Avid CNC NEMA 23 User manual

Plug and Play CNC Controller Technical Manual

v2020Q3.1, 17.4 Electronics Revision

Emergency Stop

The emergency stop system is a normally closed circuit and must be plugged in for the CNC controller to operate. It is recommended to keep it

within easy reach during machine operation so it is quickly accessible if the machine needs to be emergency stopped.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

Motor Disable Switch

The motor disable switch can be found on the side of the box below the fan. Using the motor disable switch will disconnect power to the motor

drives and motors. This works as a safety measure and allows you to perform maintenance, manually move the machine, or disconnect and

reconnect motors without any danger to the motors or drives.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

System Requirements

Size Requirements

CRP800-00E Control Box

18in (450mm)

19in (480mm)

8in (205mm)

D

C

B

A

A

B

C

D

1

2

3

4

5

6

7

8

8

7

6

5

4

3

2

1

PART REV:

SCALE:

CRP800-00E

DO NOT SCALE DRAWING

AVID CNC

DWG REV:

P/N:

1:5

00001

SHEET 1 OF 1

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

Power Requirements

NEMA 23 CNC Controller:

Input power: 100-120VAC or 200-240VAC, 50/60Hz

Voltage range must be set on main power supplies. They will be pre-configured for 100-120VAC, unless the system was specifically

ordered for 200-240VAC power.

Current draw (approx.): 6A @ 120VAC, 3A @ 240VAC

NEMA 34 CNC Controller:

Input power: 100-120VAC or 200-240VAC, 50/60Hz

Voltage range must be set on main power supplies. They will be pre-configured for 100-120VAC, unless the system was specifically

ordered for 200-240VAC power.

Current draw (approx.): 12A @ 120VAC, 6A @ 240VAC

3 HP Plug and Play Spindle / VFD System:

Input power: 200-240VAC, 50/60Hz (possible to use two legs of a 3-phase 208V supply)

Current draw (approx.): 8A at peak load

Systems utilizing a router as the cutting tool can typically run off of a single 120V 20A AC circuit. Alternatively, two 120V 15A AC circuits can be

used with the router and CNC controller on separate circuits. NEMA 23 systems with a 2.25 HP or smaller router can typically run off of a single

15A circuit without issue.

Systems utilizing a spindle typically require a single 120V 15A circuit for the CNC controller and a single 240V 30A circuit for the spindle.

Alternatively, both the CNC controller and spindle can run off of a single 240V 30A AC circuit. Our spindles come pre-wired with an L6-30P plug,

which mates with an L6-30R receptacle. This can be field retrofitted to a different 240V AC plug if necessary. Consult a qualified electrician for

assistance with any changes to the stock power cable.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

Initial Setup

Avid CNC Plug and Play Spindle Connections

Refer to the appropriate setup instructions for your Spindle/VFD package:

Plug and Play Spindle / VFD System: CRP800 VFD Setup Guide (https://www.avidcnc.com/support/accessories/spindles/spindle-

vfd/CRP800setup)

Avid PRO CNC Plasma System Connections

Refer to the PRO CNC Plasma setup instructions: PRO CNC Plasma Instructions (https://www.avidcnc.com/support/plasma)

Relay 1 Output Connections

Relay 1 is a 30A AC relay rated for 250V. The relay requires external AC power to be plugged in to "Relay 1 In" on the CNC controller. This output is

commonly used in two ways:

Control a router: When Avid CNC's version of Mach4 is configured with a router cutting tool, the router should be plugged into "Relay 1 Out".

By default it is controlled by either the Router toggle button in Mach4 or by G-code with M03 (spindle ON) and M05 (spindle OFF)

commands.

Control a dust collector, coolant system, or general AC load: When Avid CNC's version of Mach4 is configured with a spindle or plasma

cutting tool, relay 1 can be controlled either manually or using G-code. To manually operate the relay, use the relay 1 toggle button. Using G-

code, M08 will turn relay 1 on and M09 will turn BOTH relay 1 and relay 2 off.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

Relay 2 Output Connections

Relay 2 is a 30A AC relay rated for 250V. The relay requires external AC power to be plugged in to "Relay 2 In" on the CNC controller.

This output is commonly used for dust collection or coolant systems, but can be used for many general AC loads. Relay 2 can be controlled

manually in Mach4 with the relay 2 toggle button. The use of G-code to operate relay 2 will depend on your Mach4 configuration.

Router cutting tool: Use M08 to turn relay 2 on and M09 to turn relay 2 off.

Spindle or plasma cutting tool: Use M07 to turn relay 2 on and M09 to turn BOTH relay 1 and relay 2 off.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

3rd Party Spindle/VFD or non-Hypertherm Plasma Torch Connections

Use the information below to adapt external equipment to the 14-pin control cable supplied with the Avid CNC Plug and Play controller. The 14-

pin female connector is pre-wired into the Plug and Play controller with these functions. Note: "Plasma" wires are only connected in plasma-

enabled Plug and Play systems.

14-Pin Control Cable Pinout

Plasma pins are populated but not connected by default on routing controllers, and Spindle pins are populated but not connected

on plasma controllers.

ConnectorPin # Use In / Out Description Color ESS Port/Pin

1 Spindle Digital In Fault Ground Blue

2 Spindle Digital In Fault Signal White 2/13

3 Plasma Digital Out Torch ON Orange/Black 3/17

4 Plasma Digital Out Torch ON Green/Black

5 Plasma Analog In Voltage Divider - Red/Black

6 Plasma Analog In Voltage Divider + Red/White

7 Spindle Digital Out FWD Orange 2/14

8 Spindle Digital Out DCM Green

9 Spindle Analog Out AVI Red 2/1

10 Spindle Analog Out ACM Black

11 Spindle (optional) Analog 10V Ref Blue/White

12 Plasma Digital In Arc OK White/Black 3/10

13 Plasma GND Ground Blue/Black

14 Plasma Signal GND Arc OK Ground Green/White

Pin 1/2, Fault Signal/Fault Ground: This input is used to read a fault from an external VFD, typically from thermal overload or a disconnected

spindle power cable.

Pin 3/4, Torch ON: This output is from a small dry contact relay on the TMC3in1 used to trigger a CNC controllable plasma torch ON/OFF.

Pin 5/6, Voltage Divider: This input is the Tip Voltage used for Torch Height Control (THC). It is critical that the (+)(-) polarity of this signal is

correct, as well as the voltage divider ratio. The ratio must be 50:1 (used by Hypertherm and preset in the Avid CNC Mach4 profile), 40:1, 30:1,

20:1, 16.67:1, or 15:1. Note: Do not connect raw tip voltage, this will damage the TMC3in1.

Pin 7/8, Spindle Relay: This output is from a small dry contact relay on the CRP850 breakout board and is used for sending an on/off signal to

an external VFD, typically for a forward/stop command.

Pin 8/9, Spindle Analog Signal: This output is a 0-10V analog signal used to control VFD frequency/spindle RPM.

Pin 11, 10V Reference: Unused in most systems, this pin can provide a 10V reference if required by the VFD.

Pin 12/14, Arc Okay: This input signals to the CNC controller that the plasma arc has successfully transferred to the material and the cut

program can continue motion. Typically the plasma power supply will close a dry contact relay to control this signal.

Application

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

Custom M12 Inputs Connections

For custom machine applications, the M12 sensor inputs on the CRP860-00E breakout board can be used for purposes other than limits and

probes. The inputs are Normally Open, rated for 12V, and follow a standard M12 A-coded pinout. See the Schematics section for more details on

pin assignments in Mach4.

This picture is looking at a Female connector body. Pin assignments will be mirrored for a Male connector.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

The switch can be moved up or down and will display the input voltage setting of the power supply.

The second power supply in a NEMA 23 5-axis system will be smaller than those shown above. The switch to change input

voltages on that power supply will be located on the top of the power supply.

NEMA 23 5-Axis Systems

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

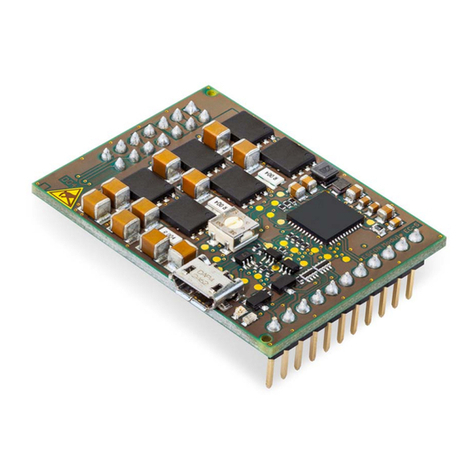

DIP switch Settings

DIP switch settings on the motor drives will vary depending on your application. The DIP switch positions are shown below.

CRP8070 for 7.0A 1/2" NEMA 34 motors

CRP5056 for 4.2A 3/8" Nema 23 motors

If you are using an Avid CNC rotary axis on a NEMA 23 system, be sure the rotary axis motor is hooked up to the 5th drive with that drive's DIP

switch positions are set as shown below.

CRP5056 for 5.0A motors

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

ESS Jumper Settings

The jumper pins shown here can provide 5V to pin 26 of their adjacent header, port 1 or port 2. The ESS comes pre-configured in the CNC

controller with these jumpers connected on port 1 and port 2.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

Peripherals

5th Drive Upgrade for NEMA 23 Plug and Play Systems

If your system has an existing 5th motor drive and you only need to install the capacitor, skip to the Capacitor Installation

section.

Ensure your plug and play control box is powered off with the power cable disconnected from the box. It is also recommended to

remove the control box from the machine for easier installation of the motor drive.

Capacitor Installation

Warning

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

1. Disconnect Components

1.1

The fist step in upgrading your NEMA 23 system with a 5th drive will be to remove the gland plate and disconnect the breakout board. Unplug the

four motor drivers and the ethernet cable connected to the breakout board.

Plug & Play CNC

Controller Manual

17.4 Electronics Revision

Version 2020Q3.1

© 2020 Avid CNC

All Rights Reserved

This manual suits for next models

1

Table of contents

Other Avid CNC Controllers manuals

Popular Controllers manuals by other brands

LMI Technologies

LMI Technologies Liquitron DP5000-1A instruction manual

Mitsubishi

Mitsubishi MELSEC-A user manual

KTM

KTM 60711912000 Fitting instructions

Victron energy

Victron energy BlueSolar MPPT 150/85 CAN-bus manual

Inovance

Inovance H3U Series Programming manual

Coopers

Coopers Variospeed MK5 V3 Technical manual