B. Braun Aesculap Manual

Aesculap®

Aesculap Power Systems

Instructions for use/Technical description

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 /

ELAN 4 electro HD handpiece (2 ring) GA865 to GA869

Gebrauchsanweisung/Technische Beschreibung

ELAN 4 electro Handstück Standard (1-Ring) GA861 bis GA864 /

ELAN 4 electro Handstück HD (2-Ring) GA865 bis GA869

Mode d’emploi/Description technique

Pièce à main ELAN 4 electro Standard (1 anneau) GA861 à GA864 / pièce à

main ELAN 4 electro HD (2 anneaux) GA865 à GA869

Instrucciones de manejo/Descripción técnica

Pieza de mano ELAN 4 electro Standard GA861 (1 anillo) a GA864 / pieza de

mano ELAN 4 electro HD (2 anillos) GA865 a GA869

Istruzioni per l’uso/Descrizione tecnica

Manipolo ELAN 4 electro Standard (a un anello) da GA861 a GA864 / mani-

polo ELAN 4 electro HD (a due anelli) da GA865 a GA869

Instruções de utilização/Descrição técnica

ELAN 4 electro peça de mão Standard (1 anel) GA861 a GA864 /

ELAN 4 electro peça de mão HD (2 anéis) GA865 a GA869

Gebruiksaanwijzing/Technische beschrijving

ELAN 4 electro handstuk Standard (1-ring) GA861 tot GA864 /

ELAN 4 electro handstuk HD (2-ring) GA865 tot GA869

Brugsanvisning/Teknisk beskrivelse

ELAN 4 electro håndstykke Standard (1 ring) GA861 til GA864 /

ELAN 4 electro håndstykke HD (2 ringe) GA865 til GA869

Bruksanvisning/Teknisk beskrivning

ELAN 4 electro handstycke Standard (1 ring) GA861 till GA864 /

ELAN 4 electro handstycke HD (2 ringar) GA865 till GA869

Käyttöohje/Tekninen kuvaus

ELAN 4 electro-käsikappale vakio (1-renkainen) GA861–GA864 /

ELAN 4 electro-käsikappale HD (2-renkainen) GA865–GA869

Kasutusjuhend/Tehniline kirjeldus

ELAN 4 electro käsiseade Standard (1 rõngaga) GA861 kuni GA864 /

ELAN 4 electro käsiseade HD (2 rõngaga) GA865 kuni GA869

Инструкция по примению/Техническое описание

ELAN 4 electro наконечник Standard (1-кольцо) GA861 – GA864 /

ELAN 4 electro наконечник HD (2-кольца) GA865 – GA869

Návod k použití/Technický popis

ELAN 4 electro násadec Standard (1 kroužek) GA861 až GA864 /

ELAN 4 electro násadec HD (2 kroužky) GA865 až GA869

Instrukcja użytkowania/Opis techniczny

Uchwyt ELAN 4 electro Standard (1-pierścieniowy) GA861 do GA864 /

uchwyt ELAN 4 electro HD (2-pierścieniowy) GA865 do GA869

Návod na použitie/Technický opis

ELAN 4 electro rukoväť Standard (1-prstencová) GA861 až GA864 /

ELAN 4 electro rukoväť HD (2-prstencová) GA865 až GA869

Kullanım Kılavuzu/Teknik açiklama

ELAN 4 electro El cihazı Standard (1 halka) GA861 ila GA864 /

ELAN 4 electro el cihazı HD (2 halka) GA865 ila GA869

1

7

5

4

2

1

7

2

6

6

4

2

1

43

2

1

43

A

B

C

D

8

9

8

9

10

11

3

2

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro HD handpiece (2 ring) GA 865 to GA869

Legend

1ELAN 4 tool coupling (1 ring or 2 ring)

2Ring marking

3Connector for motor cable

4Slider for tool release

5Symbol of the applied part type in display of ELAN 4 electro control

unit

6ELAN 4 tool (1 ring or 2 ring)

7ELAN 4 single-use spray nozzle for 1 ring or 2 ring handpieces

ELAN 4 ECCOS holder for 12 drills GB718R

8Side handles

9Holding nibs

10 Tool coupling

11 Tab

Symbols on product and packages

Contents

1. Applicable to. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Task/function within system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Application Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.4 Contraindications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Safe handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Sterile ELAN 4 tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Sterile ELAN 4 single-use spray nozzles . . . . . . . . . . . . . . . . . . . 4

4. Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Available sizes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Package includes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.3 Components required for operation . . . . . . . . . . . . . . . . . . . . . . 5

4.4 Operating principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5. Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6. Working with the applied part . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.1 System set-up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

6.2 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7. Validated reprocessing procedure . . . . . . . . . . . . . . . . . . . . . . . . 7

7.1 General safety notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

7.2 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.3 Preparations at the place of use . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.4 Preparation before cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.5 Cleaning/disinfection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

7.6 Manual cleaning with immersion disinfection - applied part . 10

7.7 Mechanical cleaning/disinfecting with manual pre-cleaning -

applied part. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.8 Mechanical cleaning/disinfecting with manual pre-cleaning -

tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.9 Inspection, maintenance and checks . . . . . . . . . . . . . . . . . . . . . 14

Caution

Observe important safety information such as warn-

ings and precautions in the instructions for use.

YYYY-MM

Maintenance label

Recommended date of next service (format: YYYY-

MM) by international B. Braun-/Aesculap agents, see

Technical Service

Machine-readable, two-dimensional code

The code contains a unique serial number which can be

used for electronic tracking of the individual instru-

ment. The serial number is based on the global stan-

dard sGTIN (GS1).

Date of manufacture

Sterilization using irradiation

Not for reuse in intended applications as defined by the

manufacturer

Use by

Manufacturer’s batch designation

Manufacturer’s serial number

LOT

SN

Manufacturer’s article number

Temperature limits during transport and storage

Air humidity limits during transport and storage

Atmospheric pressure limits during transport and stor-

age

REF

3

7.10 Packaging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7.11 Steam sterilization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.12 Sterilization for the US market . . . . . . . . . . . . . . . . . . . . . . . . . . 15

7.13 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

9. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

10. Technical Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11. Accessories/Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12. Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12.1 Classification acc. to Directive 93/42/EEC . . . . . . . . . . . . . . . . . 16

12.2 Performance data, information about standards . . . . . . . . . . . . 16

12.3 Tool speed/Setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.4 Short interval operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.5 Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

13. Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

14. Distributor in the US/Contact in Canada for product

information and complaints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1. Applicable to

►For item-specific instructions for use and information on material

compatibility, see also the Aesculap Extranet at

https://extranet.bbraun.com

2. Intended use

2.1 Task/function within system

The handheld Highspeed ELAN 4 electro Standard handpiece (1 ring)

GA861 to GA864 or ELAN 4 electro HD handpiece (2 ring) GA865 to

GA869 is an accessory of the ELAN 4 electro motor system.

The handpiece is connected by an ELAN 4 electro motor cable to the con-

trol unit.

The handpiece is used to drive Aesculap ELAN 4 tools (1 ring or 2 ring).

2.2 Application Environment

Application in the sterile area

2.3 Indications

Note

The type and area of application depend on the tools selected.

2.4 Contraindications

The ELAN 4 electro motor system is not authorized for use in the central

nervous system or central circulatory system.

Note

The safe and effective use of electrically driven applied parts depends heav-

ily on influences that only the user can control him or herself. Therefore the

specifications provided represent framework conditions only.

Note

The clinical success of the use of the ELAN 4 electro motor system is depen-

dent on the knowledge and experience of the surgeon. The surgeon must

decide which structures it is sensible to treat and take into account the

safety and warning information contained in these instructions for use.

Speed min. 0 rpm to max. 80 000 rpm

Rotational direction Right and left rotation

Short interval operation 30 second application, 30 second pause

at 60 000 RPM

Modes of application Separating, removing and shaping hard tis-

sue, cartilage and similar, as well as for drill-

ing holes in bone and bone replacement

materials.

Surgical discipline/areas

of application

Neurosurgery, ENT surgery, OMF surgery,

orthopedics and trauma surgery

4

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

3. Safe handling

CAUTION

Federal law restricts this device to sale by or on order of a physician!

■General risk factors associated with surgical procedures are not

described in this documentation.

■It is the operating surgeon's responsibility to ensure that the surgical

procedure is performed correctly.

■The operating surgeon must have a thorough understanding of both

the hands-on and conceptual aspects of the established operating

techniques.

►Remove the transport packaging and clean the new product, either

manually or mechanically, prior to its initial sterilization.

►Prior to use, check that the product is in good working order.

►Observe “Notes on Electromagnetic Compatibility (EMC)“, see

TA022130.

►To prevent damage caused by improper setup or operation, and in order

not to compromise warranty and manufacturer liability:

– Use the product only according to these instructions for use.

– Follow the safety and maintenance instructions.

– Only combine Aesculap products with each other.

►Ensure that the product and its accessories are operated and used only

by persons with the requisite training, knowledge, or experience.

►Keep the instructions for use accessible for the user.

►Always adhere to applicable standards.

►Ensure that the electrical installations at the premises where the

device is to be used meet all requirements acc. to IEC/DIN EN.

►Do not use the control unit and applied part in potentially explosive

areas.

►Carry out sterile processing in any reusable applied parts, motor cables

and tools prior to use.

►When handling, observe instructions for use that are relevant to

Aesculap holder systems TA009721, see Aesculap Extranet at

https://extranet.bbraun.com

3.1 Sterile ELAN 4 tools

The product is gamma-sterilized and supplied in sterile packaging.

►Ensure that the product and its accessories are operated and used only

by persons with the requisite training, knowledge, or experience.

►Read, follow, and keep the instructions for use.

►Use the product only in accordance with its intended use, see Intended

use.

►Do not use products from open or damaged sterile packaging.

►Prior to each use, inspect the product for: loose, bent, broken, cracked,

worn, or fractured components.

►Do not use the product if it is damaged or defective. Set aside the prod-

uct if it is damaged.

►Do not use the product after its use-by date.

3.2 Sterile ELAN 4 single-use spray nozzles

The product is gamma-sterilized and supplied in sterile packaging.

The product must not be reused.

►Ensure that the product and its accessories are operated and used only

by persons with the requisite training, knowledge, or experience.

►read, follow, and keep the instructions for use.

►Use the product only in accordance with its intended use, see Intended

use.

►Do not use products from open or damaged sterile packaging.

►Prior to each use, inspect the product for: loose, bent, broken, cracked,

worn, or fractured components.

►Do not use the product if it is damaged or defective. Set aside the prod-

uct if it is damaged.

►Do not use the product after its use-by date.

WARNING

Risk of injury and material damage due to inappro-

priate use of the product!

►Use the product only in accordance with the

intended purpose.

WARNING

Risk of injury and damage to property due to

improper handling of the product!

This product is an accessory of the ELAN 4 electro

control unit GA800.

►Follow the instructions for use of the

ELAN 4 electro control unit GA800

(TA014401).

►Follow the instructions for use of all products

used.

DANGER

Risk of infection for patients and/or users and

impairment of product functionality due to reuse.

Risk of injury, illness or death due to contamination

and/or impaired functionality of the product!

►Do not reprocess the product.

5

4. Product description

4.1 Available sizes

Note

The shaft length can be seen on the shaft of the drill handpiece.

ELAN 4 electro Standard handpiece (1 ring)

ELAN 4 electro HD handpiece (2 ring)

4.2 Package includes

ELAN 4 electro Standard handpiece (1 ring)

ELAN 4 electro HD handpiece (2 ring)

4.3 Components required for operation

■Operation-ready ELAN 4 electro control unit GA800, see TA014401

■ELAN 4 tool (1 ring or 2 ring)

4.4 Operating principle

Note

The ring marking 2shows the shaft diameter of the tool to be used. ELAN 4

tools can be only coupled to the applied part if the ring markings

(1 ring/2 ring) of the applied part and tool match.

The drill handpiece is fitted with an ELAN 4 tool coupling (1 ring or 2 ring).

It is used with ELAN 4 electro foot controls/manual controls.

With the drill handpiece, the coupled tool rotates at the set motor speed.

The motor speed of the drill handpiece can be adjusted continuously by

the manual/foot control.

The drill handpiece can be operated in right or left (clockwise or counter-

clockwise) rotation mode.

5. Preparation

Non-compliance with these rules will result in complete exclusion of lia-

bility on the part of Aesculap.

►Do not use products from open or damaged sterile packaging.

►Prior to use, inspect the product and its accessories for any visible

damage.

►Use the products and their accessories only if they are in perfect tech-

nical condition.

Art. no. Length of shaft

GA861 L4 (approx. 4 cm)

GA862 L7 (approx. 7 cm)

GA863 L10 (approx. 10 cm)

GA864 L13 (approx. 13 cm)

Art. no. Length of shaft

GA865 L7 (approx. 7 cm)

GA866 L10 (approx. 10 cm)

GA867 L13 (approx. 13 cm)

GA868 L17 (approx. 17 cm)

GA869 L22 (approx. 22 cm)

Art. no. Designation

GA861–GA864 ELAN 4 electro Standard handpiece (1 ring)

TA014443 Instructions for use of ELAN 4 electro Standard

handpiece (1 ring) GA861 to GA864 /

ELAN 4 electro HD handpiece (2 ring) GA865 to

GA869 (leaflet)

Art. no. Designation

GA865–GA869 ELAN 4 electro handpiece HD (2-Ring)

TA014443 Instructions for use of ELAN 4 electro Standard

handpiece (1 ring) GA861 to GA864 /

ELAN 4 electro HD handpiece (2 ring) GA865 to

GA869 (leaflet)

6

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

6. Working with the applied part

6.1 System set-up

Note

Operating elements on the system components of the ELAN 4 electro motor

system are labeled with a gold marking.

Connecting the accessories

Combinations of accessories that are not mentioned in the present

instructions for use may only be employed if they are specifically intended

for the respective application, and if they do not compromise the perfor-

mance and safety characteristics of the products.

All configurations must comply with basic standard IEC/DIN EN 60601-1.

Any individual connecting devices with one another is responsible for such

configuration and must ensure compliance with basic standard IEC/DIN

EN 60601-1 or applicable national standards.

►Follow the instructions for use of individual accessories.

►Please contact your B. Braun/Aesculap Partner or Aesculap Technical

Service (address: see Technical Service with any inquiries in this

respect.

Removing ELAN 4 ECCOS holder for 12 burrs GB718R from the tray

The insert of the ELAN 4 ECCOS holder for 12 burrs GB718R can be

removed from the tray together with the tools.

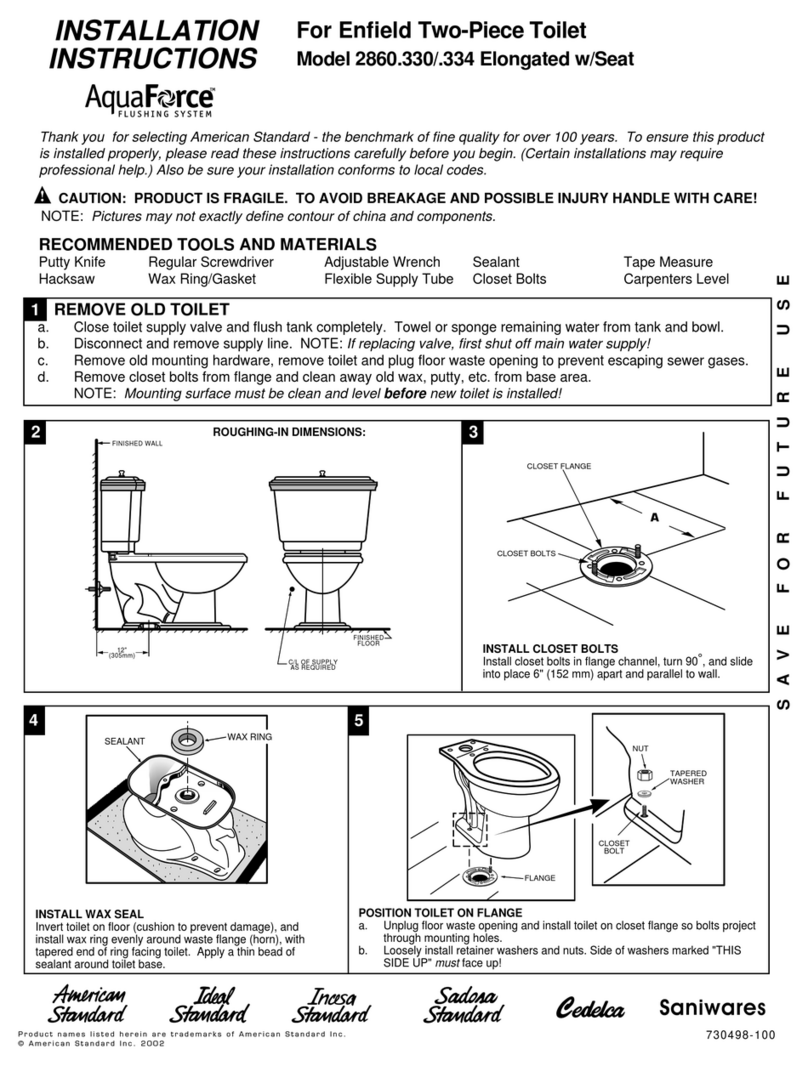

►Pull the tab 11 and remove the insert of the holder, see Fig. C.

Coupling the tool to the applied part

►Lock applied part ("Off" position), see instructions for use of

ELAN 4 electro control unit GA800 (TA014401).

►Push tool shaft 6as far as it will go into ELAN 4 tool coupling (1 ring

or 2 ring) 1, see Fig. A.

The tool engages. The tool is correctly coupled when the ring marking 2

on the tool is no longer visible.

►Pull at tool 6to check that it is securely coupled.

Uncoupling the tool from the applied part

►Lock applied part ("Off" position), see instructions for use of

ELAN 4 electro control unit GA800 (TA014401).

►Pull back slider for tool release 4on the applied part and remove tool 6

from ELAN 4 tool coupling (1 ring or 2 ring) 1, see Fig. A.

WARNING

Risk of infection and contamination!

Applied parts and motor cable are delivered unster-

ile!

►Carry out sterile processing of the applied parts

and motor cable prior to use, in accordance with

the instructions for use.

WARNING

Risk of injury and material damage due to inadver-

tent activation of the applied part!

►Secure applied parts that are not actually used

against inadvertent activation ("Off" position),

see instructions for use for ELAN 4 electro con-

trol unit GA800 (TA014401).

WARNING

Risk of injury and material damage due to inappro-

priate use of tools!

►Always follow the safety advice and information

given in the instructions for use.

►When coupling/uncoupling, handle tools with

cutting edges with care.

WARNING

Damage to the product if dropped!

►Use the products only if they are in perfect

technical condition, see Function check

WARNING

Risk of burns to skin and tissue due to blunt tools/

lack of maintenance of the applied part!

►Use tools only if they are in perfect condition.

►Replace blunt tools.

►Ensure correct maintenance of the applied part,

see Maintenance.

WARNING

Risk of injury when coupling/uncoupling tools in

the "On" position due to accidental activation of

the applied part!

►Only couple/uncouple tools in the "Off" posi-

tion.

WARNING

Risk of injury due to small parts in the operation

site!

►Do not couple/uncouple tools over the operation

site.

WARNING

Risk of injury when coupling/uncoupling tools in

the "On" position due to accidental activation of

the applied part!

►Only couple/uncouple tools in the "Off" posi-

tion.

WARNING

Risk of injury due to small parts in the operation

site!

►Do not couple/uncouple tools over the operation

site.

7

Mounting the spray nozzle and tube set

►Connect tube set GA395SU to pump of ELAN 4 electro control unit

GA800, see TA014401.

►Push application-side tube end onto tube connection of the ELAN 4

single-use spray nozzle for 1 ring or 2 ring handpieces 7.

►Push single-use spray nozzle for ELAN 4 1 ring or 2 ring

handpieces 7onto the shaft of the applied part and push/turn into the

desired position, see Fig. A.

Note

The spray tube of the ELAN 4 single-use spray nozzle for 1 ring or 2 ring

handpiece is bendable by hand and can be adapted to the requirements of

application (e.g. aligned to tool head).

6.2 Function check

►Prior to each use, check that all products to be used are in good work-

ing order.

►Check the secure connection of all products to be used.

►Check that the tool is coupled properly. To do this, pull on the tool.

►Check that the cutting edges of the tools are not showing any mechan-

ical damage.

►Briefly run the applied parts at maximum speed.

►Do not use the product if it is damaged or defective. Set aside the prod-

uct if it is damaged.

6.3 Operation

It is only possible to operate the applied part and change the setting

parameters on the control unit if:

■the applied part is connected to the control unit,

■there is no second applied part released ("On" position) at the same

time and

■the applied part type 5is shown in the display of the control unit.

Note

For further information, see instructions for use of ELAN 4 electro control

unit GA800 (TA014401).

7. Validated reprocessing procedure

7.1 General safety notes

Note

Adhere to national statutory regulations, national and international stan-

dards and directives, and local, clinical hygiene instructions for reprocess-

ing.

Note

For patients with Creutzfeldt-Jakob disease (CJD), suspected CJD, or possi-

ble variants of CJD, observe the relevant national regulations concerning

the reprocessing of products.

Note

Mechanical reprocessing should be favored over manual cleaning as it

gives better and more reliable results.

Note

It should be noted that successful reprocessing of this medical device can

only be guaranteed following prior validation of the reprocessing method.

The operator/reprocessing technician is responsible for this.

The recommended chemical was used for validation.

WARNING

Coagulation of patient tissue or risk of burns for

patients and users from hot applied part/tool!

►Cool the tool during operation.

►Put down the applied part/tool beyond reach of

the patient.

►Allow the applied part/tool to cool down.

►Use a cloth to protect against burns when

changing the tool.

WARNING

Risk of infection from aerosol formation!

Risk of injuries caused by particles coming loose

from the tool!

►Take appropriate protective measures, e.g.

watertight protective clothing, face mask and

protective goggles, suction extraction.

WARNING

Risk of injury and/or malfunction!

►Always carry out a function test prior to each

use of the product.

WARNING

Risk of injury due to application of the product

outside the field of view!

►Only use the product under vision.

WARNING

Risk of injury and damage to the tool/system!

The rotating tool may catch cover drapes (textile or

other).

►Never allow the tool to touch cover drapes (tex-

tile or other) during operation.

WARNING

Danger of injury from foreign body reactions (e.g.

inflammation, encapsulation) if particles remain in

the body!

When using diamond tools, it is always possible for

diamond grains/nickel particles to break away/off.

►Carefully rinse and vacuum while and after

working with diamond tools.

8

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

Note

If there is no final sterilization, then a virucidal disinfectant must be used.

Note

For up-to-date information about reprocessing and material compatibility,

see also the Aesculap Extranet at https://extranet.bbraun.com

The validated steam sterilization procedure was carried out in the Aesculap

sterile container system.

7.2 General information

Dried or affixed surgical residues can make cleaning more difficult or inef-

fective and lead to corrosion. Therefore the time interval between appli-

cation and processing should not exceed 6 h; also, neither fixating pre-

cleaning temperatures >45 °C nor fixating disinfecting agents (active

ingredient: aldehydes/alcohols) should be used.

Excessive neutralizing agents or basic cleaners may result in a chemical

attack and/or fading and the laser marking becoming unreadable either

visually or by machine.

Residues containing chlorine or chlorides, e.g., in surgical residues, medi-

cines, saline solutions, and in the service water used for cleaning, disin-

fection, and sterilization, will cause corrosion damage (pitting, stress cor-

rosion) and result damage to metallic products. These must be removed by

rinsing thoroughly with demineralized water and then drying.

Perform additional drying, if necessary.

Only process chemicals that have been tested and approved (e.g. VAH or

FDA approval or CE mark) and which are compatible with the product’s

materials according to the chemical manufacturers’ recommendations

may be used for processing the product. All the chemical manufacturer's

application specifications must be strictly observed. Failure to do so can

result in the following problems:

■Material damage such as corrosion, cracks, fracturing, premature

aging, or swelling.

►Do not use metal cleaning brushes or other abrasives that would dam-

age the product surface and could cause corrosion

►For further detailed information on hygienically safe and material-pre-

serving/value-preserving reprocessing, see www.a-k-i.org, link to Pub-

lications, Red Brochure – Proper maintenance of instruments.

7.3 Preparations at the place of use

►Separate the products from each other immediately after use.

►Remove any visible surgical residues as much as possible with a damp,

lint-free cloth.

►Place the dry product in a sealed waste container and forward it on for

cleaning and disinfection within 6 hours.

7.4 Preparation before cleaning

Applied part

►Prior to first mechanical cleaning/disinfection process: Mount ECCOS

holder GB082R/GB083R in a suitable tray (e.g. JF222R).

►Place the product in the correct position in the ECCOS holder

GB082R/GB083R, see Fig. B.

Tools

►Thoroughly rinse the product with running, cold water.

►Prior to first mechanical cleaning/disinfection process: Mount the bot-

tom part of the ECCOS holder GB718R in a suitable tray (e.g. JF222R).

►Place the tools in the correct position in the tool holder 10 of the

ECCOS holder GB718R, see Fig. C.

►Engage the insert of the holder in the bottom part. When doing so,

ensure that the holding nibs 9on the top part are inserted in the

recesses in the bottom part.

7.5 Cleaning/disinfection

Product-specific safety guidelines on the reprocessing procedure

Note

The indicated drying time is a guide time only. It must be checked taking

into account the specific conditions (e.g. load) and if applicable adjusted.

CAUTION

Damage to the product due to inappropriate clean-

ing/disinfecting agents and/or excessive tempera-

tures!

►Following the manufacturer's instructions, use

cleaning and disinfecting agents which

–be approved for plastic material and high-

grade steel,

–do not attack softeners (e.g., in silicone).

►Do not use cleaning agents that contain ace-

tone.

►Observe specifications regarding concentration,

temperature and exposure time.

►Do not exceed the maximum temperature of

60 °C during chemical cleaning and/or disinfec-

tion.

►Do not exceed the maximum temperature of

90 °C during thermal disinfection with DI water.

►Dry the product for at least 10 minutes at a

maximum of 120 °C.

9

Validated cleaning and disinfection procedure

Product Validated procedure Reference

Applied part Manual cleaning with immer-

sion disinfection

see Manual clean-

ing with immer-

sion disinfection -

applied part

Manual pre-cleaning with

brush and subsequent mechan-

ical alkaline cleaning and ther-

mal disinfection

see Mechanical

cleaning/disin-

fecting with man-

ual pre-cleaning -

applied part

Tools Manual pre-cleaning with

ultrasound and brush, and sub-

sequent mechanical alkaline

cleaning and thermal disinfec-

tion

see Mechanical

cleaning/disin-

fecting with man-

ual pre-cleaning -

tools

10

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

7.6 Manual cleaning with immersion disinfection - applied part

D–W: Drinking water

RT: Room temperature

*Recommended: BBraun Helizyme

**Recommended: BBraun Stabimed

►Follow the instructions for use of the ELAN 4 rinsing devices and rins-

ing adapters TA014447 and TA014448.

►Do not clean the applied part in an ultrasound bath.

Phase I

►Clean the product under running water, using a suitable cleaning brush

until all visible residues have been removed from the surfaces.

►Mobilize non-rigid components, such as release button, unlocking

sleeve, etc. during cleaning.

►Rinse the applied part through the rinsing adapter GB698R at least

3 times for 5 seconds with a water gun.

Phase II

►Using a disposable syringe, fill the inside of the applied part with

cleaning solution through the rinsing adapter GB698R.

►Place the applied part, with rinsing adapter connected, fully in enzy-

matic cleaning solution for 5 minutes.

Phase III

►Rinse the entire product (all accessible surfaces) under running water.

►Mobilize non-rigid components, such as release button, unlocking

sleeve, etc. during rinsing.

►Rinse the applied part through the rinsing adapter GB698R at least

3 times for 5 seconds with a water gun.

Phase IV

►Prior to manual disinfection, allow rinsing water to drain off the prod-

uct for a sufficient length of time and use compressed air to blow all

liquid out of the product through the rinsing adapter GB698R in order

to prevent dilution of the disinfecting solution.

►Using a disposable syringe, fill the inside of the applied part with dis-

infectant solution through the rinsing adapter GB698R.

►Place the applied part, with rinsing adapter connected, fully in disin-

fectant solution for 15 minutes.

Phase V

►Rinse the entire product (all accessible surfaces) under running water.

►Mobilize non-rigid components, such as release button, unlocking

sleeve, etc. during cleaning.

►Rinse the applied part through the rinsing adapter GB698R at least

3 times for 5 seconds with a water gun.

Phase VI

►Dry the product in the drying phase with suitable equipment (e.g. cloth,

compressed air).

►After manual cleaning/disinfection, check visible surfaces visually for

residues.

►Repeat the cleaning/disinfection process if necessary.

Phase Step T

[°C/°F] t

[min] Conc.

[%] Water

quality Chemicals

I Pre-cleaning RT (cold) - - D–W –

II Cleaning RT (cold) >5 1 D–W pH-neutral, pH ~ 9*

III Intermediate rinse RT (cold) - - D–W -

IV Disinfection RT (cold) >15 2 D–W Concentrate-free, aldehyde-free, phenol-free, QUAT-free, pH ~ 9**

VFinalrinse RT (cold) - - D–W -

VI Drying RT - - - -

11

7.7 Mechanical cleaning/disinfecting with manual pre-cleaning - applied part

Note

The cleaning and disinfection device must be of tested and approved effec-

tiveness (e.g. FDA approval or CE mark according to DIN EN ISO 15883).

Note

The cleaning and disinfection device used for processing must be serviced

and checked at regular intervals.

Manual pre-cleaning with a brush

D–W: Drinking water

RT: Room temperature

►Follow the instructions for use of the ELAN 4 rinsing devices and rins-

ing adapters TA014447 and TA014448.

►Do not clean the applied part in an ultrasound bath.

Phase I

►Clean the product with a suitable cleaning brush until all discernible

residues have been removed.

►Mobilize non-rigid components, such as release button, unlocking

sleeve, etc. during cleaning.

Phase II

►Connect the connector for motor cable 3with ELAN 4 electro rinsing

device GB692R.

►Rinse the applied part:

– For 5 min with a tap/hose or

– 3 times for 5 seconds with a water gun

Phase Step T

[°C/°F] t

[min] Conc.

[%] Water

quality Chemicals

IBrushes RT (cold) – – D–W -

II Rinsing RT (cold) 5 - D–W -

12

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

Mechanical alkaline cleaning and thermal disinfection

Machine type: single-chamber cleaning/disinfection device without ultrasound

D–W: Drinking water

FD–W: Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least)

*Recommended: BBraun Helimatic Cleaner alkaline

►Connect the connector for motor cable 3with ELAN 4 electro rinsing

device GB692R.

►Place the rinsing device on a wire basket suitable for cleaning.

►Connect the rinsing device to the rinsing connection of the rinsing cart.

►After the mechanical cleaning/disinfection process:

– Remove any residual rinsing water from the applied part using a

compressed-air gun, see instructions for use ELAN 4 rinsing device

and rinsing adapter TA014447 and TA014448.

– Check visible surfaces for residues.

Phase Step T

[°C/°F] t

[min] Water

quality Chemicals

I Pre-rinse <25/77 3 D–W -

II Cleaning 55/131 10 FD–W ■Concentrate, alkaline:

–pH~13

– <5 % anionic surfactant

■0.5 % working solution

–pH~11*

III Intermediate rinse >10/50 1 FD–W -

IV Thermal disinfection 90/194 5 FD–W -

VDrying - - - In accordance with the program for the cleaning and disinfecting machine

13

7.8 Mechanical cleaning/disinfecting with manual pre-cleaning - tools

Note

The cleaning and disinfection device must be of tested and approved effec-

tiveness (e.g. FDA approval or CE mark according to DIN EN ISO 15883).

Note

The cleaning and disinfection device used for processing must be serviced

and checked at regular intervals.

Manual pre-cleaning with ultrasound and brush

D–W: Drinking water

RT: Room temperature

*Recommended: BBraun Helizyme

**Recommended: BBraun Stabimed

►Only perform ultrasound cleaning in the ECCOS holder GB718R to pre-

vent any damage to the cutting edges.

Phase I

►Fully immerse the product in enzymatic cleaning solution for at least

30 minutes. Ensure that all accessible surfaces are moistened.

Phase II

►Rinse the entire product (all accessible surfaces) under running water.

Phase III

►Tilt up the tool holder 10 of the ECCOS holder GB718R by the side

handles 8, see Fig. C.

►Clean the product in an ultrasonic cleaning bath (frequency 35 kHz) for

at least 15 minutes. Ensure that all accessible surfaces are immersed

and acoustic shadows are avoided.

Phase IV

►Clean the product with a suitable cleaning brush until all discernible

residues have been removed.

Phase Step T

[°C/°F] t

[min] Conc.

[%] Water

quality Chemicals

I Immersion RT (cold) >30 50 D–W Enzymatic detergent*

II Rinsing RT (cold) - - D–W -

III Ultrasonic cleaning 55/131 >15 2 D–W Concentrate-free, aldehyde-free, phenol-free, QUAT-free, pH ~ 9**

IV Cleaning with brush RT (cold) - - D–W -

14

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

Mechanical alkaline cleaning and thermal disinfection

Machine type: single-chamber cleaning/disinfection device without ultrasound

D–W: Drinking water

FD–W: Fully desalinated water (demineralized, low microbiological contamination: drinking water quality at least)

*Recommended: BBraun Helimatic Cleaner alkaline

►Place the tools in the correct position in the tool holder 10 of the

ECCOS holder GB718R, see Fig. C.

►Check visible surfaces for residues after mechanical cleaning/disinfect-

ing.

7.9 Inspection, maintenance and checks

►Allow the product to cool down to room temperature.

►Inspect the product after each cleaning and disinfecting cycle to be

sure it is: clean, functional, and undamaged.

►ELAN 4 electro Connect oil spray adapter GB600860 (gray) to connec-

tor for motor cable 3and spray through the applied part for approx.

2 seconds with Aesculap-STERILIT oil spray GB600, see Fig. D.

►Check the product for any damage, abnormal running noise, overheat-

ing or excessive vibration.

►Inspect tools for broken, damaged or blunt edges.

►Set aside the product if it is damaged.

7.10 Packaging

►Always follow the instructions for use of the respective packaging and

storage devices (e.g. instructions for use TA009721 for Aesculap-

ECCOS holder system).

►Place the applied part in the correct position in the ECCOS holder

GB082R/GB083R, see Fig. B.

►Place the tools in the correct position in the ECCOS holder GB718R, see

Fig. C.

►Pack trays appropriately for the intended sterilization process (e.g. in

Aesculap sterile containers).

►Ensure that the packaging will prevent a recontamination of the prod-

uct.

Phase Step T

[°C/°F] t

[min] Water

quality Chemicals

I Pre-rinse <25/77 3 D–W -

II Cleaning 55/131 10 FD–W ■Concentrate, alkaline:

–pH~13

– <5 % anionic surfactant

■0.5 % working solution

–pH~11*

III Intermediate rinse >10/50 1 FD–W -

IV Thermal disinfection 90/194 5 FD–W -

VDrying - - - In accordance with the program for the cleaning and disinfecting machine

15

7.11 Steam sterilization

Note

For further information, see Technical Data.

►Make certain that all external and internal surfaces of the product will

be exposed to the sterilizing agent.

►Validated sterilization process

– Steam sterilization using fractional vacuum process

– Steam sterilizer according to DIN EN 285 and validated according

to DIN EN ISO 17665

– Sterilization using fractionated vacuum process at 134 °C/holding

time 5 min

►When sterilizing several instruments at the same time in a steam ster-

ilizer: ensure that the maximum load capacity of the steam sterilizer

specified by the manufacturer is not exceeded.

7.12 Sterilization for the US market

■Aesculap advises against sterilizing the device by flash sterilization or

chemical sterilization.

■Sterilization may be accomplished by a standard prevacuum cycle in a

steam autoclave.

To achieve a sterility assurance level of 10-6, Aesculap recommends the

following parameters:

*Aesculap has validated the above sterilization cycle and has the data on

file. The validation was accomplished in an Aesculap sterile container

cleared by FDA for the sterilization and storage of these products. Other

sterilization cycles may also be suitable, however individuals or hospitals

not using the recommended method are advised to validate any alterna-

tive method using appropriate laboratory techniques. Use an FDA cleared

accessory to maintain sterility after processing, such as a wrap, pouch, etc.

7.13 Storage

►Store sterile products in germ-proof packaging, protected from dust, in

a dry, dark, temperature-controlled area.

8. Maintenance

To ensure reliable operation, the product must be maintained in accor-

dance with the maintenance labeling or at least once a year.

e.g. 2016-07

For technical service, please contact your national B. Braun/Aesculap

agency, see Technical Service.

9. Troubleshooting

Note

For further information, see instructions for use of ELAN 4 electro control

unit GA800 (TA014401).

10. Technical Service

Modifications carried out on medical technical equipment may result in

loss of guarantee/warranty rights and forfeiture of applicable licenses.

►For service and repairs, please contact your national B. Braun/Aesculap

agency.

Service addresses

Aesculap Technischer Service

Am Aesculap-Platz

78532 Tuttlingen /Germany

Phone: +49 7461 95-1601

Fax: +49 7461 14-939

E-Mail: [email protected]

Or in the US:

Aesculap Inc.

Attn. Aesculap Technical Services

615 Lambert Pointe Drive

Hazelwood

MO, 63042

Aesculap Repair Hotline

Phone: +1 800 214-3392

Fax: +1 314 895-4420

Other service addresses can be obtained from the address indicated above.

Aesculap Orga Tray/Sterile container (perforated bottom)

Minimum cycle parameters*

Sterilization

method Temp. Time Minimum drying time

Prevacuum 270 °F/275 °F 4 min 20 min

DANGER

Danger to life of patients and users if the product

malfunctions and/or protective measures fail or are

not used!

►Do not perform any servicing or maintenance

work under any circumstances while the product

is being used on a patient.

►Do not modify the product.

16

Aesculap®

ELAN 4 electro Standard handpiece (1 ring) GA861 to GA864 / ELAN 4 electro

HD handpiece (2 ring) GA865 to GA869

11. Accessories/Spare parts 12. Technical Data

12.1 Classification acc. to Directive 93/42/EEC

12.2 Performance data, information about standards

The product can be reprocessed 350 times. This was proved after

350 reprocessing cycles by a high voltage test at 1,6 kV.

Art. no. Designation

GA261SU ELAN 4 single-use spray nozzle for 1 ring handpiece L4

GA262SU ELAN 4 single-use spray nozzle for 1 ring handpiece L7

GA263SU ELAN 4 single-use spray nozzle for 1 ring handpiece L10

GA264SU ELAN 4 single-use spray nozzle for 1 ring handpiece L13

GA265SU ELAN 4 single-use spray nozzle for 2 ring handpiece L7

GA266SU ELAN 4 single-use spray nozzle for 2 ring handpiece L10

GA267SU ELAN 4 single-use spray nozzle for 2 ring handpiece L13

GA268SU ELAN 4 single-use spray nozzle for 2 ring handpiece L17

GA269SU ELAN 4 single-use spray nozzle for 2 ring handpiece L22

GA395SU ELAN 4 electro single-use tube set

GB082R ELAN 4 electro ECCOS holder for reamer handpiece

GA861 to GA869, 1 handpiece

GB083R ELAN 4 electro ECCOS holder for reamer handpiece

GA861 to GA869, 3 handpieces

GB600 STERILIT Power Systems oil spray

GB600860 ELAN 4 electro oil spray adapter

GB692R ELAN 4 electro rinsing device

GB698R ELAN 4 electro rinsing adapter

GB718R ELAN 4 ECCOS holder for 12 burrs

GP111R–

GP243R

ELAN 4 tools (1 ring), reusable

GP301R–

GP397R

ELAN 4 tools (2 ring), reusable

GP398SU

GP399TC-SU

ELAN 4 tools (2 ring), single use

TA014442 Gebrauchsanweisung für ELAN 4 electro Handstück

Standard (1-Ring) GA861 bis GA864 / ELAN 4 electro

Handstück HD (2-Ring) GA865 bis GA869 (A4 für

Ringordner)

TA014443 Instructions for use of ELAN 4 electro Standard hand-

piece (1 ring) GA861 to GA864 / ELAN 4 electro HD

handpiece (2 ring) GA865 to GA869 (leaflet)

Art. no. Designation Class

GA861–

GA864

ELAN 4 electro Standard handpiece (1 ring) IIa

GA865–

GA869

ELAN 4 electro HD handpiece (2 ring) IIa

GP111R–

GP243R

ELAN 4 tools (1 ring), reusable IIa

GP301R–

GP397R

ELAN 4 tools (2 ring), reusable IIa

GP398-SU

GP399TC-SU

ELAN 4 tools (2 ring), single use IIa

Max. power approx. 140 W

Max. torque approx. 2,2 Ncm

Max. motor speed 80 000 rpm

Tool connection ELAN 4 1 ring (GA861 to GA864)

ELAN 4 2 ring (GA865 to GA869)

Applied part Type BF

EMC IEC/DIN EN 60601-1-2

Conforming to stan-

dard

IEC/DIN EN 60601-1

Art. no. Weight Dimensions (∅x L)

GA861 80 g ± 10 % 16 mm x 152 mm ± 5 %

GA862 83 g ± 10 % 16 mm x 177 mm ± 5 %

GA863 87 g ± 10 % 16 mm x 206 mm ± 5 %

GA864 91 g ± 10 % 16 mm x 237 mm ± 5 %

GA865 89 g ± 10 % 16 mm x 176 mm ± 5 %

GA866 95 g ± 10 % 16 mm x 206 mm ± 5 %

GA867 100 g ± 10 % 16 mm x 236 mm ± 5 %

GA868 108 g ± 10 % 16 mm x 276 mm ± 5 %

GA869 118 g ± 10 % 16 mm x 326 mm ± 5 %

17

12.3 Tool speed/Setting

12.4 Short interval operation

12.5 Ambient conditions

13. Disposal

Note

The user institution is obliged to process the product before its disposal, see

Validated reprocessing procedure.

►Detailed information concerning the disposal of the product is avail-

able through your national B. Braun/Aesculap agency, see Technical

Service.

14. Distributor in the US/Contact in Can-

ada for product information and com-

plaints

Aesculap Inc.

3773 Corporate Parkway

Center Valley, PA, 18034,

USA

Adjustable motor direction Clockwise/counterclockwise rota-

tion

Adjustable maximum speed set-

ting

10 000 rpm to 80 000 rpm

Step width for maximum speed

setting

5000rpm

Factory pre-setting for maximum

speed setting

75 000 rpm, right rotation

Ambient temperature 10 °C to 27 °C

Application cycle 30 second application

30 second pause

Max. application cycles ∞at 60 000 rpm

Max. temperature 48 °C

Operation Storage and transport

Temperature 10 °C to 27 °C -10 °C to 50 °C

Relative

humidity

30 % to 75 % 10 % to 90 %

Atmospheric

pressure

700 hPa to 1 060 hPa 500 hPa to 1 060 hPa

Adhere to national regulations when disposing of or recy-

cling the product, its components and its packaging!

The recycling pass can be downloaded from the Extranet

as a PDF document under the respective article number.

(The recycling pass includes disassembling instructions for

the product, as well as information for proper disposal of

components harmful to the environment.)

Products carrying this symbol are subject to separate col-

lection of electrical and electronic devices. Within the

European Union, disposal is taken care of by the manufac-

turer as a free-of-charge service.

18

Aesculap®

ELAN 4 electro Handstück Standard (1-Ring) GA861 bis GA864 /

ELAN 4 electro Handstück HD (2-Ring) GA865 bis GA869

Aesculap®

ELAN 4 electro Handstück Standard (1-Ring) GA861 bis GA864 / ELAN 4 electro Handstück HD (2-Ring) GA8 65 bis GA869

Legende

1ELAN 4 Werkzeugkupplung (1-Ring bzw. 2-Ring)

2Ringmarkierung

3Stecker für Motorkabel

4Schieber für Werkzeugentriegelung

5Symbol des Anwendungsteil-Typs im Display der ELAN 4 electro Steu-

ereinheit

6ELAN 4 Werkzeug (1-Ring bzw. 2-Ring)

7ELAN 4 Einmal-Sprühdüse für 1-Ring- bzw. 2-Ring-Handstück

ELAN 4 ECCOS-Halterung für 12 Fräser GB718R

8Seitliche Griffe

9Haltenasen

10 Werkzeugaufnahme

11 Lasche

Symbole an Produkt und Verpackung

Vorsicht

Wichtige sicherheitsbezogene Angaben wie Warnhin-

weise und Vorsichtsmaßnahmen in Gebrauchsanwei-

sung beachten.

YYYY-MM

Instandhaltungskennzeichen

Hinweis auf den nächsten empfohlenen Instandhal-

tungstermin (Datum: Jahr-Monat) bei der internatio-

nalen B. Braun-/Aesculap-Vertretung, siehe Techni-

scher Service

Maschinenlesbarer zweidimensionaler Code

Der Code enthält eine eindeutige Seriennummer, die

zum elektronischen Einzelinstrumententracking ver-

wendet werden kann. Die Seriennummer basiert auf

dem weltweiten Standard sGTIN (GS1).

Herstelldatum

Sterilisation durch Bestrahlung

Nicht zur Wiederverwendung im Sinne des vom Her-

steller festgelegten bestimmungsgemäßen Gebrauchs

Verwendbar bis

Chargenbezeichnung des Herstellers

Seriennummer des Herstellers

Bestellnummer des Herstellers

Temperaturgrenzwerte bei Transport und Lagerung

Luftfeuchtigkeits-Grenzwerte bei Transport und Lage-

rung

Atmosphärendruck-Grenzwerte bei Transport und

Lagerung

LOT

SN

REF

Other manuals for Aesculap

3

Table of contents

Languages:

Other B. Braun Personal Care Product manuals

Popular Personal Care Product manuals by other brands

American Standard

American Standard Enfield 2-PC Elongated Toilet 2860.330 installation instructions

mychway

mychway MS-21R2 user manual

Danish Care

Danish Care Epi-Care free Instructions for use

Winco

Winco 5851 manual

Carmen

Carmen CB3085 manual

bort medical

bort medical Sport 104 660 SP Instructions for use