12 © Baader Planetarium GmbH | 2019 13

Instruction manual: Baader Diamond Steeltrack®

All BDS: adjusting the drawtube to align

with the optical axis of your telescope

Baader Diamond Steeltrack®(BDS) focusers are unique in their ability to be ne-aligned (collimated),

enabling critical users to achieve accurate alignment, or ‘squaring-on’ of the focuser to the optical

axis. This is particularly useful for imagers who require the imaging plane to be accurately square

to the optical axis in order to produce sharp stars out to all corners of their images. Critical users

of SCT telescopes will also nd this alignment capability useful, to give them the necessary degree

of freedom to nally achieve accurate alignment of the focuser axis to the optical axis (alignment of

the focuser axis to the center of the secondary mirror).

Every BDS focuser is perfectly precision aligned at our factory to be square to its mounting base.

Most users will nd that this nominal alignment is sufcient to give very good performance with

most commercially produced telescopes and that adjustment of the focuser alignment is not nee-

ded or desired. This is particularly the case for visual observers, where precise squaring-on of an

eyepiece is not needed nor even detectable.

Warning, please note:

• The following adjustment procedure is provided for those users who require an accurate alignment

(‘squaring-on’) of the focuser to the optical axis. We do not recommend it for most visual uses.

• Before attempting any adjustment, we recommend that you rst read through these instructions

completely in order to familiarize yourself with the process.

• Adjusting a focuser can be very tricky. We recommend always making only small adjustments /

turning screws by a small amount in order to be able to gradually home in on the perfect setting.

Too large adjustments will give rise to a result that is uncontrollable.

• Right at the beginning of the procedure, you should rst take note of the force required to pull

out the focuser tube against the existing contact pressure. This force should not be substantially

exceeded to avoid damaging the mechanism.

• During the rst adjustment procedure, no heavy accessories should be attached – the focuser

tube is loose and could slip out. Once you are familiar with the procedure and you know how

the focuser behaves you can dare to leave your camera on the focuser while adjusting. Please

note that Baader Planetarium will not be held responsible for damages to your equipment due

to slipping of the drawtube.

• All BDS focusers have been designed so strong to carry heaviest loads without danger to any

of the components. We are convinced that any damage done to bearings or drive mechanism

represents a clear sign of improper handling. In general screws should never be tightened too

rmly as mechanical parts, such as bearings, could be subjected to high loads and thereby

destroyed. Such treatment may void the warranty and result in costly repairs.

Please read the following thoroughly and only proceed with the alignment procedure if you

feel well informed about what you are doing.

Tools Required:

1. Metric Hex Keys (2mm, 2.5mm, 4mm)

2. Collimation Tool: We recommend the use of a collimation tool to monitor changes in focuser

adjustment and to attain accurate alignment of the focuser axis to the optical axis. A laser colli-

mator such as the Baader Mark III LaserColliTM (#2450343) is ideal for this purpose (RT/NT only).

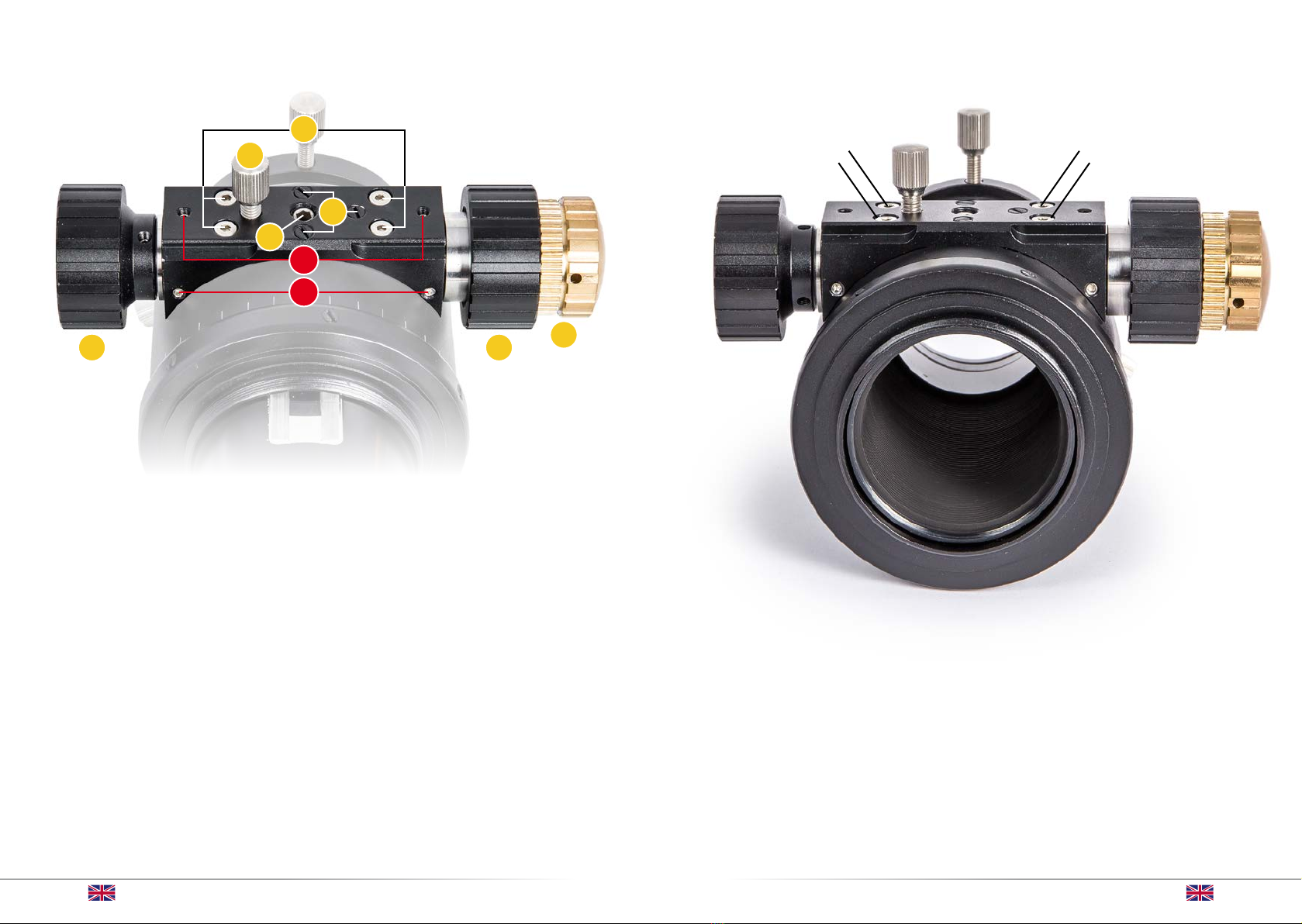

Adjustment procedure:

Screws marked No.8 are holding the bearing block in place which fastens all four roller-bearings.

These two screws are the pivot point for the bearing block. Screws no. 6-9 are the bearing adjust-

ment screws we are aiming at for this instruction. The focuser is set to a certain pressure. Tightening

down the adjustment screws will increase the pressure even more. So before you tighten something

you always must at rst release pressure at the other side (means: when you for instance tighten

screws 5+7 or 4+6 at the same time, you must first release the screw 8 at the same side).

Up and Down

A: Shifting the drawtube up on the CCD side and down on

the telescope side:

• Loosen screws 4 and 5 by ½ turn

• Tighten screws 6 and 7 by ½ turn

B: Shifting the drawtube down on the CCD side and up on

the telescope side.

• Loosen screws 6 and 7 by ½ turn

• Tighten screws 4 and 5 by ½ turn

Sideways

(This is not very handy to do as the up and down positi-

on will always simultaneously change slightly. Only VERY

slight changes should be made)

C: Shifting the drawtube sideways to the left

• Loosen screws 4 and 7 by ¼ turn

• Tighten screws 5 and 6 by ¼ turn

D: Shifting the drawtube sideways to the right

• Loosen screws 5 and 6 by ¼ turn

• Tighten screws 4 and 7 by ¼ turn

More adjustment typically is not necessary. We recommend not to change the factory centering.

Nevertheless it is possible (as shown below). If you feel comfortable with what you are doing, you

can change the entire center position of the drawtube which we had set as factory setting. This may

only become necessary if your lens is not perfectly centered with your mechanics to a large degree.

Centering can be checked by putting a star in the center of your chip and rotating the focuser. If the

star circles on the chip your focuser is not fully centered to the lens. You may be able to tilt the lens

with the tip tilt screws. However, many scopes do not offer this possibility. Therefore the BDS offers to

displace the entire drawtube to a very small degree, for nding the new optical/mechanical centerline.

You should make small iterative adjustments rather than doing one BIG change and ruin the hole adjust-

ment beyond return. Carefully watch out to not have the drawtube scratch against the outer housing.

Lifting/Lowering drawtube in parallel to the

focuser housing

E: Lifting the whole drawtube up

• Loosen screws 4-7 as well as 3.2 by ½ turn

• Tighten screws 3.1 by ½ turn as well as screws 2 and 1

by ¼ turn, then fasten screws 8 and 3.2 hand tight

Then check if every screw except 1 is tight and fasten it

hand tight if necessary. Check the lifting force and adjust

screw 2 until the payload does not slip if in vertical position.

F: Lowering the whole drawtube down

• Loosen screws 8, 3.1 and 3.2 by ½ turn as well as

screws 2 and 1 by ¼ turn

• Tighten screws 4-7 by ½ turn, then fasten all other

screws except 1 hand tight

Then check if every screw except 1 is tight and fasten it

hand tight if necessary. Check the lifting force and adjust

screw 2 until the payload does not slip if in vertical position.

In case the optimum adjustment has not yet been achieved, you should repeat the procedure. After

a short time, you will develop a feel for the interaction of the various adjusting screws. In each case,

make sure not to continue increasing the pressure in the same direction without relieving it in the

opposite direction accordingly, in order to avoid damage to the mechanics.

AB

BA

4 6

5 7

CD

DC

8

E E

FF

3 .1

3.2

2

1

4 6

8

5 7