Use and maintenance manual

Circular saw SHARK

INDEX

1.

GENERAL INFORMATION ...................................................................................................................................................... 7

1.1 ABOUT THIS MANUAL ...................................................................................................................................................... 8

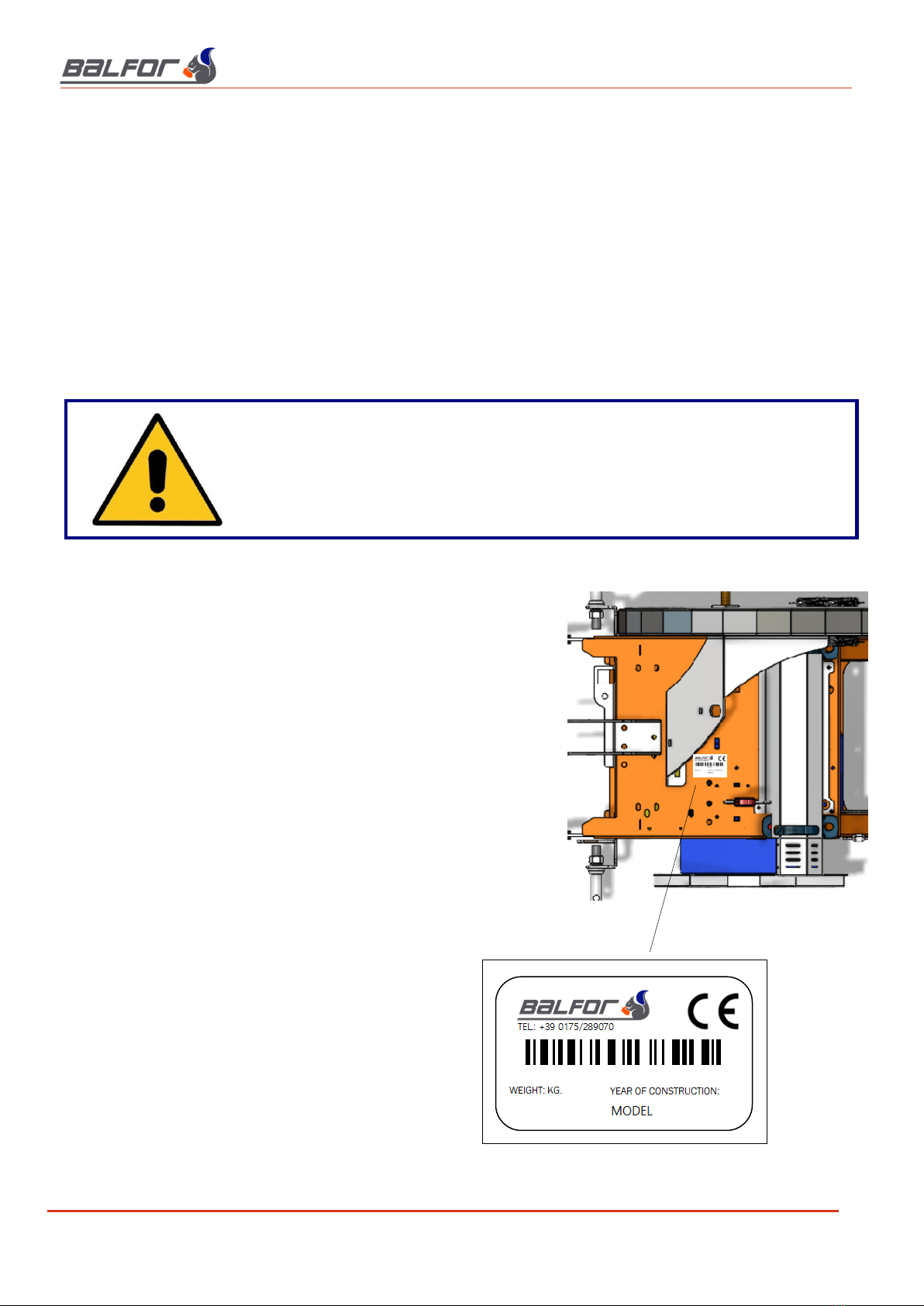

1.2 MACHINE IDENTIFICATION.............................................................................................................................................. 8

1.3 INFORMATION ABOUT THE MACHINE............................................................................................................................. 9

1.3.1 Intended uses.............................................................................................................................................................9

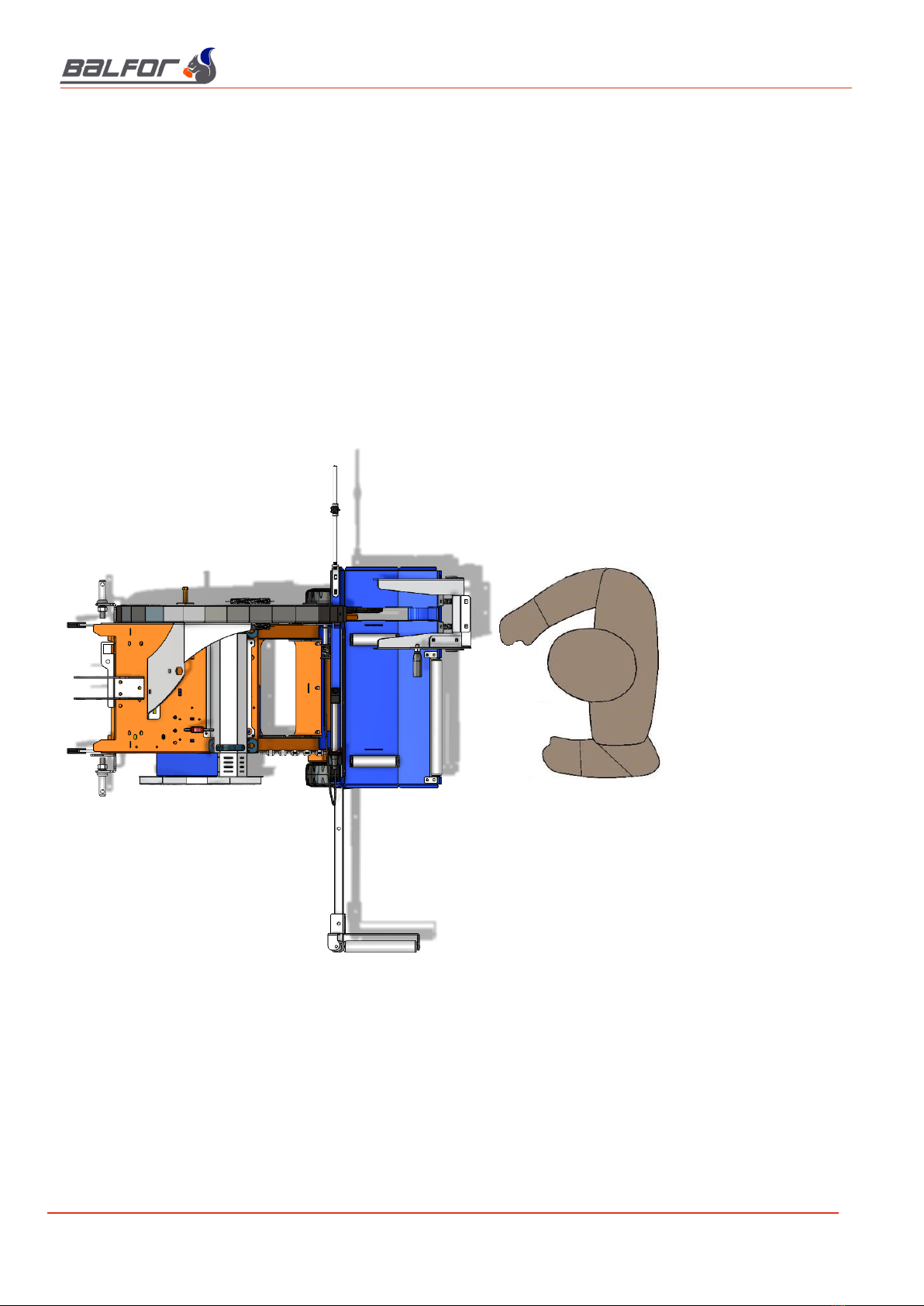

1.3.2 Machine description ................................................................................................................................................11

1.4 COMPONENTS AND TECHNICAL DATA.........................................................................................................................12

1.4.1 Cardan shaft models ...............................................................................................................................................12

1.4.2 Electric models.........................................................................................................................................................13

1.4.3 Internal combustion engine models .......................................................................................................................14

1.4.3.1 SB version ......................................................................................................................................................................... 14

1.4.3.2 SB-ROAD version............................................................................................................................................................... 15

1.4.4 Conveyor belt models ..............................................................................................................................................16

1.4.4.1 Expert version ................................................................................................................................................................... 16

1.4.4.2 Plus / Pro version ............................................................................................................................................................. 18

1.5 NOISE LEVEL .....................................................................................................................................................................21

1.5.1 Vibration level...........................................................................................................................................................22

1.5.2 Dust emission...........................................................................................................................................................22

2SAFETY REQUIREMENTS ....................................................................................................................................................23

2.1 GENERAL SAFETY AND ACCIDENT PREVENTION RULES .............................................................................................24

2.2 SPECIFIC SAFETY REQUIREMENTS...............................................................................................................................26

2.2.1 Cardan models .........................................................................................................................................................26

2.2.2 Electric models.........................................................................................................................................................26

2.2.3 Internal combustion engine models .......................................................................................................................27

2.2.4 Conveyor belt models ..............................................................................................................................................28

2.3 RESIDUAL RISK .............................................................................................................................................................29

2.4 SAFETY SIGNS ...............................................................................................................................................................30

3MACHINE TRANSPORT........................................................................................................................................................32

3.1 CHECKING THE LIFTING CAPACITY AND STABILITY OF THE TRACTOR ........................................................................34

3.2 ROAD CONDITIONS .......................................................................................................................................................35

4CONNECTIONS ....................................................................................................................................................................36

4.1 CARDAN AND CONVEYOR BELT MODELS CONNECTIONS ...........................................................................................36

4.1.1 Connection to the tractor’s three-point hitch .........................................................................................................36

4.1.2 Cardan shaft installation .........................................................................................................................................37

4.1.3 Hydraulic connections (for conveyor belt models only).........................................................................................38

4.2 ELECTRICAL CONNECTIONS .........................................................................................................................................39

5SAFETY EQUIPMENT ...........................................................................................................................................................40

6CONVEYOR BELT (

FOR EXPERT MODELS ONLY

). ..............................................................................................................42

6.1 BELT POSITIONING........................................................................................................................................................42

6.2 BELT CARPET TENSIONING...........................................................................................................................................43

6.2.1 Expert model ............................................................................................................................................................43

6.2.2 Expert Direct Drive model........................................................................................................................................43

6.2.3 Expert PLUS / PRO model .......................................................................................................................................44

6.3 PRE-USE CHECKS..........................................................................................................................................................45

7USE AND OPERATION .........................................................................................................................................................46

7.1 SB-ROAD MODEL...........................................................................................................................................................49