Avery Dennison TTX 450 User manual

Manual Scanner

01/03 Rev. 1.06 1

Manual Scanner

Fig.: TTX 450 with scanner option

Manual Scanner

01/03 Rev. 1.06 2

CONTENTS

IMPORTANT OPERATING INSTRUCTIONS.......................................................................3

Chapter 1 Initiation................................................................................................................4

General scanner information ........................................................................................................... 4

Direction of barcode ..................................................................................................................4

Maximum scan width.................................................................................................................4

Scan Speed...............................................................................................................................5

Setup Scanner................................................................................................................................. 6

Assembly of scanning module...................................................................................................6

Electrical assembly scanner .......................................................................................................... 10

Chapter 2 Set up mode.......................................................................................................11

Scanner activating......................................................................................................................... 11

Activate scanner using the menu ............................................................................................11

Select the scanner .....................................................................................................................11

Mechanical adjustment of the beam..........................................................................................11

Y – direction.............................................................................................................................12

X – direction.............................................................................................................................13

Chapter 3 Modes of operation ............................................................................................14

Scanner Mode ............................................................................................................................... 14

Program the scanner mode.....................................................................................................14

User operation ............................................................................................................................... 14

Error conditions (RAP..............................................................................................................14

Error condition (RBP................................................................................................................15

Multi Colour LED............................................................................................................................ 15

Programming................................................................................................................................. 16

Chapter 4 Information printout / parameter.........................................................................17

Info print out / parameter.........................................................................................................17

Chapter 5 Maintenance and cleaning.................................................................................18

Maintenance and cleaning..................................................................................................19

Cleaning parts are ......................................................................................................................... 19

Chapter 6 Status messages................................................................................................20

Status messages ........................................................................................................................... 20

ST51 scanner is not programmable ........................................................................................20

SCAN barcode not readable in RAP mode .............................................................................20

ST89 barcode information (RBP) not found in data base .......................................................20

ST91 barcode not readable in RBP mode ..............................................................................20

Status reports ................................................................................................................................ 21

Chapter 7 Other ..................................................................................................................25

Parameter Menu............................................................................................................................ 26

Chapter 8 Appendix ............................................................................................................27

Wiring............................................................................................................................................. 28

Spare parts .................................................................................................................................... 29

Index ...................................................................................................................................33

Manual Scanner

01/03 Rev. 1.06 3

IMPORTANT OPERATING INSTRUCTIONS

The following warning hints and precautions contained in these Operating Instructions

must be strictly observed. This will considerable contribute to the safe and expert operation

of your printer.

Warnings: Exclusively original parts and accessories available from the manufacturer are

To be used to maintain the service life of your printer. The use of parts not in

compliance with the exacting demands made by the manufacturer may result

In unnecessary sources of danger.

•The housing of the unit must exclusively be opened by authorised technical

personal.

•Insertion/Exchange of foil and material should be carried out only by especially

instructed personnel(Set Up Mode!)

•On operation with open cover, fingers, hair, clothes jewellery, et. may be

caught by and get into the unit in the foil-feed section . Do not expose or operate the unit

to

moisture nor wet conditions.

•Hazard of injury in the initialisation process and during cutting because of

moving

knife!

Attention : This unit is equipped with a Class II Laser product – do not stare into the

beam !

•Remove printhead not until 3 minutes after disconnection of unit.

•Re connect unit not until 10 seconds after disconnection’s.

•Remove, insert or exchange Plug in Card not until 60 seconds after

disconnection of

unit.

Manual Scanner

01/03 Rev. 1.06 4

Chapter 1 Initiation

General scanner information

It is a scanner we use in the printer line – not a verifier !

The scanner is programmed via the printer – an information regarding barcode and barcode

position

is sent to the scanner. The beam is switched on and the barcode checked for only the

readability !

There is no check for information and no check for the check digit calculation !

Direction of barcode

Only 0 degree and 180 degree barcodes are readable. The scanner can not be rotated to

read 90 degree or 270 degree rotated barcodes.

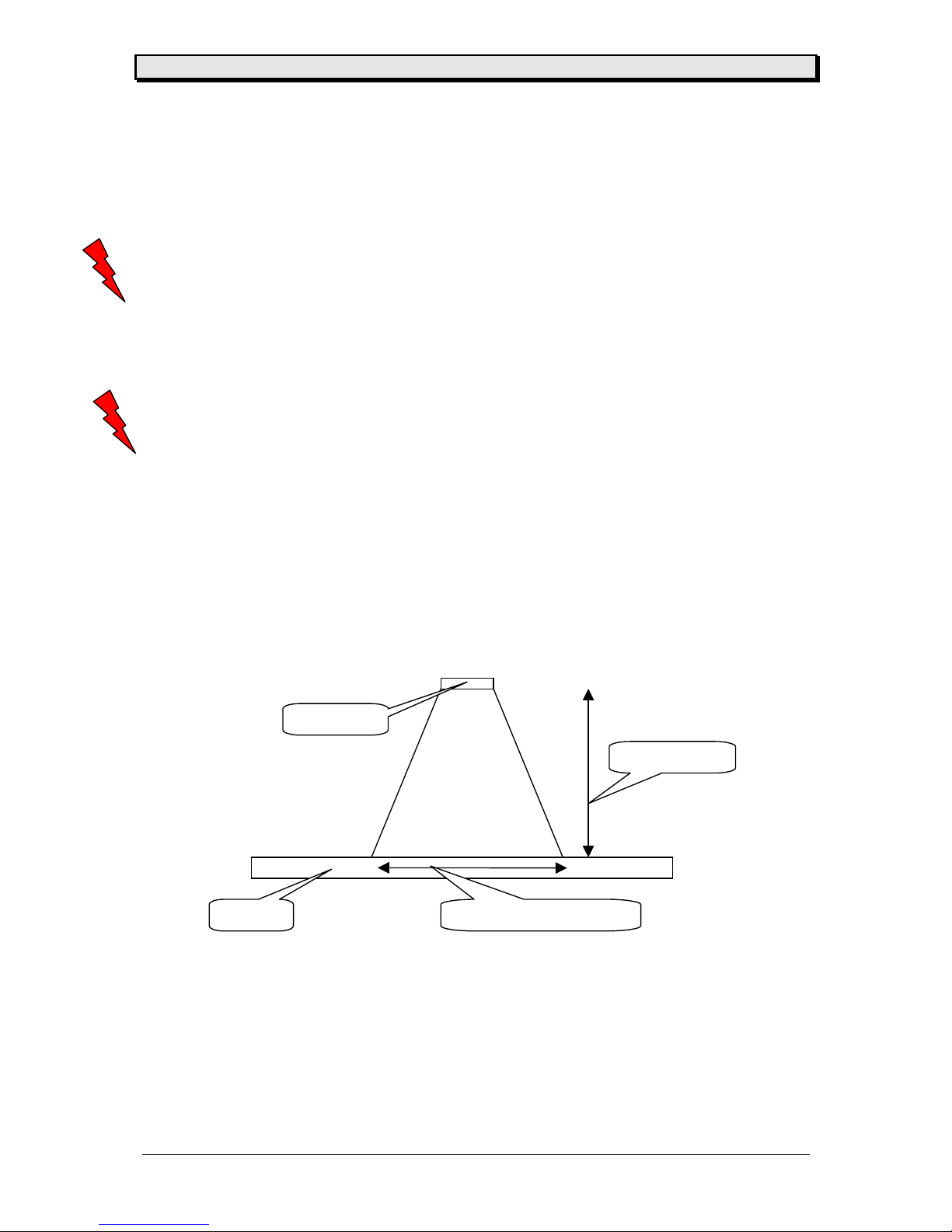

Maximum scan width

Given by the distance between lens and feed roller – the maximum scan width is 3 “ (76,2

mm). he beam is movable across the media width . This distance can not be changed !

distance

scan width 3” (76.2

scanner

label

Manual Scanner

01/03 Rev. 1.06 5

Scan Speed

The used scanner is able to scan 500 codes / second. But have in mind that this is only a

single point – as well the code information has to be send to the scanner (via printer) the

control of the scanner is done by the printer and needs time.

The printer program controls how often a scan can be without success before an error is

shown in the display.

Manual Scanner

01/03 Rev. 1.06 6

Setup Scanner

This chapter is explaining the mechanical assembly – the electrical wiring and the firmware

installation (selecting the peripheral ) !

Attention : Before starting with this work – switch of the unit and unplug from main

power supply !

Assembly of scanning module

To get the serial number – the dispensing module can be mounted to the printer – call the

factory or your service technician. Secure you can mount the scanner from serial number

05450xxxx-xxx ! Please use only the newest firmware.

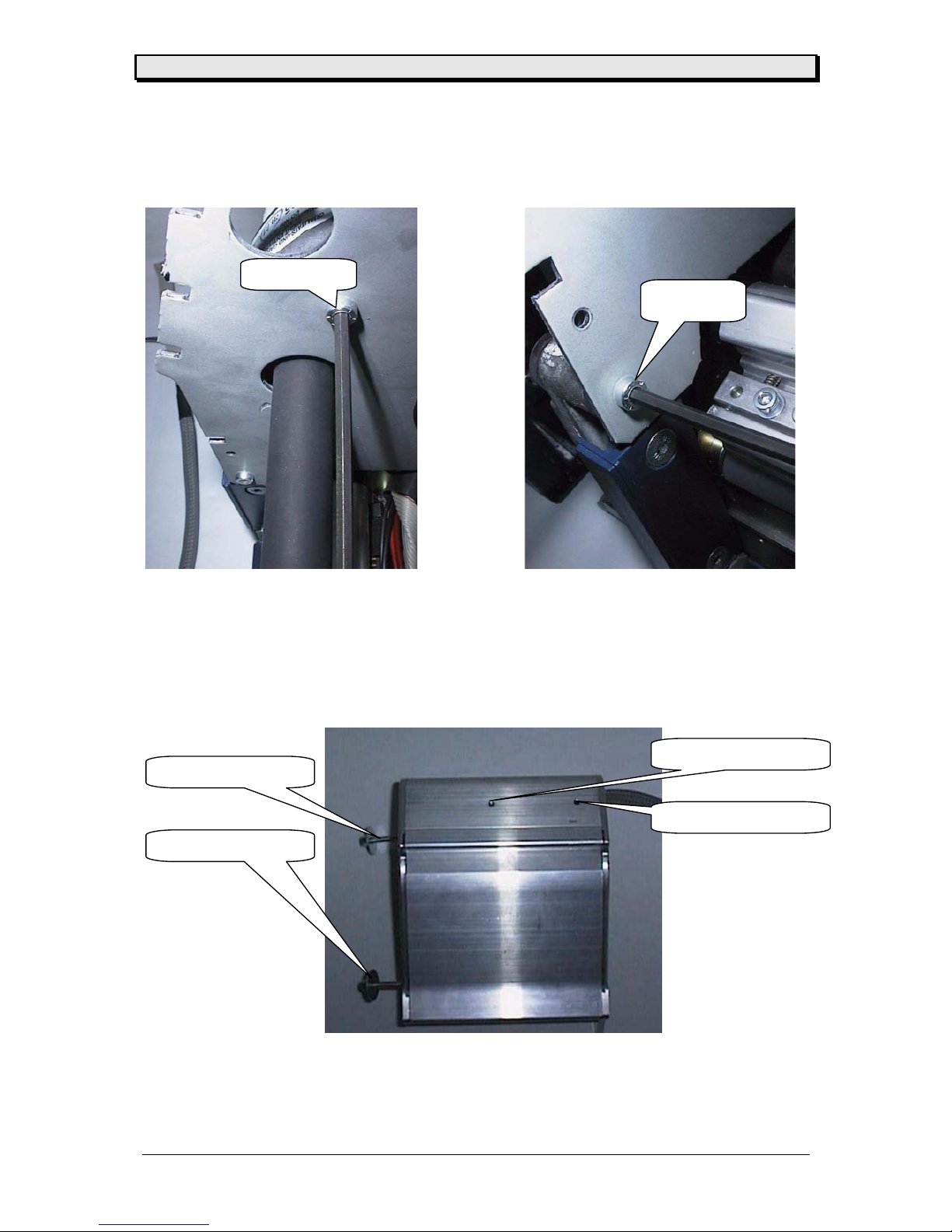

•remove cap to open the hole where the cable will go trough

Manual Scanner

01/03 Rev. 1.06 7

•open rear cover ( 6 cross recessed screws) – carefully watch the wiring of the fan

•loosen the left front cover and move it slightly away, still connected to the board ! Remove

the right front cover and replace it with the new one – remove as well the name plate from

the old cover

Manual Scanner

01/03 Rev. 1.06 8

•open the two screws shown on the pictures – the print module is fixed to the base plate

with these screws (2 out of 5)

•remove the screws – they will be replaced by two new screws out of the assembly set of

the scanner module, length and screw head are different . There is a third screw to replace

on the next page.

•mount the removed logo plate to the scanner module using the two fixation holes shown on

the picture below

screw 1

screw 2

screw set 1

screw set 2

logo plate hole

logo plate hole

Manual Scanner

01/03 Rev. 1.06 9

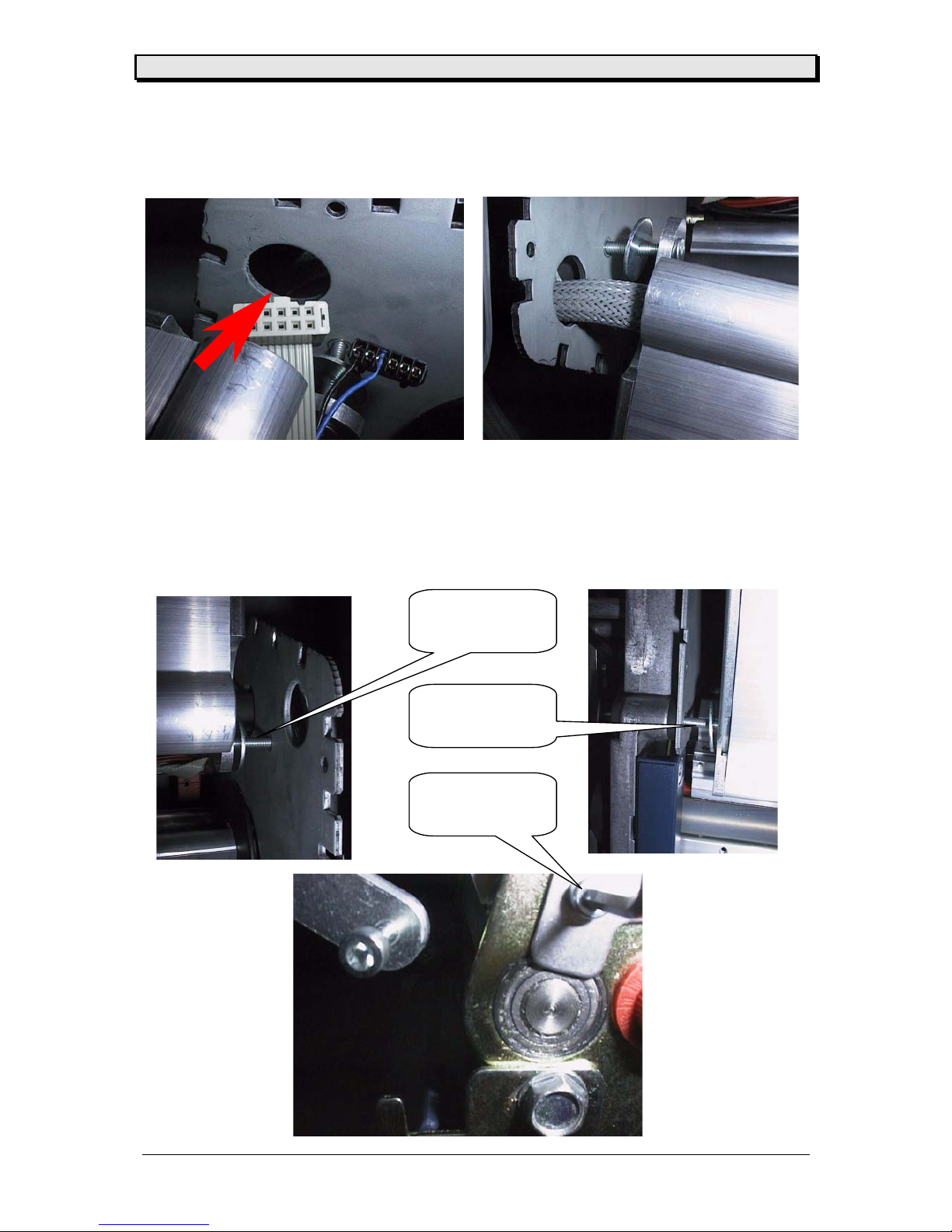

•move the shielded scanner cable through the open hole – guide only one connector at one

time through the hole

•assemble the scanner module to base plate and print module – Attention : Use the new

screws. This is shown on picture 1 and picture 2. The third screw you have to change is

placed in front of the feed unit – shown on picture three – the new screw is as well supplied

with the assembly set

picture 1

screw 1

picture 2

screw 2

picture 3

screw 3

Manual Scanner

01/03 Rev. 1.06 10

Electrical assembly scanner

As soon as the scanner module is assembled mechanically – the electrical wiring can be

done. Adjustment and programming of the scanner is shown under the point scanner

activating (see modes of operation chapter 3)

•the scanner (nr. 99171-xx to 99173-xx) – and the scanner cable (nr. 99183-xx) is equipped

with a serial connector and a power connector

•to integrate the scanner means that the scanner is using the serial interface of the printer !

That results in maybe only removing the original connector from the CPU board (CN 13) or

removing the complete cable what we recommend ! If you remove the cable, you have to

close the slot on the back side of the printer with the supplied metal plate again (reason is

properly shielding the printer).To connect the power supply to the scanner use the

connector with the two wires and plug into the I/O board (CN26) – the other end of the cable

is mounted to the scanner connector !

Attention: Please mount the cover plate on the serial slot if you remove the serial

cable ! Otherwise you will loose the CE certification.

•insert the plugs into the shown connectors on the CPU and I/O board

serial connector CN13 power supply CN26

Manual Scanner

01/03 Rev. 1.06 11

Chapter 2 Set up mode

Scanner activating

Activate scanner using the menu

After the scanner has been mechanically and electronically assembled – the printer has to be

programmed to use the scanner correct, the scanner beam has to be adjusted to scan on the

right place (in y and x direction) !

This can be done only by trained people !

Select the scanner

•using CODE (FEED, CUT, ON/OFF, ON/OFF, FEED, CUT) go into the service

menu

•select ACSC

•set ACSC to YES (select Scanner)

•press ENTER the printer is reset - INIT is flashing (for a longer time than

usual)

Mechanical adjustment of the beam

The scanner has to be adjusted mechanically ! Having in mind that the beam should work as

well if an option (like cutter) is mounted, and that the beam window has not the same width

then the printer, the scanner has to be adjusted in y and x direction.

Attention : To adjust the scanner – the beam has to be ON ! Follow the next steps carefully

to switch on the beam.

•equip printer with ribbon

•insert media into the printer (best joyce would be a white one)

•enter the menu and go to menu point OTHR

•select ADJS

•select SON – press ENTER the beam is switched on constantly, the display

shows SOFF – to switch off the beam you have to press ENTER again

•follow the steps to adjust the scanner – then switch off the beam (ENTER)

Manual Scanner

01/03 Rev. 1.06 12

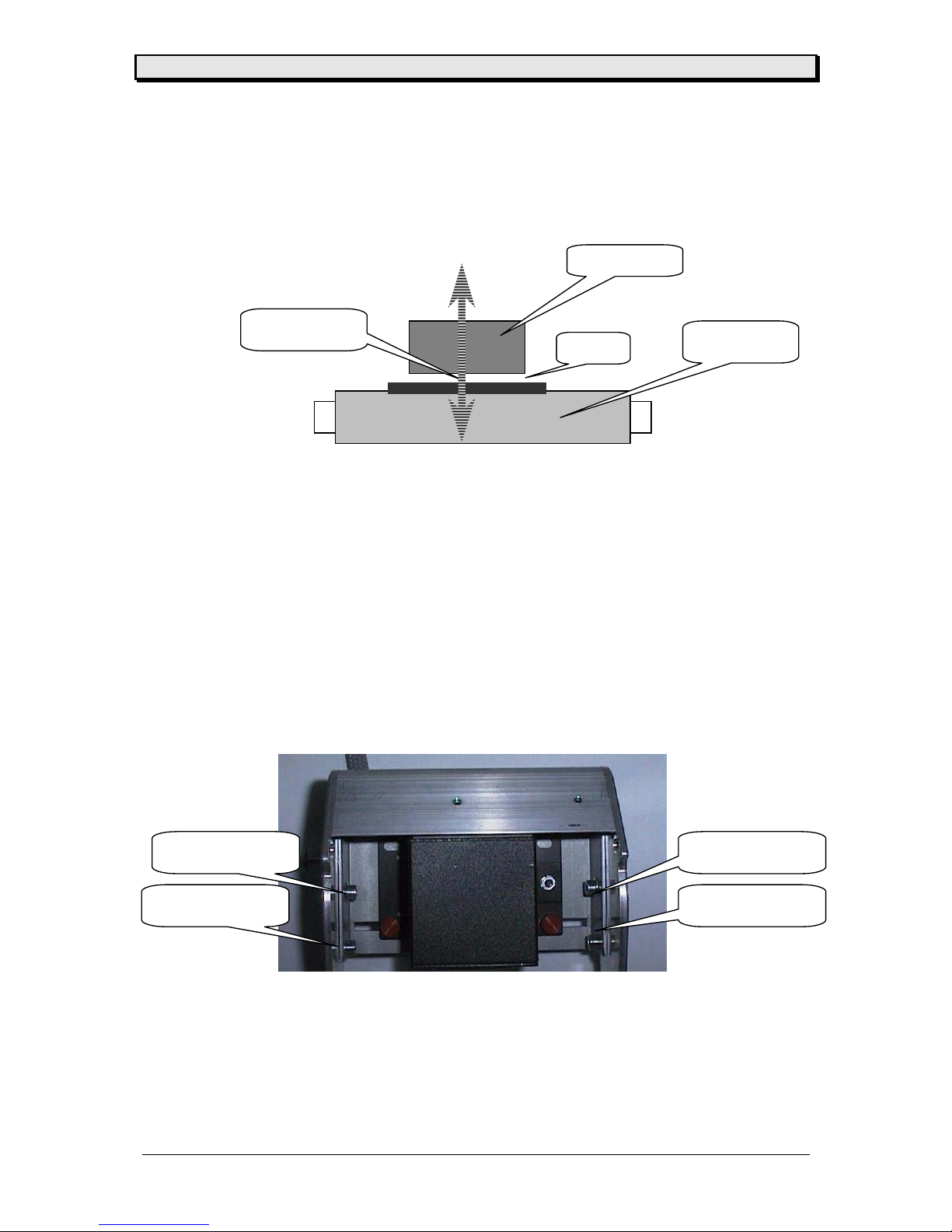

Y – direction

To be able to adjust the scanner the beam has to be ON !

This adjustment can be done by opening the front cover of the scanner module by hand (see

picture)

You will see the scanner mounted to a base plate. The base plate is mounted to the side

plates with 4 screws. Loosen that screws and adjust the beam by moving the base plate

forwards / backwards until the beam is in the middle between printhead and an option (like

cutter). The beam should be visible on the paper. Control – and if OK fix the screws again.

The next step is the adjustment in X direction !

Scanner

feed roller

Y

- direction

Beam

adjustment adjustment

adjustment adjustment

Manual Scanner

01/03 Rev. 1.06 13

X – direction

Attention : The width of the beam 3” or 76,2 mm can not be extended – it is given by the

mechanical distance between lens and feed roller (or label surface)!

This adjustment can be done by opening the front cover of the scanner module by hand (see

picture)

You will see the scanner mounted to a base plate. As well you ill see two red knurled screws

. Loosen them and you can move the scanner in x direction across the base plate to the left

and right. Adjust the beam to the place where you want to read the barcode. Depending on

the printer, beam window and print width can be different.

Attention : Never look into the beam – nor remove the scanner from the base plate with

power on and the beam ON ! Do not point out with the scanner to other people

– they or you could be hurt.

Scanner

f

eed roller

x - direction

Beam width 3”

Scanner

knurled screw

knurled screw

Manual Scanner

01/03 Rev. 1.06 14

Chapter 3 Modes of operation

Scanner Mode

Depending on the use of your system, the scanner is able to operate in two different modes –

they are called read before print (RBP) and read after print (RAP) !

Using the scanner in the RBP mode the infeed module is mounted to the printer. A single

label is introduced into that module in front of the printer. This label is pre printed with a

barcode and the scanner is reading this code. The information, stored in the code, is

transferred into the printer.

An internal data base stored on a special card (called data base card) will be checked for a

matching data stream, if a match is found the data stream information is printed to the label .

To get more information please refer to the card manual.

Using the scanner in the RAP mode – the code is printed by the printer and after that the

scanner is checking the readability (not verify – only read !) .

Not using the scanner you can deselect it – set the menu point to OFF !

Program the scanner mode

•enter the menu and go to SYSP

•select SCAN

•select the mode you want to work with (RAP or RBP or OFF)

•accept and go out

User operation

To use the scanner now in the defined mode – you have to program the scanner with the

information regarding barcode type – quantity of barcodes on the label – length of the code

and so on. This is done by sending a special EASY PLUG command to the printer. As well

the error condition has to be programmed.

Error conditions (RAP

•enter the menu and go to SYSP

•select SERR

•adjust the reaction by selecting the correct value

1 =as soon as the scanner is unable to read a code an error shows up

noise and optic

2 =having two invalid scans one after another an error shows up

.....

9 =a maximum of nine invalid scans can result in an error

•accept and leave the menu

Optical error message SCAN

Manual Scanner

01/03 Rev. 1.06 15

Error condition (RBP

An invalid – not readable barcode results in the message

Optical error message ST 89

Multi Colour LED

The scanner has a multi colour LED at the rear end of the unit. That provides you with

operational information.

The followings are descriptions of each LED :

LED is blinking yellow

The scanner is powered, not triggered and is funtioning normally.

LED is solid yellow

The scanner is triggered or the unit is in continuous read mode.

LED is green for ½ second

Scanner has successfully decoded a barcode.

LED is red for ½ second

Scanner has not successfully decoded a barcode.

LED flashes is red, yellow and green

Setup mode.

LED is solid red or flashing in red

The scanner has detected a mail function – please call the service.

Manual Scanner

01/03 Rev. 1.06 16

Programming

Using a special EASY PLUG command the scanner is programmed. The syntax for the

command is described below. A maximum of 8 codes can be programmed on one label (n)

this must be at least the quantity of activated codes (a, b, c ...). The command can be

used only outside of the format commands #ER ... #Q !

Getting the error message ST 51 on the display means that the printer could not

communicate with the scanner. Check the wiring and the scanner.

After accepting the error message the printer is LOCKED. To solve that switch OFF/ON the

printer.

Attention : The following characters STX (02h) ETX (03h) and EOT (04h) can not be

used in the codes ! Jetmark / Aragon or MVT 3 can not use this command.

The command is stored in the scanner until a new #PS command is send.

Syntax : #PSa/w/b/x/c/y/d/z/n

a, b,c,d Easy Plug number of the code

w,x,y,z number of characters in the code (0 =variable code length)

n quantity of codes on the label

Barcode Easy Plug Number Number for Scanner

no Code

EAN-8 0 0

EAN-13 1 1

UPCA 2 2

Code 93 3 3

2/5I 4 4

Code 39 (2:1) 7 7

Codabar 8 8

UPCE 9 9

Code 128 13 13

Code 39 (3:1) 16 7

Other codes can not be used !

If there are more codes of the same type on the label – with the same length or variable code

length is programmed - and all of them should be checked, it is sufficient to activate the code

only once. The quantity of codes is shown by the nabove.

Example: #PS7/10///////2label with two barcodes code 39 – 10 characters

Attention: If more then one code of the same type is activated on a label – the code

information must be different !

Manual Scanner

01/03 Rev. 1.06 17

Chapter 4 Information printout / parameter

Info print out / parameter

Not valid

Manual Scanner

01/03 Rev. 1.06 18

Chapter 5 Maintenance and cleaning

Manual Scanner

01/03 Rev. 1.06 19

Maintenance and cleaning

Cleaning parts are

•standard printer parts (see manual)

•the lens of the scanner (regular)

Attention : Do not clean the lens with power ON and beam ON – do not stare into beam –

this could hurt you.

Manual Scanner

01/03 Rev. 1.06 20

Chapter 6 Status messages

Status messages

ST51 scanner is not programmable

wrong command sequence

check wiring between scanner and printer

check scanner

SCAN barcode not readable in RAP mode

check print quality

ST89 barcode information (RBP) not found in data base

check data base and data base card

ST91 barcode not readable in RBP mode

check print quality

Other manuals for TTX 450

1

Table of contents