8

1. POOL WATER PREPARATION

a. Measure the pool size in litres to determine salt level requirements.

b. Refer to salt requirements chart (refer page 16). Add 4 kgs. of

refined Pool Salt per 1000 litres of water in shallow end of pool.

c. Connect vacuum hose and place vacuum head in deepest part of

pool and run for 24 hours to dissolve in salt.

d. THE SALT MUST BE DISSOLVED COMPLETELY BEFORE THE

CHLORINATOR IS TURNED ON.

This should take (24 hours in summer –72 hours in winter).

2. MOUNTING THE POWER PACK

a. Screw the mounting bracket to wall or post with slots facing

upwards, a minimum 1.2 meters off the ground & within 1.5 meters

of the power outlet and within 1.5 meters of the filter’s return to

Pool Line

b. Place back of Power Pack to mounting bracket and slot into place.

NOTE: DO NOT MOUNT IN DIRECT SUNLIGHT or DIRECTLY ONTO METAL

FENCE OR METAL SHED. IF THIS IS THE ONLY PLACE THEN A PIECE

OF TIMBER BOARD 400MM x 250MM x 8MM SHOULD BE

MOUNTED TO THE METAL AND THEN MOUNT POWER PACK TO THE

TIMBER. FAILURE TO DO THIS WILL VOID WARRANTY OF UNIT.

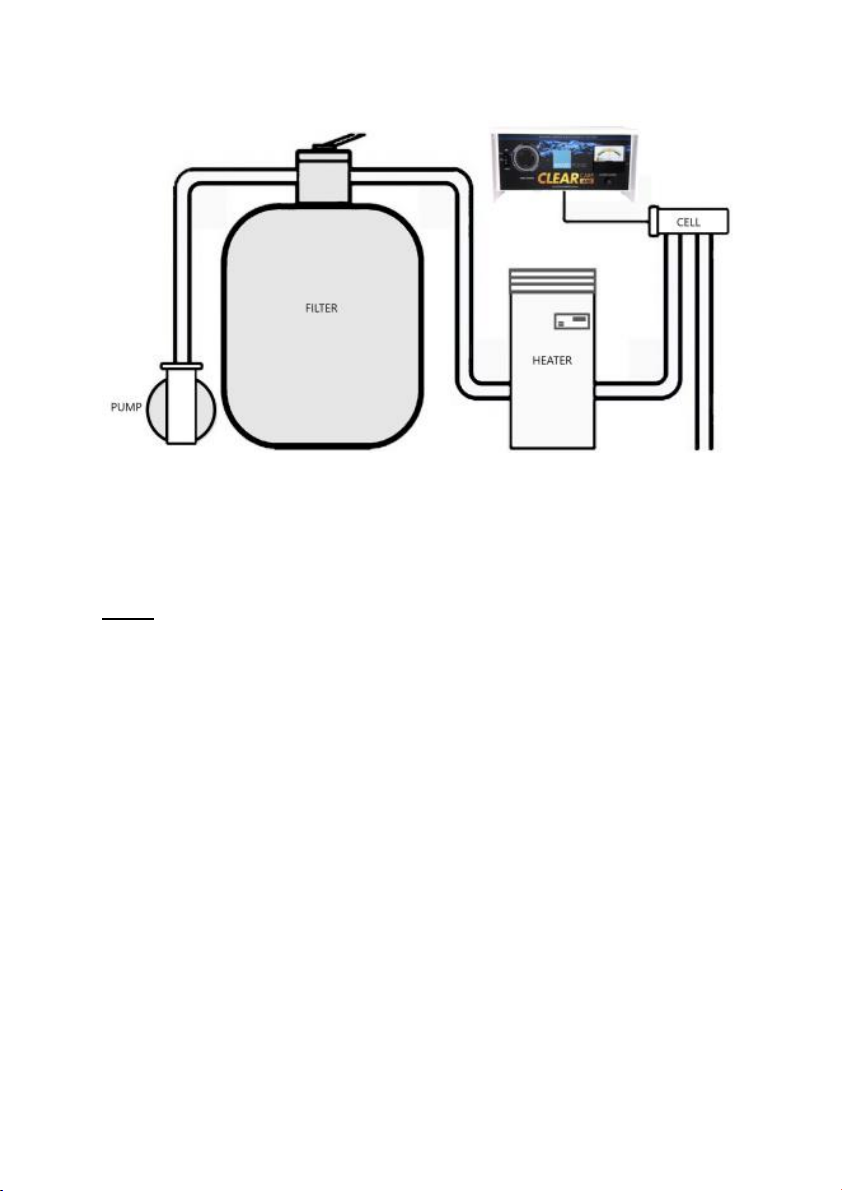

3. INSTALLATION OF THE CELL

Determine Filter Return to Pool Line.

a. Cell Housing must be in a horizontal position with inlet and outlet

sockets facing downwards as per diagram (refer page 9).

b. Cell must be installed after the heater (where fitted) and Solar

Systems (refer page 9). Pool cleaner pump motors that draw water

from the return to pool line should be fitted after the Cell for correct

pool chlorination.

c. CAUTION: It is very important that no gas generated from the Cell

can find its way back into the Filter, Pump, Heater, Solar Systems or

Spa Blowers.

d. When position of the Cell Housing has been decided, turn off the

Pump/Filter and CLOSE OFF VALVES if required.

e. If the Return to pool line is 40mm pipe, use 50-40mm reducing

bushes provided. If it is 50mm pipe, glue pipe directly into the inlet &

outlet ports on the cell housing.