Instructions for the installation, use and maintenance of Tecnicomar watermaker

TABLE OF CONTENTS

1Storage prior to unpacking and packaging content............................................................................................1-6

1.1 Storage prior to unpacking..............................................................................................................................1-6

1.2 Checking packaging content............................................................................................................................1-6

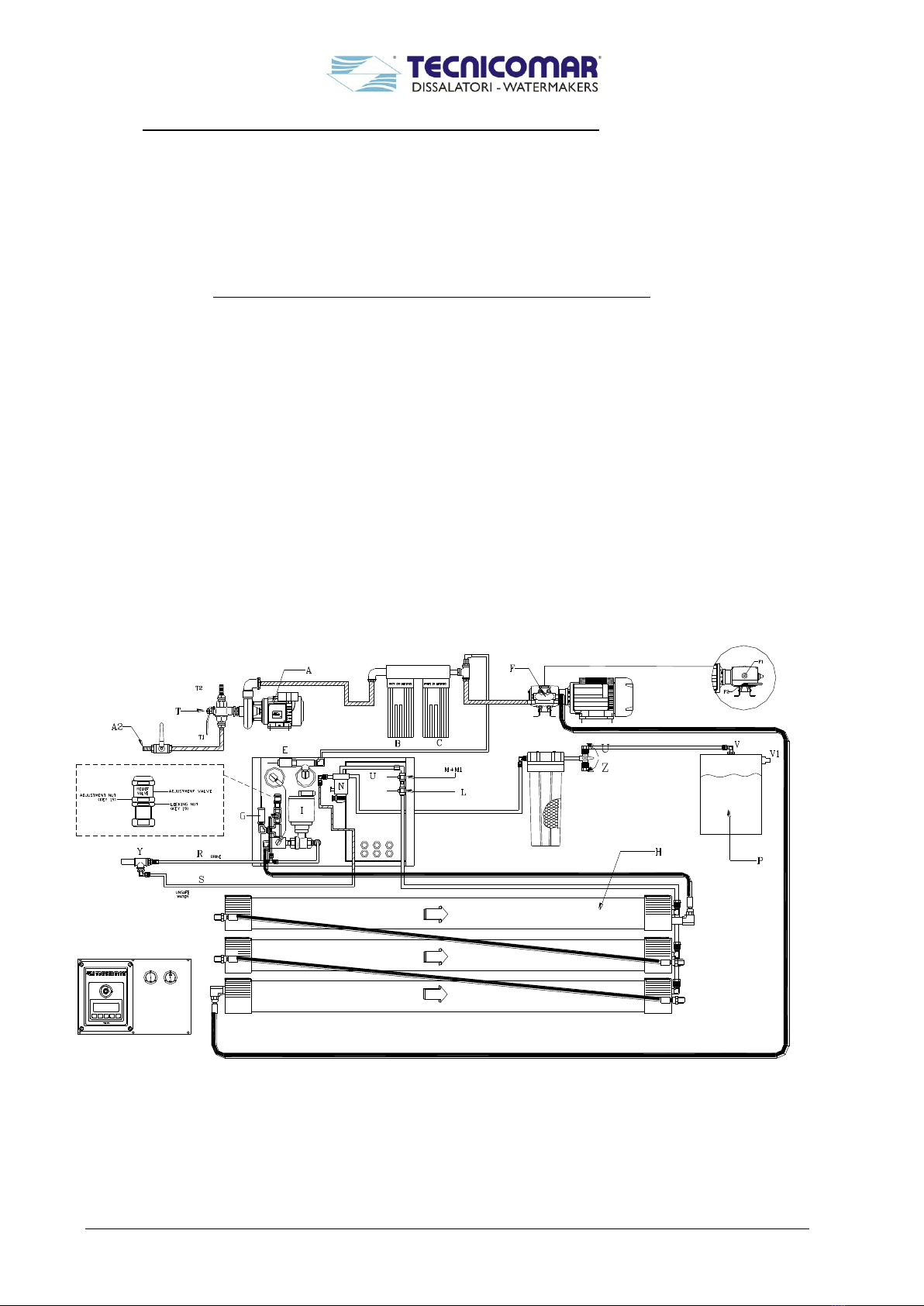

2Process description and system components identification................................................................................2-9

3Installation Procedure.........................................................................................................................................3-11

3.1 Components supplied by owner .....................................................................................................................3-11

3.2 Plumbing connections....................................................................................................................................3-11

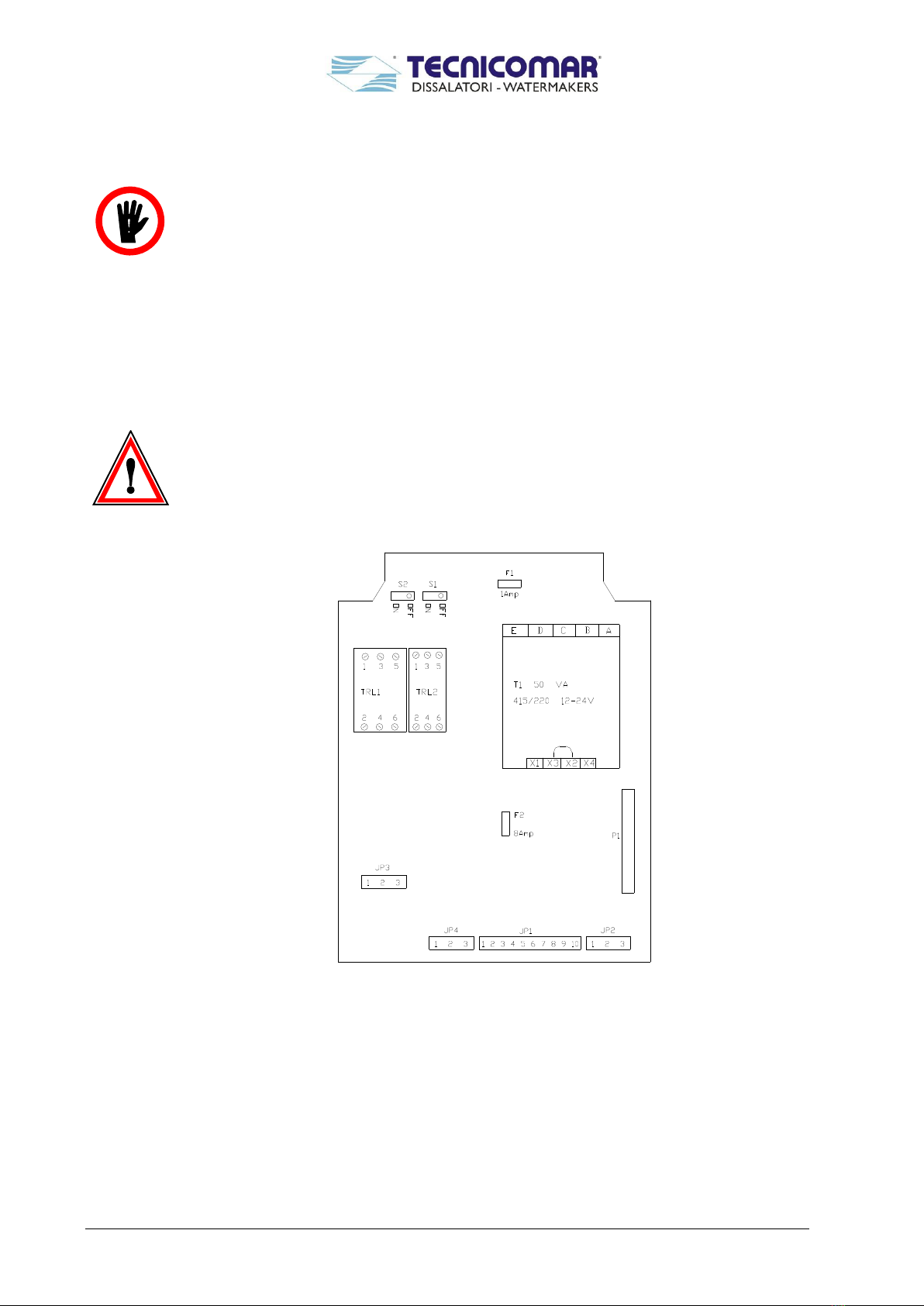

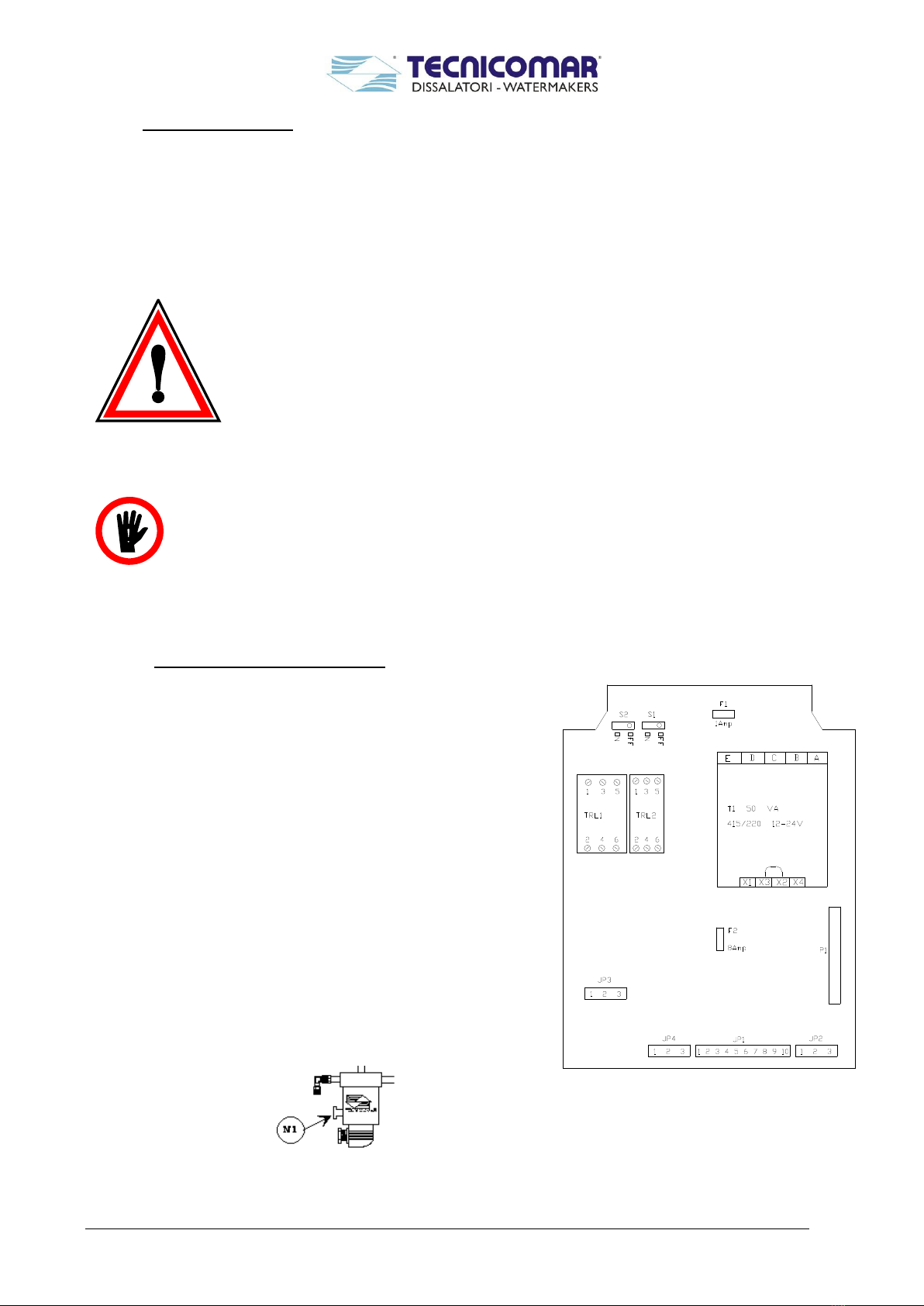

3.3 Power connection ..........................................................................................................................................3-12

4First Start-up procedure .....................................................................................................................................4-15

4.1 Shut down procedure .....................................................................................................................................4-16

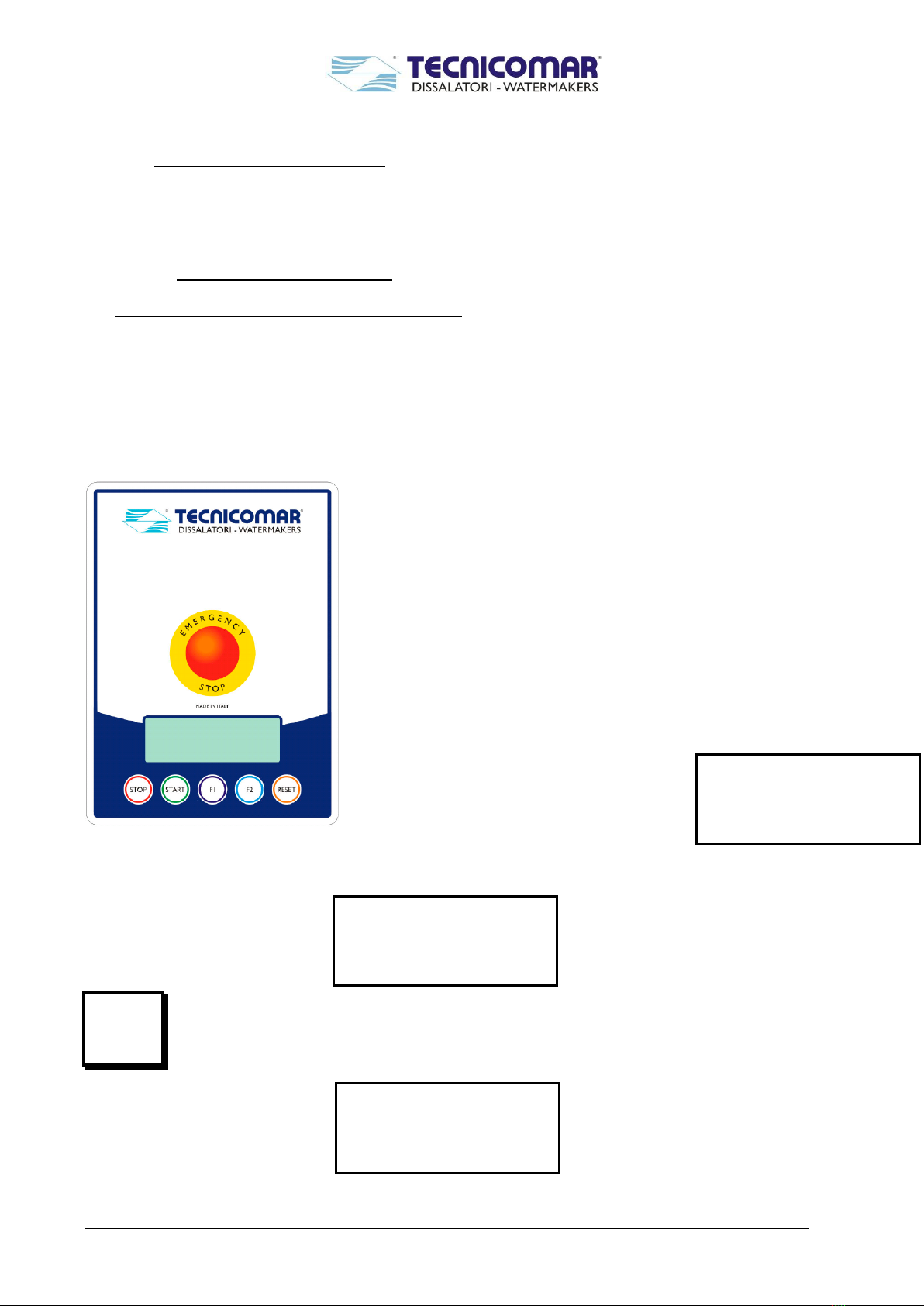

4.2 TINY 2 microprocessor control box. Description and operation...................................................................4-16

5Routine operation ................................................................................................................................................5-18

5.1 Routine operation (c/w automatic pressure regulator device).......................................................................5-18

5.2 Routine operation (c/w manual pressure regulator device)...........................................................................5-18

5.3 Manual running mode (c/w automatic pressure regulator device)................................................................5-19

5.4 Operation in low- or high-salinity areas .......................................................................................................5-19

5.5 Operation in cold areas.................................................................................................................................5-19

6Special procedures...............................................................................................................................................6-20

6.1 System normal operation. ..............................................................................................................................6-20

6.2 Emergency operation.....................................................................................................................................6-20

6.3 Preservation of membrane modules in very cold areas.................................................................................6-22

6.4 Optionals........................................................................................................................................................6-22

6.4.1 Automatic flushing system ....................................................................................................................6-22

6.4.2 Remote control.......................................................................................................................................6-23

6.4.3 Touch screen..........................................................................................................................................6-23

6.4.4 UV sterilizer...........................................................................................................................................6-23

6.4.5 Multimedia sand filter or TFD filter ......................................................................................................6-23

7Maintenance.........................................................................................................................................................7-24

7.1 Ordinary Maintenance...................................................................................................................................7-24

7.1.1 Preservation and care of the semipermeable membrane modules..........................................................7-24

7.1.2 High-pressure circuit..............................................................................................................................7-24

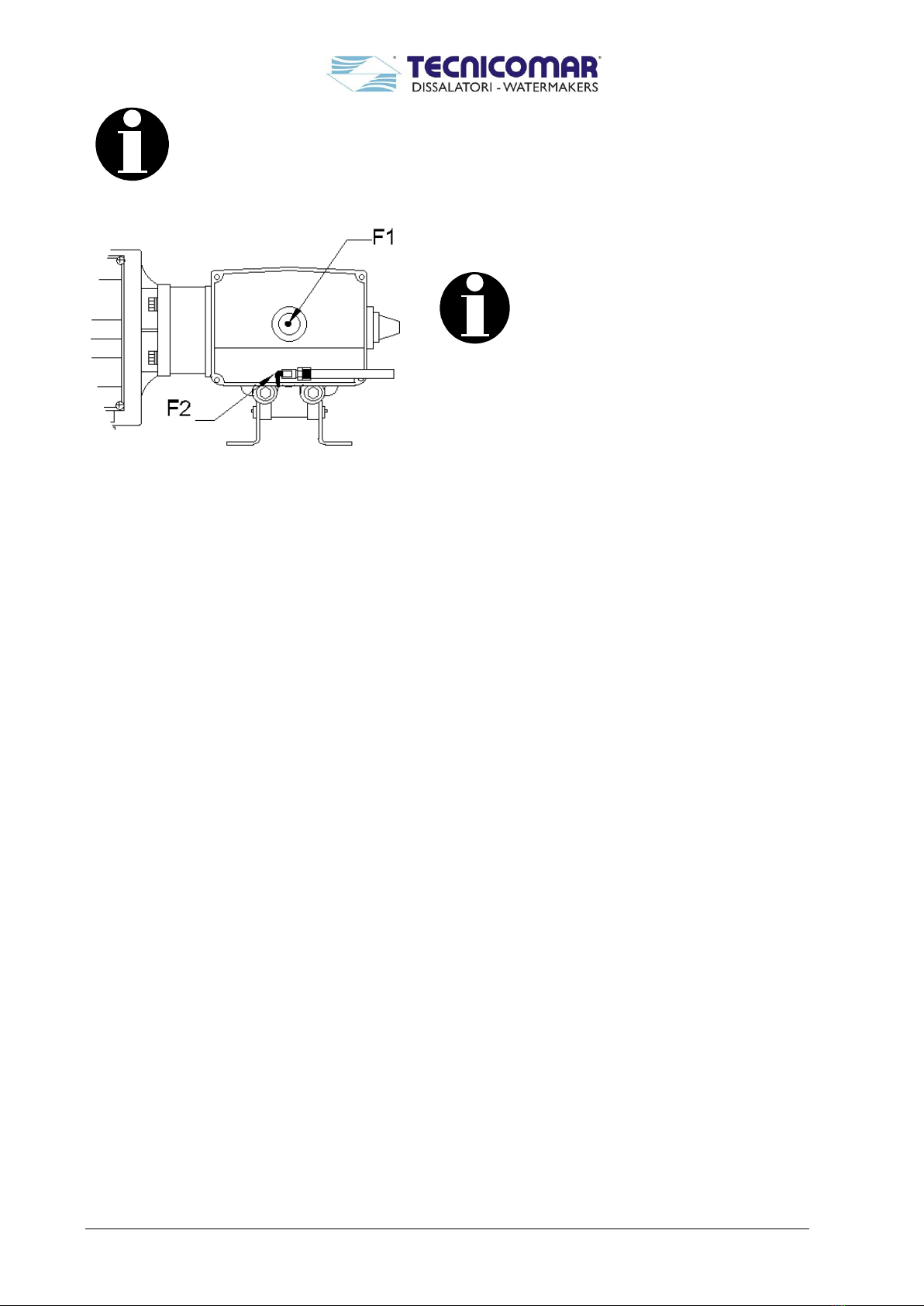

7.1.3 Oil changing in the CAT high-pressure pump .......................................................................................7-24

7.1.4 Prefilters maintenance............................................................................................................................7-25

7.1.5 Carbon filter replacement ......................................................................................................................7-25

7.2 Extraordinary maintenance ...........................................................................................................................7-26

7.2.1 Replacement of membrane modules......................................................................................................7-26

7.2.2 Salinity and temperature sensors (M+M1).............................................................................................7-26

7.3 Long-period shut down procedure.................................................................................................................7-26

7.3.1 In case of automatic pressure regulator device ......................................................................................7-26

7.3.2 In case of manual pressure regulator device ..........................................................................................7-27