Picca EN 20-03-2017 page 5

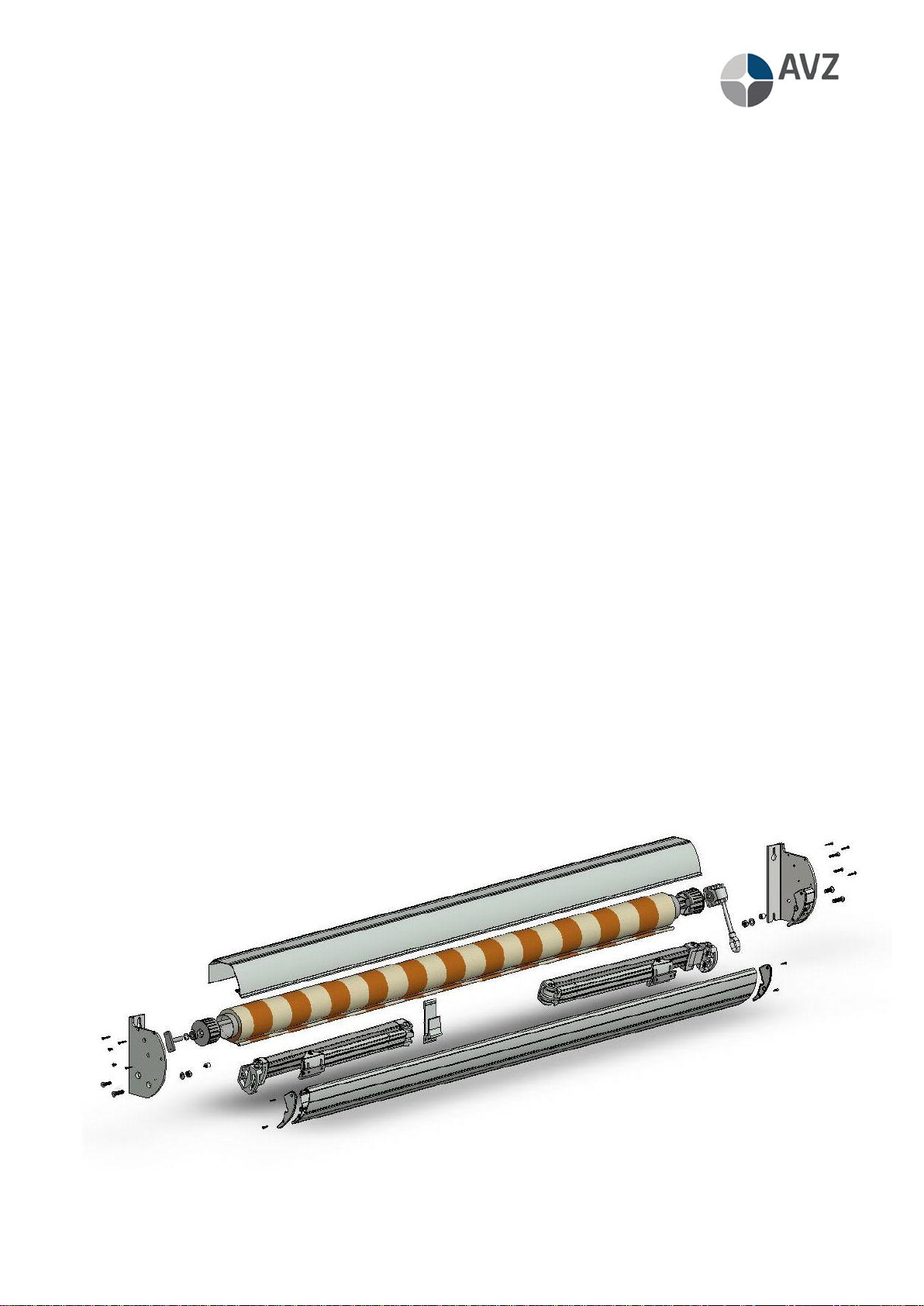

Assembly instructions folding arm awning Picca®

1. Before placing the awning, make sure that the underlying structure is suitable for the

attachment of a folding arm awning (consult a structural engineer, if necessary).

2. Provide sufficient fastening materials for your selected combination of wall and folding

arm awning (request advice from your supplier of fastening materials).

3. Measure out holes for the walls of boards and central bracket. Drill holes in the wall.

NB:Top cover supports M10 bolts and central bracket M6 bolt (if

possible, drill a hole for the central support for better positioning).

4. In case of electric controls: Drill a hole in the wall for the wiring.

5. Place the screw stud with nut or bolts in the plugs/chemical anchors

into the wall so that the wall brackets can be placed with the keyhole

over the nut.

6. Hang the folding awning with the wall brackets against the wall.

7. Fasten the wall support bolts. Ensure that the wall brackets are level

with one another and are vertically level with the wall.

NB: In case of all awnings, an uneven position of the top cover supports will result in an

unequal position of the arms as a result, the awning will not function properly.

8. Fasten the central bracket. When doing so, make sure that the top

cover does not sag.

9. Place a turn rod in case of gear box or connect a motor. Use the

instruction manual of the chosen motor and extend the awning to its

furthest position.

10. Set the desired awning angle between 5° and 35°. Adjust the awning

by slightly loosening the arm holder bolts and subsequently turning

(either in or out) the adjusting bolt between the fabric and arm.

(Tip: Lifting the front profile makes it easier to turn the bolt). Make sure that the front

profile runs parallel to the top cover in the open position. As soon as the desired

position has been realised, fasten the arm holder bolts.

11. Nearly close the awning (leave 30 cm open) and align the front profile so that it follows

the contour of the top cover supports.

12. Close the awning and check that the front profile falls neatly into

place. Is the central bracket positioned properly? Does the front profile

follow the contours of the top cover support? If not, make

adjustments.

13. In case of electric controls, adjust the motor using the accompanying

manual.