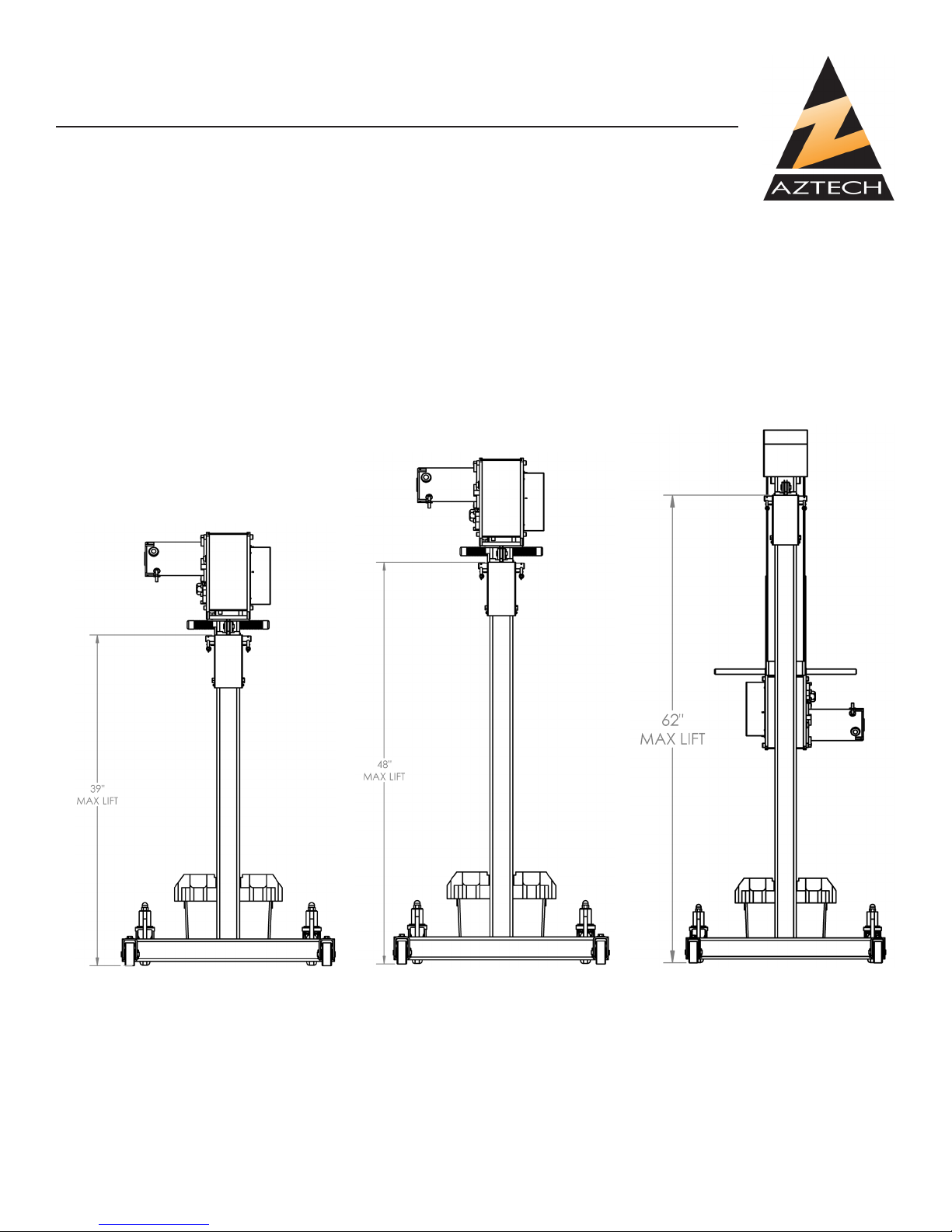

AZTECH CONVERTING SYSTEMS

MH-400E

USER MANUAL

5

1-3: Care and Maintenance

The RollRunner is relatively maintenance free, generally only re-

quiring periodic inspections. Over time, you may need to replace

the lift cable, which is simply performed by removing the old ca-

ble and inserting the new cable and crimping at the open end.

1-4: Safety

The RollRunner is equipped

with a safety brake which will

automatically engage in the

event of lift cable breakage.

(see Figure 1-5)

Fig. 1-5: SAFETY BRAKE DETAIL

NEVER:

Section 2: Machine Setup

2-1: Uncrating & Inspection

After carefully removing your

RollRunner from the crate,

check to assure that all the

bolts are tight and that no

components have come loose

during shipment. Carefully

inspect all 4 wheels making

sure they roll freely and are

free of damage. If any visible

damage has occurred in ship-

ment, contact AZTECH imme-

diately.

2-2: Safety Brake Inspection

As noted in 1-4, your RollRun-

ner is equipped with a safety

brake which will prevent a load

from falling in the event of a ca-

ble break. To assure it is work-

ing properly, check to see

that the 2 springs that activate

the safety brake have tension

and are attached at both ends.

2-2 Battery Connection

The RollRunner’s motorized

lift utilizes a 12 Volt deep-cycle

battery (not provided) which

may be purchased at virtually

any automotive or department

store. To connect the battery,

simply connect red cable to

the positive (+) terminal, and

the other cable to the negative

(-) terminal. The RollRunner

comes with an auxillary battery

charger and will need to be

charged periodically dependant

on use. Generally the higher

the cold cranking amps (CCA)

the battery is rated at, the less

frequently it would need to be

charged.

2-4: Winch & Cable Inspec-

tion

Before lifting a load for the

rst time, remove the protec-

tive winch cover and visually

inspect to assure that the

cable is seated properly in the

grooves of the pulleys.

-Operate the ROLL RUNNER without the safety cover.

-Lift load over people

-Exceed the 400 LB weight limitation

-Use the ROLL RUNNER to transport people