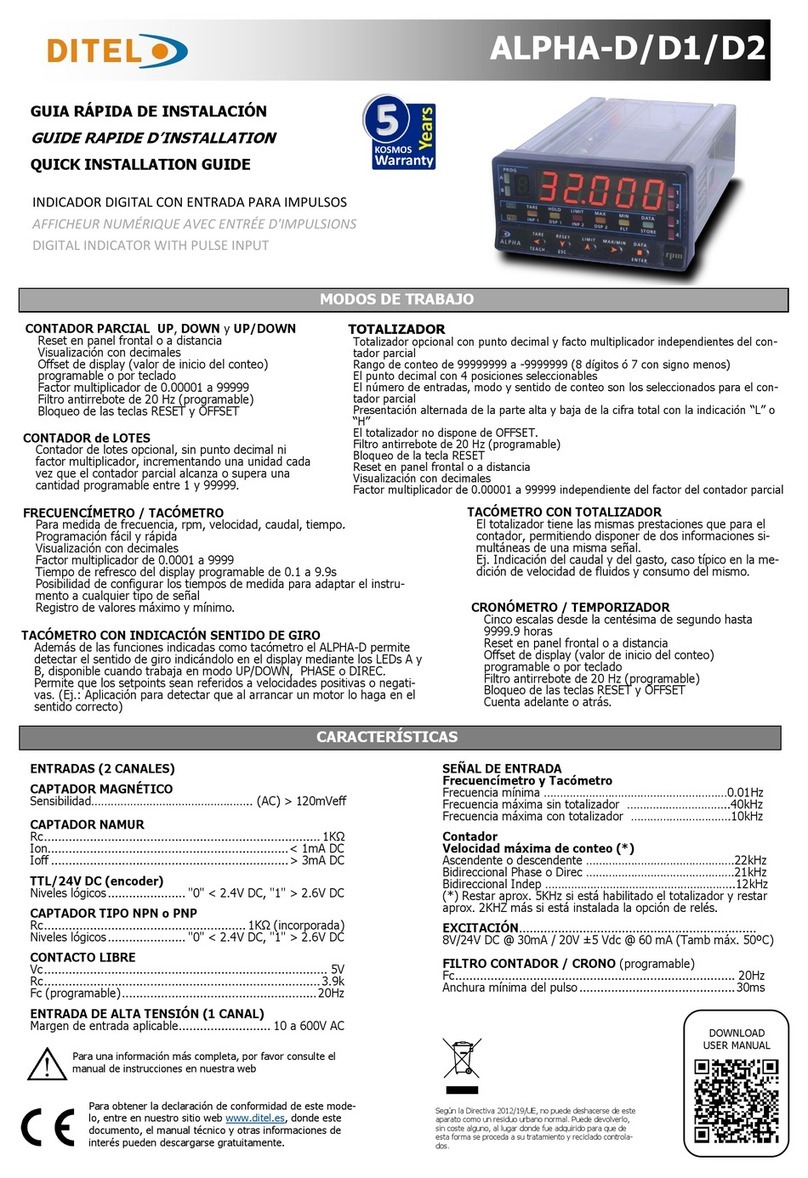

sources including switch contact, outputs from TTL circuits,

magnetic pickups ,NAMUR, PNP, NPN or encoder (TTL/24V).

uration is like one channel counter, where

one in

ut counter and the other can

be used like active input, direction or counting inhibit, other

uration is like a three channel counter, where two

endent

counters and with the

to make arithmetical

operations between them and generate a third counter.

In both cases, every counter carr

a totalizer shown thanks

to the second display of the BETA

-

D.

Alwa

e the main counter to a

tachometer, b

menu selection. The tachometer

has also a totalizer allowin

to show at the same time the

flow and Total volume ac

cumulated.

If the totalizer associated to the tachometer is bi

-

this has in addition indication of rotating direction

General characteristics :

Count signals in

quadrature x1, x2 y x4

.

Multiplier factor

pr

ogrammable from 0.0001 to 9999

Anti

-

debounce filter

100Hz, selectable

Counting selection by fall and rise edge or only by

rise

edge.

Batch counter with automatic cycle

(increases of one

unit of batch counter and automatic reset ever

time that

the main variable overcomes the programmed level)

or

manual

(increases one unit the batch counter ever

time

that is done a reset of partial counter).

Offset

programmable or stored from display

Function re-

load

(manual introduction of startin

count of

the variables)

I nhibition of keyboard functions

offset, reset, load and

visual

Refresh of display

every 10ms

Store of process , batch and total

values on Power

-

off

4 logical inputs with programmable functions of

:

Printing setpoints and its situation

Selective printing

of variables

Selective reset of variables,

ulse, with hold or with sto

of

counter

Hold of display, of setpoints and outputs

Inhibition of inputs

1.1. Introduction to BETA

uts from TTL circuits,

magnetic pi

ckups ,NAMUR, PNP, NPN or encoder (TTL/24V).

uration is like one channel counter, where

one in

ut counter and the other can

be used like active in

inhibit, other

configuration is like a three channel counter, where two

endent

counters and with the

to make arithmetical

operations between them and generate a third counter.

In both cases, every counter carry a totalizer shown thank

s

to the second display of the BETA

-

D.

Alwa

e the main counter to a

tachometer, b

menu selection. The tachometer

has also a totalizer allowin

to show at the same time the

flow and Total volume accumulated.

If the totalizer

associated to the tachometer is bi

-

this has in addition indication of rotating direction

General characteristics :

Count signals in

quadrature x1, x2 y x4

.

Multiplier factor

programmable from 0.0001 to 99

99

Anti

-

debounce filter

100Hz, selectable

Counting selection by fall and rise edge or only by

rise

edge.

Batch counter with automatic cycle

(increases of one

unit of batch counter and automatic reset ever

time that

the main variable overcomes the programmed level)

or

manual

(increases one unit the batch counter ever

time

that is done a reset of partial counter).

Offset

programmable or stored from display

Function re-

load

(manual introduction of startin

count of

the variables)

I nhibition of keyboard func

tions

offset, reset, load and

visual

Refresh of display

every 10ms

Store of process , batch and total

values on Power

-

off

4 logical inputs with programmable functions of

:

Printing setpoints and its situation

Selective printing of variables

Selective reset of variables,

ulse, with hold or with sto

of

counter

Hold of display, of setpoints and outputs

Inhibition of inputs

1.1. Introduction to BETA