Due to continuous research, product improvements and enhancements, Badger

Meter reserves the right to change product or system specifications without notice,

except to the extent an outstanding contractual obligation exists.

BadgerMeter, Inc.

6116E.15thStreet,Tulsa,Oklahoma74112

(918)836-8411/Fax:(918)832-9962

www.badgermeter.com

Please see our website at www.badgermeter.com

for specific contacts.

Copyright©BadgerMeter,Inc.2008.Allrightsreserved.

Register Functions

Pulse Count: The pulse count is stored as an unsigned 32bit

integer. This allows for 2^32 pulses (4.2billion) to be counted

beforerollover.OnModbussystemsthatdonotallowyoutoread

32 bit values, you can calculate the pulse count as follows:

count = (MSW * 65535) + LSW

Instantaneous Pulse Rate:The pulse rate values for instan-

taneous, min and max rates are calculated based on the time

betweenarrivingpulses.Forexample,ifInstPulse1=30,and

instpulsecountsizeis5,thentheaveragerateforthelast5

pulses is 6 seconds per pulse. To convert the register values

(in seconds) to a rate value, use the following formula.

RatePerHour=(N*60*60/Inst_Register)

Where InstRegister is any of the 6 register values 4 through 9.

Nistheinstantaneouspulsecountsizeatoffset10.

Min/Max pulse rate: These four registers are calculated from

the instantaneous pulse rate. These latching registers are

updated whenever the minimum or maximum rate fields are

exceeded by the instantaneous rate. These four registers may

beclearedbywritingazerototheregister.Writingtoonemin/

max register clears all four min/max registers.

FIRMWARE UPDATE

Fromtimetotime,BadgerMetermayreleasefirmwareupdates

with additional features and system changes. To find out what

firmware your Badger®Data Industrial®Model 345WT has

installed, read the firmware version register with a Modbus

utility, or use the Advanced Configuration page in the Model

3700setup menu. Firmwareupdateles maybeobtained

from Badger Meter Technical Support.

ThefirmwareupdateprocessrequiresanRS232serialportand

a windows computer to run the firmware update utility. Before

starting this process, verify your computer has a serial port

available. You may need to deactivate other software such as

the palm pilot utility or ups monitor software. USB connected

serial ports may be used, however these are not as fast or reli-

able as standard computer serial ports and may fail to upgrade

the firmware correctly.

To update the firmware, use the following procedure.

Step 1:InstallthePhilipsLPC2000softwareasprovidedby

Badger Meter.

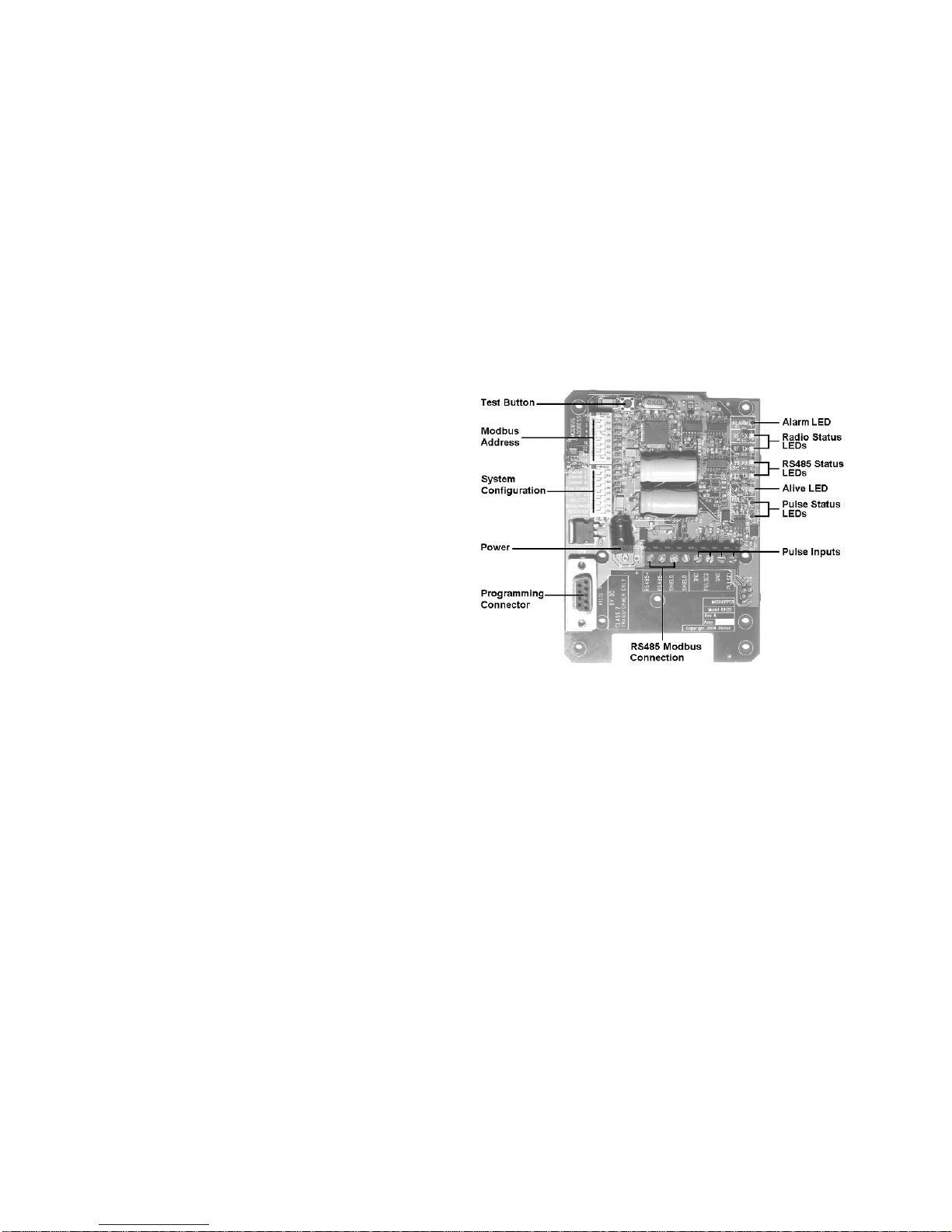

Step 2: Remove power from the Model 345WT. Attach the

Model 345WT to your computer with an RS232 serial

cable. The Model 345WT programming connector is

the 9 pin RS232 connector to the side of the power

jack.

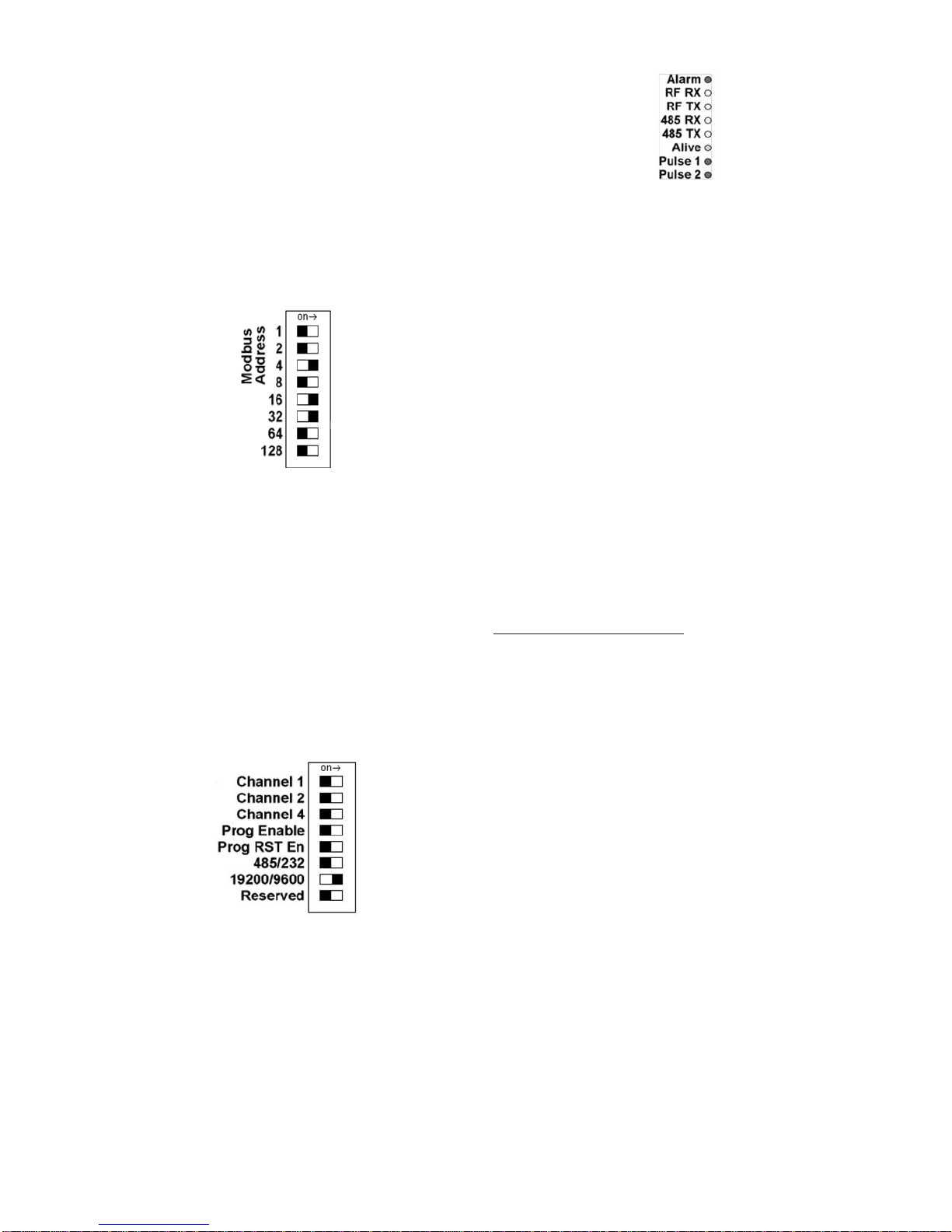

Step 3: Set the following dip switches:

Prog Enable = on

ProgRstEn = on

485/232=on

Step 4: Power up the Model 345WT. The Green Alive LED

should light up and stay on solid.

Step 5:RuntheLPC2000FlashUtility.Thefollowingscreen

will be displayed.

Step 6: Set the following communications options:

COM1 or COM2 depending on your computer

serial port.

Usebaudrate:38400orslower.

Check Use DTR/RTS for Reset

XTALFreq[kHz]=20000

Step 7: Click the Read Device ID button. The PartID

and BootLoaderIDfieldswillbeshownifsuccessful.

Also, the Device dropdown menu should switch to

LPC2124.The bottomofthewindowwilldisplayRead

Part ID Successfully.

Step 8: Click the Filename...button. A dialog box will appear.

Locate and select the Model 345WT firmware image

le.Intheexampleabove,thisisnamedR9120_v1.13b.

hex.

Step 9: ClicktheUpload toFlash button.Thefirmwareupdate

willstart,andablueprogressbarwillbeshownacorss

the bottom of the screen.

Step 10: When the update is complete, disconnect power from

the Model 345WT. Remove the RS232 serial cable.

Turn off the three switches noted in step 3 above.

Prog Enable = OFF

Prog Rst En = OFF

485/232=OFF

Step 11: Powerup theModel345WT.The newfirmwareshould

nowoperate. Toconfirmthenewfirmwareisinstalled,

use the Model 3700 device details page, click the

Configure button, and then the Advanced button.The

firmwareversionnumberwillbedisplayedonthelower

right side of the advanced details page.

Badger®and Data Industrial® are registered trademarks of Badger Meter Inc.