Snow plow 2023 1

CONTENTS

1. FOREWORD ........................................................................................................................................ 4

Warning symbols used in this manual ...................................................................................................................................5

2. DESIGNED PURPOSE OF USE.......................................................................................................... 6

3. SAFETY INSTRUCTIONS FOR USING THE ATTACHMENT...................................................... 7

3.1 Personal protective equipment...............................................................................................................................9

3.2 Safe shutdown procedure ........................................................................................................................................9

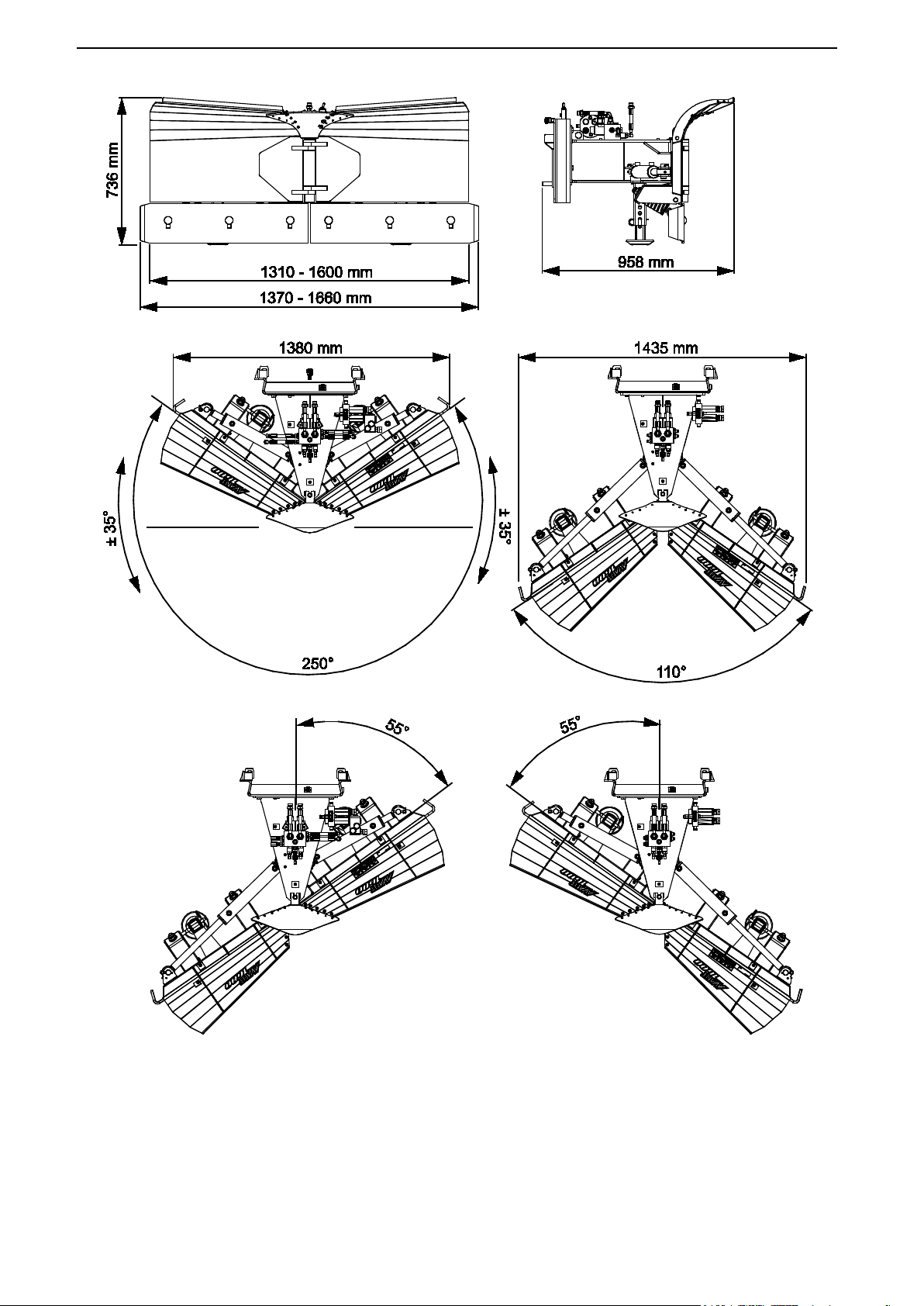

4. TECHNICAL SPECIFICATIONS ....................................................................................................... 10

4.1 Safety labels and main components of the attachment ....................................................................................11

4.2 Lifting.............................................................................................................................................................................13

5. ATTACHING THE ATTACHMENT ................................................................................................. 14

5.1 Connecting and disconnecting hydraulic hoses..................................................................................................15

5.2 Electric connection ....................................................................................................................................................17

5.2.1 To connect the electric harness of the attachment to the loader........................................................17

6. INSTRUCTIONS FOR USE ................................................................................................................ 19

6.1 Checks before use .....................................................................................................................................................20

6.2 Operator qualification...............................................................................................................................................20

6.3 Operating the snow plow ........................................................................................................................................21

6.3.1 Preparing for use................................................................................................................................................21

6.3.2 Correct operating position .............................................................................................................................22

6.3.3 Tips for use..........................................................................................................................................................23

6.4 To turn plow blade sections....................................................................................................................................23

6.4.1 Using the hydraulic functions of the Snow plow with Opticontrol®...................................................25

6.5 Hinged lower blade sections ...................................................................................................................................25

6.6 Support legs.................................................................................................................................................................26

6.7 Cutting edges of the plow........................................................................................................................................26

6.8 Transport position.....................................................................................................................................................27

6.9 Storing the attachment .............................................................................................................................................27

7. MAINTENANCE AND SERVICE ....................................................................................................... 28

7.1 Inspection of hydraulic components .....................................................................................................................28

7.2 Inspection of metal structures................................................................................................................................29

7.3 Cleaning the attachment...........................................................................................................................................29

7.4 Lubrication ...................................................................................................................................................................29

7.5 End of life disposal......................................................................................................................................................30

8. WARRANTY TERMS .......................................................................................................................... 31