Avery Dennison Cutter 2000 User manual

03/10 Rev. 5.04-01 TECHNICAL MANUAL

Cutter 2000

Connection, Setup, Service

Safety Notes ................................................. 2

General Notes ............................................... 3

Proper Usage ............................................ 3

Technical Specifications ............................ 3

System requirements .................................... 4

Preparation for peripheral devices ............ 4

Connecting the cutter .................................... 5

Activating the cutter ...................................... 7

Activating the TTX 350 / TTK ....................7

Activating the 64-xx / AP 5.4 / AP 5.6 /

AP7.t ......................................................... 7

Error message after activating the printer . 7

Parameter settings .................................... 8

Status reports ............................................9

Triggering a cut ..........................................9

Servicing the cutter ......................................10

General notes ..........................................10

Cutter motor .............................................10

Toothed belt .............................................11

Photoelectric switch .................................11

Oscillator Disc, Toothed Wheel ...............12

Circular cutter ..........................................13

Bottom cutter ...........................................15

Accessories .................................................16

Stripper plate ...........................................16

Appendix .....................................................17

Cable harness ..........................................17

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

2

Safety Notes

WARNING!

Danger of getting your fingers cut by the cutter blades!

«Cleaning of the cutter must be done very carefully.

«Don´t touch the cutter during printing/cutting operation.

«Don´t use the cutter as a handle to carry the printer.

«Switch off the printer and pull out the mains connector before any operation

that requires touching the cutter (e.g. mounting, cleaning, inserting label

material, …).

«Don´t use sharp edged objects to clean the cutter blades.

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

3

General Notes

Proper Usage

The cutter option (subsequently referred to as the "cutter") is a peripheral de-

vice for label printers of the type TTK, TTX 350, 64-xx, AP 5.4, AP5.6 or

AP7.t. The cutter is designed for cutting label material after it has been prin-

ted.

Technical Specifications

Properties The cutter blade cuts self-adhesive, cardboard and synthetic materials up to

240g/m2anduptoamaterialthickness of 0.9 mm–consideringthefollowing

exceptions:

Cut width Cutters of varying widthsare intended for use with printers ofthe 64-xx series

to allow labels to be cut up to the maximum material width of the printer being

used.

Double cut With the double cut function, the operator can remove gaps from the label

material where required. Here the cut gap can be set from 1 to 5 mm.

CAUTION! - Keep to the following rules in order not todamage or to soil the

cutter blade.

«The 8" wide cutter must not be used for materials exceeding 160 g/m2.

«Fiber strengthened materials (e.g. Tyvek) must not be cut.

«If using self-adhesive material, cut between the labels (backing paper).

Otherwise, the adhesive will stick to the cutter blades and will have a

negative effect on the cutting function.

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

4

System requirements

Cutters in the appropriate width can be operated with the following printers:

System Requirements

Preparation for peripheral devices

For using the printers with a cutter, they must be especially equipped

(Tab. 2). This so called peripherals preparation consists mainly of an additio-

nal output stage board for the motor of the peripheral device and of some ad-

ditional connection cables.

Peripheral test TTK/TTX 350:

«Set parameter SYSP > PEPH to KNIF.

If the printer displays the status message ST68 after the ENTER key is pres-

sed, the peripheral board is not installed. If ST68 does not appear or if a dif-

ferent status message is displayed, then the printer has been set up for

peripheral devices.

64-xx / AP 5.4 / AP5.6 / AP7.t:

«Make a service status printout: Call parameter PRINT INFO > Service Status.

64-xxandAPx.x printers are equipped withperipheralpreparationifthetopic

“Peripheraldriver” can be found below the header “Peripheraldriver” on the

printout.

Printer Cutter width

64-04 / TTK / TTX 350 / AP 5.4 / AP7.t 4"

64-05 5"

64-06 6"

64-08 8"

[Tab. 1] The cutter width must match the printwidth of the printer.

Printer Peripherals preparation

64-xx optional

TTX 350 optional

TTK standard

AP 5.4/5.6 standard with printer version „Peripheral“

AP7.t standard

[Tab. 2] Only the TTK is in any cases equipped with the peripheral preparation. For the

other printer types this is an option.

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

5

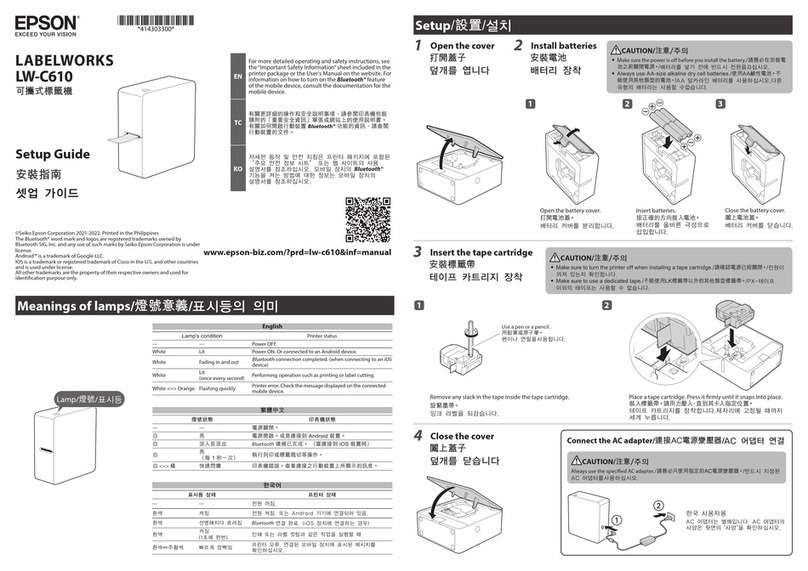

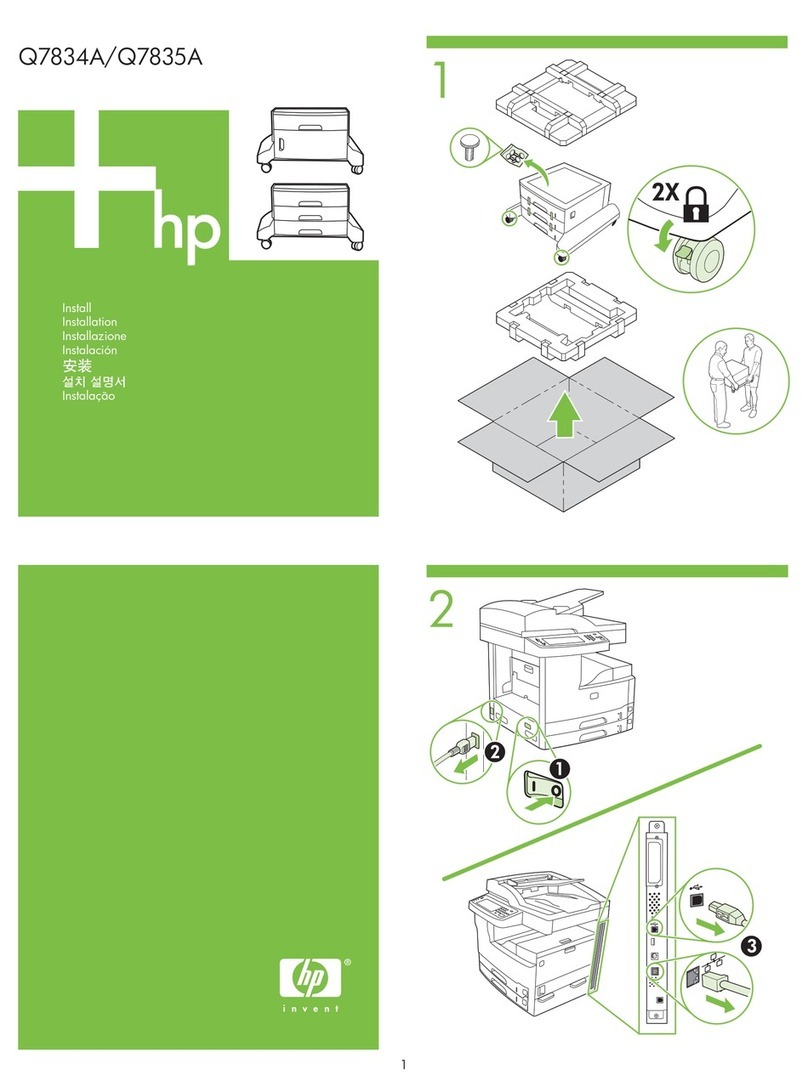

Connecting the cutter

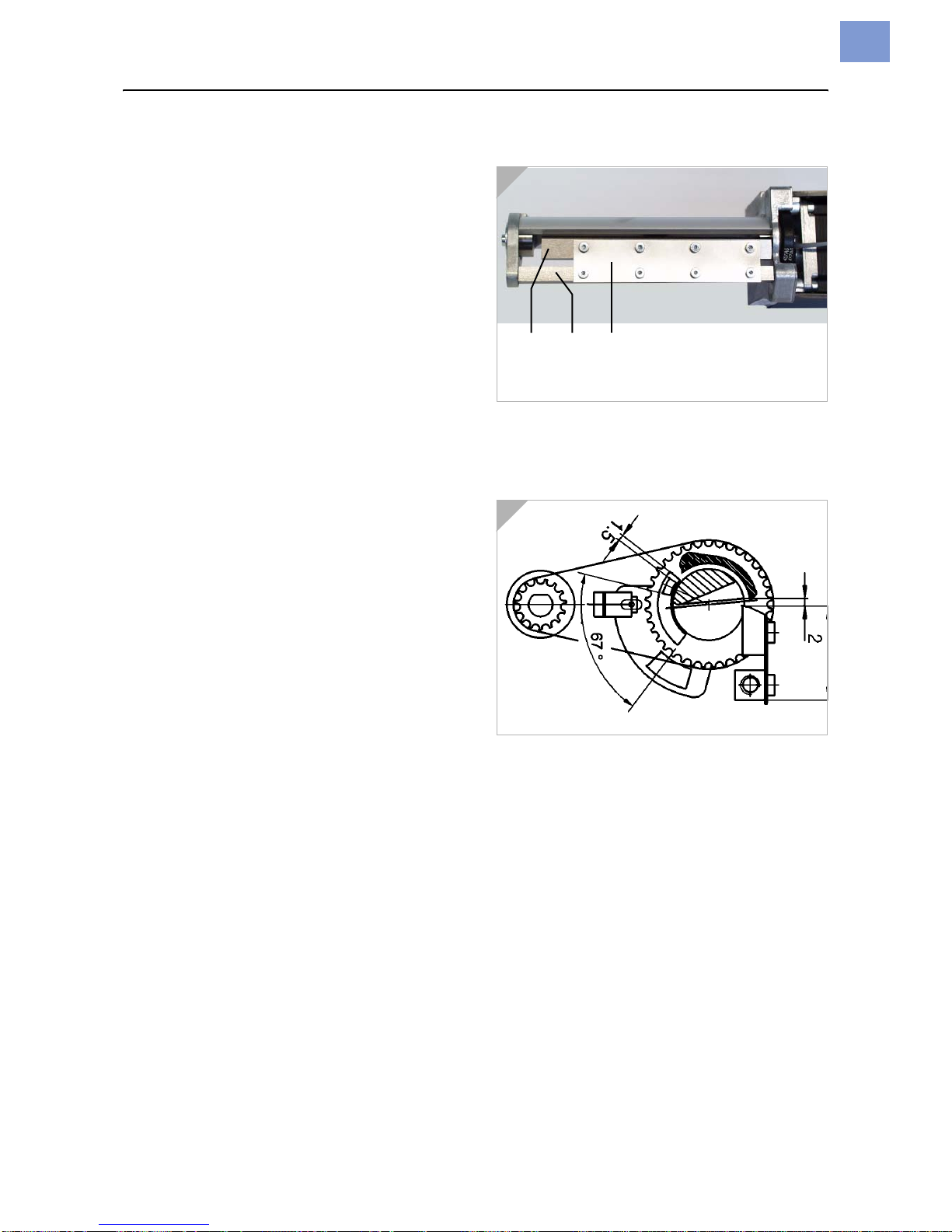

The cutter (fig. 1) is secured to the printer

by two screws and an adjustment plate. By

moving the adjustment plate, the cutting

line can be set parallel to the print image.

Tools

•Allan key 3mm

•Socket wrench, size 8

Assembly / Disassembling

1. Remove the tear-off edge (3) by

unscrewing the thumb screw (4).

2. Remove the cutter cover (1) by

unscrewing the two fastening screws (2,

fig. 2).

3. Screw on the cutter in place of the cutter

cover. To do this use the fastening screws

of the cutter cover (2) (2x Allan key screws

M 5x20). Initially just screw them in

slightly.

PContinued overleaf.

WARNING!

Danger of injury if the cutter is

activated unintentionally!

«Before beginning service work,

switch off the printer and pull out

the mains power supply plug.

1

3

2

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

6

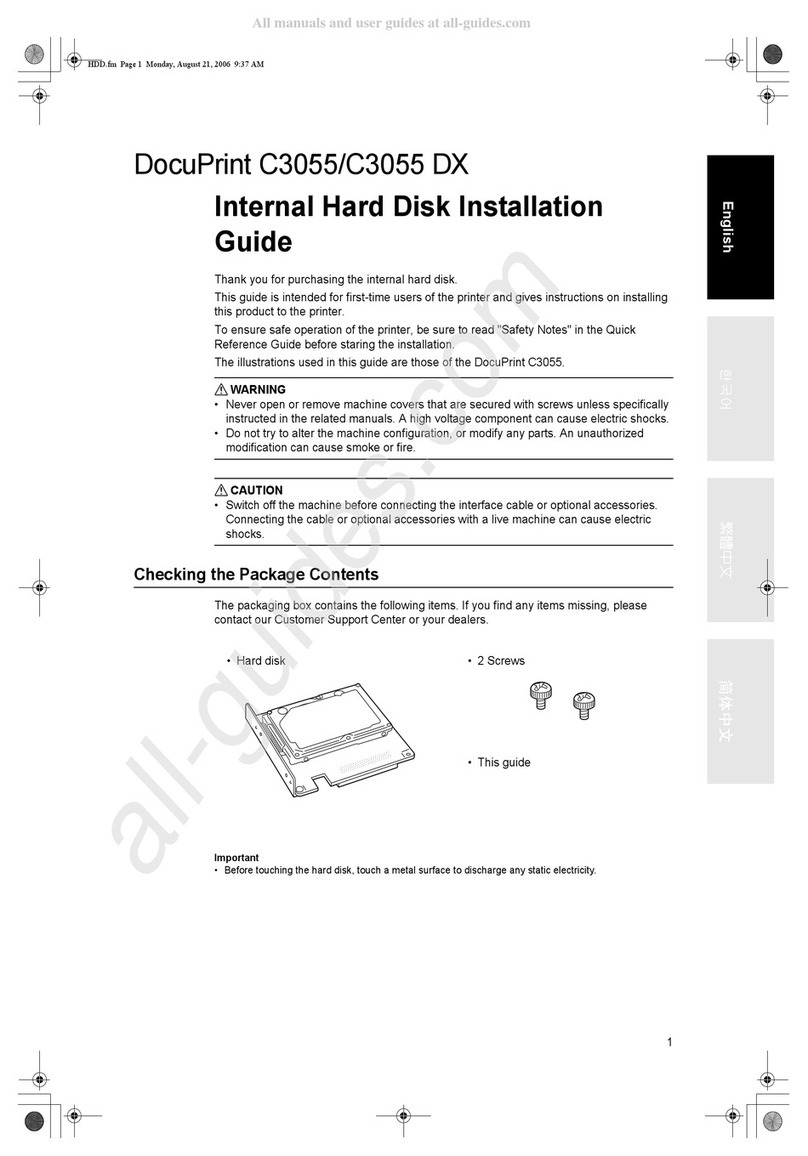

4. Attach the adjustment plate (5) by

unscrewing the top left hexagonal screw

(6) on the print or draw unit, place the

adjustment plate underneath, and then

tighten the screw again - initially only

lightly (fig. 4).

¯The square axle of the cutter unit must

rest in the square recess of the adjustment

plate.(fig. 4)

¯AP 5.4/5.6 only:

The adjustment plate differs from the

64-xx/TTX 350/TTX version. It is provided

with every AP 5.4/5.6 printer (fixed on the

printer bottom with adhesive tape).

5. If necessary, position the adjustment

plate (4) with the help of the hex screw (6)

so that the cut image and print image are

lying parallel (fig. 5).

6. Tighten all three fastening screws.

7. Plug the knife motor cable into the socket

on the front of the printer (fig. 6).

Function check for AP 5.4 / AP5.6 /

AP7.t

For testing purposes can be triggered a cut

by calling parameter SERVICE FUNCTION >

Cutter Test. This way, the cutter function can

be tested without changing the printer peri-

pheral setting.

CAUTION! - Under no circumstances

should the plug be attached or re-

moved when the device is switched

on, as otherwise the device electron-

ics could be damaged.

4

5

6

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

7

Activating the cutter

After installation, the cutter must still be activated by setting the correspon-

ding parameters in the parameter menu.

Activating the TTX 350 / TTK

«Call parameter SYSP > PEPH and set it to KNIF.

The printer will now be reset. The cutter is rotated automatically to its correct

starting position.

Activating the 64-xx / AP 5.4 / AP 5.6 / AP7.t

«Call parameter SYSTEM PARAMETERS > Peripheral device and set it to „Cutter“.

The printer will now be reset. The cutter is rotated automatically to its correct

starting position.

Error message after activating the printer

If the starting position of the cutter blade can not be found, the following sta-

tus message appears (depending on the printer type):

64-xx/AP5.4/

AP5.6/AP7.t

TTX350/TTK

«Press the Online button to acknowledge the message.

If this status message occurs repeatedly, the cutter light sensor may be dirty

or defective.

«Usecompressedairtoblowthedirt offthelightsensor (1). To do so, unmount

the cutter of the printer (see [1]).

WARNING!

Danger of cutting hands and fingers! Activating a non-existent option (peri-

pheral device) can cause the device to malfunction.

«Never touch the knife blade with your fingers while operating the

cutter/printer.

«Only activate options which are mounted and connected properly.

Status 5005

Cutter

ST14

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

8

[1] Unmount the cutter to clean the light sensor (1).

«Check, if the cutter cable is damaged. If so, replace the cable.

«Adjust the oscillator disc (see section “Oscillator disc” – “Setting the oscillator

disc”).

PA complete description of all parameters can be found in the printers user

manual, topic section "Info Printouts and Parameters".

PA list of all status reports can be found in the printers user manual, topic

section “Status Reports”.

Parameter settings

The following parameters govern the cutter function and may need to be

adjusted:

PFor more detailed information, see the chapter "Info Printouts and

Parameters".

¯After a print job has been downloaded, the programmed cut function is

carried out automatically by the device.

TTX 350 TTK 64-xx AP7.t AP 5.4/5.6 Meaning

PEPH PEPH Peripheral

device Peripheral

device Peripheral

device Selection

parameter for

peripheral

devices

CSPD CSPD Cut speed Cut speed Cut speed

CPOS CPOS Cut position Cut position Cut position Cut position

CWID CWID Cut width Cut width Cut width

CDIS CDIS Double cut Double cut Double cut Double cut

function

CMOD CMOD Cut mode Cut mode Cut mode Cut mode

[Tab. 1] Parameters which are important for the cutter function.

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

9

Status reports

The following status reports may be displayed in conjunction with the cutter

function:

PFor more detailed information, see the chapter "Status Reports" in the

printers user manual.

PTroubleshooting, see the chapter "Troubleshooting" in the printers service

manual.

Triggering a cut

If the cutter is properly mounted and activated, a cut can be triggered the

following ways:

•Press the Cut button, while the printer is in offline mode.

•Include a cut command in the print job, e.g. by setting the respective

parameter in the Easy Plug #ER command.

TTX 350 TTK 64-xx / AP5.4 / AP5.6 / AP7.t Example, comment

ST14 ST14 5005 Cutter Cutter malfunction

ST68 No peripheral device

preparation

[Tab. 2] Status messages caused by printer operation with cutter.

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

10

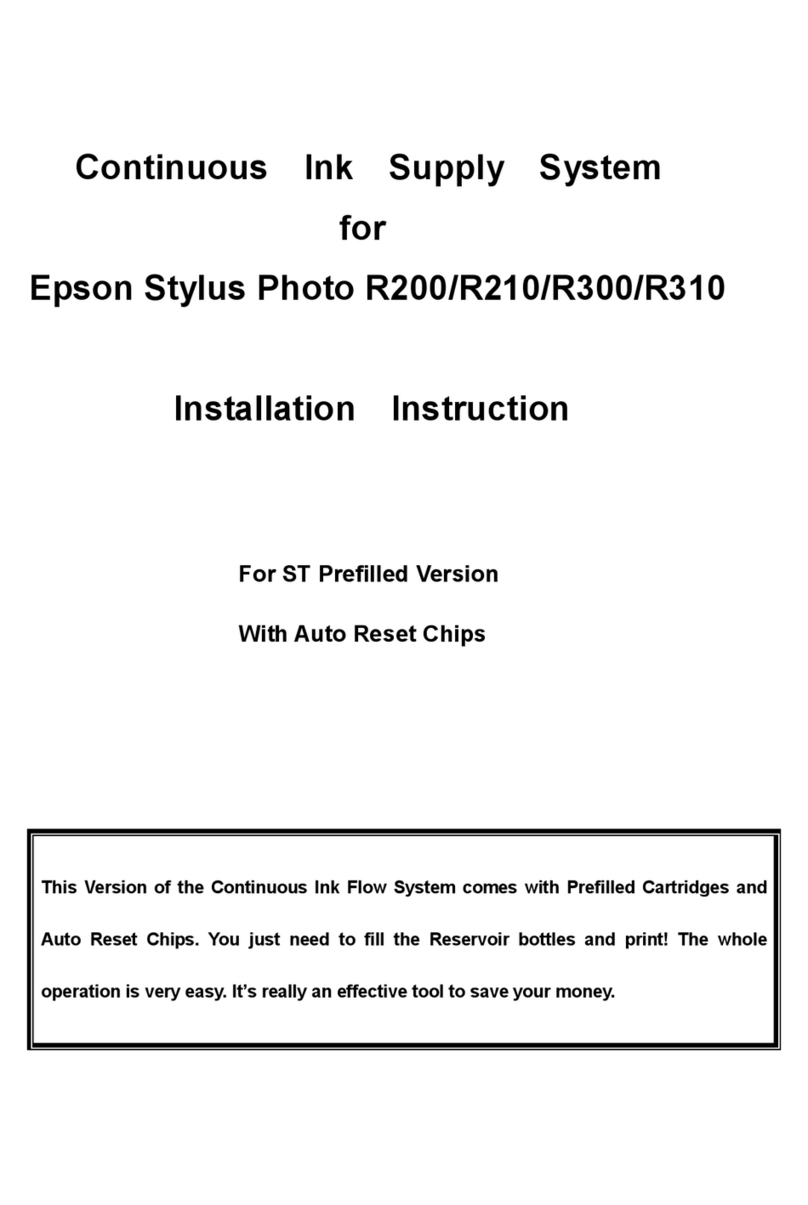

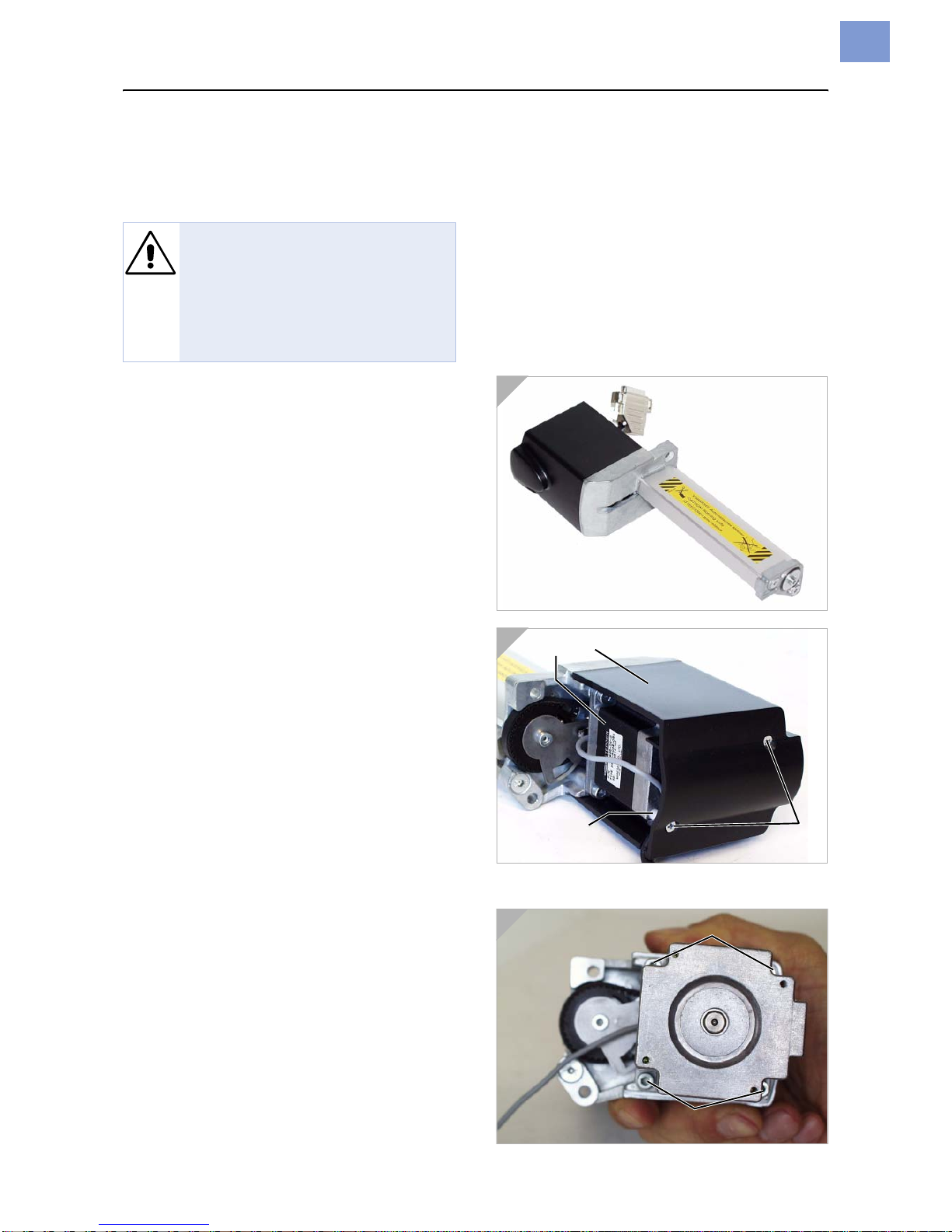

Servicing the cutter

General notes

«Before taking the following steps remove

the entire cutter unit (fig. 1), including the

plug connectors, from the device.

Cutter motor

Almost all service work initially requires dis-

mantling of the cutter motor (1) including

the cutter motor cover (2), as described

below.

Tools

•Phillips screwdriver, small

•Allan key 3mm

Disassembling/assembly

1. Remove the two Phillips screws (3) on the

cutter motor cover. Remove the cover.

¯Donotlose thesleeve(4)whenyoupull

out the screw!

2. Detach the connector cable from the

motor.

3. Unscrew the four screws (5) on the motor

flange. Remove the motor.

WARNING!

Danger of injury! There is a risk of

beingcutwhilecarryingoutservice

work on the cutter!

«Avoid touching the cutter blades.

«Handle the cutter very cautious.

1

2

3

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

11

Toothed belt

Tool

Allan key 3 mm

Disassembling/assembly

1. Remove the motor cover and the motor.

PFor more detailed information, see the

section "Cutter motor".

2. Remove the toothed belt (1). Turn the

oscillator disc (2) somewhat (including the

circular cutter) so that you can guide the

toothed belt past the oscillator disc (fig. 1).

¯Donotunscrewthescrew(3)otherwise

you will have to reset the cutter!

PHow to? - See in paragraph Setting the

oscillator disc on page 12.

¯Assembly: tension the belt by pushing

sideways against the motor while

tightening the fastening screws.

Photoelectric switch

Thephotoelectricswitch(4) is permanently

connected to the cable tree (fig. 2).

Tool

Allan key 3mm

Disassembling/assembly

1. Remove the motor cover and the motor.

PHow to? - See in paragraph Cutter motor

on page 10.

2. Unscrew the Phillips screw (5). Remove

the photoelectric switch.

1

2

3

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

12

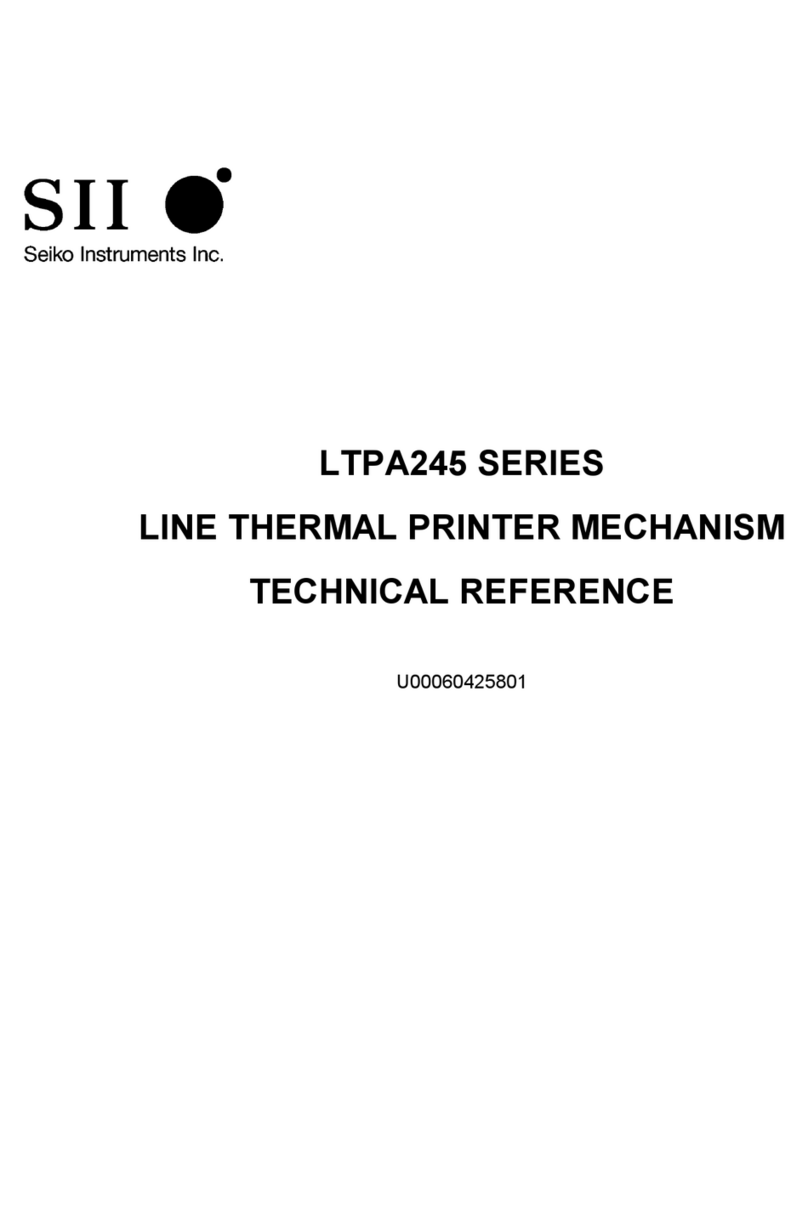

Oscillator Disc, Toothed Wheel

The oscillator disc (1) and toothed

wheel (2) both sit on the motor end of the

circular cutter (fig. 1).

Tool

Allan key 3 mm

Disassembling/assembly

1. Remove the motor cover, motor, toothed

belt and photoelectric switch.

PFor more detailed information, see the

sections"Cuttermotor", "Toothed belt"and

"Photoelectric switch".

2. Unscrew the Allan key screw (3).

3. Remove the oscillator disc and toothed

wheel (fig. 2).

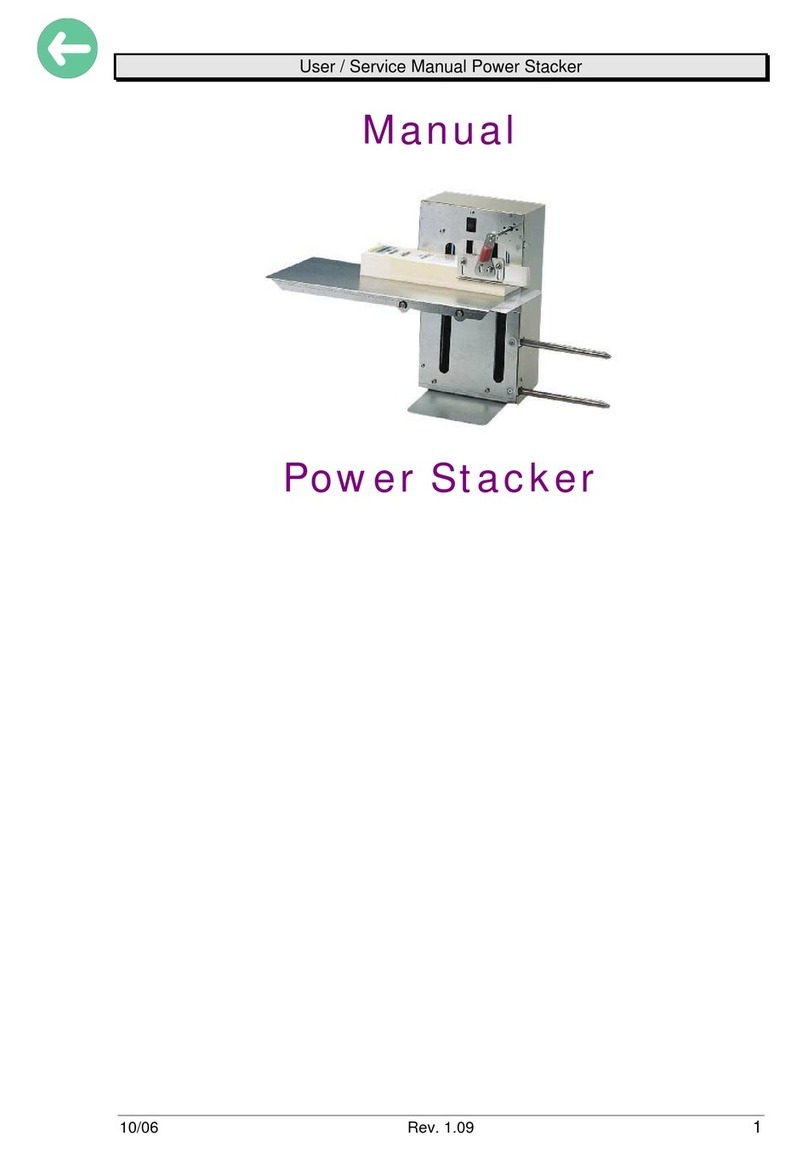

Setting the oscillator disc

1. Turn the toothed wheel (fig. 3, white arrow)

in a clockwise direction until a gap of

approx. 1.5 mm remains between the stop

tab (4, figs. 2 and 3) of the cutter casing

and the toothed wheel groove (fig. 3).

2. Loosen the screw (3). Turn the oscillator

disc (fig. 3, black arrow) until the short

recess (5) in the oscillator disc is

positioned in front of the photoelectric

switch (6).

3. Tighten the screw (3).

2

1

3

1,5mm

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

13

Circular cutter

Tools

•Allan keys, 2.5 mm and 3 mm

•Fork spanner SW 8

Disassembling/assembly

1. Remove the motor cover, motor, toothed

belt, photoelectric switch, oscillator disc

and toothed belt.

PFor more detailed information, see the

previous sections.

2. Loosen the two fastening screws (1, figs. 1

and 2) on the square axle. Fold back the

bottom cutter.

3. Extract the circular cutter (2, fig. 2).

PContinued overleaf.

WARNING!

Danger of injury! There is a risk of

being cut while carrying out ser-

vice work on the cutter!

«Avoid touching the cutter blades.

«Handle the cutter very cautious.

1

2

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

14

Adjustment

1. Set the position of the oscillator disc as

described in the section "Oscillator disc,

toothed wheel".

2. Secure the cutter in a bench vice (fig. 1).

3. Bring the circular cutter into the illustrated

position (fig. 1) by turning the toothed

wheel (1).

4. Clap up the bottom cutter onto the circular

cutter (fig. 2).

5. Press the bottom cutter onto the circular

cutter and at the same time tighten the

fastening screws on the square axle. In

order to push in the bottom cutter, gently

turn the square axle by several degrees

(approx. 5) using a fork spanner (fig. 2).

WARNING!

Danger of injury! There is a risk of

cutting oneself while carrying out

service work on the cutter!

«Only grasp the toothed wheel to

turn the circular cutter!.

1

2

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

15

Bottom cutter

The bottom cutter (1) is attached to the

square axle (2) by a spring plate (3). The

bottom cutter, spring plate and square axle

are only available as pre-configured spare

parts.

Tool

Allan keys, 2.5 mm and 3 mm

Disassembling/assembly

«Unscrew the screws (2x Allan key) at the

ends of the square axle. Remove the

square axle together with the spring plate

and the cutter.

¯Set the contact pressure: see Steps 4

and 5 in the previous section "Circular

cutter".

¯The bottom cutter must be readjusted

during assembly if you unscrew the

fastening screws. Dimensions, see

drawing cutout (fig. 2).

1

2

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

16

Accessories

Stripper plate

If the applied label material is very thin and flexible, it may happen, that the

label material is drawn upwards together with the ribbon, instead of being fed

into the cutter.

The stripper plate avoids this effect.

[1] The stripper plate is a simple plastic strip, which is supplied with adhesive foil on one side.

Assembling 1. Dismantle the cutter from the printer.

2. Clean the rim (1) – best by means of some cleaning fuel.

3. Remove the cover paper off the stripper plate.

4. Glue the stripper plate (2) to the rim as illustrated (see Fig. 2 right side).

[2] Middle: Clean the rim (1) with cleaning fuel. Right and left sides: Glue the stripper plate

(2) justified to the one edge – the stripper plate should loom above towards the paper-

insertion side.

PThe part numbers of the stripper plate can be found in topic section "Spare

Parts", section "Accessories".

Abstreifer/

Stripper plate

Z0164.cdr

03/10 Rev. 5.04-01 TECHNICAL MANUAL Connection, Setup, Service

Cutter 2000

17

Appendix

Cable harness

Other manuals for Cutter 2000

1

Table of contents

Other Avery Dennison Printer Accessories manuals

Avery Dennison

Avery Dennison JUNIOR REWINDER Guide

Avery Dennison

Avery Dennison ALS 104 User manual

Avery Dennison

Avery Dennison Power Stacker User manual

Avery Dennison

Avery Dennison Cutter 2000 Guide

Avery Dennison

Avery Dennison SONIC Knife Operating manual

Avery Dennison

Avery Dennison Monarch 9433 User manual

Avery Dennison

Avery Dennison ALS 306 User manual

Avery Dennison

Avery Dennison ALX 720 User manual

Avery Dennison

Avery Dennison Monarch AAFES kit User manual

Avery Dennison

Avery Dennison Mobile Work Station (MWS) Monarch 9876 Installation and operation manual