page 2

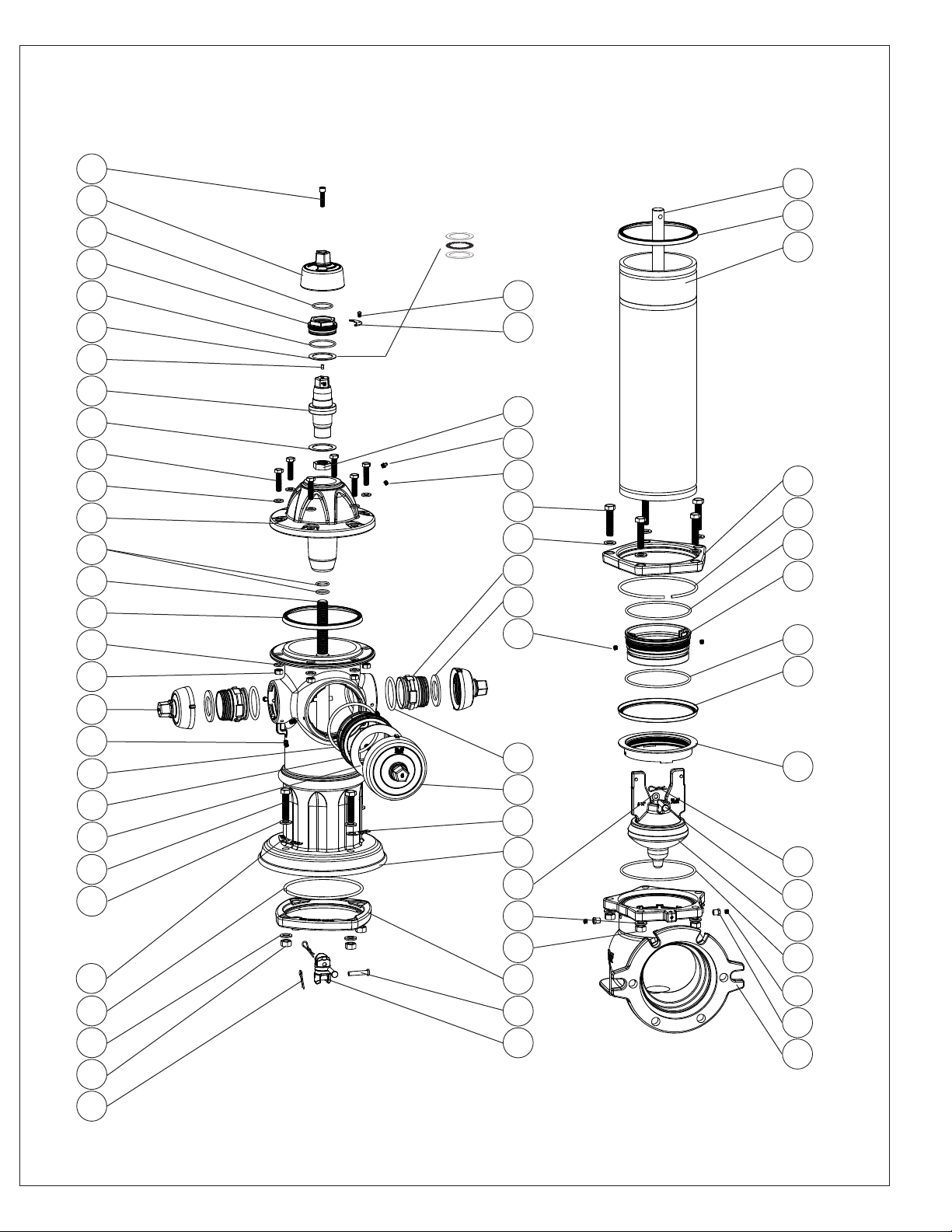

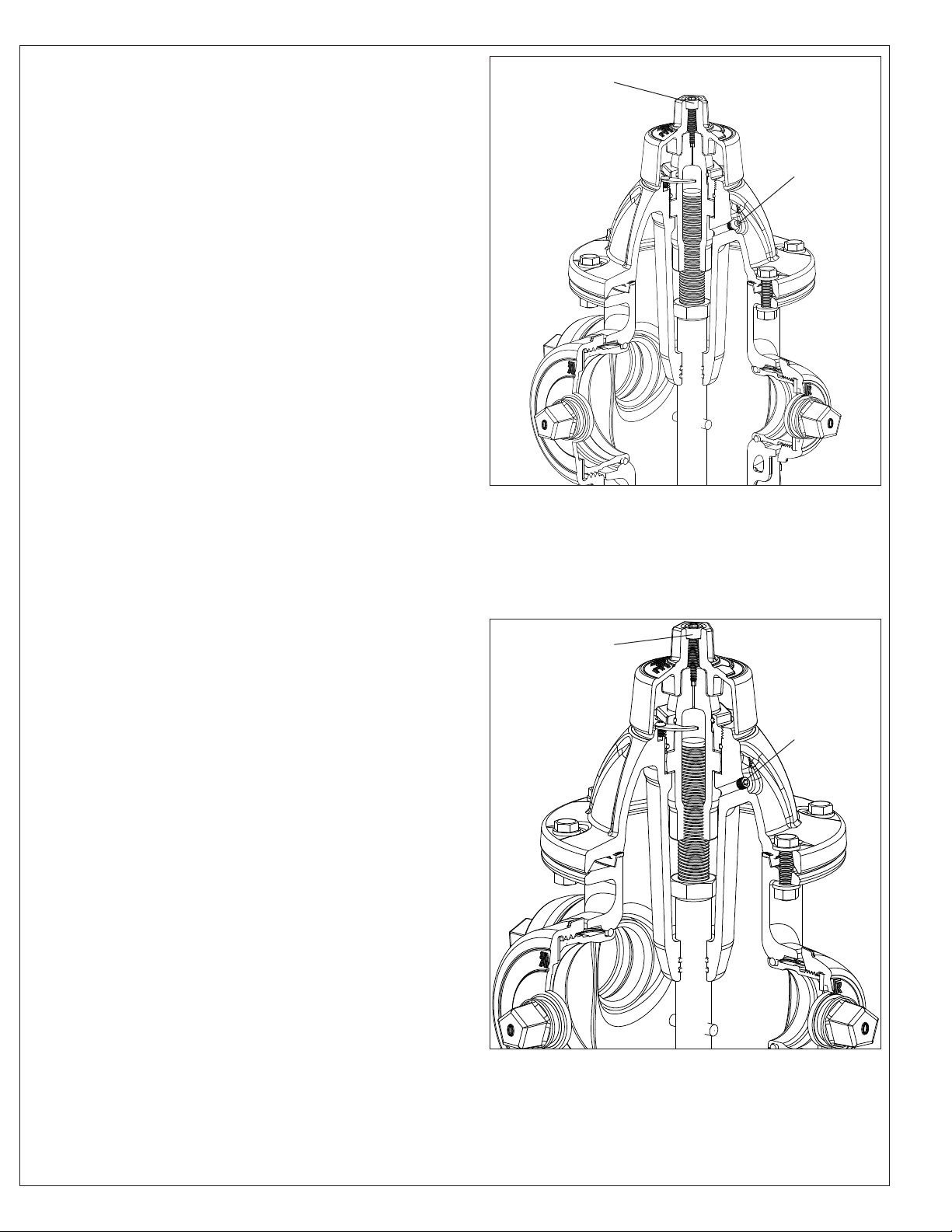

Item No. Description Material

F1 Weathershield Bolt 304 Stainless steel

F2 Weathershield Grey Iron, ASTM126, Class “B”

F3 Lockplate Bolt 304 Stainless steel

F4 Lock Plate 304 Stainless steel

F5 Inner Thrust Nut O-ring NBR

F6 Thrust Nut Copper Alloy

F7 Outer Thrust Nut O-ring NBR

F8 Anti Friction Washer Nylon

F9 Lubrication Hole Seal NBR

F10 Operating Nut Copper Alloy

F11 Stop Nut Zinc plated steel

F12 Bonnet Bolt Zinc plate, 304, 316 Stainless steel

F13 Bonnet Washer Zinc plate, 304, 316 Stainless steel

F14 Bonnet Ductile Iron, ASTM A536

F15 Stem Seal O-rings NBR

F16 Upper Stem Rod 304 Stainless steel, Epoxy coated steel

F17 Barrel Gasket NBR with stainless steel insert

F18 Bonnet Nut Zinc plate, 304, 316 Stainless steel

F19 Hose Nozzle Cap Grey Iron, ASTM126, Class “B”

F20 Hose Nozzle Copper Alloy

F21 Hose Nozzle Cap Gasket NBR

F22 Hose Nozzle O-ring NBR

F23** Set Screw - (Nozzle) 304 Stainless steel

F24* Chain Assembly Zinc Plated Steel

F25 Pumper Nozzle O-ring NBR

F26 Pumper Nozzle Copper Alloy

F27 Pumper Cap Gasket NBR

F28 Pumper Cap Grey Iron, ASTM126, Class “B”

F29 Nozzle Section Ductile Iron, ASTM A536

F30 Nozzle Section Bolt Zinc plate, 304, 316 Stainless steel

F31 Nozzle Section Washer 304 Stainless steel

F32 Lock Ring 304 Stainless steel

F33 Breakable Flange Ductile Iron, ASTM A536

F34 Nozzle Section Nut 304 Stainless steel

F35* Upper Barrel Ductile Iron, ASTM A536

F36 Coupler Pin 420 Stainless steel

F37 Breakable Stem Rod Coupling 431 Stainless steel

F38 Spring Pin 304 Stainless steel

F41 Lower Stem Rod Mild Steel, 304 Stainless steel

F42* Extension Coupling 304 Stainless steel

F43* Extension Barrel Ductile Iron, ASTM A536

F44 Upper.Extension Barrel Bolt Zinc plate, 304, 316 Stainless steel

F45 N/A

F46 Standpipe Flange Ductile Iron, ASTM A536

F47* Monitor Elbow Ductile Iron, ASTM A536

F48* Extension Stem Rod Mild Steel, 304 Stainless steel

F49 Lower Barrel Ductile Iron, ASTM A536

F50 Lower Barrel O-ring NBR

F51 Valve Seat Ring Copper Alloy

F52 N/A

F53 Valve Seat O-ring NBR

F54 Drain Ring Copper Alloy

F55 Brass Plug Copper Alloy

F56 Brass Fitting Copper Alloy

F58 N/A

F60 Main Valve Retaining Pin 420 Stainless steel

F61 Main Valve EPDM, Encapsulated Ductile Iron

F62 Base Gasket NBR

F63* Straight Inlet Ductile Iron, ASTM A536

F65 N/A

F66 N/A

F67 Base Ductile Iron, ASTM A536

F68 N/A

F69*** Thrust Bearing Race Hardened Steel

F70*** Thrust Bearing Hardened Steel

F71* Modern Nozzle Section Bolt Zinc plate, 304, 316 Stainless steel

F72* Base Gasket - Specify type NBR

F73* Storz Cap O-ring EPDM

F74* Cap/Cable Assembly

F75 Zerk Fitting Case Hardened Steel, Zinc Plated

F88 Main Valve Retaining Pin Washer 304 Stainless steel

F90* Hose Nozzle Position Clip 300 Series Stainless

F91* Pumper Nozzle Position Clip 300 Series Stainless

F92* Inner Storz Cap O-ring NBR

F93* Storz Adaptor Copper Alloy

F94 Bury Tag Aluminum

F95 Extension Bury Tag Aluminum

* Not Shown in Exploded Parts Breakdown

** As of July 2015, secondary Set Screws were added to

all dry barrel nozzle outlets

*** As of Dec. 2018, the upper Anti Friction Washer has been

replaced with a 3 piece roller bearing assembly comprised of 2,

F69 Thrust Bearing Races and 1, F70 Thrust Bearing.