3 Technical Description

3.1 Intended Use

Thes::canmicro::stationandnano::stationaredesignedforonlinemonitoringofwaterqualityparameters.The

requiredcomponents(probes,sensorsandoperatorterminal)aremountedwiththerequiredowcells,mounting

ttingsandpipeworkonacompactpanel.Thestationscanbeusedforrawwater,drinkingwater,tapwaterand

cleansurfacewater.Forwastewaterandwaterwithhighamountofparticlesaspecicmicro::stationwithlarger

pipeworkandowcellsforwastewaterisavailable.

Inalltypesofapplications,therespectiveacceptablelimits,whichareprovidedinthetechnicalspecicationsin

therespectives::canmanuals,havetobeobserved.Allapplicationsfallingoutsideoftheselimits,andwhichare

notauthorisedbys::canGmbHinwrittenform,donotfallunderthemanufacturer’sliability.

Thedevicemustonlybeusedforthepurposedescribedinthismanual.Useinapplicationsnotdescribedinthis

s::canmanual,ormodicationofthedevicewithoutwrittenagreementfroms::can,isnotallowed.s::canisnot

liableforclaimsfollowingfromsuchunauthoriseduse.Insuchacase,therisksarethesoleresponsibilityofthe

operator.

3.2 Functional Principle

All s::can stations are equipped with an inlet and outlet and designed for continuous discharge of the water

throughthedierentowcells.Aninletstrainerwillpreventparticlesfromenteringthestationandaowrestrictor

ensurescorrectpressureanddischarge.Aowdetectoralarmswhentheowistoolow.Thewaterleavesthe

stationpressure-free(freeatmosphere).Withthehelpofashut-ovalveaftertheinlet,theowcanbecompletely

shutoincaseofserviceactivities.

Optionalthestationcanbeequippedwithananalogpressuresensorandaseperatefeedpump.

3.3 Product

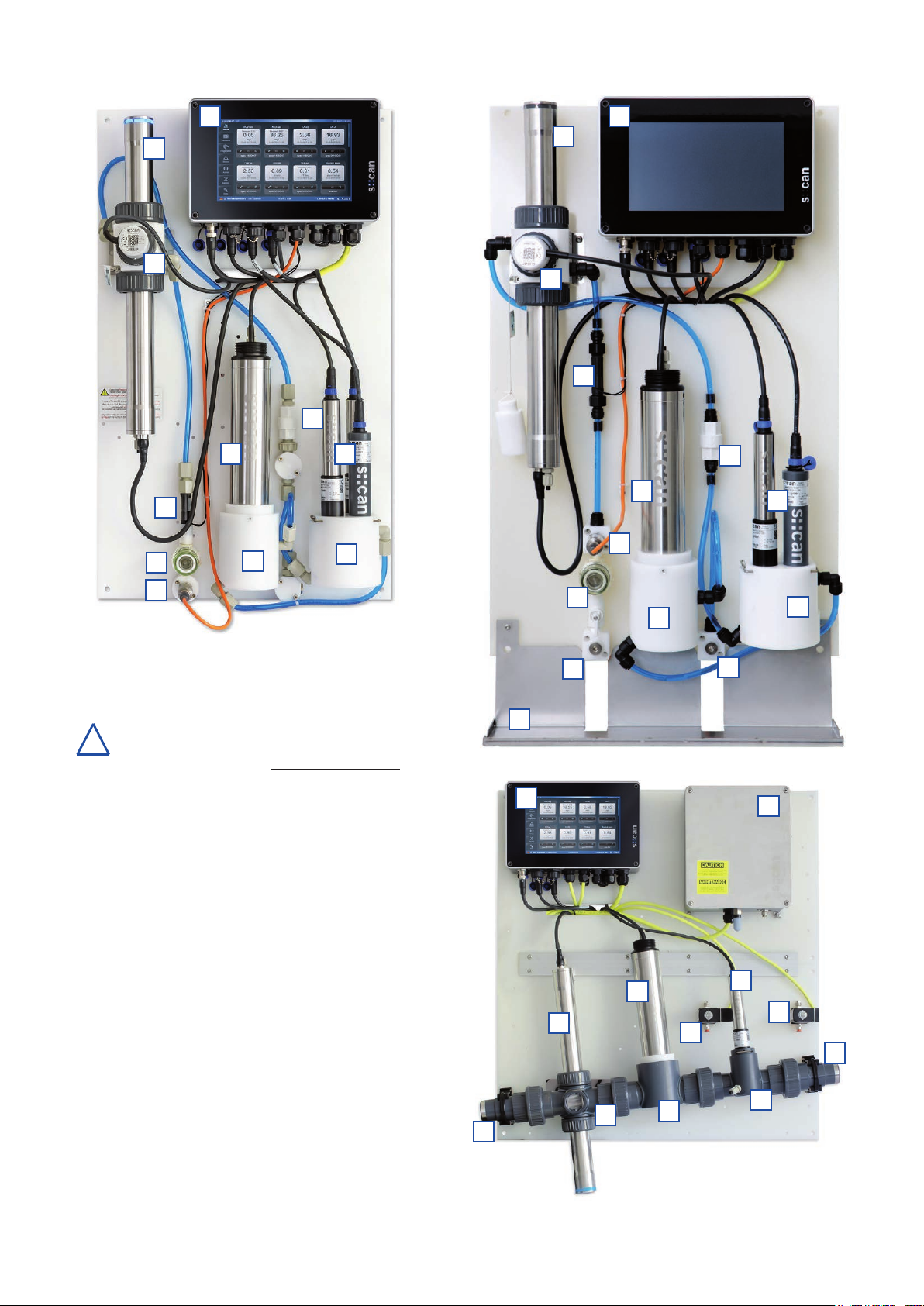

Thefollowingvariantsofcompletelyassembledmonitoringstationsaswellassingelcomponentsofmonitoring

stationsareavailable.Regardingdetailedinformationofthestationspleaserefertosection9(accessories)as

wellasthetechnicalspecicationslocatedattheendofthismanual.Ifneeded,themonitoringstationscanbe

conguredcustomerspecicalso.

Type Specication

M-100-MICRO-S Turbidity,NO3,TOC,DOC,pH,EC,Temp,Alarms,mountedonpanelwith2ow

cells,autobrush,owdetectorandcon::cubeoperatorterminal;eventdetection

software included.

M-100-MICRO-M Turbidity,NO3,TOC,DOC,NH4-N,pH,Temp,Alarms,mountedonpanelwith2ow

cells,autobrush,owdetectorandcon::cubeoperatorterminal;eventdetection

software included.

M-100-MICRO-L Turbidity,NO3,TOC,DOC,pH,EC,Temp,onedisinfectionparameter,Alarms,

mountedonpanelwith2owcells,autobrush,owdetector,andcon::cubeopera-

torterminal;eventdetectionsoftwareincluded.

M-100-MICRO-XL Turbidity,NO3,NO2,TOC,DOC,pH,EC,2disinfectionparameters,Temp.,Alarms,

mountedonpanelwith2owcells,autobrush,owdetector,andcon::cubeopera-

torterminal;eventdetectionsoftwareincluded.

micro::station / nano::station, 03-2023 Release

www.s-can.at

Copyright © s::can GmbH

7 / 36