UMAX090690. Version: 1.2 Preliminary Documentation –May Be Subject To Change 3-37

TABLE OF CONTENTS

1. INTRODUCTION.......................................................................................................................6

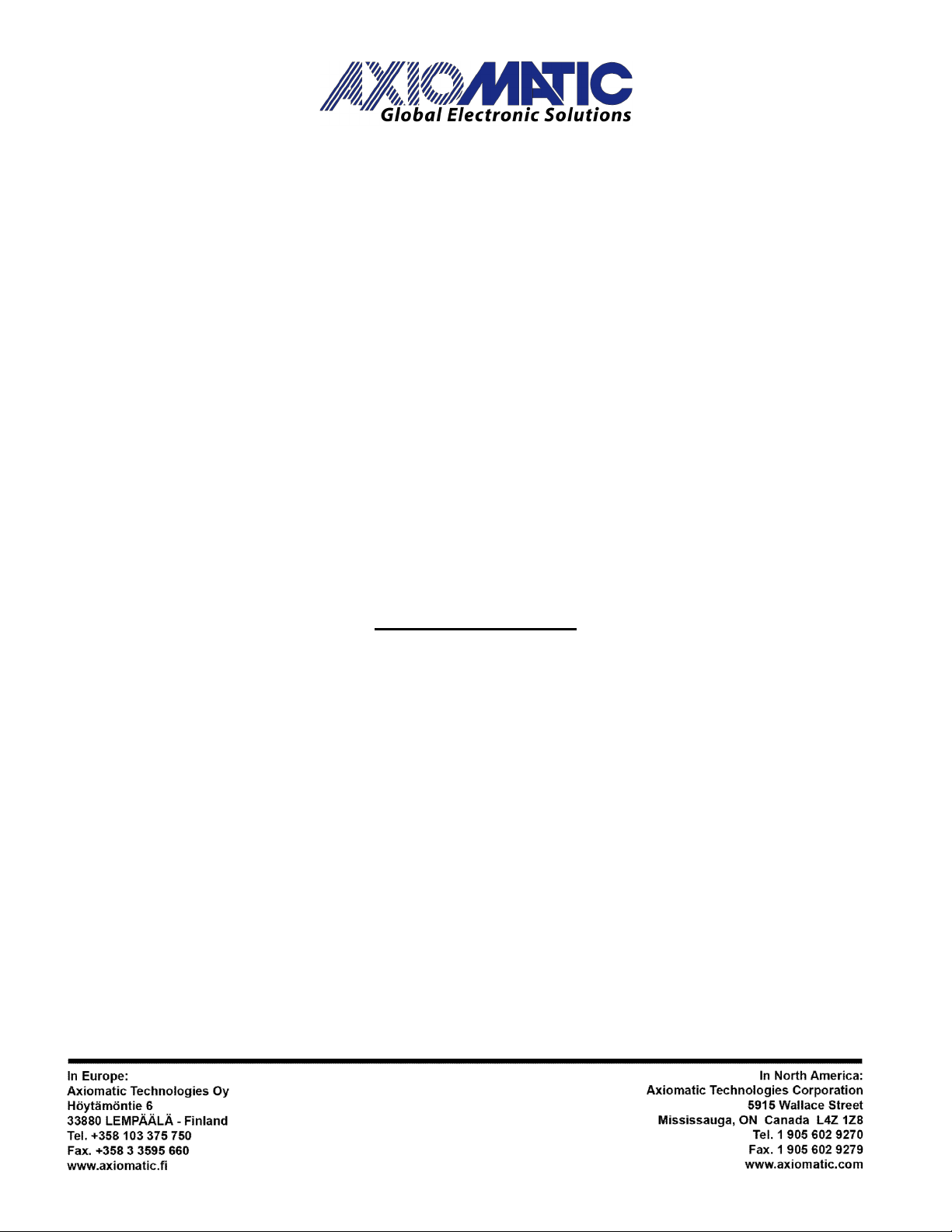

2. BATTERY CHARGER THEORY OF OPERATION...................................................................7

2.1. BATTERY CHARGER MODES ............................................................................................................................... 7

Charger Temperature...................................................................................................................................................8

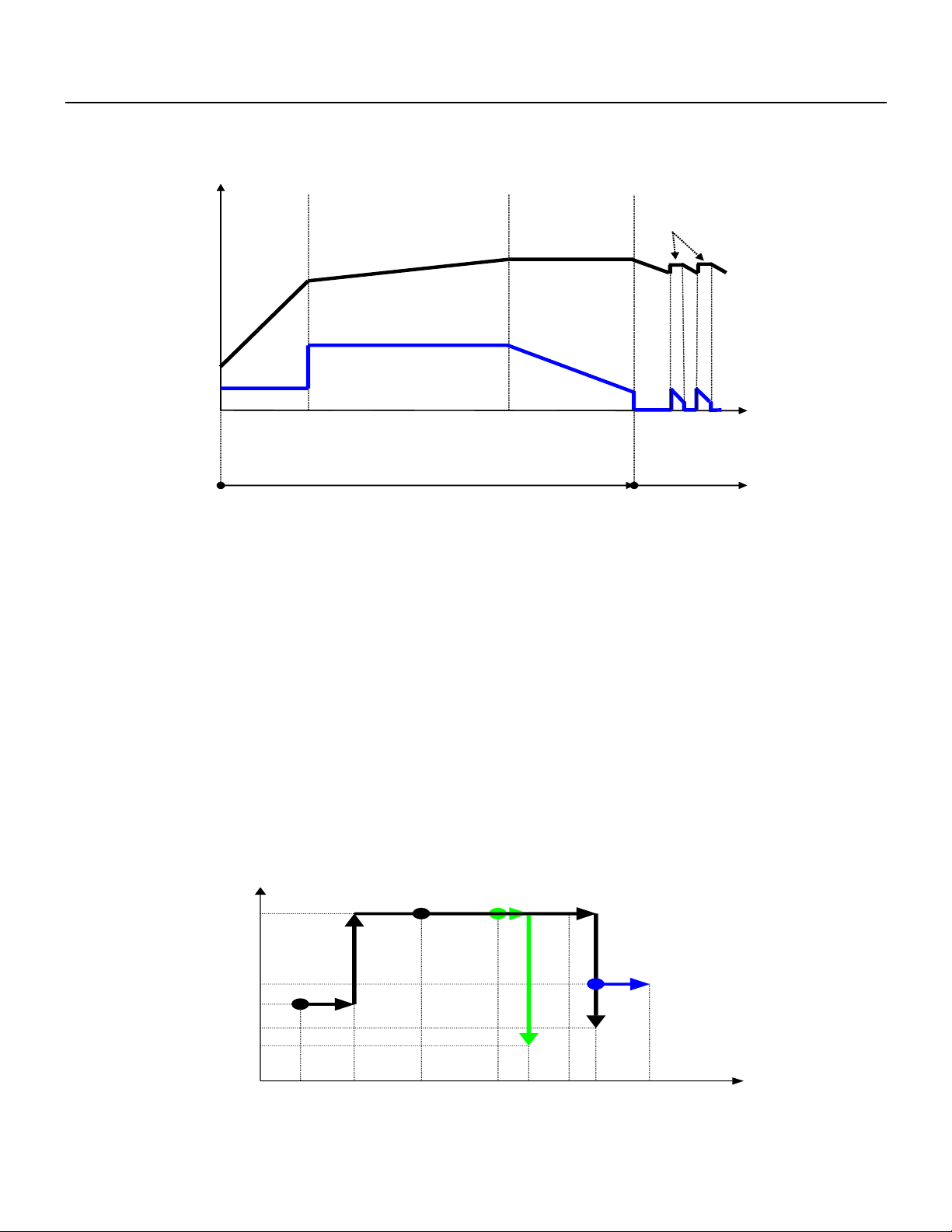

2.2. BATTERY CHARGER STATE DIAGRAM ................................................................................................................. 9

2.3. BATTERY PROTECTION....................................................................................................................................... 9

3. OVERVIEW OF J1939 FEATURES........................................................................................11

3.1. INTRODUCTION TO SUPPORTED MESSAGES....................................................................................................... 11

3.2. NAME,ADDRESS AND SOFTWARE ID................................................................................................................. 12

J1939 Name................................................................................................................................................................ 12

ECU Address ............................................................................................................................................................... 12

Software Identifier .....................................................................................................................................................13

4. BATTERY CHARGER FUNCTION BLOCKS.........................................................................15

4.1. CHARGING PROFILE FUNCTION BLOCKS............................................................................................................ 15

4.2. MISCELLANEOUS INPUT FUNCTION BLOCK ........................................................................................................ 15

4.3. J1939 NETWORK FUNCTION BLOCK ................................................................................................................. 15

4.4. DIAGNOSTIC INPUT FUNCTION BLOCKS ............................................................................................................. 15

4.5. CAN TRANSMIT FUNCTION BLOCK.................................................................................................................... 18

4.6. CAN RECEIVE FUNCTION BLOCK...................................................................................................................... 19

5. ECU SETPOINTS ACCESSED WITH ELECTRONIC ASSISTANT .......................................21

5.1. NETWORK SETPOINTS ...................................................................................................................................... 21

5.2. COMMON CAN SETPOINTS............................................................................................................................... 21

5.3. CHARGING PROFILE SETPOINTS........................................................................................................................ 22

5.4. MISCELLANEOUS INPUT SETPOINTS .................................................................................................................. 24

5.5. DIAGNOSTIC INPUT SETPOINTS ......................................................................................................................... 24

5.6. CAN RECEIVE SETPOINTS................................................................................................................................ 25

5.7. CAN TRANSMIT SETPOINTS.............................................................................................................................. 26

6. BATTERY CHARGER ERROR CODES.................................................................................28

6.1. BATTERY ERROR CODES.................................................................................................................................. 28

7. REFLASHING OVER CAN WITH EA BOOTLOADER.......................................................29

8. INSTALLATION INSTRUCTIONS...........................................................................................34

9. TECHNICAL SPECIFICATIONS.............................................................................................35

9.1. INPUT SPECIFICATIONS..................................................................................................................................... 35

9.2. OUTPUT SPECIFICATIONS ................................................................................................................................. 35

9.3. GENERAL SPECIFICATIONS ............................................................................................................................... 35

10. VERSION HISTORY................................................................................................................37