Axminster Professional AP3327B User manual

Other Axminster Saw manuals

Axminster

Axminster MJ12-1600 MK11 User manual

Axminster

Axminster Professional AP2552B User manual

Axminster

Axminster WORKSHOP AW216TS User manual

Axminster

Axminster 200024 User manual

Axminster

Axminster AP305SB User manual

Axminster

Axminster Professional AP254TS User manual

Axminster

Axminster TS-200 User manual

Axminster

Axminster AWHBS250N User manual

Axminster

Axminster WorkShop AW2305B User manual

Axminster

Axminster WORKSHOP AW1400B User manual

Axminster

Axminster UE-127DV1 User manual

Axminster

Axminster TS-200-2 User manual

Axminster

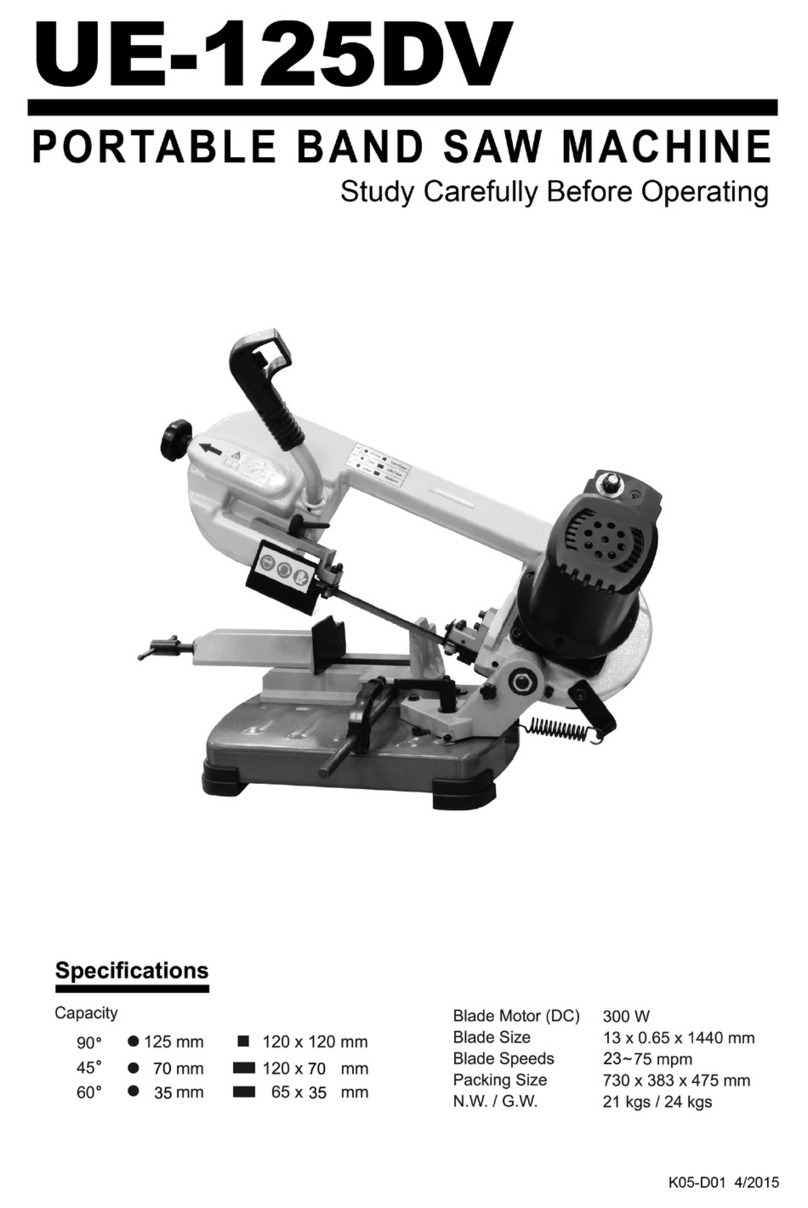

Axminster UE-125DV User manual

Axminster

Axminster AWSS-18 Flex User manual

Axminster

Axminster RSS16E Hobby Series Installation instructions

Axminster

Axminster UV-180DS User manual

Axminster

Axminster WorkShop AW1950B User manual

Axminster

Axminster Excalibur EX-16 User manual

Axminster

Axminster 100090 User manual

Axminster

Axminster TSCE-400R-1 User manual