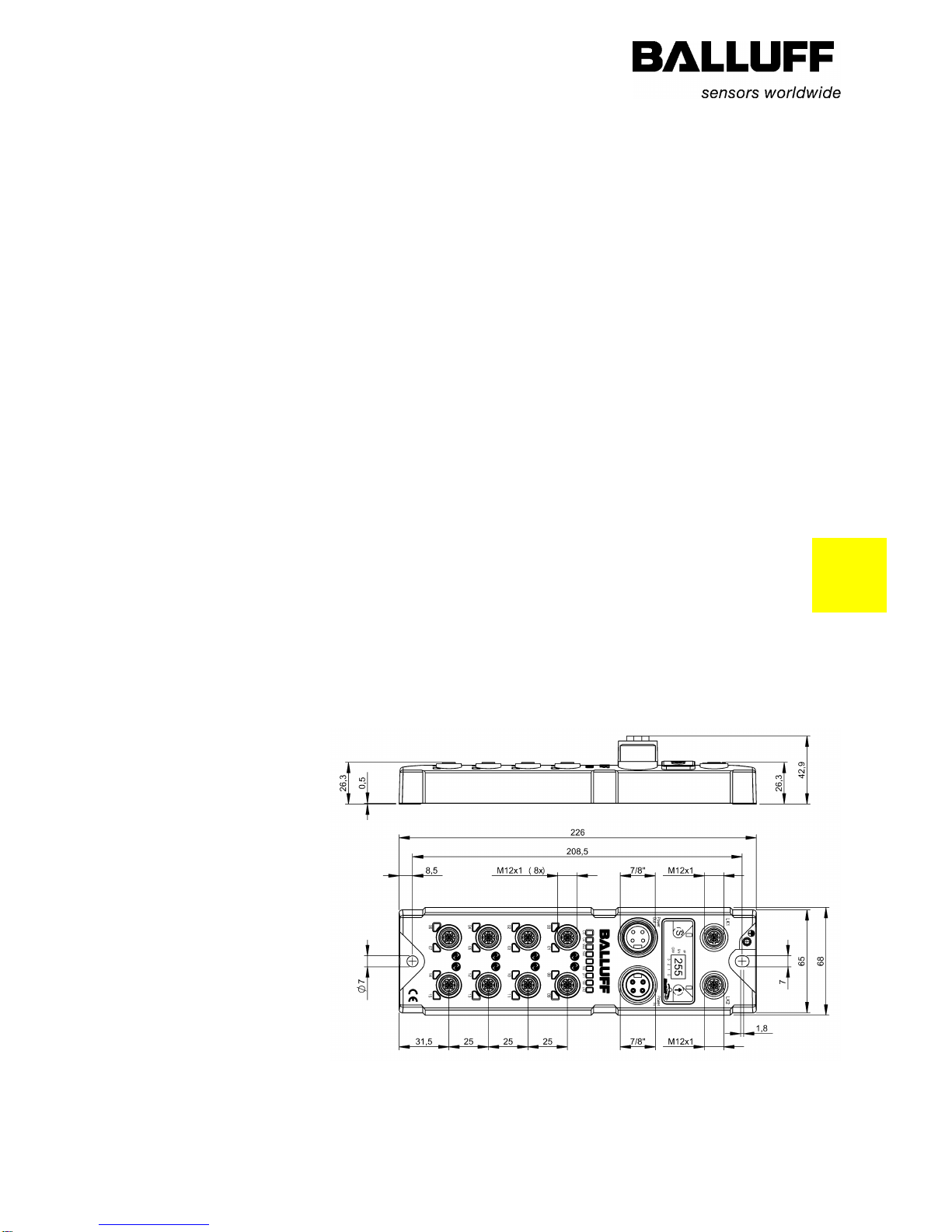

Balluff Network Interface EtherNet/IP™, BNI EIP-50x-105-R015

www.balluff.com

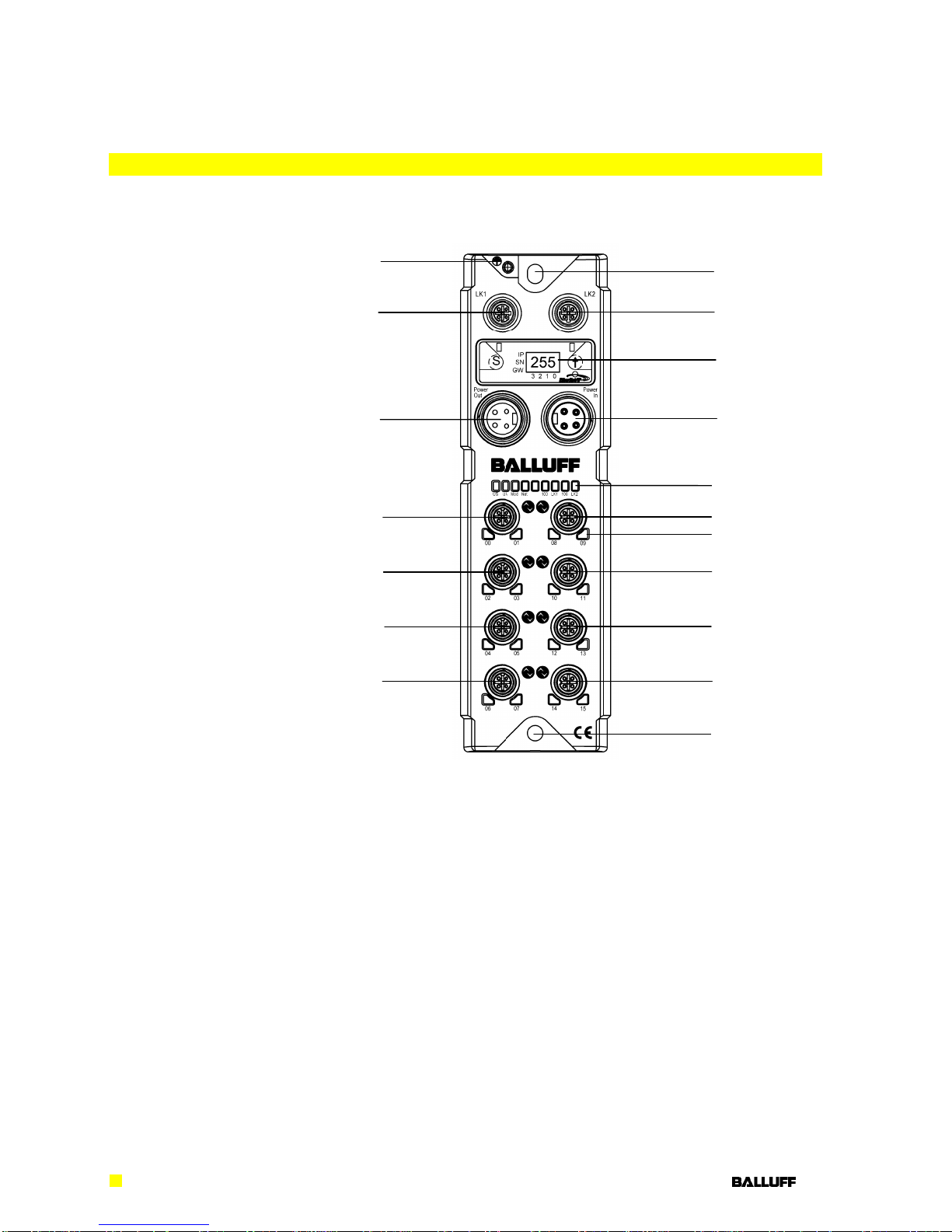

The BNI EIP-… is a decentralized IO-Link, input and output module for connecting to the

EtherNet/IP™ network.

2.2. Installation and

Startup

Note

Installation and startup are to be performed by trained technical personnel only.

Skilled specialists are people who are familiar with the work such as installation

and the operation of the product and have the necessary qualifications for these

tasks. Any damage resulting from unauthorized tampering or improper use shall

void warranty and liability claims against the manufacturer. The operator is re-

sponsible for ensuring that the valid safety and accident prevention regulations are

observed in specific individual cases.

2.3. General Safety

Notes

Commissioning and inspection

Before commissioning, carefully read the User's Guide.

The system must not be used in applications in which the safety of persons depends on the

function of the device.

Intended use

Warranty and liability claims against the manufacturer shall be rendered void by damage

from:

Unauthorized tampering

Improper use

Use, installation or handling contrary to the instructions provided in this User's

Guide.

Obligations of the owner/operator

The device is a piece of equipment in accordance with EMC Class A. This device can pro-

duce RF noise. The owner/operator must take appropriate precautionary measures against

this for its use. The device may be used only with a power supply approved for this. Only

approved cables may be connected.

Malfunctions

In the event of defects and device malfunctions that cannot be rectified, the device must be

taken out of operation and protected against unauthorized use.

Intended use is ensured only when the housing is fully installed.

2.4. Resistance to

Aggressive Sub-

stances

Note

The BNI modules always have good chemical and oil resistance. When used in

aggressive media (such as chemicals, oils, lubricants and coolants, each in a high

concentration (i.e. too little water content)), the material must first be checked for

resistance in the particular application. No defect claims may be asserted in the

event of a failure or damage to the BNI modules caused by such aggressive

media.

Note

Before working on the device, switch off its power supply.

Note

In the interest of continuous improvement of the product,

Balluff GmbH reserves the right to change the technical data of the product and

the content of these instructions at any time without notice.