Table of Contents

1. Critical Product Notes ......................................................................2

2. Introduction ......................................................................................3

3. New features in the AFR500v2........................................................3

4. Kit Contents......................................................................................4

5. Functional Description .....................................................................4

6. Wiring Installation............................................................................5

6a. Dyno Specific Wiring & Grounding ..............................................6

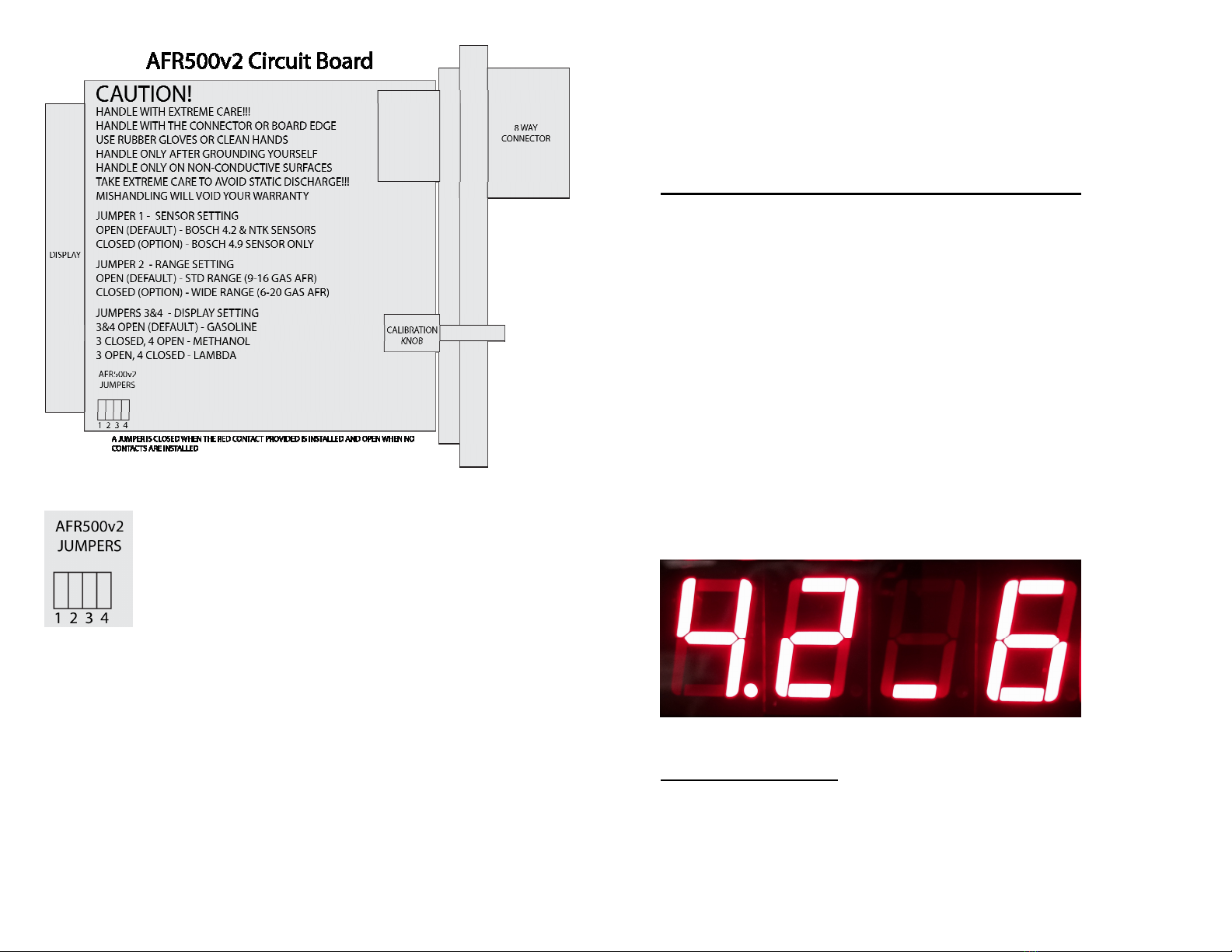

7. Setting & Explanation of Options ....................................................7

8. How to set Jumper Configuration Options.......................................8

9. Display of Configuration Options (Check Settings) ......................10

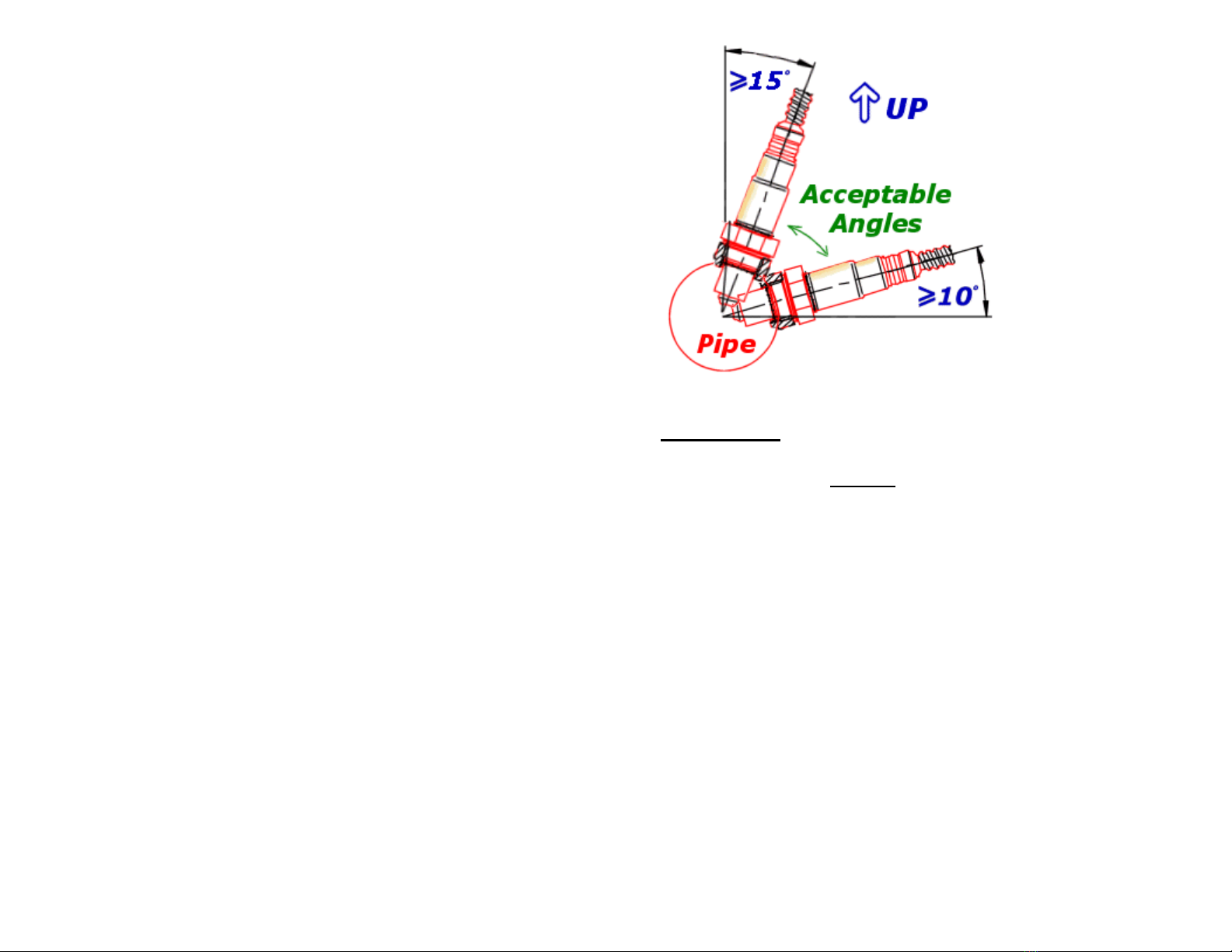

10. Sensor Installation ........................................................................10

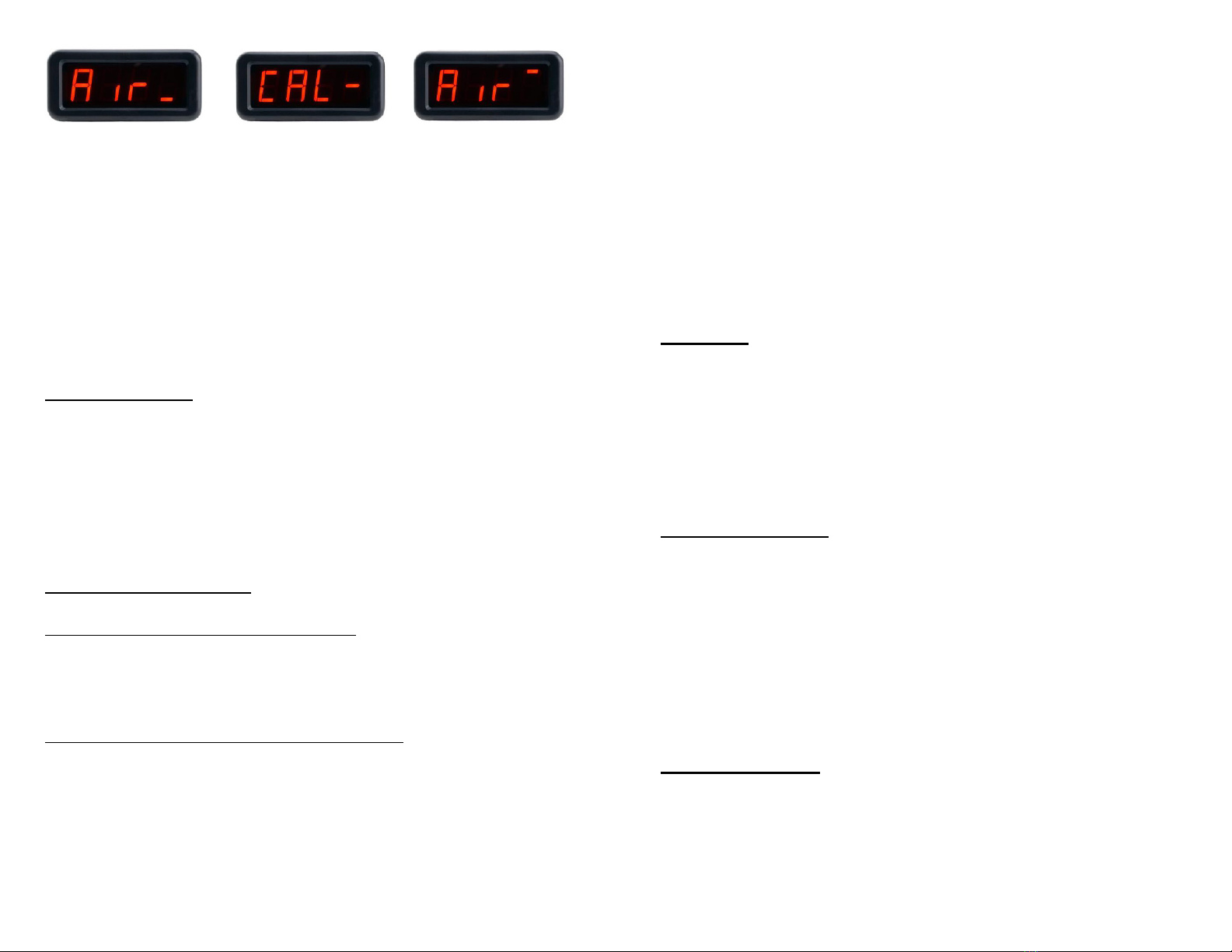

11. Calibration....................................................................................12

12. Analog Output ..............................................................................13

13. Analog Output Values..................................................................13

14. Display .........................................................................................14

15. Compatible Fuels..........................................................................14

16. Troubleshooting ...........................................................................14

17. How to maximize sensor life........................................................16

18. Spare Parts....................................................................................17

2. Introduction

The AFR500v2 is a precision oxygen concentration measurement

system. Unlike conventional oxygen sensors which only work near a

stoichiometric ratio (14.64:1 or 1.00λ), the AFR500v2 uses unique

wideband technology to sense gasoline air-fuel ratios in the range of

9:1-16:1 (0.62-1.10 λ[lambda], 4:1-7.1:1 Methanol) or 6:1-20:1

(0.411-1.373 λ, 2.66:1-8.88:1 Methanol). The system is capable of

working with most fuel types.

3. New features in the AFR500v2

The AFR500v2 is a major iteration on the AFR500. All features &

functions of the original AFR500 remain intact with the added

improvements below:

• Lambda & Methanol AFR display options

• Extreme Range option for FI methanol & laboratory applications

• (0.411-1.373 Lambda)

• (6-20 Gas AFR)

• (2.66-8.88 Methanol AFR)

• Increased display speed

• Bosch LSU 4.9 option

• Faster analog output

• All harnesses, control units, accessories, etc (except the LSU 4.9)

are backwards and forwards compatible

• Options are selectable at any time via internal jumpers

• NTK Calibration grade sensor highly recommended for low AFR

methanol applications

4. Kit Contents

• AFR500v2 Controller

• Wideband oxygen sensor (Bosch LSU 4.2, 4.9, or NTK Sensors)

• 13ft (standard), 7ft, or 24ft wiring harness

• AFR500v2 Tuning Manual

• Weld-in sensor bung

• Screw-in sensor plug

• Adhesive backed hook & loop pair

• 3 red configuration jumper contacts

5. Functional Description

The wideband sensor infers an air fuel ratio relative to the

stoichiometric (chemically balanced) air fuel ratio by balancing the

amount of oxygen pumped in or out of a measurement chamber. As

the exhaust gasses get richer or leaner, the amount of oxygen that

must be pumped in or out to maintain a stoichiometric air fuel ratio in

the measurement chamber varies in proportion to the air fuel ratio. By

measuring the current required to pump the oxygen in or out, the air

fuel ratio (lambda) can be estimated. Note that the measured air fuel

ratio is the output from the AFR500v2 pumping current controller and

not a signal that comes directly from the sensor. Wideband sensors