Axminster WORKSHOP AW1400B User manual

Other Axminster Saw manuals

Axminster

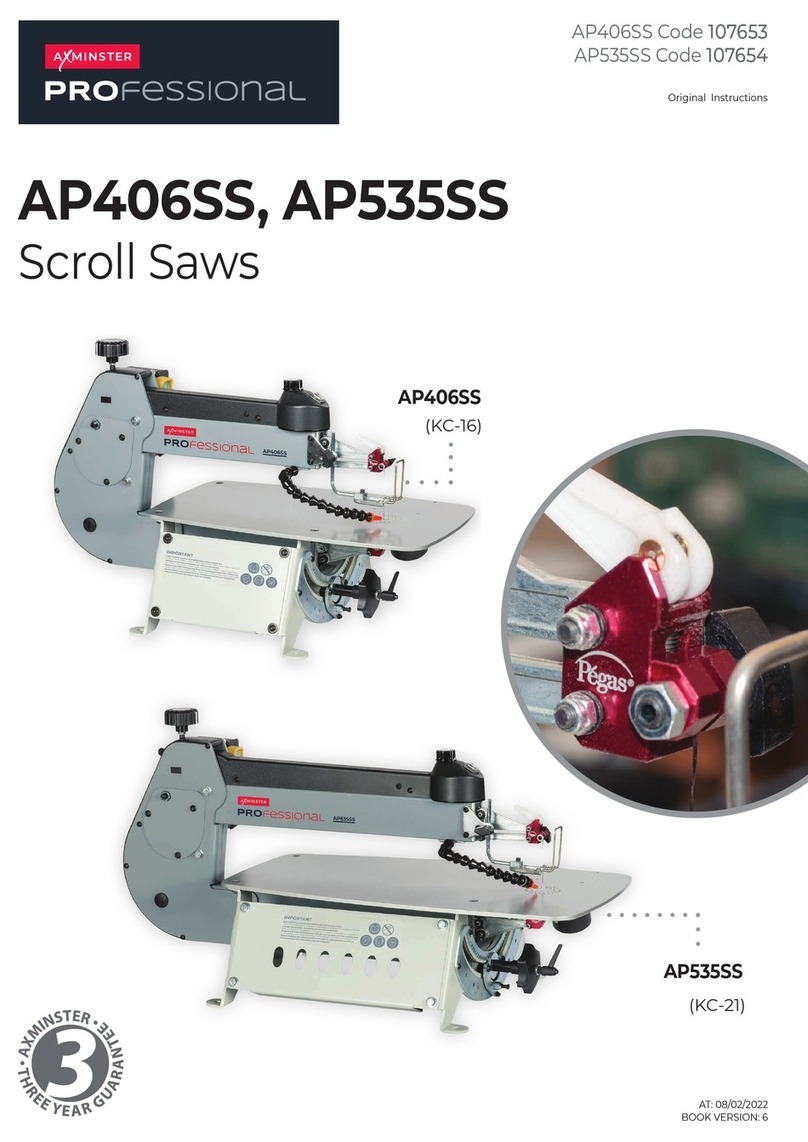

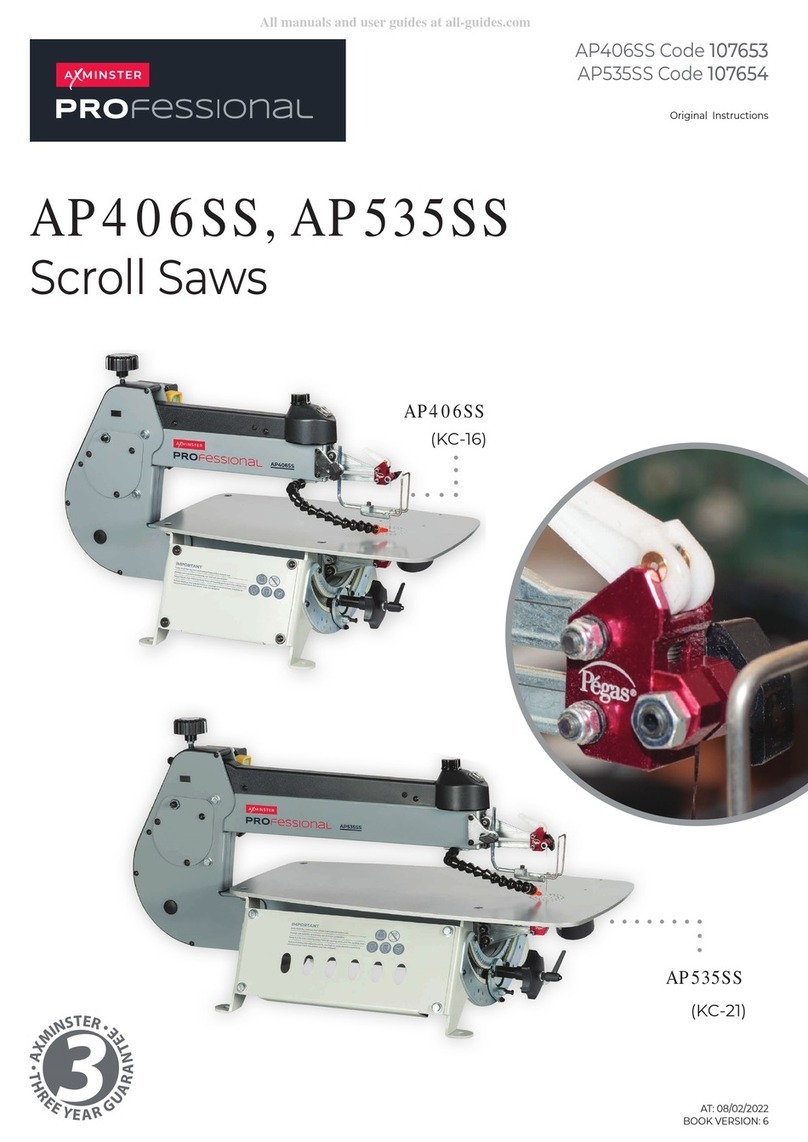

Axminster PROFESSIONAL AP406SS User manual

Axminster

Axminster Trade AT2552BE User manual

Axminster

Axminster KS 120 E User manual

Axminster

Axminster PROFESSIONAL AP535SS User manual

Axminster

Axminster AWHBS250N User manual

Axminster

Axminster 200387 User manual

Axminster

Axminster TS-250M User manual

Axminster

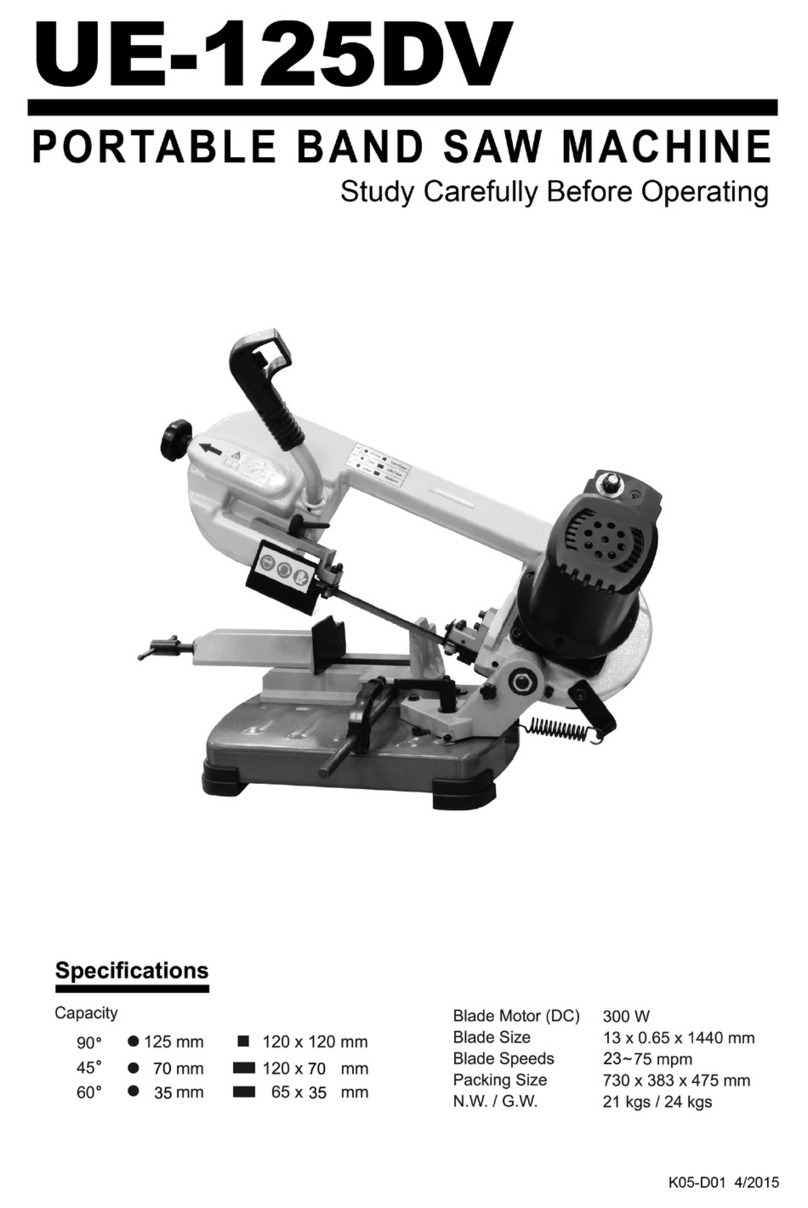

Axminster UE-125DV User manual

Axminster

Axminster AWHBS350N User manual

Axminster

Axminster BS11 User manual

Axminster

Axminster PROFESSIONAL AP2920B User manual

Axminster

Axminster Trade AT3327B User manual

Axminster

Axminster 250mm Slide Mitre Saw User manual

Axminster

Axminster RSS16E Hobby Series Installation instructions

Axminster

Axminster Excalibur EX-16 User manual

Axminster

Axminster Hobby MS210S User manual

Axminster

Axminster MCB100A User manual

Axminster

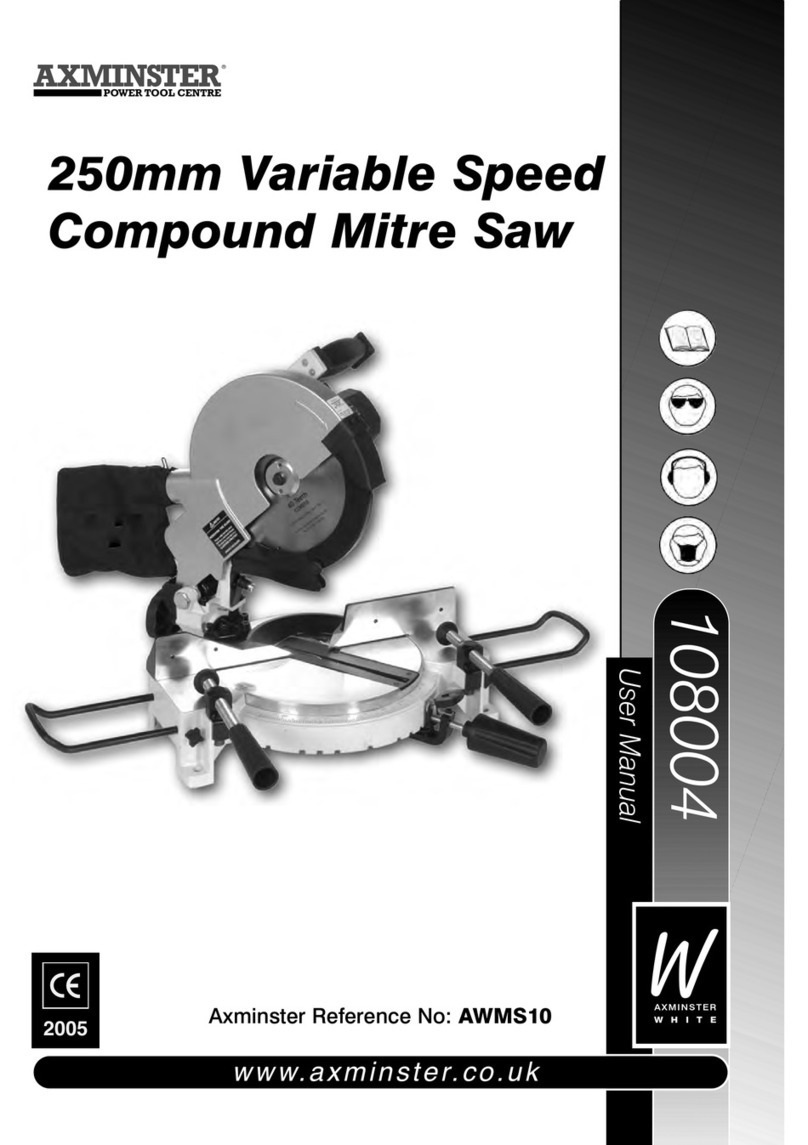

Axminster AWMS10 User manual

Axminster

Axminster HBS200N User manual

Axminster

Axminster Excalibur EX-16 User manual