- 2 -

The product is in conformity to the CE Directive for electromagnetic compatibility

Supplying must come from a very low security-tension circuit, featuring a limited-power

source protected by fuse.

THE INSTALLATION MUST BE EXECUTED BY QUALIFIED PERSONNEL

Index

Chapter 1: General Description .................................................................................pag. 3

Compatibility with existing models ....................................................................pag. 3

Filter of selection and compensation .................................................................pag. 3

Detection Area ......................................................................................................pag. 3

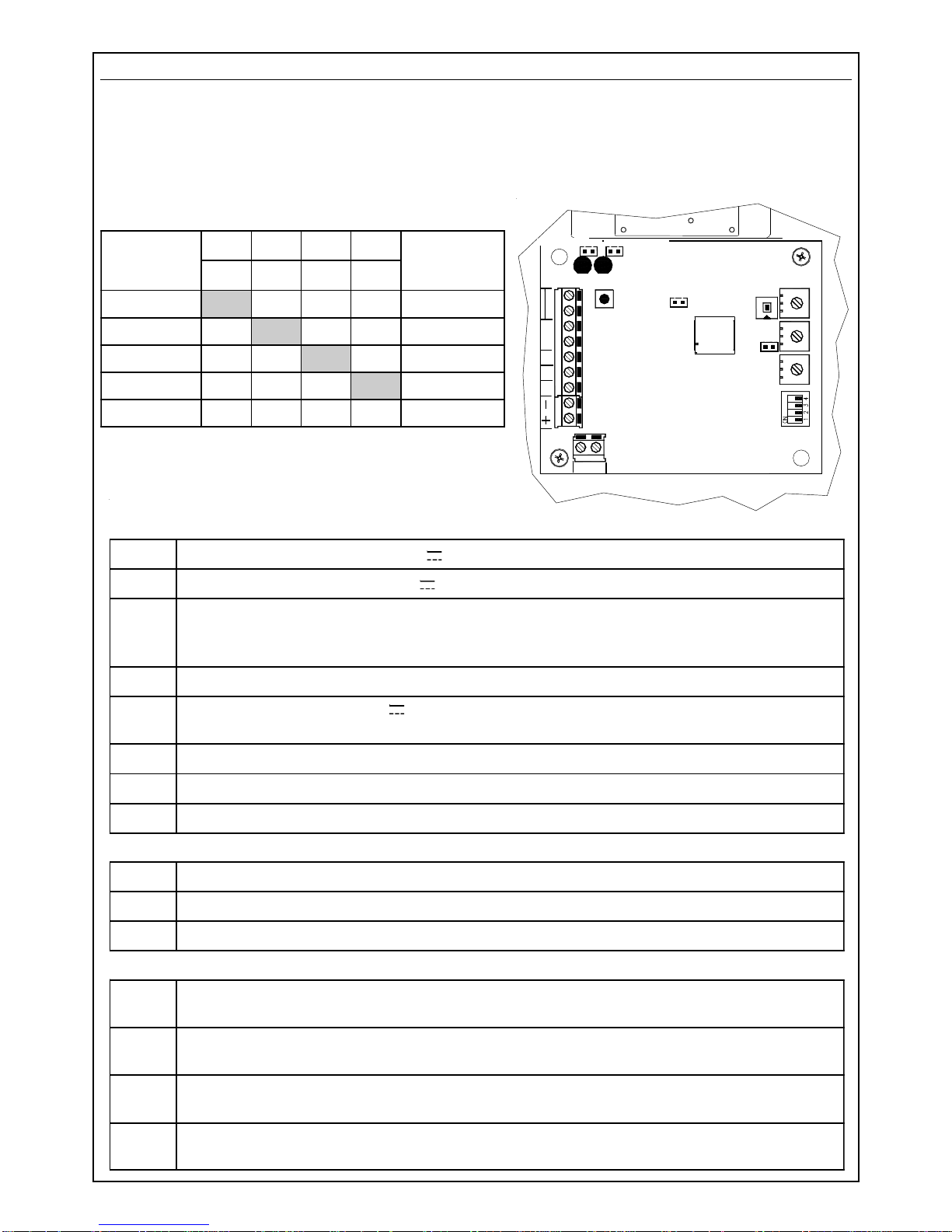

Chapter 2: Transmitter................................................................................................pag. 3

Chapter 3: receiver of hard-wired systems BM60M, BM120M, BM200M................pag. 4

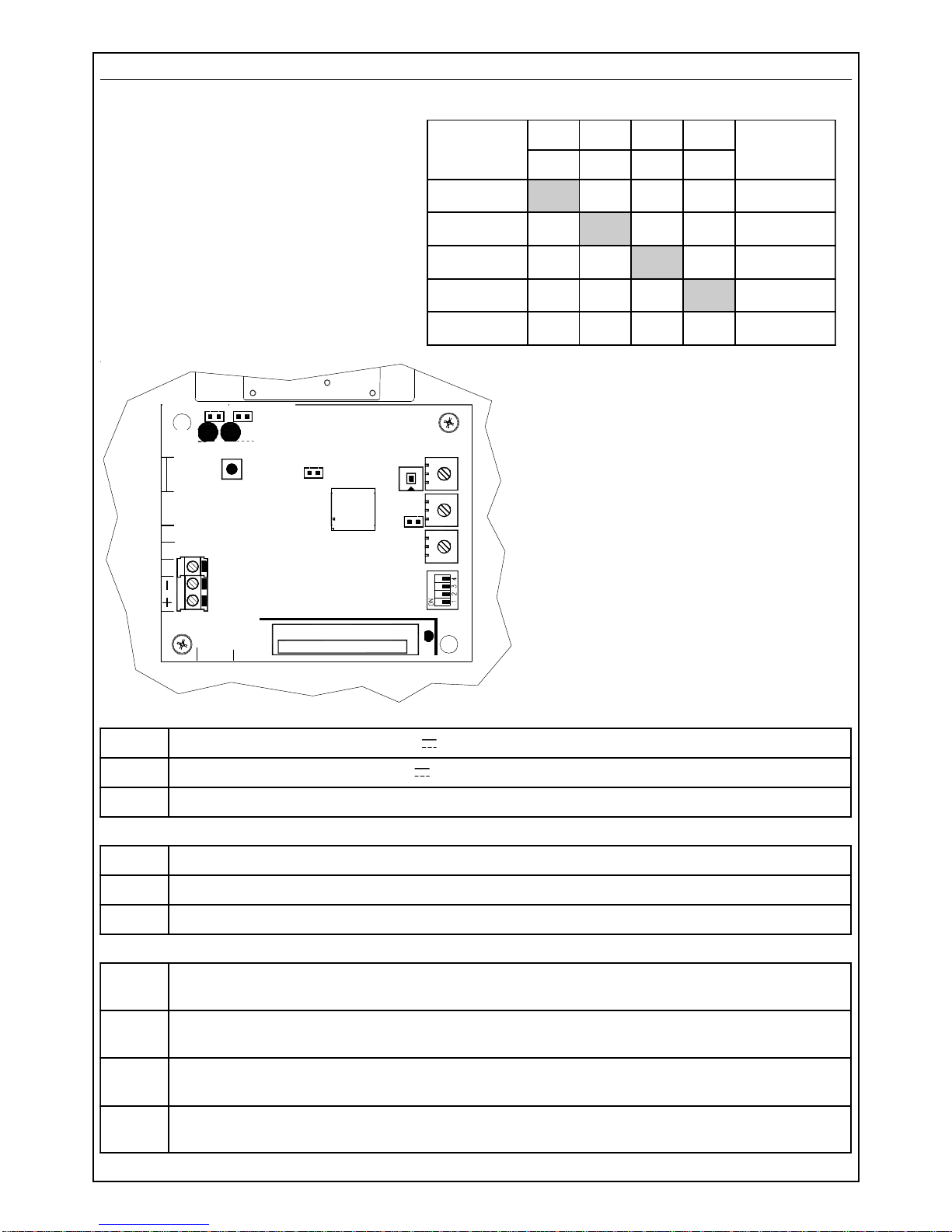

Chapter 4: Receiver of the wireless system BM60M WS.........................................pag. 5

Chapter 5: Description of working ............................................................................pag. 6

Working.................................................................................................................pag. 6

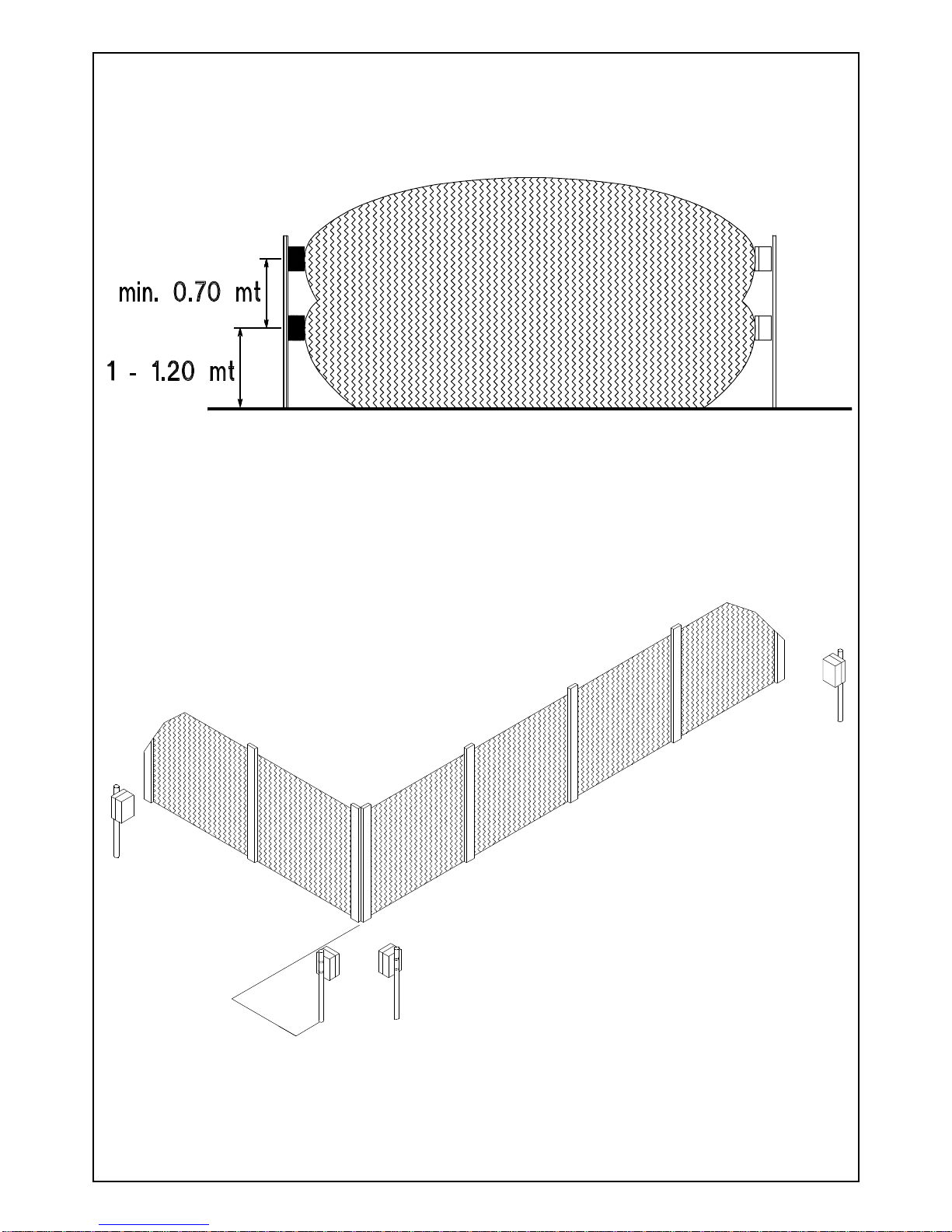

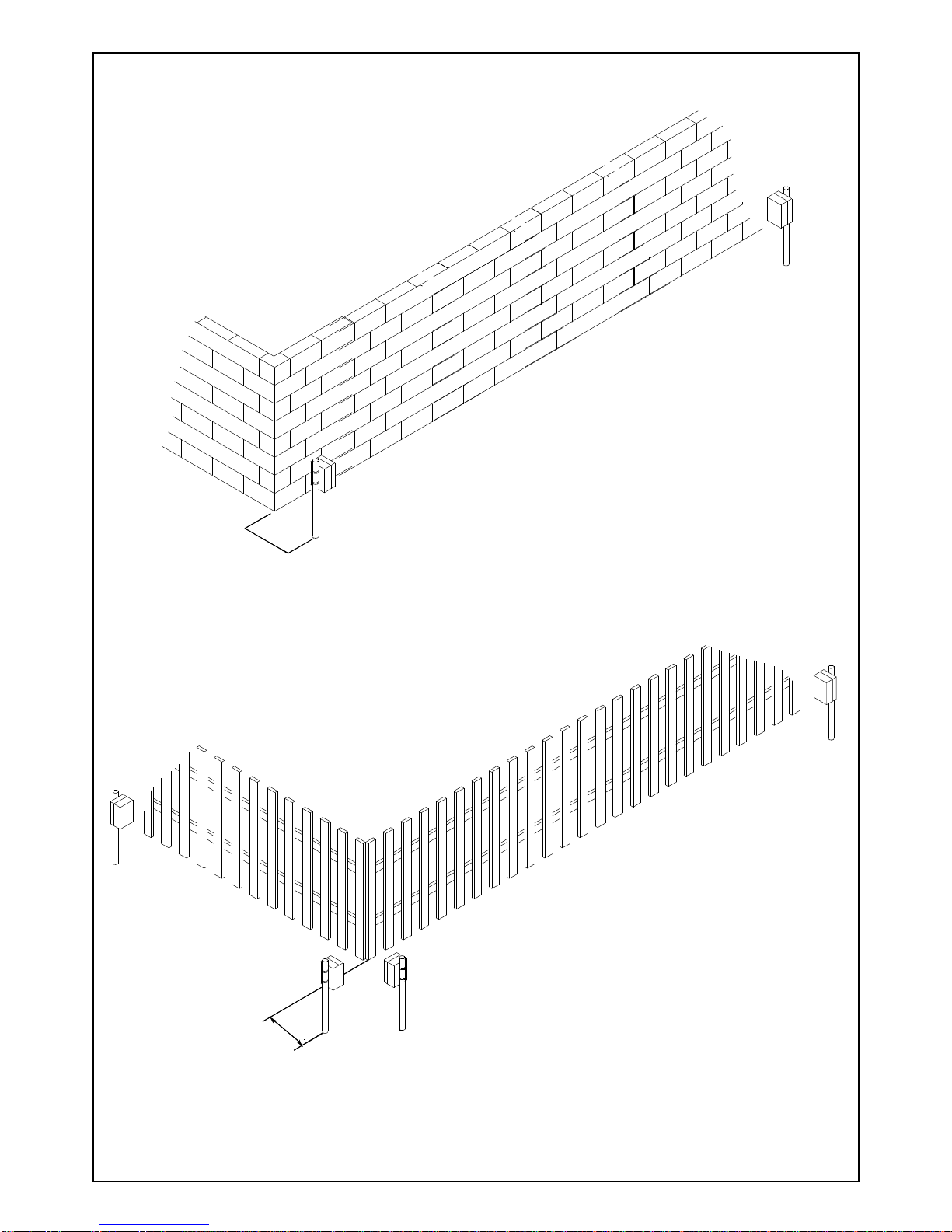

Chapter 6 : Positioning of the beams........................................................................pag. 7

Chapter 7: Advice for installation ............................................................................pag. 13

Chapter 8: Installation of the transmitter in the hard-wired system.....................pag. 14

Chapter 9: Installation of receiver in the hard-wired system ................................pag. 14

General Warning for the hard-wired system....................................................pag. 14

Chapter 10: Installation of transmitter in the wireless system .............................pag. 14

Chapter 11: Installation of the receiver in the wireless system............................pag. 14

General Warning for wireless system ..............................................................pag. 14

Chapter 12: Adjustments..........................................................................................pag. 15

Chapter 13: Measurements of the signal by oscilloscope ....................................pag. 16

Chapter 14: Sensitivity Adjustment .........................................................................pag. 17

Chapter 15: Kit TERM (optional) Resistence fo inside heating.............................pag. 18

Chapter 16: Kit AMP (optional) Anti-removal..........................................................pag. 18

Chapter 17: Disqualification (Important Warning) .................................................pag. 19

Chapter 18: Additional supply unit for BM60M WS................................................pag. 19

Chapter 19: BR100 Kit and LCD W (optional) signal remoting-device .................pag. 20

Chapter 20: Optional Brackets.................................................................................pag. 21

Information in conformity to the Directive 1999/5/CEE for model BM_M.............pag. 22

Information in conformity to the Directive 1999/5/CEE for model BM60M WS....pag. 23

Technical Characteristics.........................................................................................pag. 24