17

W H I T E

AX MI NS T ER

W

W H I T E

AX MI NS T ER

W

Operation of the Laser...

06

General Instructions for 230v Machines...

FREEPHONE 0800 371822

Once the saw is mounted, carry out any setting operations, (mitre, tilt..?),

and remove all tools used in the setting operations (if any) and place safely

out of the way. If you are using long lengths of material arrange for extra

support beyond the boundary of the machine.

It is good practice to leave the machine unplugged until work is about to

commence, also make sure to unplug the machine when it is not in use. Always

disconnect by pulling on the plug body and not the cable.

DO NOT use your hands to hold the work on the machine, use the clamp provided, and

observe the old woodworkers adage of 'never putting your hands closer than one

handbreadth to the cutting tool'. Do not attempt to cut or re-cut short pieces that cannot be

held by the clamp.

Make sure you are comfortable before you start work, balanced, not reaching etc.

If the work you are carrying out is liable to generate flying grit, dust or chips, wear the

appropriate safety clothing, goggles, gloves, masks etc., If the work operation appears to be

excessively noisy, wear ear-defenders. If you wear your hair in a long style, wearing a cap,

safety helmet, hairnet, even a sweatband, will minimise the possibility of your hair being

caught up in the rotating parts of the tool, likewise, consideration should be given to the

removal of rings and wristwatches, if these are liable to be a 'snag' hazard.

DO NOT work with cutting tools of any description if you are tired, your attention is

wandering or you are being subjected to distraction. A deep cut, a lost fingertip or worse, is

not worth it!

DO NOT work with cutting tools if you are taking prescribed medicine, unless you have

confirmed that this medicine will not impair your awareness or your reactions.

DO NOT use the machines within the designated safety areas of flammable liquid stores or

in areas where there may be volatile gases. There are very expensive, very specialised

machines for working in these areas, THIS IS NOT ONE OF THEM.

CHEC that saw blades are undamaged and are kept clean and sharp, this will maintain

their operating performance and lessen the loading on the tool.

Above all, OBSERVE…. make sure you know what is happening around you, and USE

YOUR COMMON SENSE; for no matter how many precautions we list, remember your

safety is ultimately your responsibility.

WARNING!!

!

UNDER NO CIRCUMSTANCES SHOULD

CHILDREN BE ALLOWED IN WOR AREAS

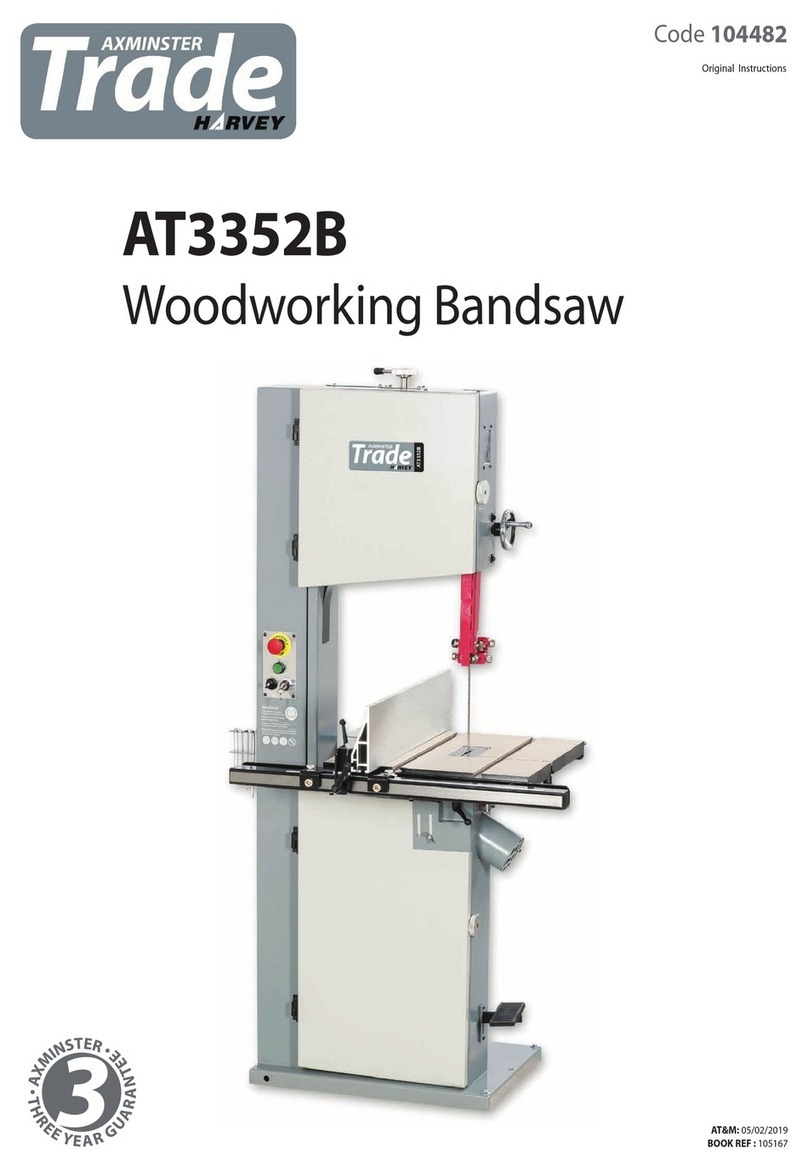

Before using the saw read the instructions thoroughly and make sure you understand them.

Carry out a visual inspection of the saw, checking for damage, or anything untoward, (Do

you know who used it last? That person may be able to confirm that the saw was “fine”

when last used or not, blades need sharpening/replacing etc.

The laser fitted to the AWSMS10 Sliding Mitre Saw provides a convenient visual guide for

lining up the saw blade with a line marked on the timber.

Power comes to the laser from the mains input via a transformer and a toggle switch

mounted in the handle of the saw (See fig ). It should be noted that power is fed to the

input side of the transformer for as long as the machine is connected to the mains and that

the on/off switch operates only on the low voltage output from the transformer to the laser.

The position of the laser can be adjusted to align the beam precisely with the saw blade.

There are no serviceable parts in the laser so if a problem occurs you will need to

contact Axminster Power Tool Centre Customer Services Department.

0800 371822

Pencil mark

Pencil mark Laser line

Square

Take a wide board with a true straight edge and mark a line across the width using an

accurate square. (See fig L) Position the board up against the fence, lower the blade onto

the board and line up the left hand side of the blade with the line. (See fig M) Switch on the

laser and check the alignment of the laser beam with the line marked on the board.

(See fig N) If the alignment is out, the laser can be adjusted as follows:

Check that the laser line is a fine line, not dispersed or splayed. Adjust this by loosening the

caphead screw of the holder slightly, and twist the laser to give a fine straight line;

(See fig O) retighten the holding screw. Loosen the caphead bolt that secures the

mounting bracket to the frame. (See fig P) Move the fitting until the laser is lined up,(this

can involve a small amount of twisting) almost lined up etc. Tighten the bolt very lightly and

check again. Unfortunately, even a very small movement will move the laser line

appreciably. Tightening the bolt must be done with care and may require several attempts

to get 'right' correctly. When all is correct remove the board and any tools you have used

during the setting up procedure, reconnect the saw to the mains supply.

Setting the Laser...

Warning. Under no circumstances should you tamper with or

modify the laser to try to increase its power output.

!

WARNING!!

THIS PRODUCT IS EQUIPPED WITH A

CLASS 2 LASER. DO NOT LOO

DIRECTLY INTO THE LASER BEAM

ig L ig M ig N

General Safety Precautions for Mitre Saw...