TITLE

SUB TITLE

SHEET No.

4:02

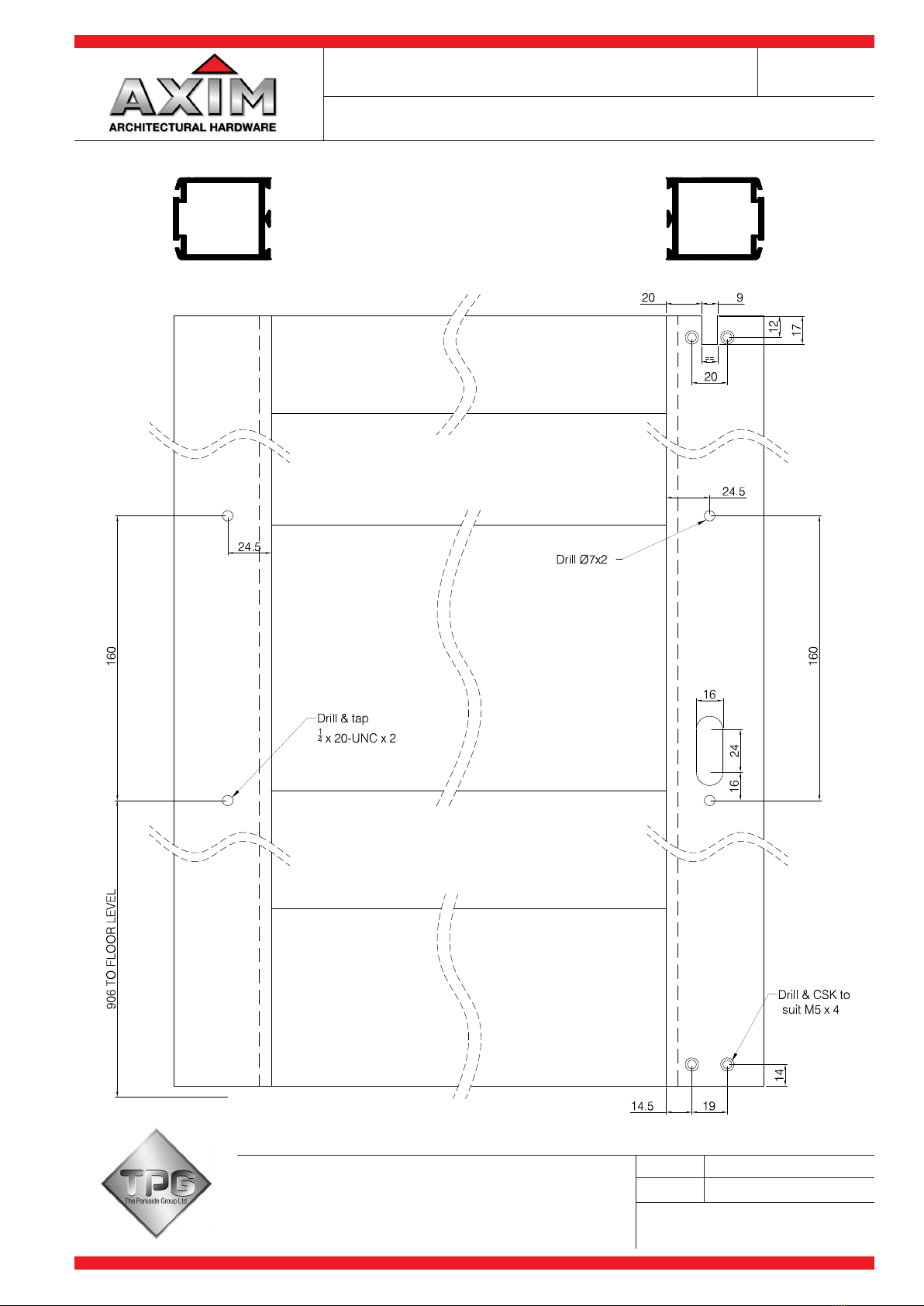

160mm

906mm

to floor

17mm 17mm

9.5mm

(.375)

Drill 5mm

(.188) and

countersink

(2)

16mm

9.5mm

(.375)

24mm

16mm

48mm

25mm

51mm

10mm

17mm

10mm

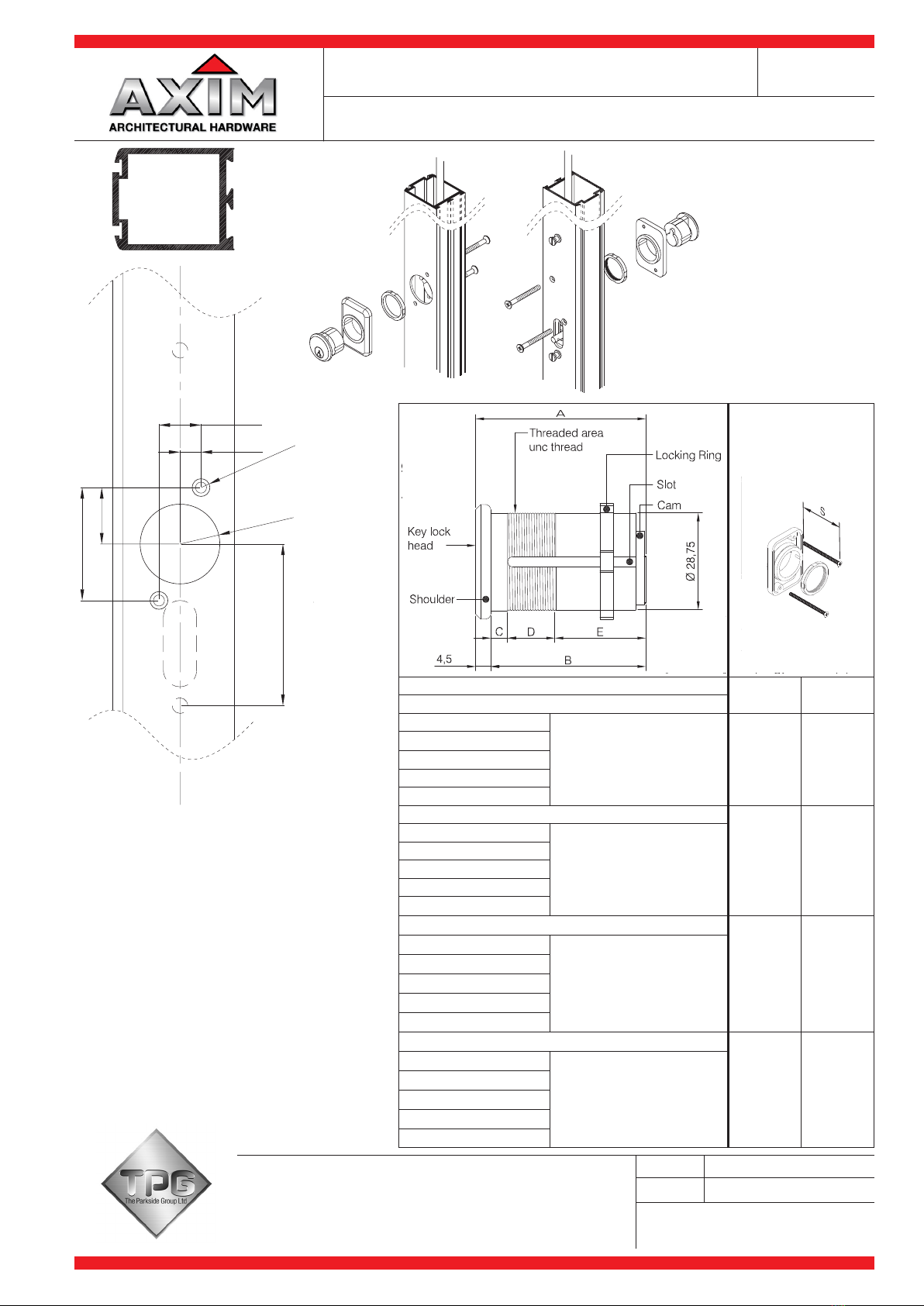

For lock cylinder only

Drill 5mm (.203)

clearance holes (2)

and 36mm

cylinder hole

Hinge stile (inside) Lock stile (inside) Lock stile (outside)

Drill 5mm

(.203) and tap

1/4-20 (2) Drill 7mm (.266)

holes (2)

Lock

cylinder

Actuator

link

Connecting

pin

160mm

25mm

25mm

25mm

47.5mm (1.875)

906mm

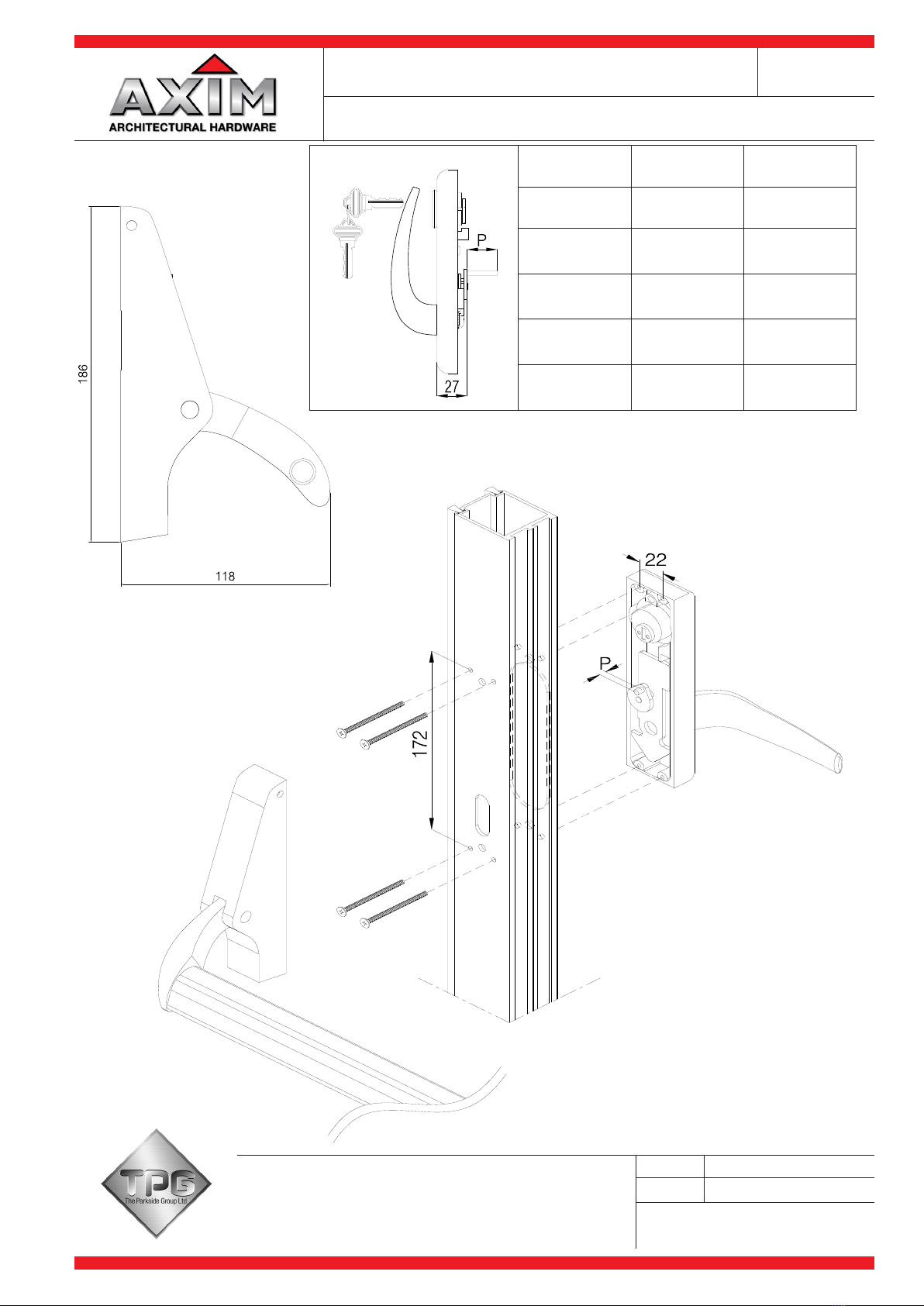

INSTALLATION OF

ACTUATOR LINK

Cross bar length (see note #8)

Dogging

pin

Actuator

pin

Place actuator link over actuator

pin & connect using connecting pin

22mm

40mm

Drill 3mm (.125) holes (4)

22mm x 27mm hole

for strike or 17mm

hole if strike not used

Strike

Adjustment screw

Trip bracket used as

release when door

stop is not used

HEADER PREPARATION

THRESHOLD PREPARATION

Strike

22mm x 27mm hole

for strike or 17mm

hole if strike not used

Drill 3mm (.125) holes (2)

17mm

9mm

12mm

Drill 5mm (.203)

& countersink (3)

See note #6

14mm

See note #6

Drill 5.2mm

(.203) and

countersink (3)

10mm

19mm

Floor line

MOUNTING INSTRUCTIONS

1. Determine hand of door and prepare inside of lock and hinge

stiles as show.

2. If Cylinder Key Lock is to be used, prepare inside and outside

of lock stile as shown.

3. Insert Rod and Case Assembly into lock stile and secure with

(2) 1/4-20 Shoulder Studs.

4. If Key Lock is used, insert Cylinder in Mounting Pad and

secure with Locking Ring. Install using (2) #8-32x49mm Flat

Head Machine Screws.

5. Position Exit Pad over stile and attach Actuator Link to Actuator

Pin using Connecting Pin provided. Place on stile over 1/4-20

Shoulder Studs and tighten 3 Socket Head Set Screws to

secure in place.

6. Adjust length of top and bottom Latch Bolts by turning in or

out. When the Panic Arm is fully depressed, the Latch Bolts

should be slightly recessed from flush with the top and bottom

of the door. NOTE: Flat notch side of Bolt must face the

outside of the door. Install top and bottom Latch Bolt Guides

using (6) #10x13mm Flat Head Self-threading Screws.

7. Install (2) 1/4-20 Shoulder Studs on hinge stile. Place other

Exit Pad over Studs and tighten 3 Socket Head Set Screws to

secure in place.

8. Measure distance from inside edge to inside edge of Exit pads

for proper Cross Bar length. Cut Cross Bar. CAUTION: Cross

Bar length must be within ± 1mm for unit to function properly.

9. Loosen 3 Set Screws on hinge stile Exit Pad and install Cross

Bar using (2) 1/4-20x25mm Oval Head Self-threading Screws.

Tighten 3 Set Screws to secure in place.

10. Prepare header and threshold as shown. If Header and

Threshold Strikes are required, install using (4) #8x25mm Flat

Head All-purpose Screws.

DOGGING EXIT DEVICE USING DOGGING PIN:

Fully depress Cross Bar and hold, push up Dogging Pin with

screwdriver and rotate 90oin either direction.

TO RELEASE EXIT DEVICE:

Hold Cross Bar down and rotate Dogging Pin with screwdriver

in either direction until Dogging Pin releases.

DOGGING EXIT DEVICE USING CYLINDER KEY:

Fully depress Cross Bar and hold, turn Key clockwise

approximately 60o, return Key to centre and remove.

TO RELEASE EXIT DEVICE:

Turn key counterclockwise 90o, return Key to centre and remove.

SCALE

DATE

For scaled technical or CAD drawings,

please contact AXIM.

NTS @A4

MARCH 2014

ASSEMBLY DETAILS PR-7085

CONCEALED ROD CRASH BAR

PR-7085 SERIES EXIT DEVICE

The Parkside Group Ltd

The Willow Centre

17 Willow Lane, Mitcham, Surrey, CR4 4NX

Tel: 020-8685 9685 Fax: 020-8646 5096

Web Site: www.axim.co.uk