User / Service Manual Power Stacker

10/06 Rev. 1.09 2

Contents

Contents...............................................................................................................................2

General.................................................................................................................................3

Copyright..........................................................................................................................................3

What is a "power stacker" ? .............................................................................................................3

Initiation................................................................................................................................4

Unpacking ........................................................................................................................................4

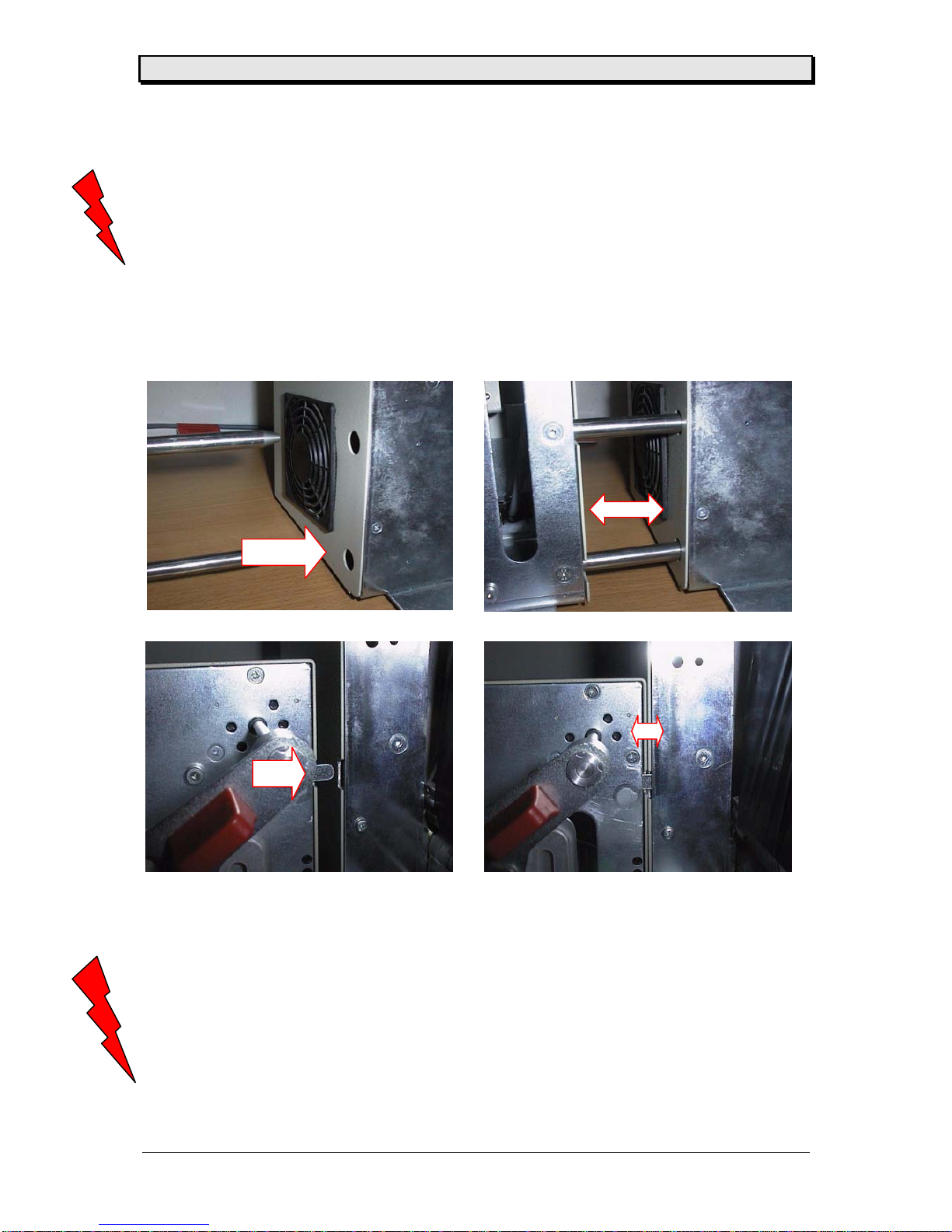

Assembling the Power Stacker ........................................................................................................5

Mounting the option to the TDI.........................................................................................................6

Assemble light cover........................................................................................................................7

Set up mode.........................................................................................................................8

Modes of operation - operation.............................................................................................9

Activating the sensor........................................................................................................................9

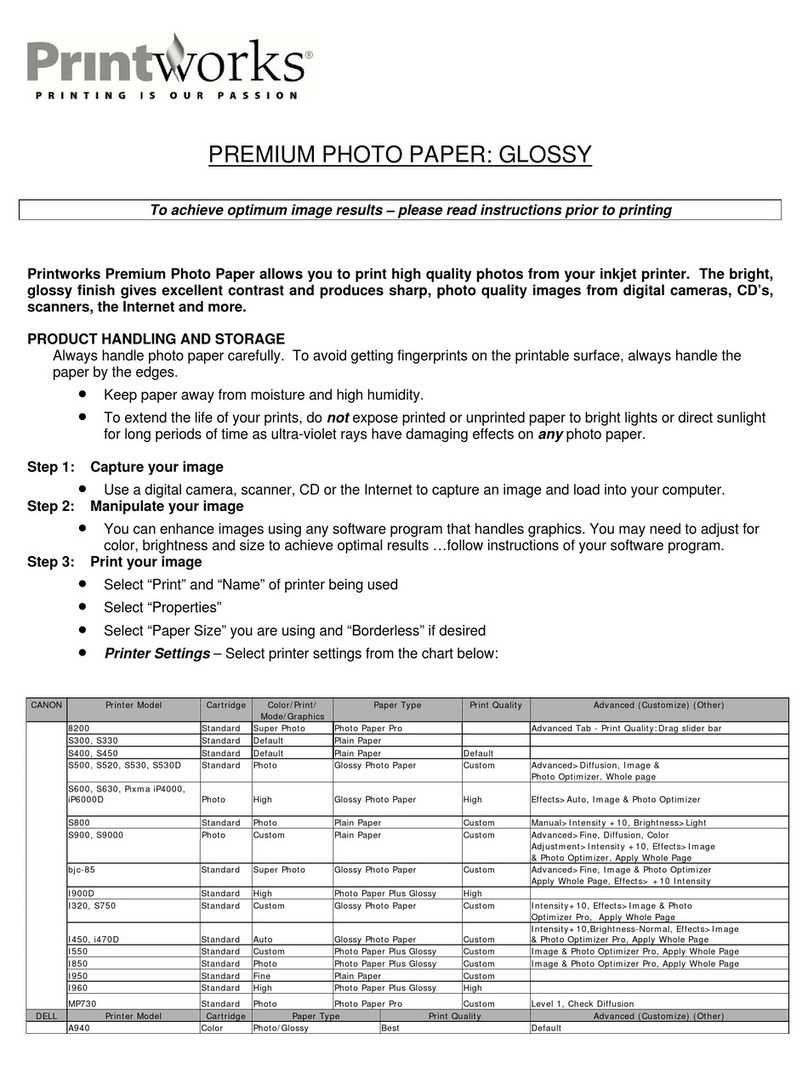

Adjusting the label width.................................................................................................................10

Adjusting the label length...............................................................................................................10

Magazine full..................................................................................................................................11

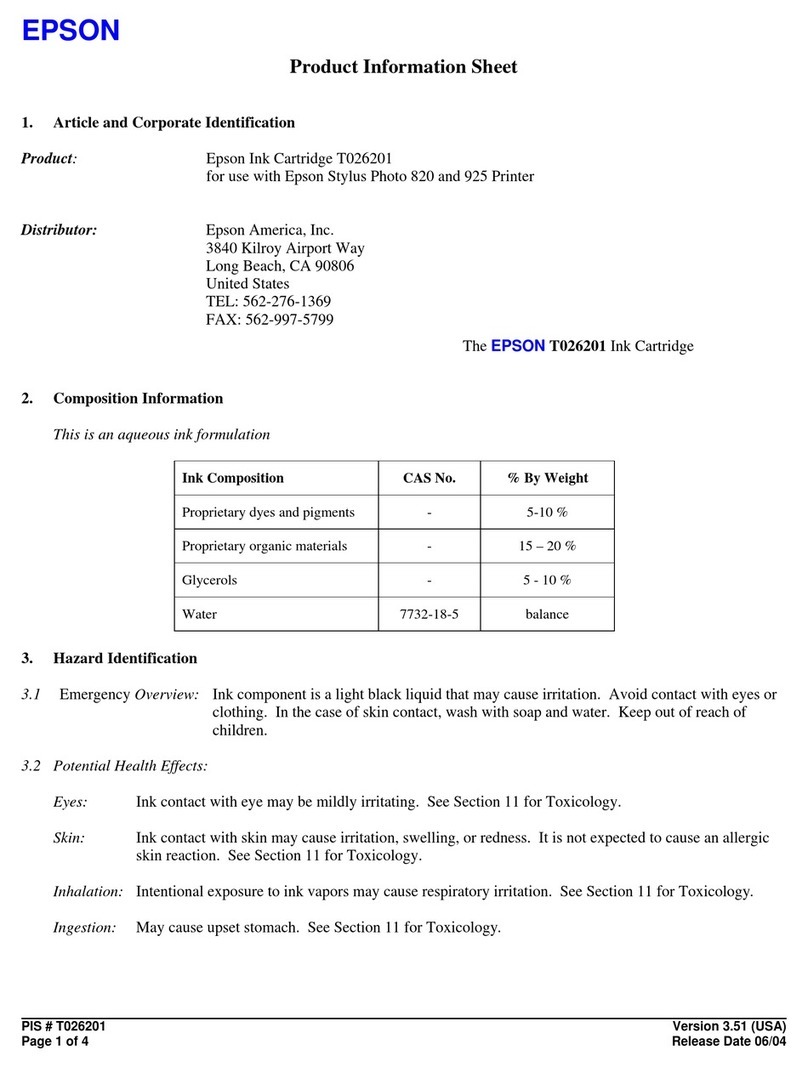

Information printout / parameter .........................................................................................12

Parameter Menu TDI......................................................................................................................12

Status printout ....................................................................................................................13

Status reports.....................................................................................................................14

ST04 Power stacker full .................................................................................................................14

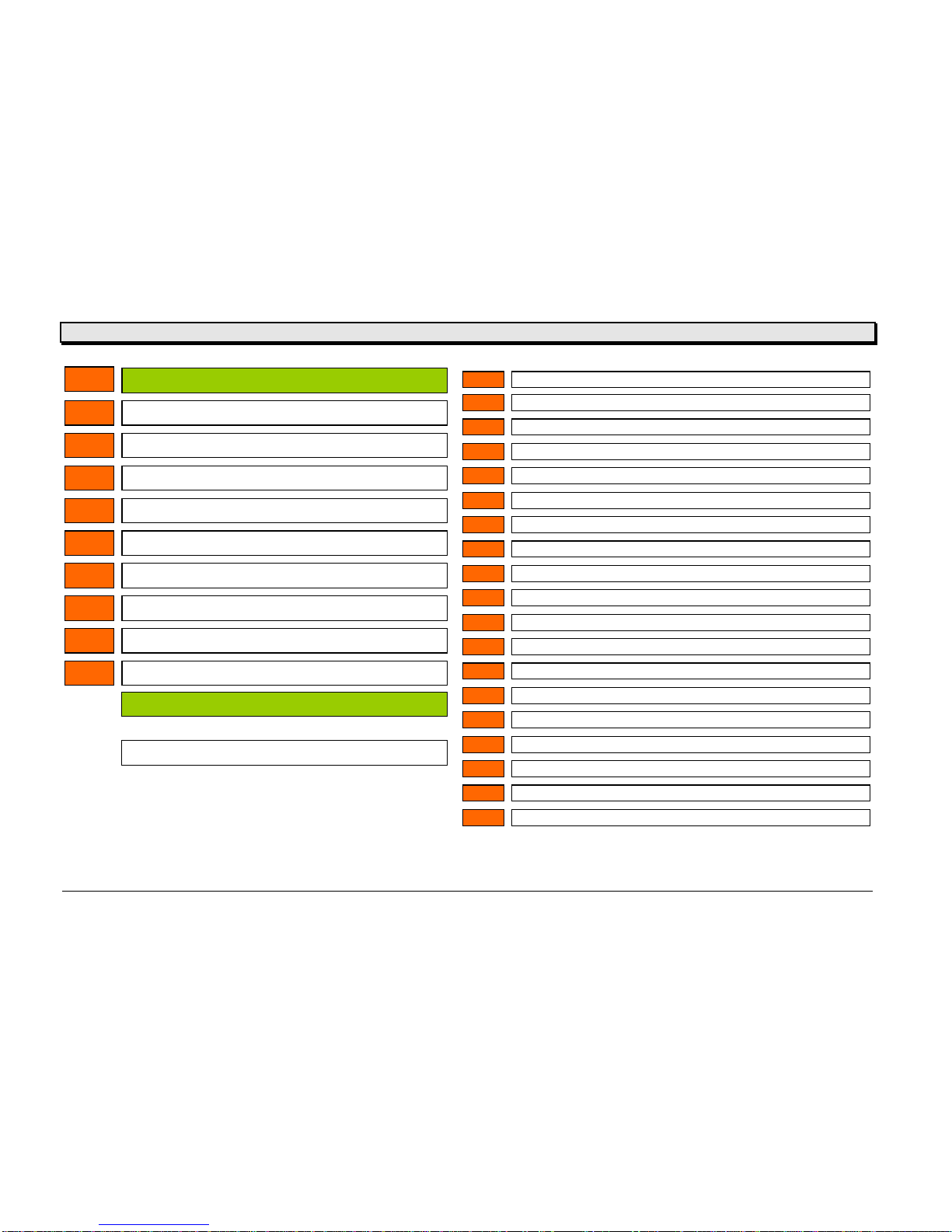

Overview - Status reports...............................................................................................................15

Maintenance, cleaning and service....................................................................................19

Maintenance and cleaning .............................................................................................................19

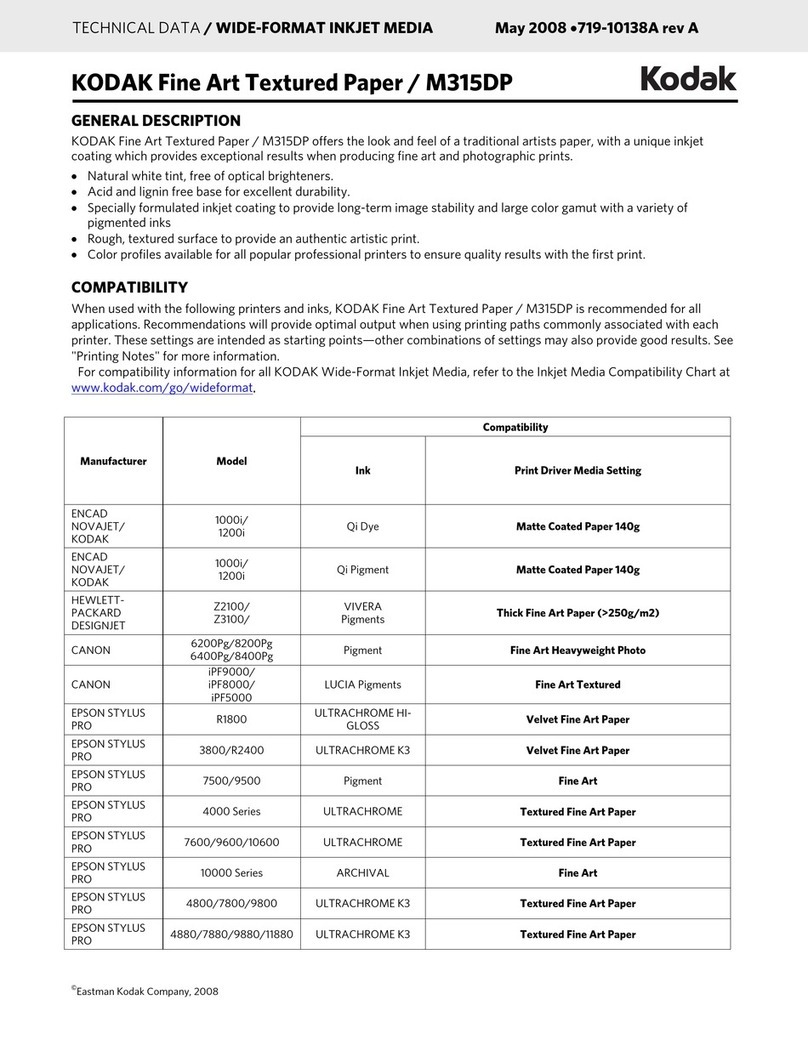

Service............................................................................................................................................19

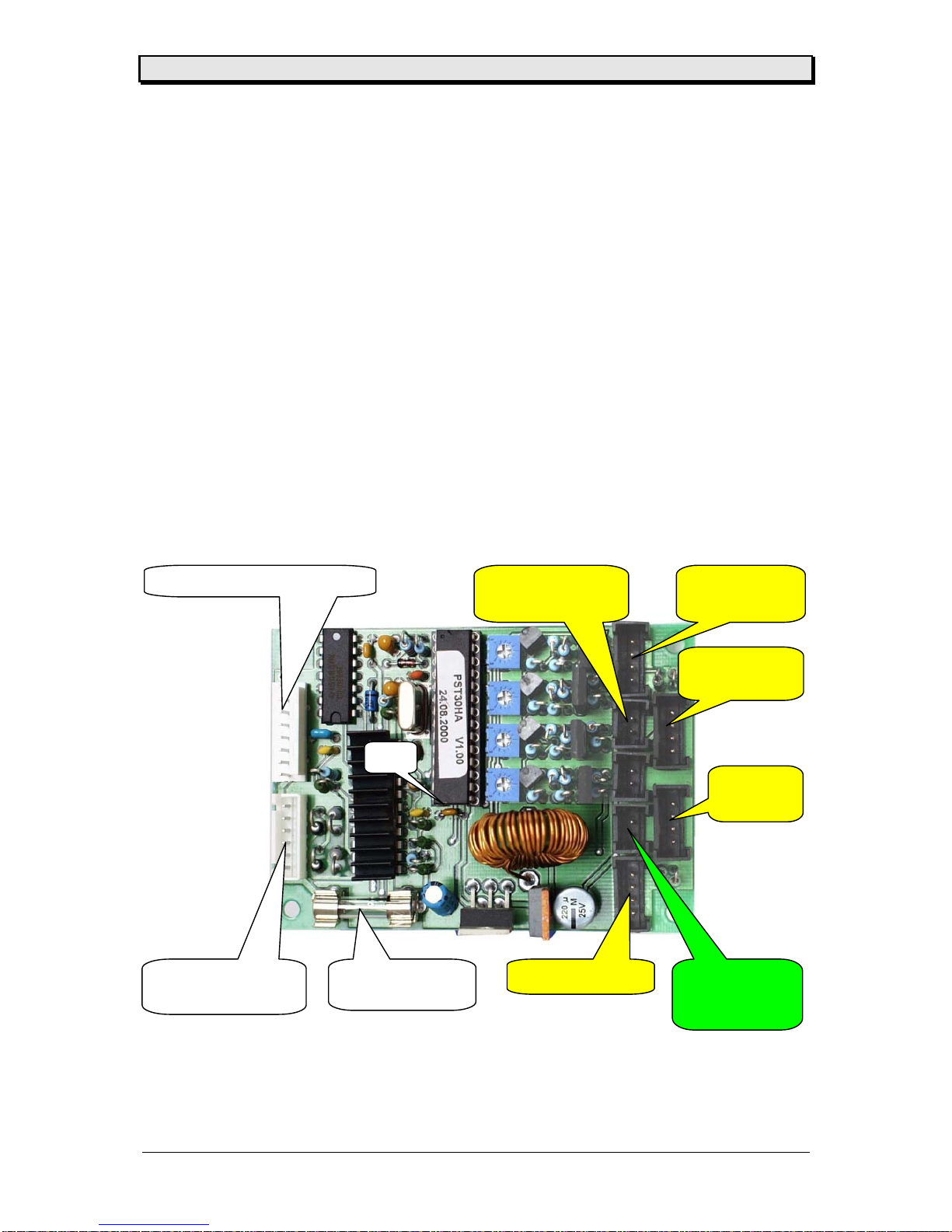

CPU board............................................................................................................................... 19

Micro switch ............................................................................................................................ 20

Reflex Sensor.......................................................................................................................... 20

Stepper motor ......................................................................................................................... 21

Diagrams............................................................................................................................22

Cable drawings...............................................................................................................................23

Circuit diagram CPU board ............................................................................................................27

Component diagram CPU board....................................................................................................28

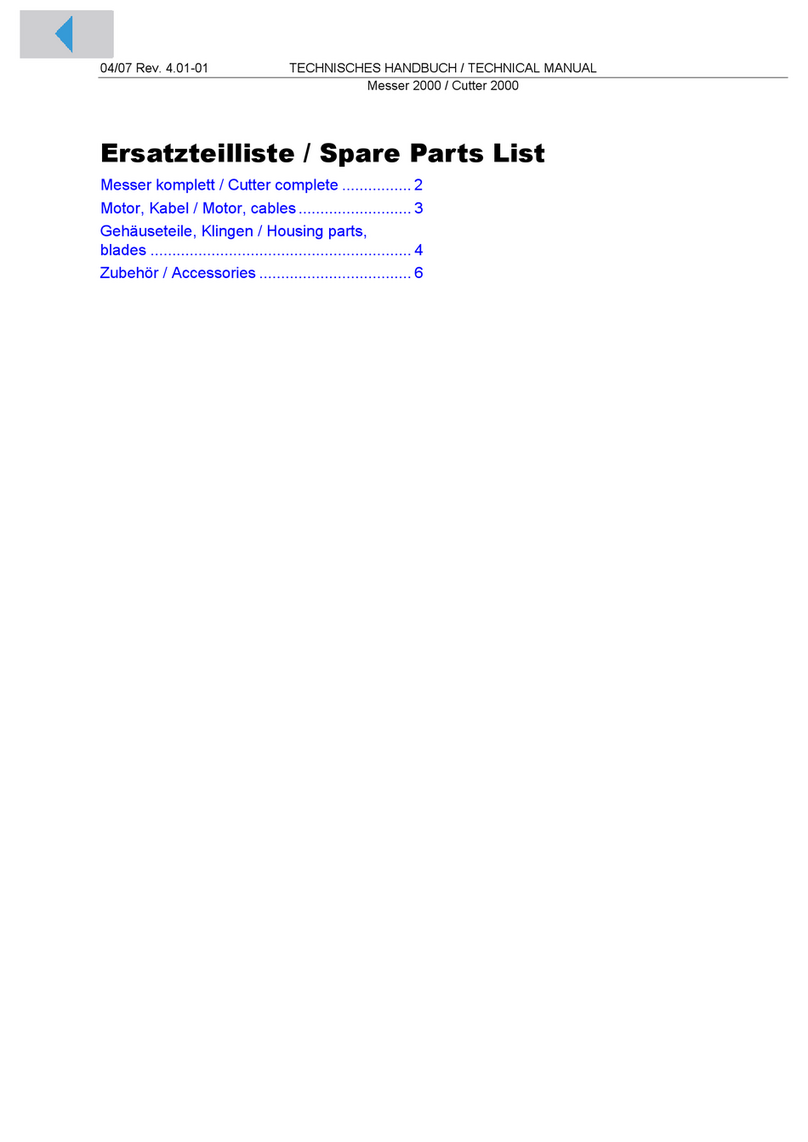

Spare parts list....................................................................................................................29

Index...................................................................................................................................39