2

BEFORE YOU START

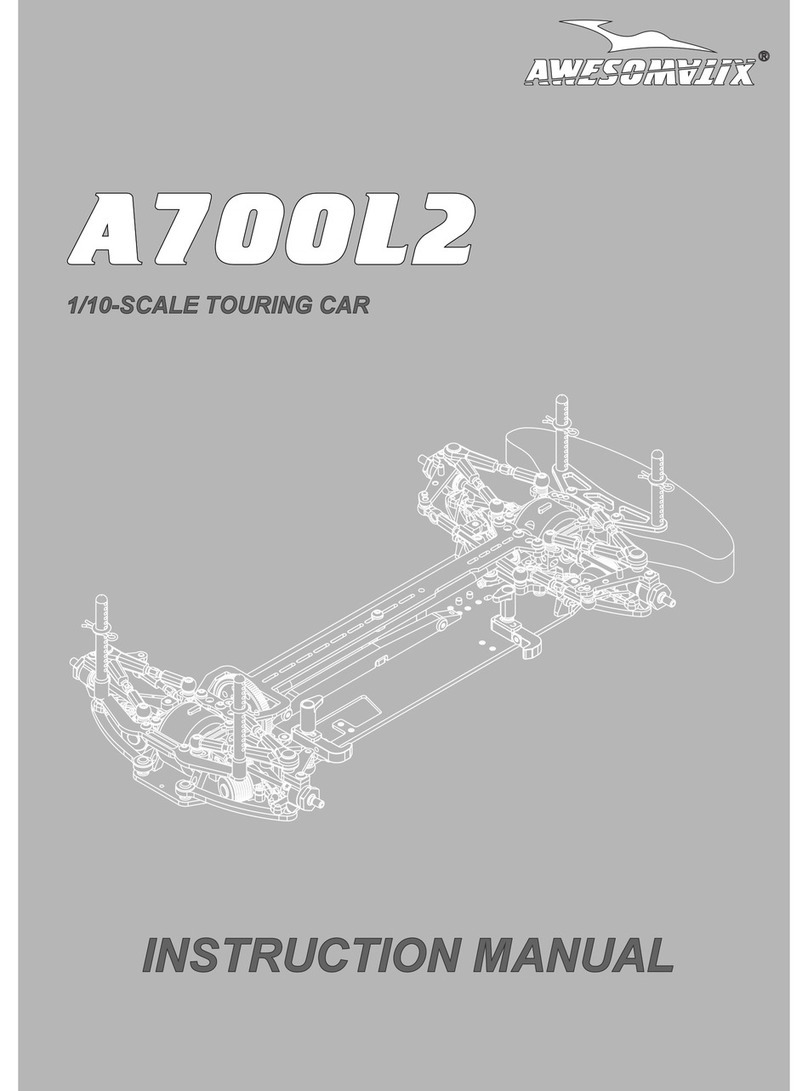

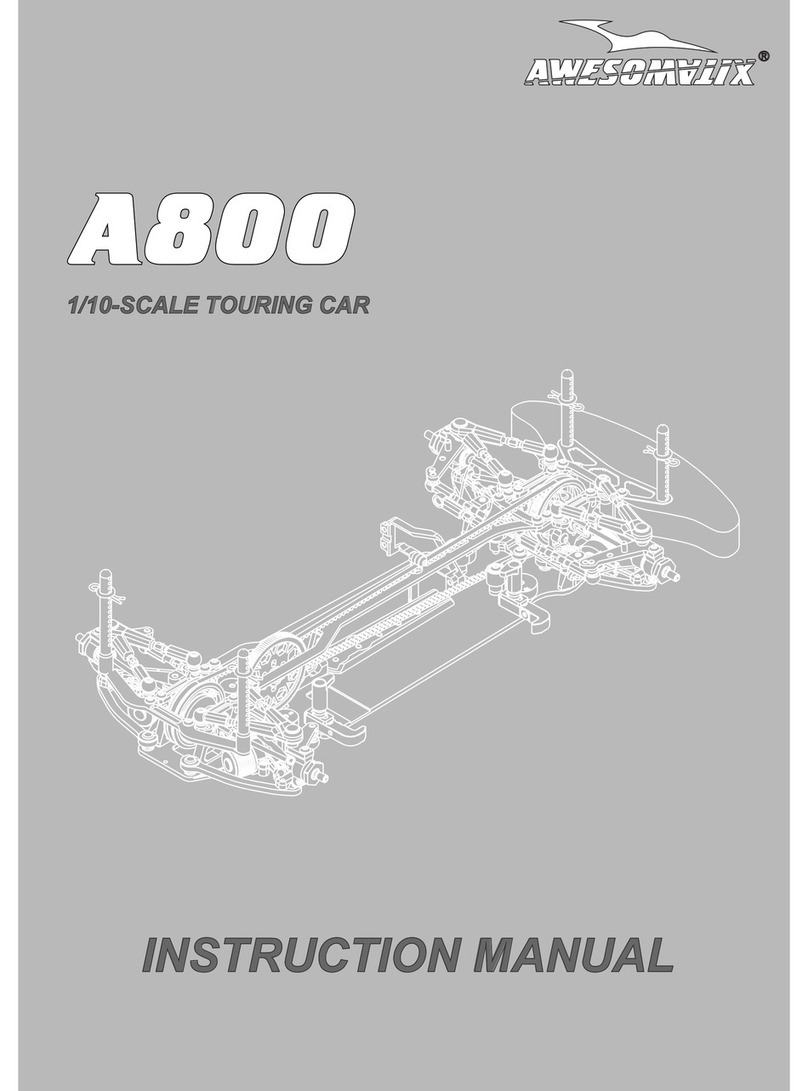

The A700 is a high-quality,innovative 1/10-scale touring car and should be built only by persons with previous experience

building R/C model racing cars. This is not a toy and is not intended for use by children without direct supervision

of a responsible,knowledgeable adult. Read the instruction manual carefully and fully understand it before beginning assembly.

If you have any problems or questions please do not hesitate to contact the Awesomatixteam at support@awesomatix.com.

If,for any reason,you decide that you do not want your A700,you must not begin assembly. Your A700 cannot be

returned to AwesomatixInnovations LLP for a refund or exchange if it has been fully or partially assembled.

This kit is a radio controlled model racing product and could cause harm and personal injury.

The A700 car is designed for use on r/c car race tracks. It should not be used in general public areas.

Awesomatix Innovations LLP accept no responsibility for any injuries caused by making or using this kit.

Due to policy of continuous product development the exact specifications of the kit may vary.

Awesomatix Innovations LLP do reserve all rights to change any specifications without prior notice. All rights reserved.

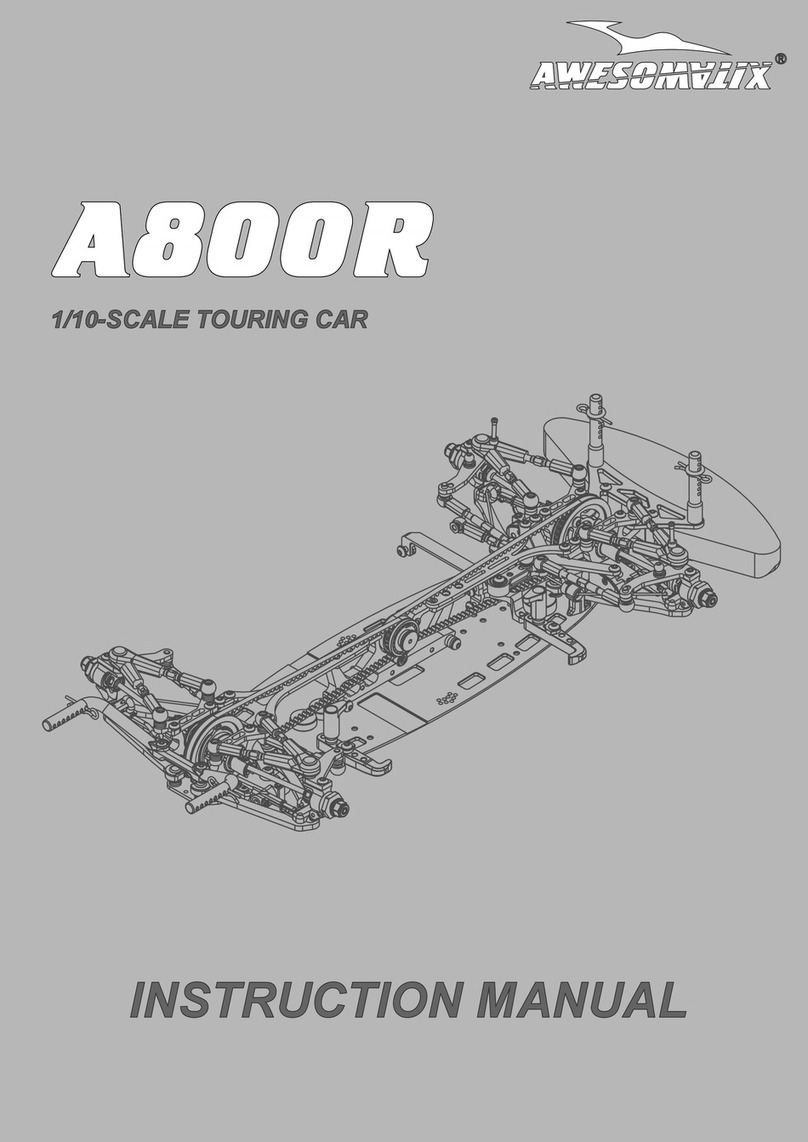

INTRODUCTION

Congratulations on purchasing your A700 car!

The A700 car was designed in Russia and produced by AwesomatixInnovations LLP registered in UK.

The A700 car utilise many unique features,including some patented innovations.

GENERAL PRECAUTIONS

•Many of the items in this kit are small enough to be accidentally swallowed and are therefore potential choking hazards, making them potentially fatal.

Please ensure that when assembling the kit you do so out of the reach of small/young children.

•Take care when building, as some parts may have sharp edges.

•Please read this manual carefully to understand which ancillary items (tools, electrics, electronics etc) are used with this kit.

Awesomatix Innovations LLP accept no responsibility for the operation of any such ancillary items.

Exercise care when using tools and sharp instruments.

•

Follow the operating instructions for the radio equipment at all times.

•

• Never touch rotating parts of the car as this may cause injury.

Keep the wheels of the model off the ground when checking the operation of the radio equipment.

•

To prevent any serious personal injury and/or damage to property, be responsible when operating all remote controlled models.

•

The model car is not intended for use on roads or areas where its operation can conflict with or disrupt pedestrian or vehicular traffic.

•

• Do not run your car in poor light or if it goes out of sight. Any impairment to your vision may result in damage to your car or, worse, injury to others

or their property.

• As a radio controlled device, your car is subject to radio interference from things beyond your control. Any such interference may cause a loss of

control of your car so please consider this possibility at all times.

When not using RC model, always disconnect and remove battery.

•

Insulate any exposed electrical wiring to prevent dangerous short circuits.

•

Take maximum care in wiring, connecting and insulating cables. Make sure cables are always connected securely.

Check connectors for if they become loose and if so reconnect them securely. Never use R/C models with damaged wires.

A damaged wire is extremely dangerous and can cause short-circuits resulting in fire.

ASSEMBLY NOTES

Before starting each build-stage checkthat you have the right quantity and size of items for the build-stage. To assist you with

the assembly of your A700 car we have included full-size images of all the small hardware parts laid out so that you can place

items on top of the images to checkthey are the correct size/length.

EQUIPMENT RECOMMENDED (NOT INCLUDED)

Radio Transmitter

•

Radio Receiver

•

Electronic Speed Control

•

Steering Servo

•

Electric Motor

•

Pinion Gear (64 or 48 Pitch)

•

Spur Gear (64 or 48 Pitch)

•

7.4 VLi-Po Battery or 4-6 Cell Sub-C NiMH Battery Pack

•

Battery Strapping Tape

•

• 190mm Body Shell

M4mm Wheel Nuts

•

Touring Car Wheels, Tires,Inserts

•

TOOLS RECOMMENDED (NOT INCLUDED)

1.5mm, 2.0mm Hex Driver

•

• 2.0mm Ball End Hex Driver

• 5.5mm, 7mm, 9mm, 10mm, 12mm Wrench

• 2.5mm Flat Screwdriver

• Callipers

Hobby Knife

•

Camber Gauge

•

Ride Height Gauge

•

• Thin CA Glue

Thread Lock

•

Diff Silicone Oil

•

Thrust Grease, Diff Grease, Joint Grease

•