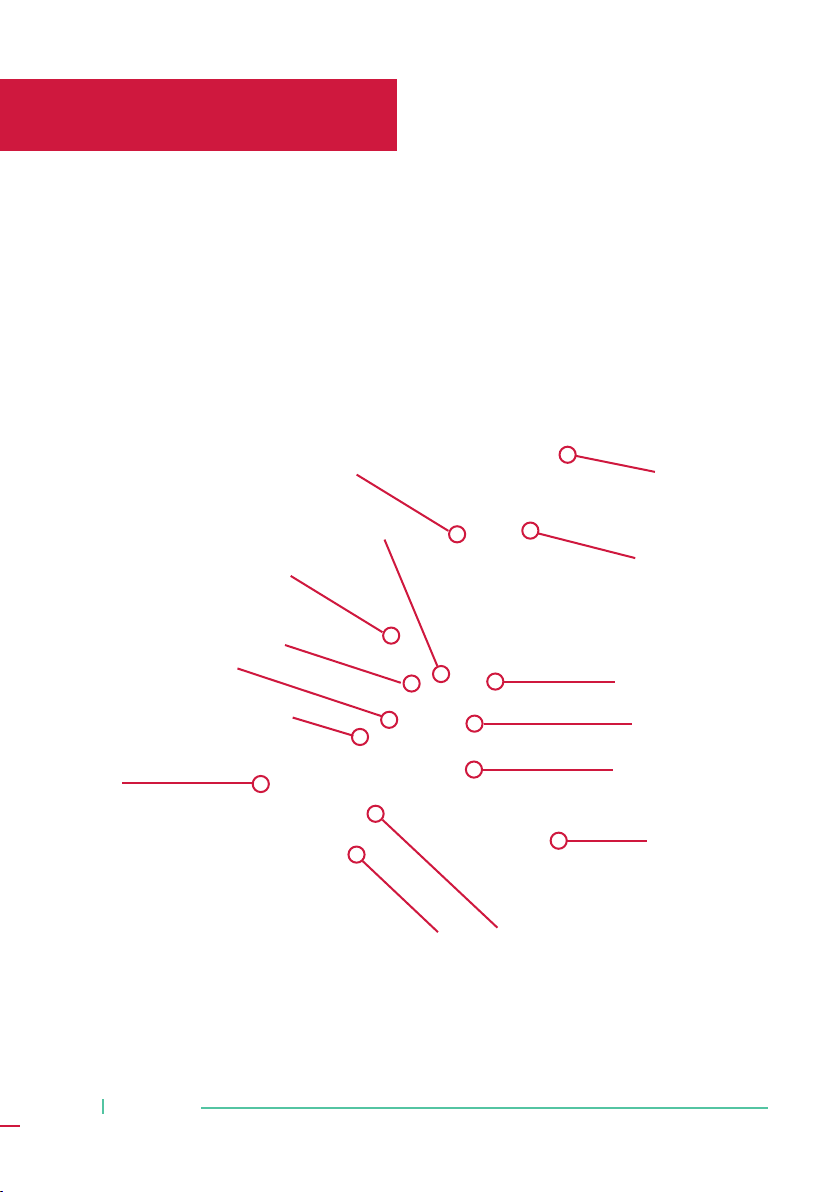

Paper Inlay diameter = Foil diameter

Always cut the paper clean and round, preferably with a

circle cutter or a paper punch.

Basically, you CAN also use other, thicker or thinner paper or other

material, for example fabric, wrapping paper, even leaves, etc... The

thing is, we simply cannot guarantee you that it will work out. We

can not give you a universal recipe to make a 100% perfect button

anyway. You cannot make any damage , so don`t worry. Just try

it out!

There are some tricks how you will be able to use the material any-

way. For example, by cutting it out to a smaller diameter (so that it

doesn‘t have to be crimped), by placing an additional paper inlay

underneath, or by using the foil and then peeling it off the finished

button later.

Illustration: Paper used is too thick

08

The Paper Inlay

80-90g strong „normal“ copy paper

English

IMPORTANT: BEFORE YOU START