Ballantine 1620A User manual

INSTRUCTION MANUAL

For

MODEL 1620A

TRANSCONDUCTANCE AMPLIFIER

Ballantine Laboratories, Inc.

www.ballantinelabs.com

e-mail: sales@ballantinelabs.com

9 Saddle Rd., Cedar Knolls, New Jersey, 07927, USA

Phone: (973) 984-1900, Fax: (973) 984-1479

90-10296-5CMARCH 2007

CERTIFICATION

Ballantine Laboratories, Inc. certifies that this equipment meets all applicable Ballantine specification

at

time of shipment from the factory as determined by thorough testing and inspection. Ballantine further

certifies that its measurements are traceable to the United States National Institute of

Standards and

Technology. All instruments used in calibrating Ballantine products are standardized by systematic reference

to NIST-traceable Standards äs described in the validation procedures shown

below.

REFERENCE STANDARDS

DC

10 mV –750 V 0.002 –0.003%

20 Hz -50 kHz

0.5 V –500 V 0.004%

20Hz -10 MHz

0.5 V –100 V 0.05%

DC -30 MHz

0.5 V –100 V 0.35%

DC -700 MHz

10 uV –0.5 V 1% -NIST

10 MHz -1000 MHz

1 V –300 V 1% -NIST

WORKING STANDARDS

THERMAL VOLTAGE CONVERTERS, BALLANTINE 1397A

TRANSFER STANDARD, BALLANTINE 1605A

MICROPOTENTIOMETERS, BALLANTINE 440

RATIO TRANSFORMERS, GERTSCH

Ballantine's Quality Assurance program satisfies the requirements of MIL-l-45208.

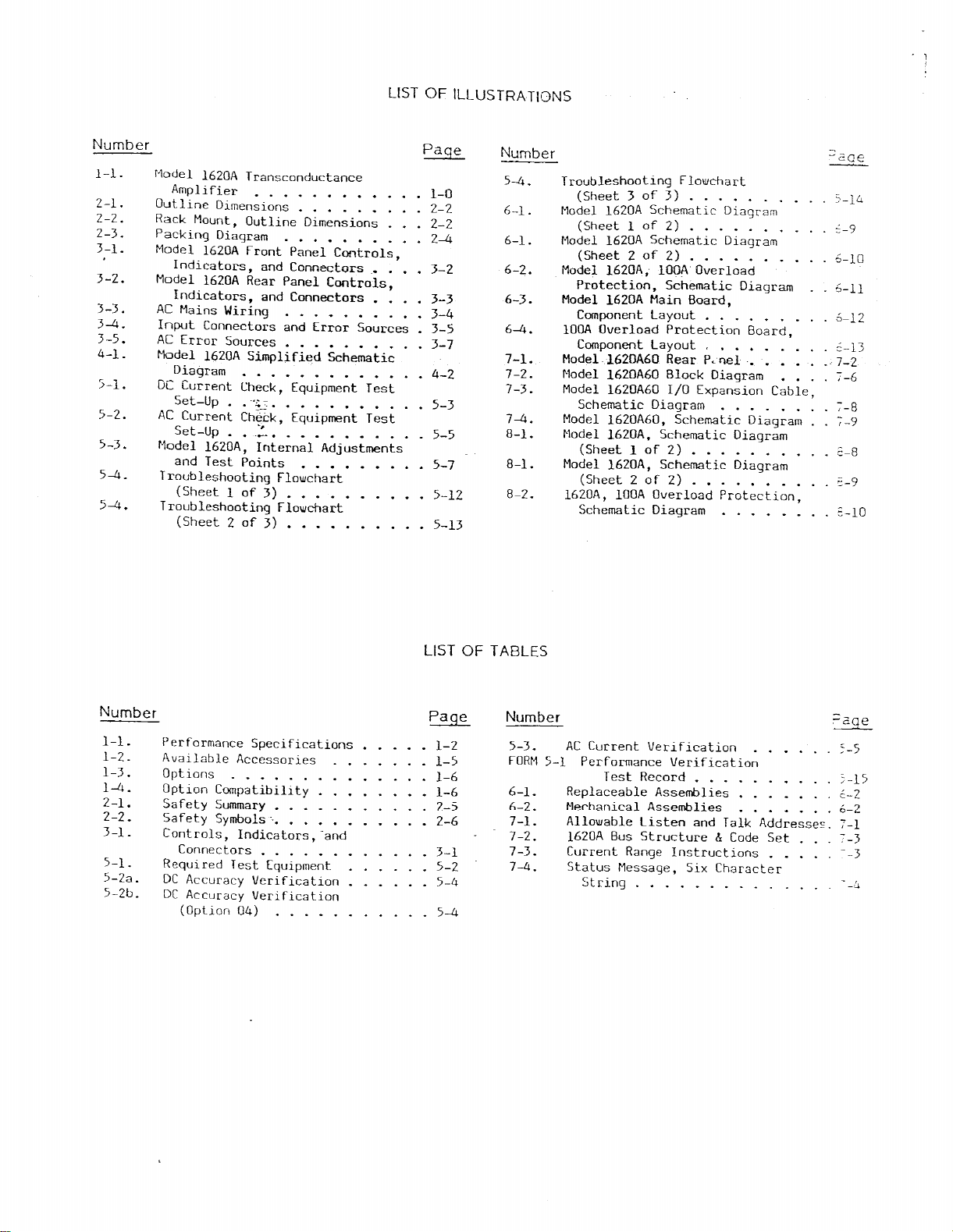

Paragraph Page

SECTION 1

GENERAL INFORMATION

1-1. Introduction ................... 1-1

1-11. Specifications ................ 1-1

1-13. Accessories .................. 1-5

l-16. Options ..................... 1-5

1-18. Instrument and Manual

Identification 1-5

SECTION 2

INSTALLATION

2-1. Introduction ............ 2-1

2-3. Unpacking and Initial Inspection . . 2-1

2-5. Performance Checks ......... 2-1

2-7. Power Requirements ......... 2-1

2-9. Grounding Requirements ....... 2-1

2-13. Installation and Mounting ..... 2-2

2-15. Bench Mounting ........... 2-2

2-17. Rack Mounting ........... 2-2

2-19. Short Term Storage ......... 2-2

2-21. Long Term Storage or Repackaging

For Shipment ........... 2-3

SECTION 3

OPERATING INSTRUCTIONS

3-1. Introduction ................. 3-1

3-3.

Controls, Indicators, and

connectors

.................... 3-1

3-5. Power Requirements ......... 3-4

3-6. Input Voltage ........... 3-5

3-14. Range Selection .......... 3-5

3-17.Output Current Connections ..... 3-6

3-20. Output Current and Load

Consideration ................ 3-6

3-22. Limit Indicators .......... 3-6

3-26. Standby - Operate ......... 3-6

3-28. Error Sources and Application

Limits ..................... 3-6

SECTION 4

PRINCIPLES OF OPERATION

4-1. General .............. 4-1

SECTION 5

MAINTENANCE AND CALIBRATION

5-1. Introduction .................. 5-1

5^4. Required Test Equipment ...... 5-1

5-6. Performance Verification Checks .... 5-1

5-8. Calibration Accuracy Verification .. 5-1

5-9. DC Calibration Check ............ 5-1

5-11. Zero Adjust ............ ....... 5-1

5-16. DC Current Checks ......... 5-1

5-21. AC Current Checks ......... 5-4

5-23. Checking Input Overvoltage ...... 5_4

Paragraph Page

SECTION 5

MAINTENANCE AND CALIBRATION - Cont'd

5-26. Checking Overcompliance

Indicator.... 5-5

5-29. Checking Output Overcurrent Protection 5-5

5-30. Conclusion of Performance

Verification Checks ....... 5-5

5-32. Calibration and Alignment

Procedure. . 5-6

5-34. Removal of Covers ......... ..... 5-6

5-36. Preliminary Inspection ....... .... 5-6

5-38. Internal Adjustments and Test Points . 5-6

5-42. Initial Power Supply Check ..... 5-6

5-43. DC Calibration ........... 5-6

5-44. Front Panel Zero Adj (R26) ..... 5-6

5-48. 200u Range Calibration (RJ8) .... 5-8

5-55. 2A Range Calibration (R52) ..... 5-8

5-60. 200m Range Calibration (R73) .... 5-8

5-65. High Accuracy DC (Option 04) .... 5-8

5-67. 20m Range Calibration (R71) .... 5-8

5-72. 2m Range Calibration (R72)..... 5-8

5-74. 100A Range Calibration (R55) .... 5-9

5-80. 20A Range Calibration (R51) .... 5-9

5-88. 20A Stability Adjustment (C14) ... 5-9

5-94. 100A Distortion Adjustment (R38) . . 5-9

5-104. AC Calibration ............... 5-10

5-111. Troubleshooting and Fault Finding . 5-10

5-115. Fuse Replacement ............. 5-10

5-117. Preventive Maintenance ....... 5-10

SECTION 6

PARTS LIST AND SCHEMATIC DIAGRAMS

SECTION 7

OPTIONS

7-1. Introduction ............ 7-1

7-2. Option 60 ............. 7-1

7-4. Specifications ........... 7-1

7-6. Operating Features ......... 7-1

7-8. Operating Notes .......... 7-2

7-9. Programming Instructions ...... 7-2

7-11. Instrument Control ......... 7-2

7-13. Clear ............... 7-2

7-15. Reset ............... 7-2

7-17. Local Lockout ........... 7-3

7-19. Output Control ........... 7-3

7-21. Output Current ........... 7-3

7-23. Operating Mode ........... 7-3

7-25. Status Response .......... 7-4

7-27. Serial Poll Response . . ...... 7-4

7-29. Pin Assignment For I/O Remote

Expansion . . .......... 7-5

7-30. Theory of Operation ........ 7-5

7-32. Listen Mode . ........... 7-5

7-35. Talk Mode ............. 7-5

7-38. Maintenance . . . . . . . ..... 7-5

7A-1. Option 30 ............... 7-11

TABLE OF CONTENTS

1-0

Figure 1-1. Model 1620A Transconductance Amplifier

Table of contents