Flintec DSB7-7.5T Instruction sheet

MSB Flintec 26 November 2014

These guidelines provide guidance for the safe installation and operation of Flintec load cells.

Installations should be carried out by suitable qualied engineers.

Please read this manual carefully.

Chassis-body mounted

on board weighing load cells

Trucks, Agricultural Machines

and Axle Weighbridges

DSB7 7.5t & 15t Load Cell

Installation guidelines For use onboard trucks and machines

7.5 Tonne (16500 Lbs) capacity

15 tonne (33000 Lbs) capacity

MSB Flintec 26 November 2014

Contents

1. Introduction&Weighingsystemoverview

2. Accuracy,Performance&Applications

3-4. Installationstyles

4. Cableorientation

5. Preparation

6-10. Body-ChassisAlignment&Installation

11. Weldingprocedure

12. Torquevaluesandxingselection

13. Installationexamples,axle,sidebody-railmount

14. Technicalspecicationanddimensions

15. Cable,connectorsandcableinstallation

16. Routinemaintenance&Installationchecklist

MSB Flintec 26 November 2014

Introduction

Disclaimer

Wereservetherighttomakechangestotheproductscontainedinthismanualinordertoimprovedesign,performance

andreliability.

Theinformationinthismanualisbelievedtobeaccurateinallrespectsatthetimeofpublication,butissubjectto

changewithoutnotice.Flintecoritsdistributorsassumesnoresponsibilityforanyconsequencesresultingfromtheuse

oftheinformationprovidedherein.

TheFlinteconboardmountedloadcellisahighlyadvancedelectronicmeasuringdevice.Weightismeasuredbyload

cellsinstalledbetweenthebodyandthechassis.Theseruggedloadcellsarestrongenoughtoprovideyearsofreliable

service,yetaresensitiveenoughtodetectachangeinweightofjustafewkilos.Duetodifferencesfromapplication

toapplicationtheremaybesomesignicantassemblyvariations.Theinstallationprocessisvirtuallythesamewhether

itisbeingperformedasaretrotortoanewvehicleormachine.Itisextremelyimportanttofollowtheseinstallation

guidelinesandusethespeciedmaterialstoensurethatthecompletedassemblywillmaintainitshighstrengthfor

maximumsafety.Itwillalsoresultinminimuminstallationcosts,highaccuracyandlonglifeforyourweighingsystem.

WARNING

Failuretofollowtheseinstructionscouldcauseahazardousoperatingcondition.Uponcompletionoftheloadcell

installation,youoranappropriatelytrainedserviceengineerwillneedtoinstallaweighingindicatorandcalibratethe

system;Calibrationissimplyanelectronicadjustmentofthescaletocompensateforminuteinstallationvariations.

Completeinstructionsfortheseprocedurescanbefoundintheweighingindicator'soperator’smanual.

Installationmustbeinaccordancewithnationallawsandregulations.Aninstallationchecklisthasbeenprovidedinthe

backofthismanual.Pleaserefertoitduringinstallationandcheck-offtheimportantstepsastheyarecompleted.

1

Weighing system overview

Flinteconboardweighingsystemsareidealforindustrialweighingapplicationsandsuitableformeasuringeithergross

vehicleweightorthenetweightofcargobeingloadedordelivered.Thebasicsystemconsistsofload-supporting

transducers(loadcells)andanelectronicmeter(weighingindicatorordisplay)capableofbeingcalibratedtodisplay

theweightinconvenientlbsorkgs,electricalcablingconnectingtheloadcellsandindicator:seediagrambelow.

FRONTNEARSIDELoadcell REAROFFSIDELoadcell

Truckbody

FRONTOFFSIDELoadcell REAROFFSIDELoadcell

JunctionBox

4,60r8PortsAvailable

WeighingIndicatororCPU

vehiclemanagementsystem

InputChannel1

AnalogueLoadCells

PowerInput

Typically9-30VoltsDc

FromIgnitionSystem

Typicalfourcell

arrangement

Typically4,6or8DSB7cellsarefttedto3.5-50tonnesgrossweightvehicles.

MSB Flintec 26 November 2014

2

Applications

Installationsaretypicallyaccomplishedbyseparatingthebodyframefromthechassisortrailerframeandinstalling

loadcellsbetweenthesetypicalvehiclestructures;

Accuracy and Performance

ThismanualisprimarilyconcernedwiththemechanicalinstallationoftheFlintecDSB77.5tonne(16500Lbs)and

15tonne(33000Lbs)capacitytruckloadcellsandcables.Pleaserefertotheappropriateoperator'smanualforthe

installationanduseoftheindicator.Optimumonboardweighingperformanceisobtainedwhentheloadcellsare

installedbetweentheload-carryingbody(compactorbody,tipperbody,box,tank,atbed,etc.)andthevehiclechassis

andcarryingtheentireweightofthesuperstructureandpayload.Noweight-supportingstructureotherthantheload

cells,suchasbracesorgussetsshouldattachthesuperstructuretothechassis;thiswillresultinanalternateload-path

thatwilldegradeweighingsystemaccuracy.Typicalapplicationsinclude:wastetrucks,tippers,tankers,atbedsand

vantypestructuresmountedoneithertruckchassisortrailers.Truckbodiesandpayloadsaresupportedabovethe

chassiswithloadcellsmounteddirectlytothetruckframe(seeexampleillustrationsbelow)areusuallyaccomplished

byseparatingthesuspensionsubframefromthetrailerframeandinstallingloadcellsbetweenthesestructures.

Tipping Trailer

Under-bodytippingarrangement

Tipping Trailer

Frontendtippingarrangement

Loadcell

Loadcell

Loadcell

Loadcell

Loadcell Loadcell Loadcell

Chassis

4 Axle Rigid Fixed Body

Waste/Garbagetruck,boxedtruck

Loadcell Loadcell

Chassis

2/3 Axle Rigid Fixed Body

Waste/Garbagetruck,boxedtruck

Loadcell Loadcell

Chassis Chassis

Loadcell Loadcell

4 Axle Rigid Tipping Body 2/3 Axle Rigid Tipping Body

Loadcell

Agricultural machines

Loadcell

LoadcellLoadcell

Agricultural machines

MSB Flintec 26 November 2014

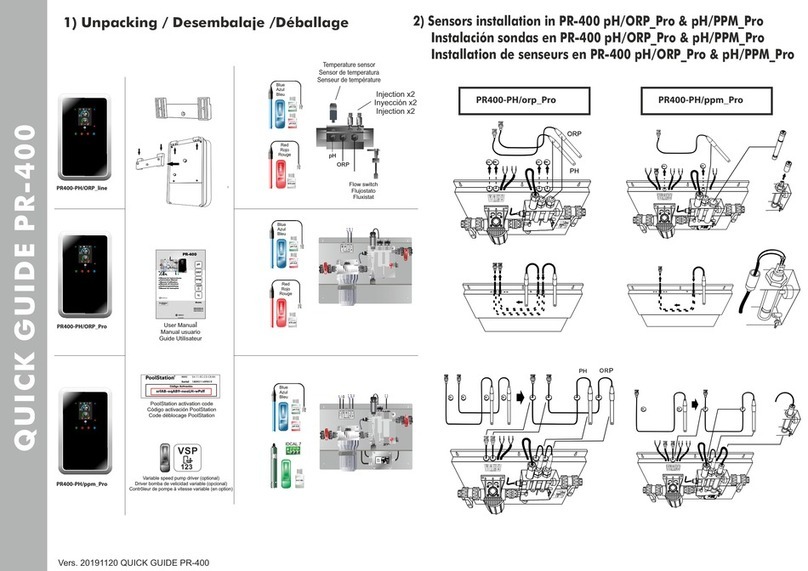

Installationstyles

Mounting Styles:

Twobasicmountingstylesareusedforinstallingchassismountedonboardweighingloadcells:thein-linemountand

theout-boardmount.

Out-board mounted load cell

Anout-boardmountedloadcellisinstalledalongsidetheframemembersusingbracketslocatedout-boardofthechassis

andbodyframerails.Shownherearebothboltedandweldedmethodsofattachmentthetop&bottomloadcellbrackets.

Bodysuperstructure

framemember

Chassissuperstructure

framemember

Mountingangles

(providesadditional

strength)

Spreader/coverplate

3

Topwelded

mountingbracket

Bottomwelded-on

mountingbracket

Topbolted

mountingbracket

In-line mounted load cell

Anin-linemountedloadcellisinstalledbetweentheangesoftheupperbody-railandlowerchassisframeandalignedwith

thoseframemembers.Loadspreadingplates,sometimescalledcoverplates,sh-platesoranglesectionsarefrequently

usedtospreadtheloadoveragreaterarea.Achassisorbodysubframemayberequiredwherethebodyispronetoexing.

Bottombolted-on

mountingbracket

Chassissuperstructure

framemember

Bodysuperstructure

framemember

Framestiffener

(gussetorrib)

MSB Flintec 26 November 2014

Considerationssuchasavailablespace,tyreclearanceandrestrictionsforoverallvehicleheightwillgenerally

determinewhichmountingstylewillbeused.Thefollowingchartillustratesthefeaturesofeachmountingstyle:

Themostcommonpositionforloadcellmountingistopositiontheloadcellsothatthespacerblocksareunderneath

theloadcell.However,installationcansometimesbesimpliedbyinvertingtheloadcellandinstallingwiththebearing

platesabovetheloadcell,especiallywhencombinedwiththeoutboardmountingstyle.Anairgapisrecommendedto

preventthebuild-upofdebrisbeneaththeloadcell.

Cable Orientation

Theloadcellcanbeorientatedsothatthecableconnectorislocatedoneithertheoutboardorinboardsideofthe

loadcell.Outboardlocatedcableexitisgenerallymoreaccessibleforinstallationandservice,butmayneedacover

plateforprotectionfromroaddamage.Inboardfacingcableexitprovidesimprovedprotectionforthecable.Outboard

mountedloadcellsgenerallyhavelimitedaccessforinboardfacingcableexit.Forthisreason,inboardfacingcablingis

usuallyusedonlywithin-linemountedloadcells.Connectorprotection;Flintecrecommendsthataprotectivecoverbe

providedtoprotectoutboardfacingconnectorsfromroaddamagesuchasyingstones.

In-line mounting Outboard mounting

Used when outboard clearances or suspension systems means

space is limited Requires space for load cell installation outboard of chassis

Requires only one mounting bracket per load cell Requires an upper and lower mounting bracket per load cell

Will raise the overall vehicle height by approx. 50 mm (2.0") unless

frame is recessed Will raise the overall vehicle height by approx. 15-20 mm (5/8"-3/4")

Mounting holes for the load cell must be added to the body frame

structure Load cell mounting holes are located in the mounting brackets

Allows for either inboard or outboard facing cable connectors Outboard facing cable connector is usually required

4

Out-boardfacing

cablegland

In-boardfacing

cablegland

Typicalbolted-oninstallation.

Anall-weldedinstallationisalso

possible-bothattachmentmethods

areapplicationspecic.

Typical installations.

Don'tallowbolts

toprotrudehere

Minimumairgap:

7.5t=6mm(1/4")

15t=10.00mm(3/8")

MSB Flintec 26 November 2014

Loadcellmountingbracketsareattachedtothesuperstructurebymeansofweldingorbolting.Inordertoprovideforthe

mountingofloadcellsandmountingbrackets(illustratedinlatersections),somemodicationtothesuperstructuremay

berequired.Themodicationsmaybeassimpleasprovidingaatsurfaceforbracketweldingormaybeasextensive

asprovidingarecessintheunderframeforthemountingoftheloadcells.

Modicationtothesuperstructurewillvaryaccordingtothespecictypeofinstallationtobeperformed;whetheritis

foratrailersuspensionsubframeassemblyorfortruckframemountedsystemssupportingentirepayloadcarrying

superstructures.Outboardmountedloadcellsmayonlyneedspacetoweldorboltloadcellmountingbrackets,whileanin-

linemountedloadcellsystemwillneedholesdrilledintheunderframeofthesuperstructurefortheloadcellmountingbolts.

Whenevermakingmodicationstoastructure,caremustbetakentoprovideforboltstrengthandrigidity(stiffness)for

thenishedinstallation.Everystructurewilldeform(bend,twistorsag)toacertaindegreewhencarryingaload.The

installermustensurethatthemodiedstructureisstrongenoughtopreventnotonlypermanent(elastic)bendingso

thatupperstructuralelementswillnotcontactlowerelementsandcreateanalternativeloadpatharoundtheloadcells.

Excessiveframebendingcanbepreventedbyeitheraddinga‘glove’(astructuralsupportingsleeve)totheframe,orby

addingadditionalloadcellsinthatareaformoresupport.

Frame Stiffeners:

Iftheframesectionabovetheloadcellisanopensection,suchasachannelor‘I’beam,webstiffenersarerequiredto

avoidframetwist(seeillustrationbelow).Thestiffenersarelocatedneartheendsofeachbearingplateforinvertedload

cellmounting,orbetweenthemountingholesforloadcellsinstalledwiththebearingplatesbeneaththeloadcells.

Recess Mounting:

Oftenthemostpracticalmethodforinstallingon-boardframemountedscales(particularlywithanin-linemounted

system)withoutanundesirableheightincreaseofthetrailerorbody,istoprovidearecessinthesuperstructureunder

frame.Ageneralrecommendationforthisapproachisshowninthefollowingillustration.Theinstallershouldassurethat

anymodiedstructurewillretainthestrengthandstiffnesspropertiesoftheoriginalstructure.

Preparation

5

Framestiffeners

(ribsorgussets)

10mm(3/8")thick

Coverplateorglove

10mm(3/8")thick

Flange20mm(0.75")thick Don'tallowbolts

toprotrudehere

MSB Flintec 26 November 2014

Body-chassisalignment

Flintecloadcellsaredesignedtobeinstalledbetweenthebodyandchassisofindustrialtrucks.Itisimperative

theloadcellsareinstalledin-linewiththechassisandbodyrailswithnomisalignmentortwistingforces

projectedontotheboltsorfixings.

Alignment:

Becausetheinstallationofloadcellsinvolvestheseparationofthebodysuperstructurefromthesupportingchassis

frame,caremustbetakentoensuretheseparatedelementsareinstalledandinalignment;newbuildorretrots.The

bodymustsitatandloadcellmountingbolt-holesalignwithouttheuseofadditionaltools.e.g.jemmybarsorjacks.

Boltsshouldbeinsertedbyhandandscrewedbyhandpriortonaltighteningwithatorquewrench.

Markingtherelativepositionsontheframeelementsbeforeassemblyisaneffectivemeansofassuringproperalignment.

Alsoensurethestraightnessofframeelementswhencuttingorweldingtopreventundesirablebendingorwarpingduring

assembly.Theuseofasimpleframestiffener(rib,gussetorstiff-back),weldedintoplacepriortomodication,iseffective

forthispurpose.

Mounting Structure:

OptimumperformanceofDSB7isdependentuponasolidmountingbasefortheloadcells.Steelbracketsof

heavyconstructionarerequired.Sincethisisathickersectionthanusuallyfoundontrucks,acoverplatemaybe

necessarytoevenlydistributeforcestoavoidstressconcentrationsandpossiblecrackinginthethinnersectionsofthe

superstructure.Locatingloadcellsintheimmediatevicinityofcrossmembersorotherframestrengthening/stiffening

elementstoprovidemaximumsupportisalsoimportantforprovidingastructurallysoundinstallation,aswellasa

reliableon-boardweighingsystem.Whenseparatingand/oraligningthebodytothesupportingchassisframe,be

carefulwhenre-routinghoses,airlines,fuellinesetc.Someoftheseitemsmayneedtobereplacedbylongeronesto

preventsecondaryloadpathswhichcausepoorweighingperformance.

Theseitemsarealsosusceptibletodamageiftheyarenotofsufcientlengthtoallowforframeseparationorarenot

properlyprotectedatinstallation.Uponcompletionoftheinstallation,lookcloselyatalltheelementsofthemechanical

installationtoavoidproblemswithpinchedwires,rupturedhoses,etc.,especiallyduringtherstoperationofany

movingstructuresuchasadumpbody.

6

Topmountingbracket

Spreaderplate

Bodyrail

Pocketweld

Bracket welded to chassis example

MSB Flintec 26 November 2014

Loadcellmountingbracketinstallationmethodsdifferdependinguponwhetherthesupportingstructureisatruck

chassisoratrailersuspensionsubframe.Truckchassisframesaremanufacturedfromheattreatedhighstrengthsteel,

requiringloadcellmountinganglesorbracketstobeboltedtotheseframes.Trailersubframeshowever,arenotheat

treatedandmountingbracketscanbeweldedtotheseframes.

CAUTION:Reviewtruckortrailerbodyorchassismanufacturer’srecommendationsbeforeweldingtoframe.

Bolting Requirements:

Thestructuralrequirementsfortheloadcellmountingbracketsareaffectedbytheactualweightbeingsupportedby

theloadcellsandbydynamicservicefactorscausedbyroadconditions.Boltedload-carryingbracketsaresusceptible

toslippageifthepropernumberofboltsarenotusedoriftheboltsarenottightenedtotherecommendedtorque.Use

thefollowingcharttodeterminethepropernumberofboltsforboltedinstallations.Refertothechartonpage12forthe

recommendedtorquevalueswhentightening.

Forin-lineinstallations,usetheboltingrecommendationsforhighwayuseregardlessofroadcondition.

FrameRailInspection:Inspecttheframerailstoensuretheyareclean,straightandfreeofcracks,corrosion,pitting,burrsor

anyotherimperfectionsthatmayaffecttheinstallationandtofthemountingangles/brackets,orthestrengthoftheframe.

MountingBracket/AngleInstallation:Setthemountingangles(forin-lineinstallations)ormountingbrackets(foroutboard

installations)inplaceontheframerails.Determineifandwheretheymustbecutorcontouredtoallowclearancefor

existingbolts,rivets,springhangers,etc.,ontheframe.Marktheselocationsonthemountingangles/brackets,allowing

foraminimum25mm(1")radius-nosharpcorners.Removeangles/brackets,trimasrequired,andgrindedgessmooth.

NOTE:Itisnotnecessarytocutoutloadcellmountinganglesandbracketsforeasilyremoveditemssuchasfueltanks,

batteryboxes,etc.Theseitemsaresimplyrepositionedorspacedouttoconformtotheaddedthicknessoftheloadcell

mountingangles/brackets.

7

Numberofboltsused

-Topand

Bottombrackets

Maximumloadonloadcells-

normalhighwayuse

DSB77.5t

(16500Lbs)

M12-1.75

DSB77.5t

(16500)

1/2"(0.5")

DSB715t

(33000)

M16-2

DSB715t

(33000)

1/2"(0.5")

3 5,000kg 11000Lbs 5,000kg 11000Lbs

4 7,500kg 16500Lbs 10,000kg 22000Lbs

5 7,500kg 16500Lbs 15,000kg 33000Lbs

6 N/A N/A 15,000kg 33000Lbs

MSB Flintec 26 November 2014

Clampthemountingangles/bracketstightlytotheframe.Besurethattheclearancesandcut-outsarecorrect.Locate

anddrillholespertherecommendationsinthechartonthepreviouspageandbracketdrawingsinthexingsectionon

page12ofthismanual.

NOTE:

Boltholesinmountingstructuresmustbedrilled,notburned.Holesshouldnotbeoversizedmorethan1mmtoensure

asnugtforbolts.Useaminimumofboltsaccordnigtotheguideonpreviouspagepermountingangleorbracket.

Alsolocateboltswithin25mmto38mmofeachendofthemountingangle/bracket.Dothesamefortheedgeofeach

cutoutdeeperthan25mm.

Attachthemountingangle/bracketusingBS/ISO/DINGrade10.9(SAEGrade8)qualitybolts,GradeClocknutsanda

hardenedwasherundereachlocknut.TheboltsmusthaveadiameterofM16(5/8”)minimumfor15tcellsandM12(3/8")

for7.5tcellsandsufcientlengthtoprovideaminimumof3threadspasttheendofthelocknut.Tightenallboltstothe

propertorquevaluelistedinthetableonpage12.Whenweldingbracketstonon-heattreatedframes,usealowhydrogen

processandAWSE7018rodorequivalent.Checkthelengthsofallconnectionsforitemsthathavebeenmovedduring

theinstallationofthemountingangles/brackets.Theseconnectionsmayincludebatterycables,fuellines,airlines,and

electricalcables.

8

Framemountingbolts

Chassisframe(rail)

Chassisframe(rail)

Out-board installation

In-line installation

MSB Flintec 26 November 2014

Assembleuppermountingbracketstotheloadcellsusingthexingkitswhereprovided,(forin-linemountedsystems

wheretheloadcellsboltdirectlytotheupperframestructure,simplymounttheloadcellassembliestotheupper

frame).Makesurethexingsaretheproperlengthanddonotbottomoutinthetappedholes.Ifthemountingboltsare

toolong,damagetotheloadcellsispossible.Adangerousoperatingconditioncouldexistiftheboltsarenotsecure.

Placetheloadcellassembliesonthevehicleframemountingbracketswhichwereinstalledin‘FramePreparation’.

Adjusttheloadcellassembliesintotheirnalposition,verifyingtandclearanceswiththesuperstructure.Boltor

welduppermountingbracketsecurelytothesuperstructureusingalowhydrogenprocessandAWSE7018rodor

equivalent(DONOTWELDBEARINGPLATESYET).See‘CAUTION’onpage10beforeproceedingwithwelding.Lift

thesuperstructureandremovethetemporaryspacers.

Theloadcell/uppermountingbracketassembliesarenowreadytobeinstalledonthesuperstructure.Todothis,place

temporaryspacersusually20mmto25mm(3/4"-1")onthevehicleframetoprovidetheproperspacingbetweenthe

superstructureandthevehicleframe.Lowerthesuperstructureontothesespacers.Besuretocheckthesuperstructure

forproperalignmentwiththevehicleframe.

Weldassemblytobodyframealong

threesides&plugweldthroughholes

Uppermountingbracket

(outboardmount)

Topmountingbolts

Temporaryspacerblock

9

Spacerblocks

(seepage14fordimensions

-squareplateissufcient)

Loadcelluppermounting

bracketassembly-

(weldedorbolted)

MSB Flintec 26 November 2014

Thesuperstructurewiththeloadcellassembliesattachedisnowreadytobesecuredtothevehicleframemountingand

angles/brackets.Lowerthesuperstructuresothattheloadcellbearingplatessitintheproperpositiononthevehicle

framemountingangles/brackets.Checktheproperalignmentbetweenthesuperstructureandthevehicleframe,and

checkallbearingplatesforcontactwiththeframemountingangles/bracketsshimanygapsgreaterthan1.5mm(1/16").

Caution:

BearingPlateWelding:Pleasereadtheweldingproceduresonthefollowingtwopagescompletelybefore

proceeding.Theweldingofthebearingplatesisthemostcrucialstepintheinstallationprocess.

Takeprecautionstoensurethatthevehicleelectricalsystemisnotdamagedbythewelding.Topreventelectrical

currentowthroughtheloadcell,attachgroundstrapdirectlytothestructureonthesamesideoftheloadcellon

whichweldingisbeingdone.

Completetheattachmentofthesuperstructure/loadcellassemblyinthefollowingorder(inaccordancewiththe

weldingproceduresonpage11):

1. Tackweldthebearingplatestothemountinganglesorbrackets.

2. Removetheslagfromtacksand‘feather’endoftackwithagrindertoprovideasmoothtransitionfortheroot

topassasitpassesthroughthetack.Weldingcanbecompletedwithoutdisassemblyofloadcellsfrombearing

plates.Directelectrodeawayfromunprotectedundersideofloadcell.

3. Alternateweldsfromside-to-sideandend-to-endtoavoidwelddistortion.

10

Chassisframerail

framemember

Weldloadcellbracketsinplace(seecaution

below,andweldingprocedureonpage11before

proceedingwithwelding)

Bodysuperstructure

framerail

Bottomwelded-on

mountingbracket

Topbolted

mountingbracket

Bracket welded to chassis example

MSB Flintec 26 November 2014

Weldingprocedure

Thefollowingprocedureguidesthewelderthroughtherecommendedproceedureforweldingbracketsandbearing

platestoframemembers.

WARNING:Allwelding,metalworking,andassemblymustbeperformedbyaqualiedpersonusingpropertoolsand

safeworkhabits.Whenwelding,useaprocedurethatassuresasound,goodqualityweld.Overweldingmaycause

distortionanddamage;underweldingmaynotdevelopsufcientstrength.

CAUTION: Takeprecautionstoensurethatthevehicleelectricalsystemisnotdamagedbythewelding.Attachground

strapdirectlytovehicleframemember(notloadcellbody)towhichthebearingplatesarebeingweldedtoprevent

electricalowthroughloadcell.

Welding Process:UsealowhydrogenprocessandAWSE7018rodorequivalent.Thebearingplatemaybewelded

usingSMAWstick,GMAWspraytransfer,orFCAW.TheusershouldnotuseGMAWshortcircuittransfer.

WeldConguration:Thebracketplatesshallbeattachedusingasingleormultipasslletweldsequence

DepositedWeldMetalFilletSizes:Thenishmultipasslletassemblyshallbeaminimumof8mm(1/3”).

Preheat:Thebearingplateandthebasemetalmountingsurfaceshallbewarmedinpreparationforweldingto

reduceshrinkagestress.Anysuitabletorcharrangementissatisfactory.Spotheatingshallbeavoided.Thepreheat

temperatureshallbeaMINIMUMof20°C(68°F)andaMAXIMUMof65°C(150°F).

Cleaning Before Welding:

Bracketcomponentsandbearingplatesshallbevisuallyinspectedtoverifythatthereisnooil,grease,dirt,paintorother

foreignsubstancethatwillreducetheweldquality.Weherebracketsareweldedtothebodyand/orchassis,mounting

surfacesshouldbepreparedusingandanglegrinderorpowerwirebrushtoremoveallpaint,primer,orothersurface

coating.Anareathesizeofthebearingplateplus25mm(1")shouldbecleanedandgroundtobarebasemetal.

In process Cleaning:

Eachlletshallbevisuallyinspectedwithallslagcoverremoved,beforeproceedingwiththenextbead.Astiffwire

brushorneedlescalermaybeusedforslagremoval.

Final Inspection:

LongservicelifedependsonqualityapplicationofthelletweldsandTHEFINALSIZEOFTHEFILLET.Thereshall

benoundercutoneithertheupperleg(onthebearingplate)orthelowerleg(framebasemetal).Anyundercutshall

berepairedwithanadditionallletorcontouredbygrindingtoremovethemechanicalnotch.Visuallyinspectallweld

stopsandstarts.Weldcratersshouldbelled.Allweldstopsshallbestaggered.Alightcoatofprimerandpaintmay

beappliedafternalinspection.PeriodicInspection:Theseprimaryloadcarryinglletweldsshouldbeinspected

duringroutinemaintenance.

11

WARNING:

HEATFROMWELDINGMAYLOOSENBOLTS.THEREFORE,

ALLTORQUEVALUESSHOULDBERECHECKEDAFTER

INSTALLATIONWHENALLWELDSHAVECOOLED.

MSB Flintec 26 November 2014

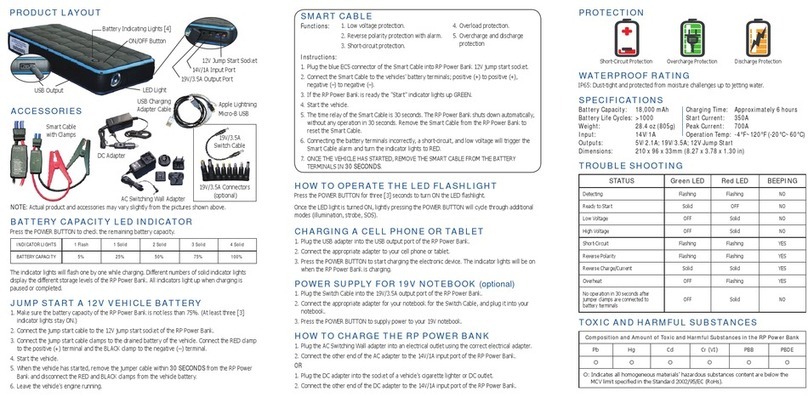

Torque values and xing selection

Torquevaluescanvarysignicantlydependinguponthelubricationofthreads.Thefollowingvaluesarebasedonnew,

cleanthreadsin'asreceivedcondition'withoutadditionallubrication.Flintecrecommendstheuseofathreadlubricant,such

asLocktite767orequivalenttopreventtheseizingofthreadsoveralongperiodoftime.Thesetorquevaluescanbeused

forboltswiththislubricantwithoutover-stressingbolts.AllframeboltsaretobeISO/DIN961grade10.9(orSAEGrade8),

alllocknutsGradeC.Usenewxingsatalltimes.Forloadcelltopandendboltswhereloadsarelikelytoreach100%ofits

ratedcapacityandinhighdynamicapplicationssuchasagriculturalaxlesusegrade12.9,(SAEgrade9)usegrade10.9

(SAEgrade8)forallotherapplications.Aminimumof14turnsor28mm(1-1/8")threadengagementisrecommended.

Flexible Mounts -Wheresolidrubberand/orpolyurethaneblocksaretted,ensure28mm(1-1/8")minfor15t

cellsand22(7/8")mmminfor7.5t.ofthreadengagementintoloadcellsandthatanti-rotationdevicessuchastab

washersorNordlockwashersareused.

Application Fastener size Grade Tightening torque

Framemountbrackets

7.5t(16500Lbs)

3/8"16TPIUNF SAE8 37-44FtLbs

M12-1.75(standard) 8.8 90-110

M12-1.75(standard) 10.9 100-120(Recommended)

Framemountbrackets

15t(33000Lbs)

5/8"11TPIUNF SAE8 180-212FtLbs

M16-2(standard) 8.8 200-215Nm

M16-2(standard) 10.9 285-305Nm(Recommended)

DSB77.5t(16500Lbs)

Topandendbots

M16-1.5(ne) 10.9 300-315Nm(Recommended)

M16-1.5(ne) 12.9 350-380Nm(High&dynamicloads)

DSB715t(33000Lbs)

Topandendbolts

M24-2(ne) 10.9 1000-1100Nm(Recommended)

M24-2(ne) 12.9 1200-1300Nm(High&dynamicloads)

12

Socket Head Cap Screw

Fullthreadfromendtobolthead.

Suitablefortheendandtopxings.

Washersnotnormallyneeded.

Allowstheheadtoberecessedintothebracketry.

Hexagon Head Screw

Fullthreadfromendtobolthead.

Usewasehers.

Suitablefortheendandtopxings.

Suitableforframemountxings.

Hexagon Head Bolt

Straightshank-partthreadfromendtobolthead.

Usewasehers.

Strongestxing.

Suitablefortheendandtopxings.

Suitableforframemountxings.

Flat Countersunk Socket Cap Screw

Fullthreadfromendtobolthead.

Suitablefortheendandtopxingswhereloadsarelowto

moderatesuchasaweighplatform.

Washersnotnormallyneeded.

Suitableforframemountxingswherecosmeticsandavailable

spaceistight.

Idealwhereatopplateneedtobeushtting

ThexingsintotheDSB7loadcellaremetriconly:M16-1.5(ne)andM24-2(ne)metricxingstoISO/DIN961are

widelyavailableinvariouslengths,checkwiththeFlintecsalesteamsforavailabilityofstockedxings.

Fixings - TherearemanyapplicationsfortheDSB7onawidevarietyoftrucksandmachines.Mountingstyles,bracket

designandchoiceofxingsaretoonumeroustocovereverypossibilityinthisdocument.Thefollowingxingtypes

givesinstallersachoiceoftechniquesandchoiceofxingsforagivenapplication.Factorssuchasappliedforces,

availablespace,xingavailabilityandcosmeticsallcontributetothechoiceofxing.Threadrolledboltsarethe

preferedchoiceinmostcases.Fixinglengthsdependonthicknessofbracketplatesdeployed.

Example xing styles

MSB Flintec 26 November 2014

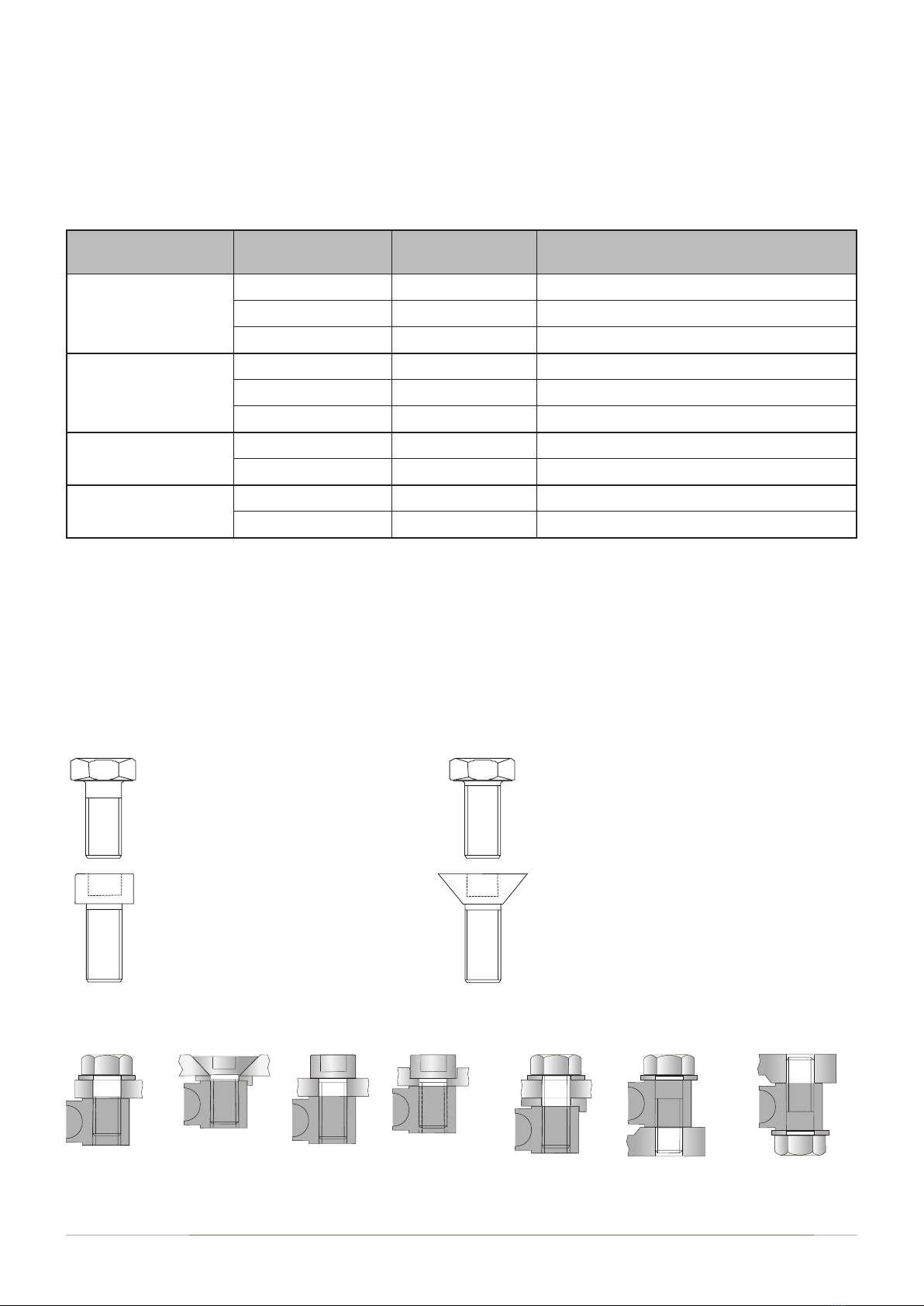

Installation mounting techniques - axles and axle beams on agricultural machines

13

l In-line

l Bolted to body

l Top and end spacers

l Welded body stiffeners

BODYRAIL

AXLE

or

BEAM

BODY

l Outboard

l End spacers

l Bolted to body rail

l In-line

l Welded ribs

l Load cell inverted

l In-line

l Top spacer

l Welded ribs

l Outboard

l No spacers

l Bolted to body

l Load cell inverted

l In-line

l No spacers

l Welded to body

l Load cell inverted

l Plug welded upper body brackets

l Outboard

l Welded to body

l Load cell inverted

l Load cell on axle beam

l Plug welded upper body brackets

l Outboard

l Bolted to body

l Load cell inverted

minimumairgap:

7.5t=6mm(1/4")

15t=10mm(3/8")

Don'tallowbolts

toprotrudehere

MSB Flintec 26 November 2014

14

DSB 7 footprint dimensions

DSB7 - 7.5T

(16500 Lbs)

DSB7 - 15T

(33000 Lbs)

mm Inch mm Inch

L1 200 7.87" 310 1.22"

L2 96 3.78" 160 6.30"

L3 29 1.14" 40 1.57"

C1 171.5 6.75" 270 10.63"

C2 67.5 2.65" 110 4.33"

H30 1.18" 40 1.57"

H1 0.5 0.02" 2.5 0.09"

W40 1.57" 54 2.13"

T1 M16X1.5 M16X1.5 M24X2.0 M24X2.0

D17-18 0.67"-0.7" 25-26 1"-1.0.4"

X42 1.67" 56 2.20"

Y20 0.79" 30 1.18"

Y1 36 1.42" 48 1.90"

Y2 42 1.65" 54 2.13"

Z6 0.24" 8 0.32"

Z1 12 0.5" 14 0.55"

Optional spacer-canbeaat

squareifpositionedin-linecarefully.

Y2

X

Y

Y1

ZZ1

D

L3 L3

L2

L1

C1

C2

H

4xT1

Optionalspacer

D

D

Specications DSB7 - 7.5 t DSB7 - 15 t

Rated 0utput (RO) 2.0 mV/V ± 1 % at 7.5t 2.0 mV/V ± 1 % at 15 t

Zero balance ≤ ± 0.2 %*RO (or better)

Combined error ≤ ± 0.15 %

Ultimate overload 300 %

Excitation voltage 5...10 Vdc

Input impedance (RLC) 800 ± 50 Ω

Output impedance (Rout) 700 ± 2 Ω

Insulation resistance (100 V DC) ≥ 5 000 MΩ

Operating temperature range °C–30...+70

Stainless steel 17-4 PH

Fully hermetically sealed IP68 up to 2 m (6-1/2") water depth

Protection according EN 60 529 Cable jacket PVC 4 core unshielded cable (AWG 24)

Cable length 5 m, longer or shorter on request

Connector M12 4-pin

Cable diameter 5.5 mm (0.22")

12-15(0.5-0.6")

10-12(0.4-0.47")

NottoScale

8mm

(0.32")

llet

H1

H1

W

12-15(0.5-0.6")

MSB Flintec 26 November 2014

15

MALEplug

mouldedplugconnector

Moulded 4-pin M12 Connector with 5 meters (16.5 ft) of cable

Pin1 Brown +Excitation 5VoltsDC

Pin2 WHITE +Signal millivoltsfromthejunctionbox&loadcells

Pin3 BLUE -Excitation 0Volts

Pin4 BLACK -Signal millivoltsfromthejunctionbox&loadcells

SIGNAL channel 1 & 2, load cell plug is MALE. Cable plug is MALE

Note,wheretheM12connectorisnotrequired,simplycuttheconnectoroff

anduseanalternativeconnectionmethod.

TheIP65modularM12electricalconnectorsystemisaquickandeasywaytowire-up

onboardweighinginstallations,itsavestimeandcutsdownonmistakes.Together,

witharangeofversatileinputs,combinationsofloadcells,sensorsandtransducers

tosuitthousandsofapplicationsarestraightforward.Powerandsignalconnectors

arekey-wayed,genderedandthumbtightened.

Junction boxes

Junction(splitter)boxesareinternallywiredinparallelforanaloguesystemsand

serialforCANOpensystems.4,6and8wayjunctionboxeshaveFEMALE

signalsockets&MALEindicatorcablesockets.

Extender cables & Junction box to indicator cabeles

Onboardweighingloadcellsandextensometershave5metercable

completewithmoulded4-pinM12MALEcableasstandard.Male-Female

extendercablesforlongerreachapplicationsareavailablein1,2,3,5,7.5

&10metrelengths.A2into1‘Y’cableisavailabewheretwoloadcellare

deployed.

Rewirable 4-pin

M12 Connectors

(alsoknownaseldattachments)

MALE

Wirablewithcablegland

CableInstallation

Flinteccablesarespeciallydesignedtoprovidemaximumsignalstrengthand

highreliability.SubstitutionofcablingotherthanFlintecsuppliedcablingmay

causeinconsistentanderraticreadings.Careshouldbetakenwhenrouting

cabletoprovideprotectionfromsharpedges,drivelinerotation,exhaustpipe,

oranyotherpotentialdamage.Secureinplacewithcabletiestoasnugt.

Assemblyofthecableconnectortothejunctionboxandindicatorshould

notbeforced.Alignthe'keyways'andinsertthecableconnector.Asthe

cableconnectorisbeinginserted,rotatethethreadedsleeveclockwise

untilhandtight.Ensuretheconnectorhasbeenfullyinsertedformaximum

moistureprotectionbywrigglingtheconnectorandretighteningthesleeve.

Cable, connectors and cable installation

MSB Flintec 26 November 2014

Installationchecklist

Mountinganglesorplaceshavebeeninspectedforburrs,inconsistenciesandtrueness

Frameshavebeeninspectedandareingoodcondition

Surfacesforloadcellmountingblocksarerigidandhavebeenreinforced

Checkallbearingbracketwelds(seeweldingprocedurepage10)

Checkallboltsaretorquedtospecications(seepage12)

Checkallconnectorsareproperlyinsertedandtightened

Checkallcablesareroutedandsecuredinprotectedareasoftheframe

Indicatorinstallation:seeIndicatorOperatorsManual

Systemcalibration:seeIndicatorOperatorsManual

RoutineMaintenance

Toensureyouronboardweigheroperatessafelyandaccuratelyfollowthesefourperiodicsteps:-

1. Inspectallweldforsignsofcrackingorcorrosion

2. Retightenallfastenerstospeciedtorquevalues

3. Inspectcableandconnectorsfordamage,tightnessandcleanliness

4. Cleantruck/trailersuziconnectors

16

Flintec Group AB

W4/5 Capital Point, Capital Business Park

Wentloog Avenue, Cardiff, CF3 2PW - UK

Tel +44 (0) 29 2079 7959

Fax +44 (0) 29 2079 7939

www.intec.com

This manual suits for next models

1

Table of contents

Other Flintec Accessories manuals