7

Specific Safety Precautions for Grinding Machines

1. Do not operate your machine until it is completely

assembled and installed according to the instructions.

2. If you are not familiar with the operation of grinding

machines obtain advice from your supervisor or

instructor or another qualified person.

3. Only use grinding wheels or attachments rated higher

than 3600 rpm with a 5/8”(16mm) arbor on this

machine.

4. Never use a chipped or cracked wheel. Always inspect

each wheel before mounting it on the grinder. If during

inspection you discover a damaged grinding wheel;

replace it immediately.

5. Do not over tighten wheel nuts.

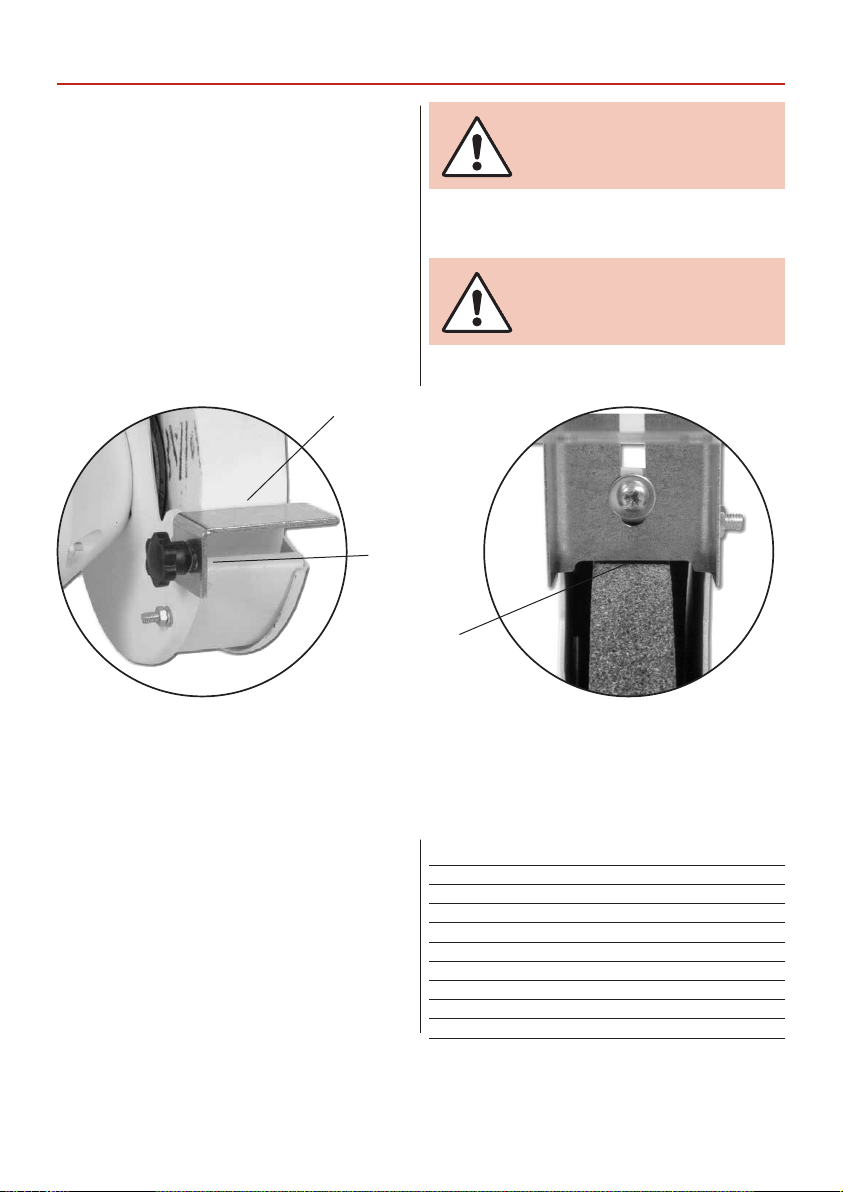

6. Always maintain a distance of 2mm or less between

the wheel and the tool rest. Adjust the tool rests as the

wheels decrease in size.

7. Ensure the tool rests are tightened so they cannot move

while in use.

8. Never grind on a cold wheel. The grinder should always

be run for at least one minute before applying work to it.

9. Never grind on the side of the wheel. Always grind on

the face of the wheel only.

10. Never apply coolant directly to a grinding wheel,

it may cause the bonding to fail. If the work piece

becomes hot, dip it into a water pot to cool it down.

11. Hot sparks are a hazard! Never carry out grinding

operations near flammable gas or liquid.

12. Always make sure the spark guards and eye shields are

in place, that they are properly adjusted and secured.

13. Keep the sparks guards close to the wheels and

re-adjust them as the wheels wear.

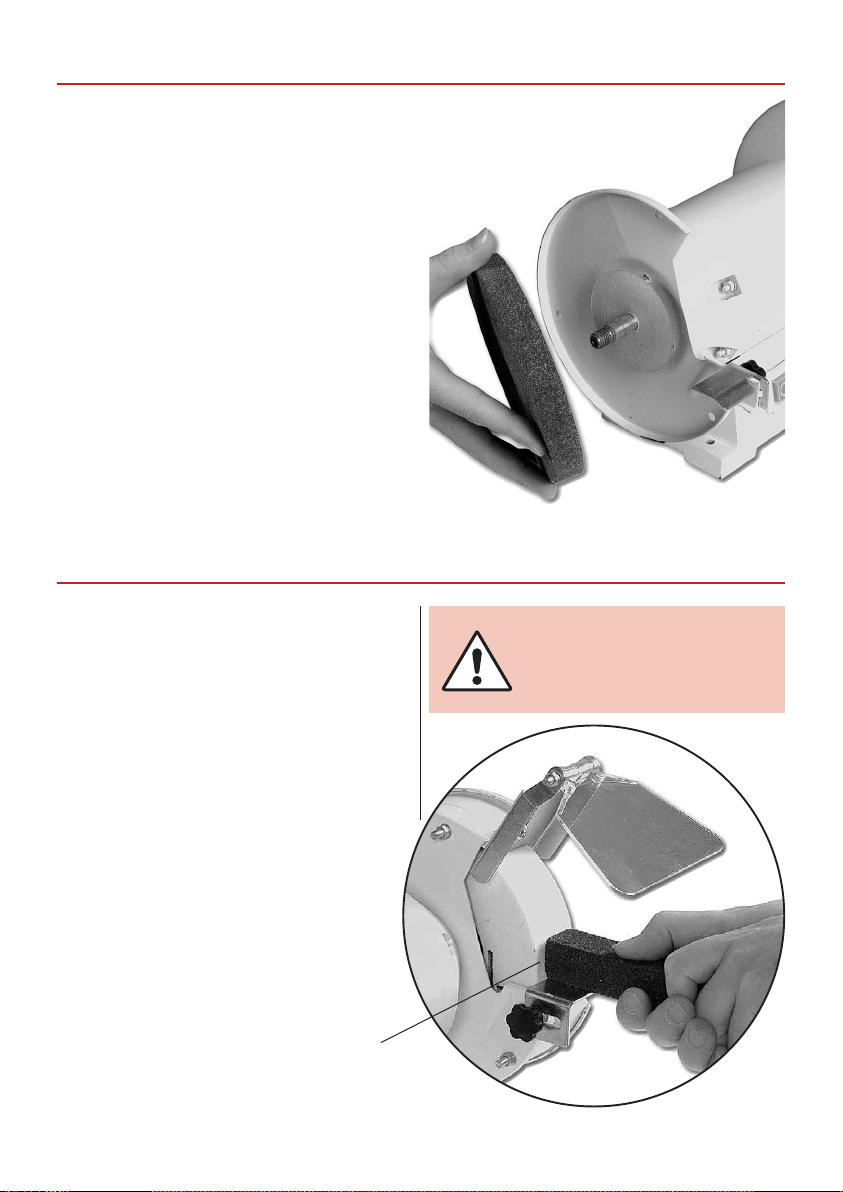

14. Ensure the soft washer and the flanges furnished

with the grinder, are used to mount any attachments

(grinding wheels, wire brushes, buffing wheels, etc)

onto the shaft.

15. Always stand to one side of the grinder when starting

the machine.

16. Avoid awkward hand positions where a sudden slip

could cause the hands to come into contact with a

grinding wheel, wire brush etc.

17. If the wheel requires dressing, dress only the front of

the wheel, do not dress the sides.

18. Do not use any attachments that causes the machine

to vibrate. If after changing grinding wheels or adding

attachments, the machine does vibrate; remove the

recently replaced item and change again.

19. Grinding creates heat. Do not touch the work face of

the work piece until you are sure it has cooled down

sufficiently.