UMAX090600 Version 1 Preliminary Documentation – May be Subject to Change 7-48

1.2.3.

Bulk Charge Stage

Bulk charge is the stage which restores the battery’s charge level in the shortest amount of time.

This is done by applying a high constant current level to the battery. The battery voltage will

continue to increase during the time the constant current is being applied to the battery. Once the

battery has charged enough during bulk charge its voltage will reach a certain level at which point

the operation will shift to Absorption Stage.

1.2.4.

Absorption Stage

This stage is used to bring the battery to one hundred percent capacity by applying a constant

voltage to the battery while it draws as much current as it needs to reach that full capacity.

1.2.5.

Maintaining Charge/Float Stage

Once the battery has reached full capacity, the profile will shift to the float stage which will maintain

the battery at full capacity by adjusting the duration of the constant voltage level.

1.2.6.

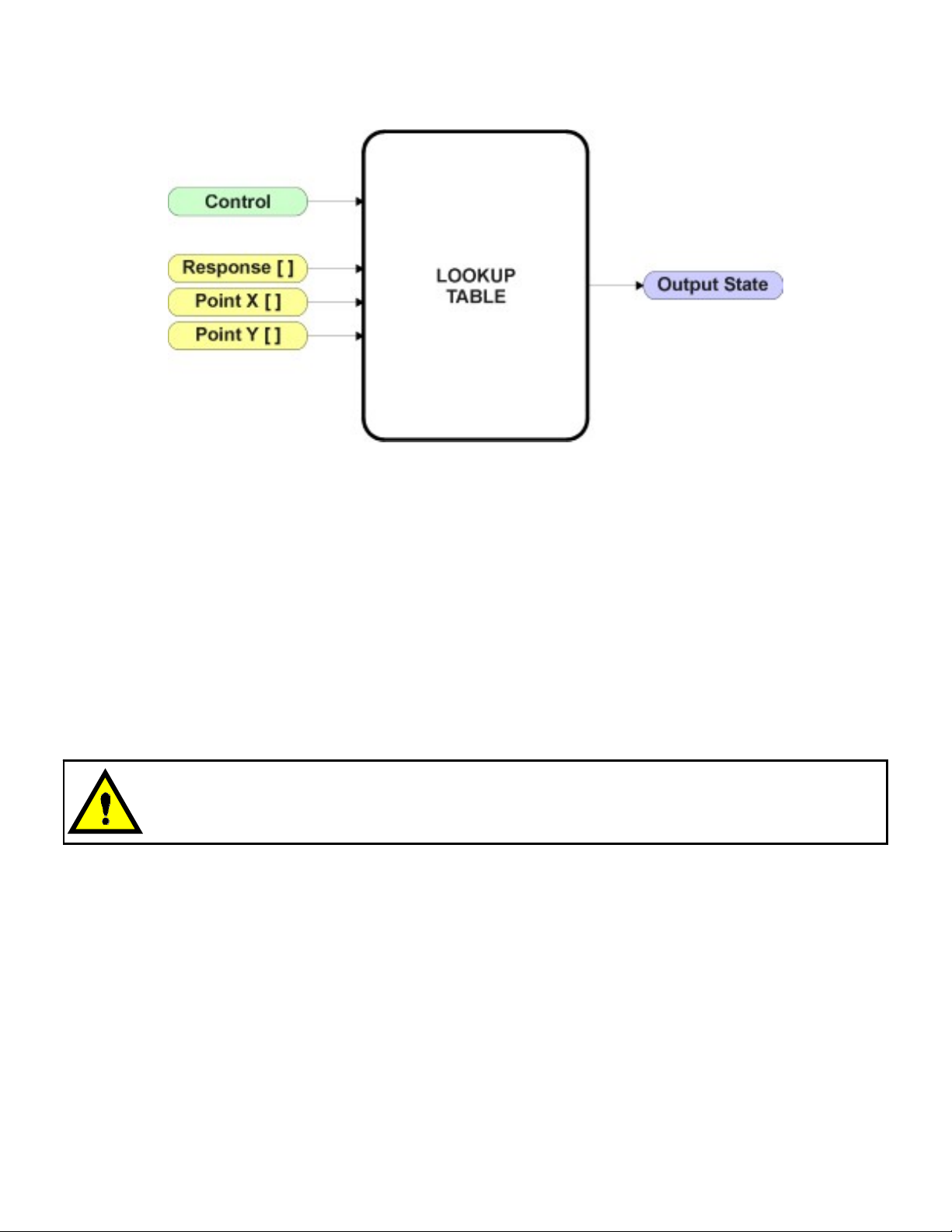

Battery Charger Configurable Setpoints

During initialization of the controller, the CAN-BC-LED will monitor the battery voltage and

determine which stage of profile shown in Figure 1 the controller will engage. The points at which

the stages transition from one to the next are configurable by the user. This section will explain

how these points are interpreted by the controller.

When the battery is completely discharged, the stage that will be active will be the Pre-charge

mode. At this stage, the controller will begin constant current mode at the current level entered in

Pre-Charge Stage Current Level. This current level should be low enough as to prevent damage

to the battery. The battery will pre-charge at this constant current level while the CAN-BC-LED is

continuously monitoring the battery voltage. When the battery voltage has reached the level Bulk

Charge Stage Voltage Threshold the controller will then shift the Bulk Charge mode. Once in

Bulk Charge mode, in the case the battery voltage drops lower than Bulk Charge Stage Voltage

Threshold minus Voltage Hysteresis Value the controller will shift to Pre-charge mode.

At Bulk Charge mode, the controller will increase its constant current level to Bulk Charge Stage

Current Level to charge the battery more rapidly. The controller will remain in this mode until the

battery voltage has reached Absorption Stage Voltage Threshold.

When this transition to Absorption Stage occurs, the controller will shift to constant voltage so that

the battery is able to reach full charge capacity. To determine if the battery has reached its full

charge monitoring the sourced current is necessary. When the current sourced by the CAN-BC-

LED is less than Float Stage Current Threshold it is an indication that the battery is fully charged

and move to Float Stage mode.

Float Stage is used in order to maintain the battery at full charge by adjusting its constant voltage

on time. The amplitude of this constant voltage level is determined by Float Stage Voltage Level.

It is recommended that the battery is not connected to a load until it has been fully charged (in

Float Stage mode). When the battery is connected to a load during Float Stage mode, the