Condenser Microphone Capsule CM16

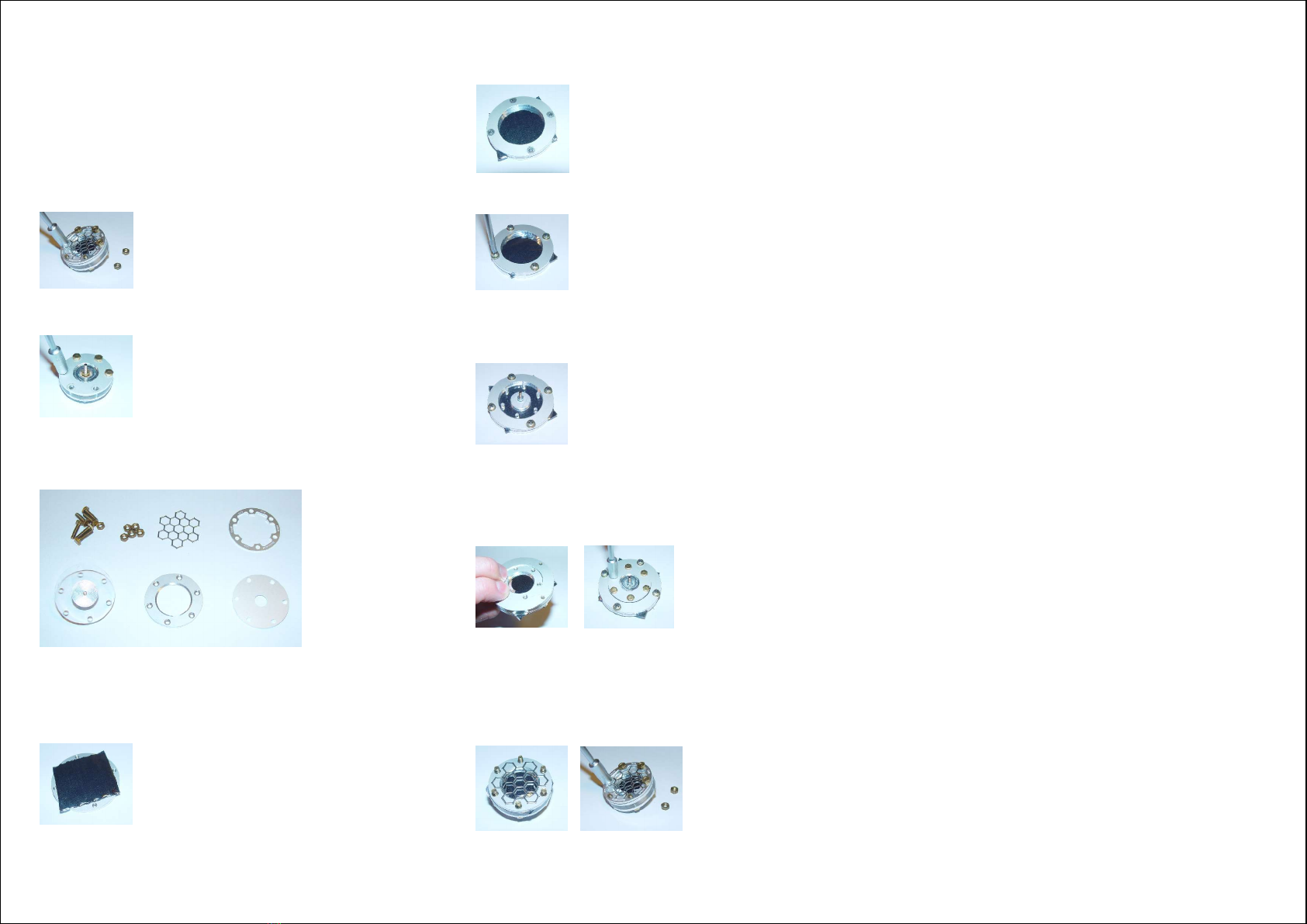

The microphone capsule consists of a thin metalized polyester film

and a metal back plate. Do not touch the diaphragm because its

metalization could be destroyed. It is recommended to use the

capsule always with the protective grid. However, depending on the

grid type, the frequency response may be degraded in some way.

Therefore, it is possible to remove or replace the grid by releasing

the nuts on the front side use the supplied 5.5 mm box spanner).

Due to its thin metalization, the diaphragm may deteriorate

especially under humid conditions. Therefore, it is recommended to

store the microphone in a dry place. Spare capsules are available

on request and deteriorated diaphragms will be replaced by Avisoft

Bioacoustics at a small fee. With some skill, it would also be

possible to replace the membrane foil on your own by releasing the

screws on the back of the capsule).

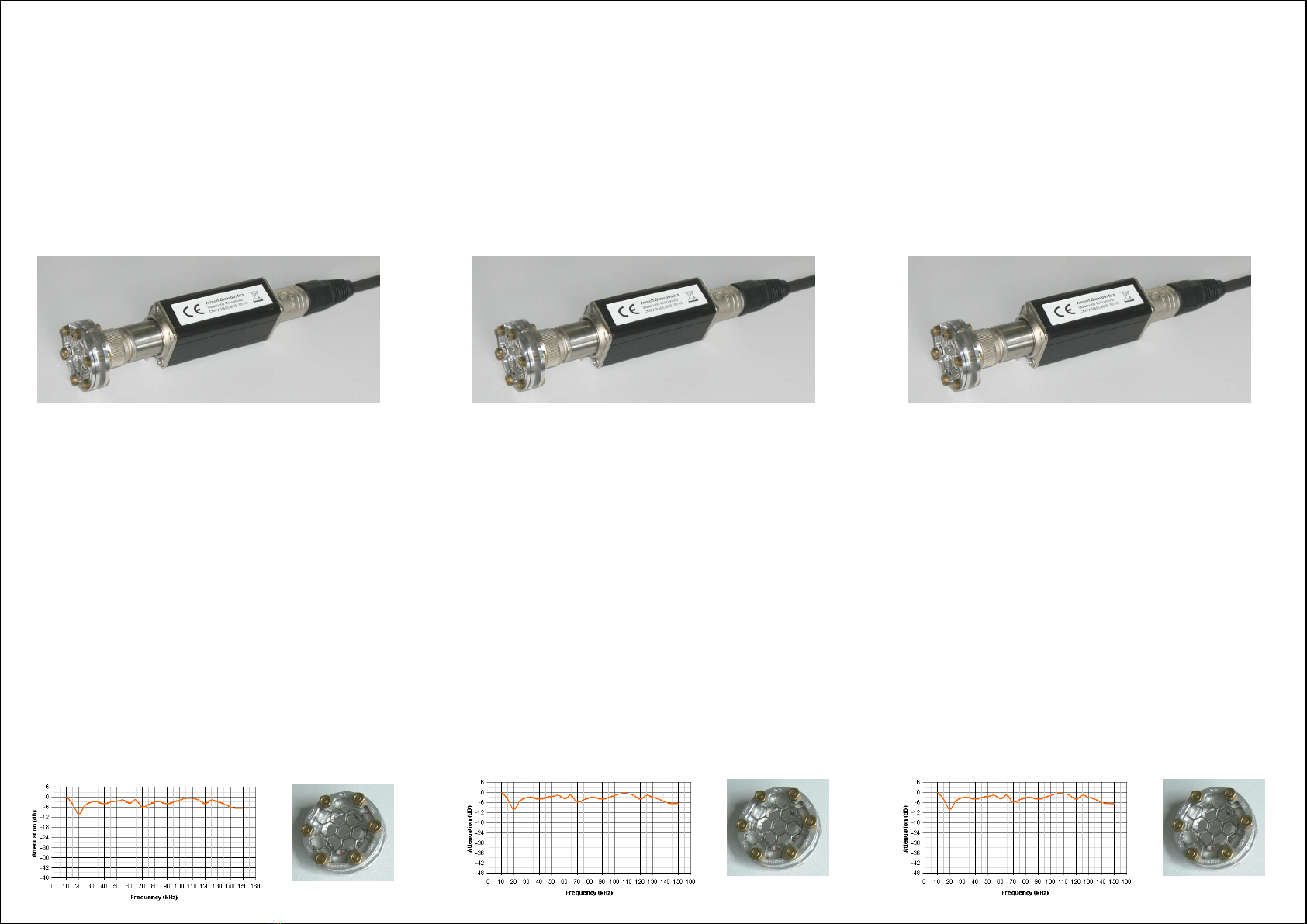

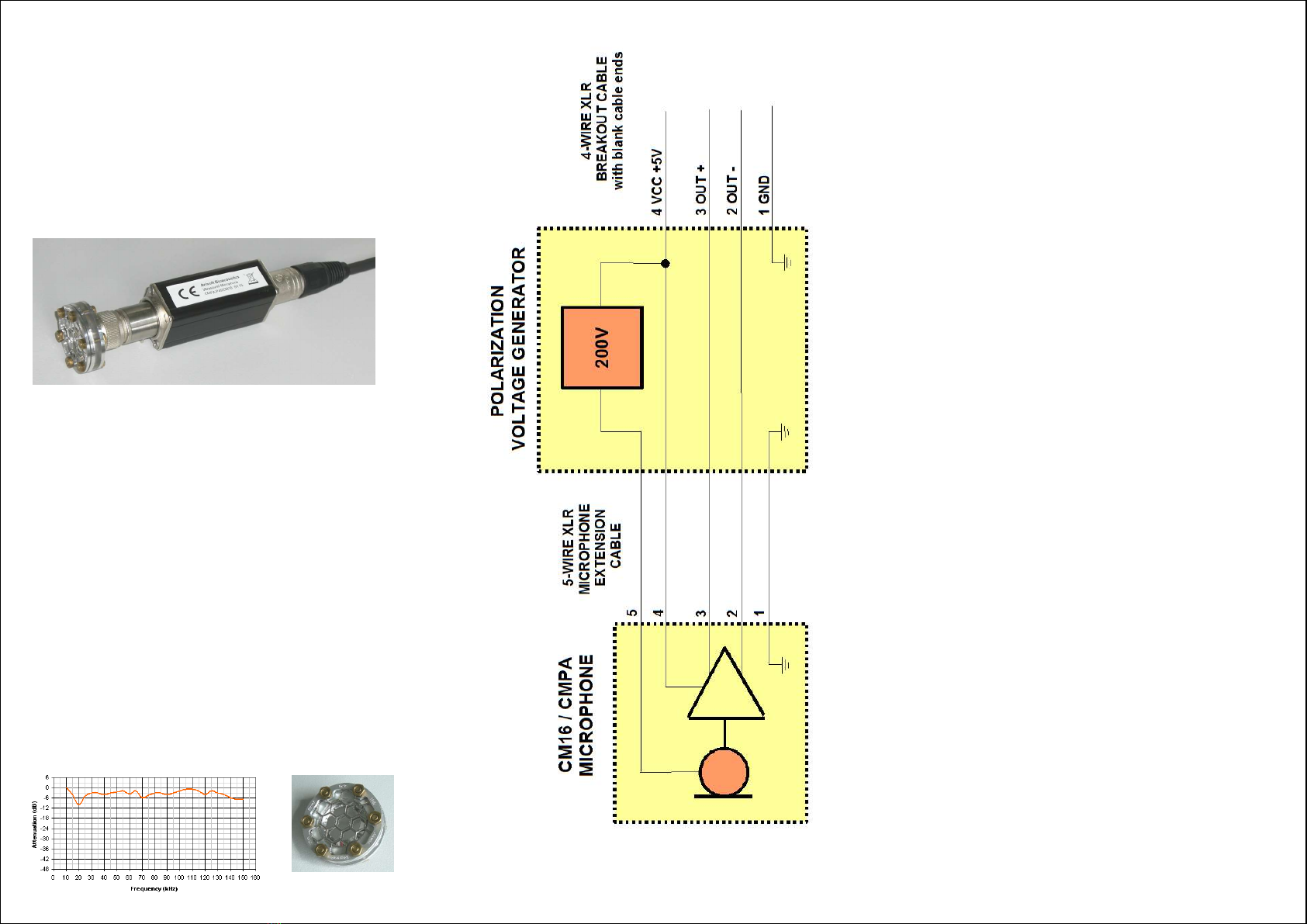

The condenser microphone CMPA-P48/CM16 consists of three

components. The microphone capsule CM16 #1) is connected to

the cylindric preamplifier module CMPA #2) by means of a 2.5 mm

thread. This allows to replace the capsule easily. For proper

operation, both this 2.5 mm thread and the 17 mm thread on the

preamplifier module must be fastened. However, use only moderate

forces in order to prevent mechanical damages. The P48

polarization voltage supply unit #3) provides the polarization voltage

for the microphone capsule and the XLR-3 connector that allows to

connect the microphone to a standard microphone input that

supplies P48 phantom power at a current of up to 10mA . The CMPA

module #2) can be attached either directly to the polarization

module #3) or via the supplied 5-pole XLR extension cable.

The integrated preamplifier has an internal compensation circuit that

slightly boosts frequencies above 50 kHz.

Condenser Microphone CM16/CMPA-P48

2

1

3

Condenser Microphone Capsule CM16

The microphone capsule consists of a thin metalized polyester film

and a metal back plate. Do not touch the diaphragm because its

metalization could be destroyed. It is recommended to use the

capsule always with the protective grid. However, depending on the

grid type, the frequency response may be degraded in some way.

Therefore, it is possible to remove or replace the grid by releasing

the nuts on the front side use the supplied 5.5 mm box spanner).

Due to its thin metalization, the diaphragm may deteriorate

especially under humid conditions. Therefore, it is recommended to

store the microphone in a dry place. Spare capsules are available

on request and deteriorated diaphragms will be replaced by Avisoft

Bioacoustics at a small fee. With some skill, it would also be

possible to replace the membrane foil on your own by releasing the

screws on the back of the capsule).

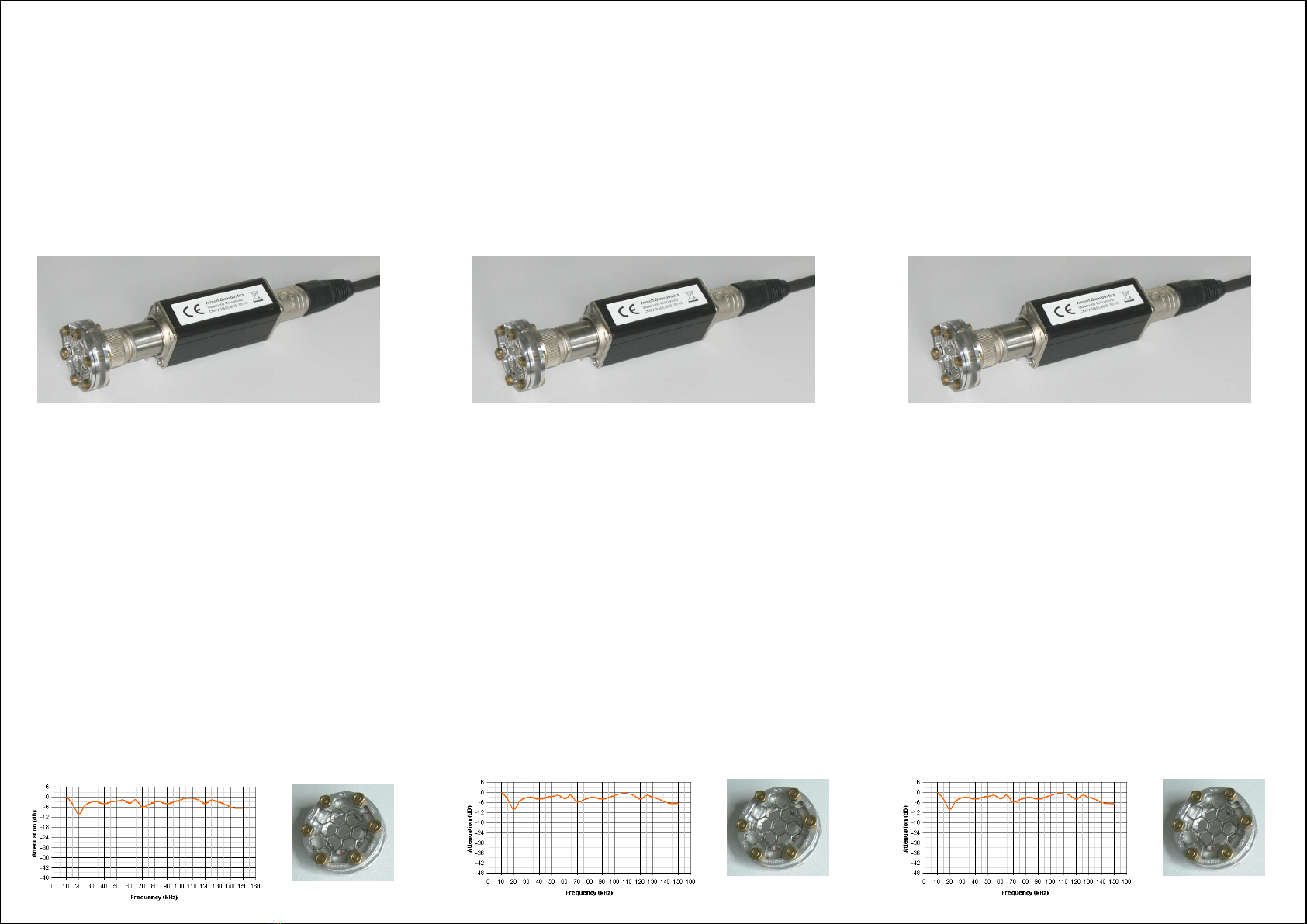

The condenser microphone CMPA-P48/CM16 consists of three

components. The microphone capsule CM16 #1) is connected to

the cylindric preamplifier module CMPA #2) by means of a 2.5 mm

thread. This allows to replace the capsule easily. For proper

operation, both this 2.5 mm thread and the 17 mm thread on the

preamplifier module must be fastened. However, use only moderate

forces in order to prevent mechanical damages. The P48

polarization voltage supply unit #3) provides the polarization voltage

for the microphone capsule and the XLR-3 connector that allows to

connect the microphone to a standard microphone input that

supplies P48 phantom power at a current of up to 10mA . The CMPA

module #2) can be attached either directly to the polarization

module #3) or via the supplied 5-pole XLR extension cable.

The integrated preamplifier has an internal compensation circuit that

slightly boosts frequencies above 50 kHz.

Condenser Microphone CM16/CMPA-P48

2

1

3

Condenser Microphone Capsule CM16

The microphone capsule consists of a thin metalized polyester film

and a metal back plate. Do not touch the diaphragm because its

metalization could be destroyed. It is recommended to use the

capsule always with the protective grid. However, depending on the

grid type, the frequency response may be degraded in some way.

Therefore, it is possible to remove or replace the grid by releasing

the nuts on the front side use the supplied 5.5 mm box spanner).

Due to its thin metalization, the diaphragm may deteriorate

especially under humid conditions. Therefore, it is recommended to

store the microphone in a dry place. Spare capsules are available

on request and deteriorated diaphragms will be replaced by Avisoft

Bioacoustics at a small fee. With some skill, it would also be

possible to replace the membrane foil on your own by releasing the

screws on the back of the capsule).

The condenser microphone CMPA-P48/CM16 consists of three

components. The microphone capsule CM16 #1) is connected to

the cylindric preamplifier module CMPA #2) by means of a 2.5 mm

thread. This allows to replace the capsule easily. For proper

operation, both this 2.5 mm thread and the 17 mm thread on the

preamplifier module must be fastened. However, use only moderate

forces in order to prevent mechanical damages. The P48

polarization voltage supply unit #3) provides the polarization voltage

for the microphone capsule and the XLR-3 connector that allows to

connect the microphone to a standard microphone input that

supplies P48 phantom power at a current of up to 10mA . The CMPA

module #2) can be attached either directly to the polarization

module #3) or via the supplied 5-pole XLR extension cable.

The integrated preamplifier has an internal compensation circuit that

slightly boosts frequencies above 50 kHz.

Condenser Microphone CM16/CMPA-P48

2

1

3