D-86 Inductive Sensors

Amplifier Units

Note:Communications are disabled if the detection mode is selected during super-high-speed sensing mode, and the communications functions

for mutual interference prevention and the Mobile Console will not function.

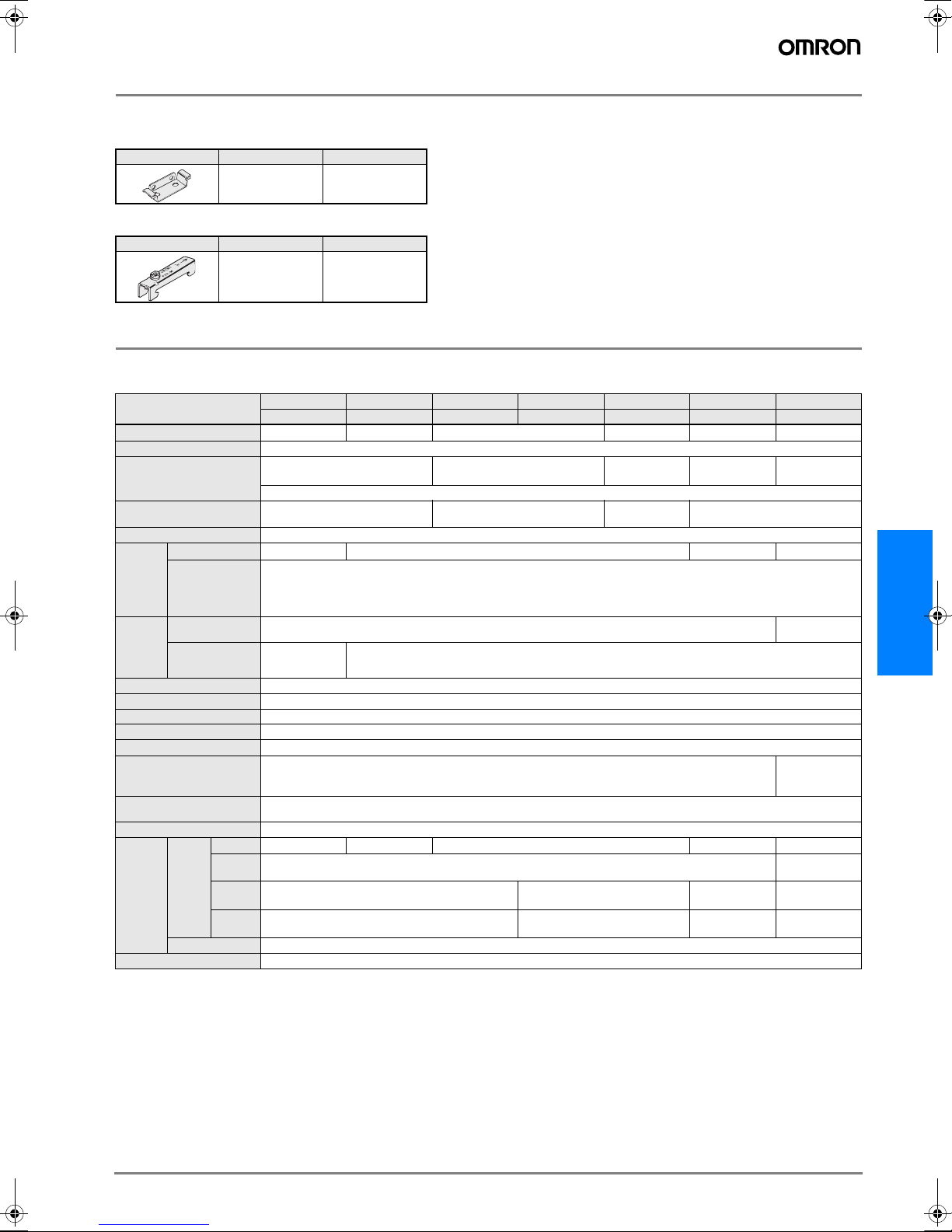

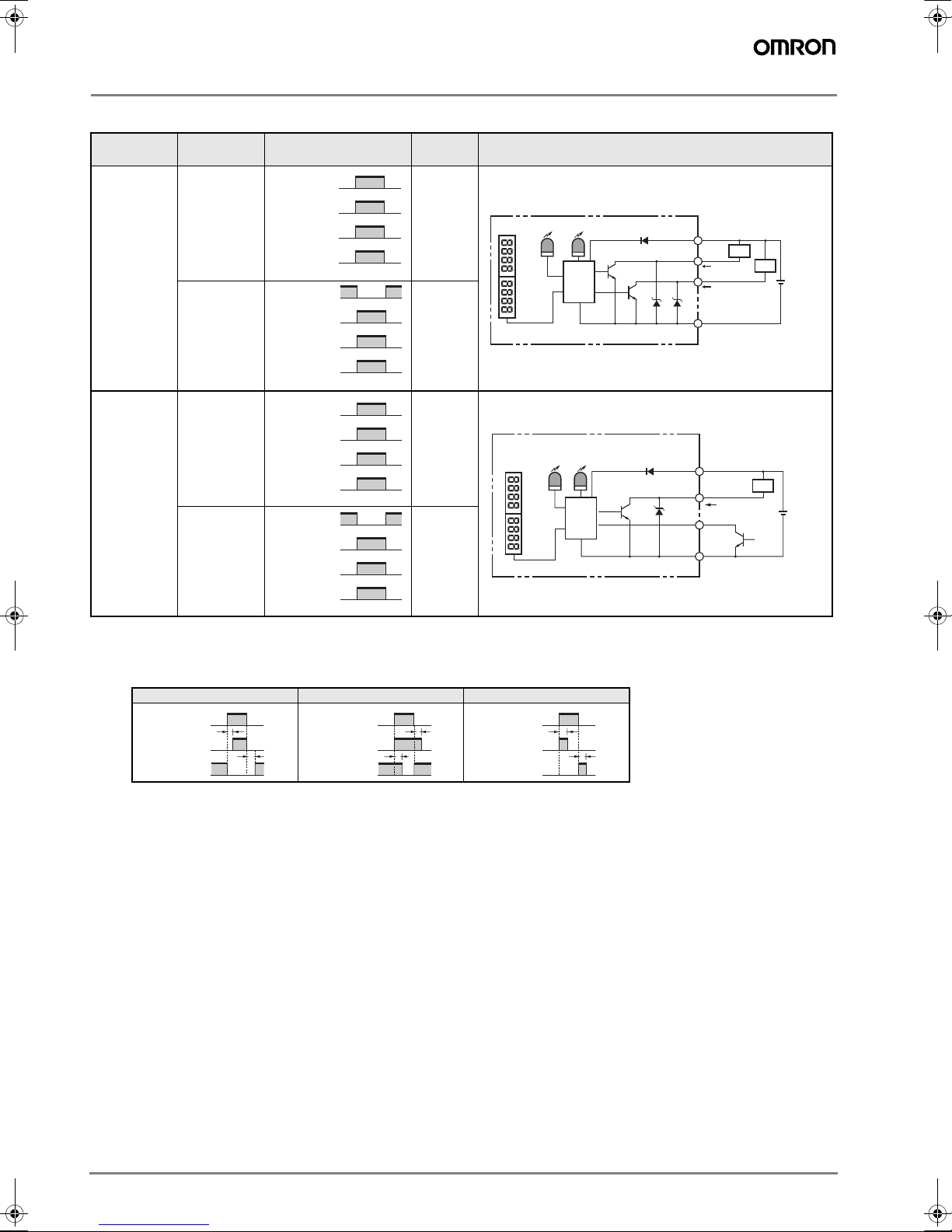

Type Advanced Models with Twin Outputs Advanced Models with External Inputs

Model NPN output E2C-EDA11 E2C-EDA6 E2C-EDA21 E2C-EDA7

Item PNP output E2C-EDA41 E2C-EDA8 E2C-EDA51 E2C-EDA9

Supply voltage 12 to 24 VDC ±10%, ripple (p-p): 10% max.

Power consumption 1,080 mW max. (current consumption: 45 mA at power supply voltage of 24 VDC)

Control output Load power supply voltage: 26.4 VDC max.; NPN/PNP open collector output; load current: 50 mA max. (residual voltage: 1

V max.)

Response time Super-high-speed

mode 150 µs for operation and reset respectively

High-speed mode 300 µs for operation and reset respectively

Standard mode 1 ms for operation and reset respectively

High-resolution

mode

4 ms for operation and reset respectively

Functions Differential detec-

tion Switchable between single edge and double edge detection mode

Single edge: Can be set to 300 µs, 500 µs, 1 ms, 10 ms, or 100 ms

Double edge: Can be set to 500 µs, 1 ms, 2 ms, 20 ms, or 200 ms.

Timer function Select from OFF-delay, ON-delay, or one-shot timer.

1 ms to 5 s (1 to 20 ms set in 1-ms increments, 20 to 200 ms set in 10-ms increments,

200 ms to 1 s set in 100-ms increments, and 1 to 5 s set in 1 s-increments)

Zero-reset Negative values can be displayed. (Threshold is not shifted.)

Initial reset Settings can be returned to defaults as required.

Mutual interfer-

ence prevention Possible for up to 5 Units. (See note.)

Intermittent oscillation method (Response time = (number of Units connected + 1) ×15 ms)

Hysteresis set-

tings Setting range: 10 to 4,000

I/O settings Output setting (Select from channel 2 output, area output,

self-diagnosis, or open circuit detection.) Input setting (Select from teaching, fine positioning,

zero-reset, synchronous detection.)

Digital display Select from the following: Incident level + threshold, incident level percentage +threshold, incident light peak level + incident

light bottom level (updated with output), long bar display, incident level + peak hold, incident level + channel

Display orientation Switching between normal/reversed display is possible.

Ambient temperature Operating:

When connecting 1 to 2 Units: –10°C to 55°C

When connecting 3 to 5 Units: –10°C to 50°C

When connecting 6 to 16 Units: –10°C to 45°C

When used in combination with an EDR6-F

When connecting 3 to 4 Units: –10°C to 50°C

When connecting 5 to 8 Units: –10°C to 45°C

When connecting 9 to 16 Units: –10°C to 40°C

Storage: –20°C to 70°C (with no icing)

Ambient humidity Operating/storage: 35% to 85% (with no condensation)

Insulation resistance 20 MΩmin. (at 500 VDC)

Dielectric strength 1,000 VAC at 50/60 Hz for 1 min

Vibration resistance Destruction: 10 to 55 Hz, 1.5-mm double amplitude for 2 hours each in X, Y, and Z directions

Shock resistance Destruction: 500 m/s2for 3 times each in X, Y, and Z directions

Degree of protection IEC60529 IP50

Connection method Prewired Connector Prewired Connector

Weight (packed state) Approx. 100 g Approx. 55 g Approx. 100 g Approx. 55 g

Material Case PBT (polybutylene terephthalate)

Cover Polycarbonate

F502-EN2-04.book Seite 86 Dienstag, 26. Juli 2005 5:48 17