11/13

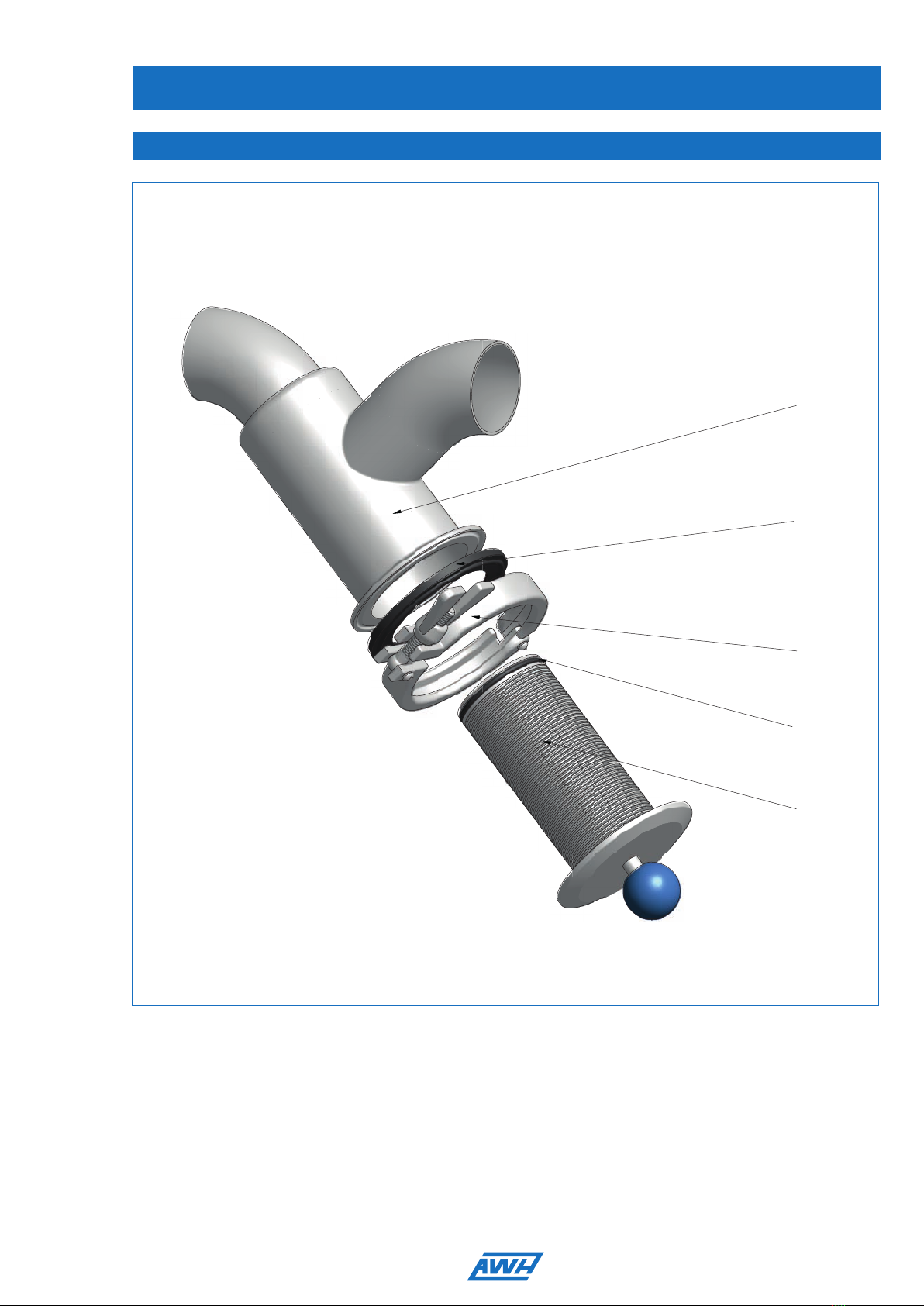

Dirt Trap - Type: DN25 - DN100 / PN10

Operating Instructions

Guideline/ standard Title Version Comments

DIN EN 62079 Preparation of instructions - structuring,

content and presentation

2001

97/23/EC EC Pressure Equipment Directive 2003

DIN EN 12516-2 Industrial ttings – Shell design strength

- Part 2: Calculation method for steel

tting shells

10/2004

AD 2000 data sheets Speci cations for pressure equipment

(national standards)

The ttings are designed for liquids of uid group 1 and for gases of uid group 2. According to this,

the nominal diameters are categorised as DN25 – DN100 in accordance with article 3, section 3.

2006/42/EC EC Directive: Machinery 2006

DIN EN ISO 12100 Safety of machinery -

General principles for design -

Risk assessment and risk reduction

2010

AWH Armaturenwerk Hötensleben GmbH

Schulstraße 5 - 6

D-39393 Hoetensleben

Declaration of Installation

as required by the

-EC Directive: Pressure Equipment Directive 97/23/EC, Annex II A

- EC Directive: Machinery 2006/42/EG, Annex II B

We hereby declare that design of

Description: Dirt Trap

Type: DN25 - DN100 / PN 10

in its delivered version is consistent with the listed directives and standards

(harmonised standards in accordance with the directives):

5

1.3 Declaration of Installation

If any modi cations are made to the non-return valve without our agreement, this declaration is void.

Note:

Commissioning is prohibited until it is certain that the overall system fulfi ls the provisions of the

directives. For information about proper use of the fi ttings, see the operating instructions.

Hoetensleben, of October 24th, 2013

..............................................................................

Thomas Erhorn / CEO

Person authorised to compile the technical documentation:

Armaturenwerk Hötensleben GmbH

Mr. Guth, Schulstr. 5 - 6, D-39393 Hoetensleben

Hoetensleben, of October 24th, 2013

..............................................................................

Person authorised to compile the technical documentation: