2

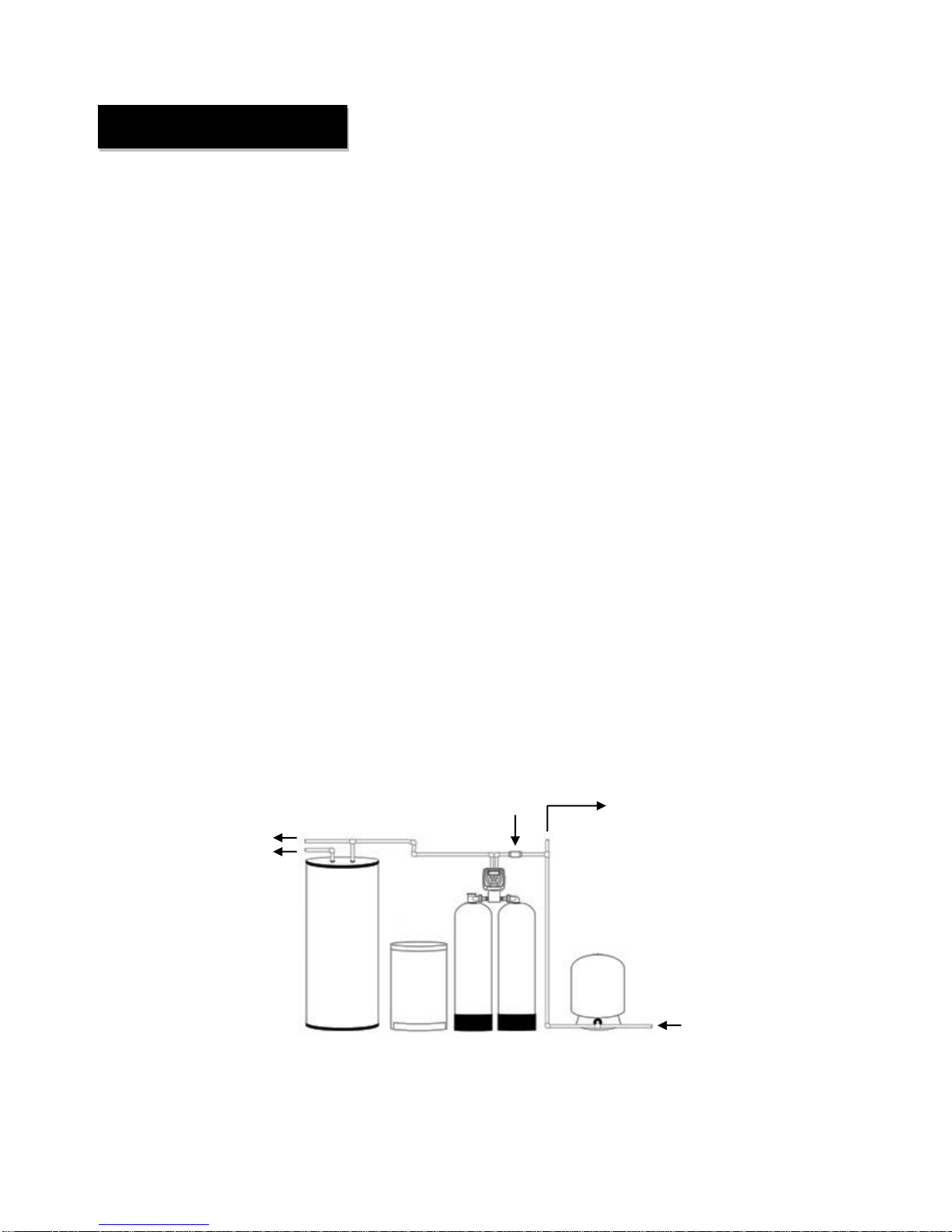

Description of the iron filter / softener system

The AFS system includes a filtration tank, softener tank, brine tank, and a backwashing control valve.

Incoming water flows into the control valve and is directed into the filtration tank. Exposure to the air in this tank

will start oxidizing the iron and the filtration media will trap this iron. The water then flows through the back

connector tube and into the softener tank where the water is then softened. The iron-free softened water then

returns to the control valve where it is directed into the service lines.

Periodically the control valve will go through a backwash cycle. This cycle will typically begin at 2:00

A.M. flushing the accumulated iron and hard elements to the drain. Part of this backwashing process includes

an air draw cycle which will replenish the pocket of air in the filtration tank and a brining cycle which recharges

the softening resin in the softener tank. After the backwashing process the unit is now prepared for the next

period of service.

Water Quality

While the AFS filter/softener will perform under a variety of water qualities there are a few things that

need to be considered to ensure satisfactory performance. The water should be tested to determine the

concentration, or levels of the items listed below.

pH - A measurement of the acidity of the water. pH is reported on a scale from 0 to 14. Neutral water

has a pH of 7.0, lower values indicate acidic water. The AFS performs best when the pH is 7.0, or higher. pH

values below 7.0 require a special media blend in the filter in order to elevate the pH for proper iron oxidation.

Iron - A naturally occurring metallic element. Iron concentrations in excess of 0.3 milligrams/liter (mg/l)

combine with oxygen causing orange or red (rust) stains on plumbing fixtures. Iron naturally exists in some

water sources in either clear water (ferrous) state, red water (ferric) state or bacterial form. The AFS iron filter

portion can reduce any of these forms of iron.

Manganese - A naturally occurring metallic element. Manganese concentrations as low as 0.05

milligrams/liter (mg/l) can combine with oxygen to cause dark brown or black staining on fixtures. Additionally,

manganese can cause an odor in the water similar to a “rotten egg” smell. The AFS reduces manganese as

well as iron, however, manganese oxidation requires the pH of the water to be elevated to 8.2 or higher.

Special media might need to be added to elevate the pH of manganese bearing waters.

Tannin - A naturally occurring humic acid. Tannin is an acid caused bywater passing through decaying

vegetation. Coffee and Tea are prime examples of tannin in water. As hot water passes over the coffee beans,

or tea leaves, the tannin is extracted causing color and flavor in the water. Tannin concentrations as low as 0.3

milligrams per liter can cause a yellow discoloration in the water and may interfere with the AFS’s long-term

ability to remove the iron as the media becomes coated with the tannic acid.

Hydrogen Sulfide - A naturally occurring gas. Hydrogen sulfide, more commonly referred to as sulfur

gas, causes a distinct odor similar to “rotten eggs.” Due to its gaseous nature, hydrogen sulfide must be tested

at the well site within 1 minute of drawing the sample. If a water sample has been sitting for a while the sulfur

gas will dissipate and cause the hydrogen sulfide test to be lower than the actual concentration. If sulfur is

present, the filter should be set to backwash more frequently to prevent the gas from building up. The AFS can

typically treat up to 1 to 2 milligrams per liter of sulfur gas.

Preinstallation Instructions