MOL81 485 1312/MOL81 485 1337

MOL81 485 1312-MOL81 485 1337-UM-1.4-EN

2/20

TABLE OF CONTENTS

1

FOREWORD...............................................................................................................................................................3

1.1

P

URPOSE OF THIS MANUAL

.................................................................................................................................. 3

1.2

D

OCUMENT STATUS SHEET

................................................................................................................................. 3

1.3

N

OTES

.................................................................................................................................................................. 3

2

GENERAL INFORMATION ......................................................................................................................................4

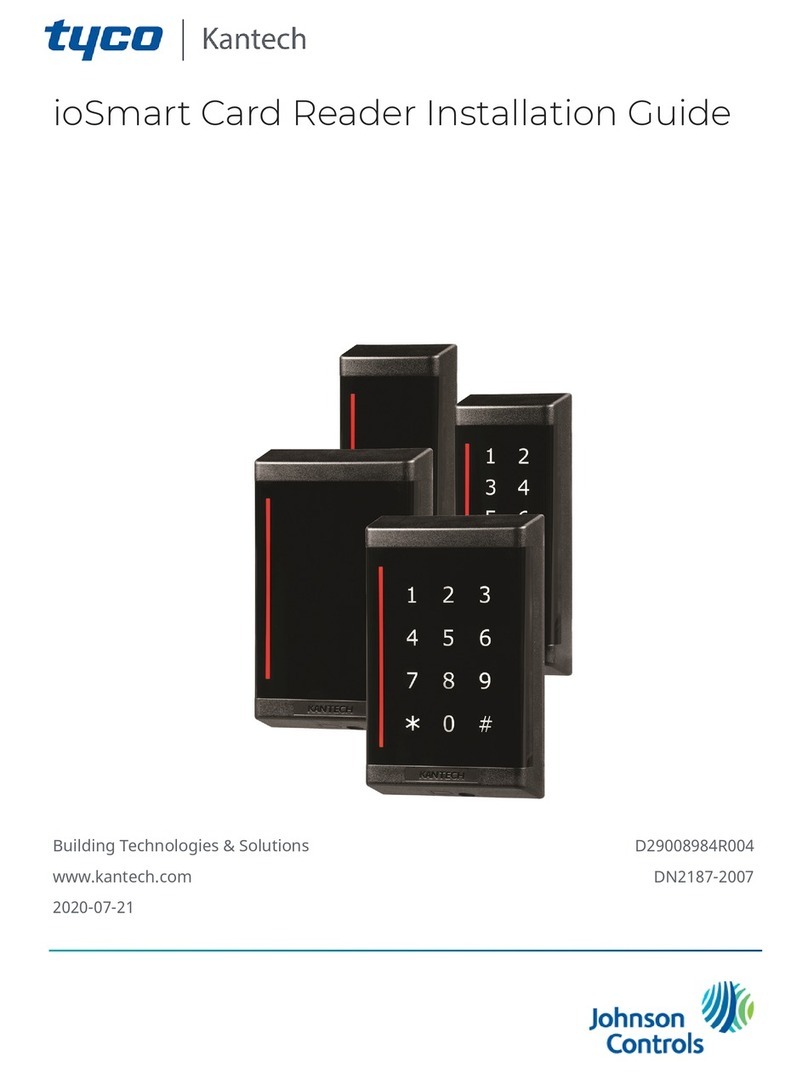

2.1

D

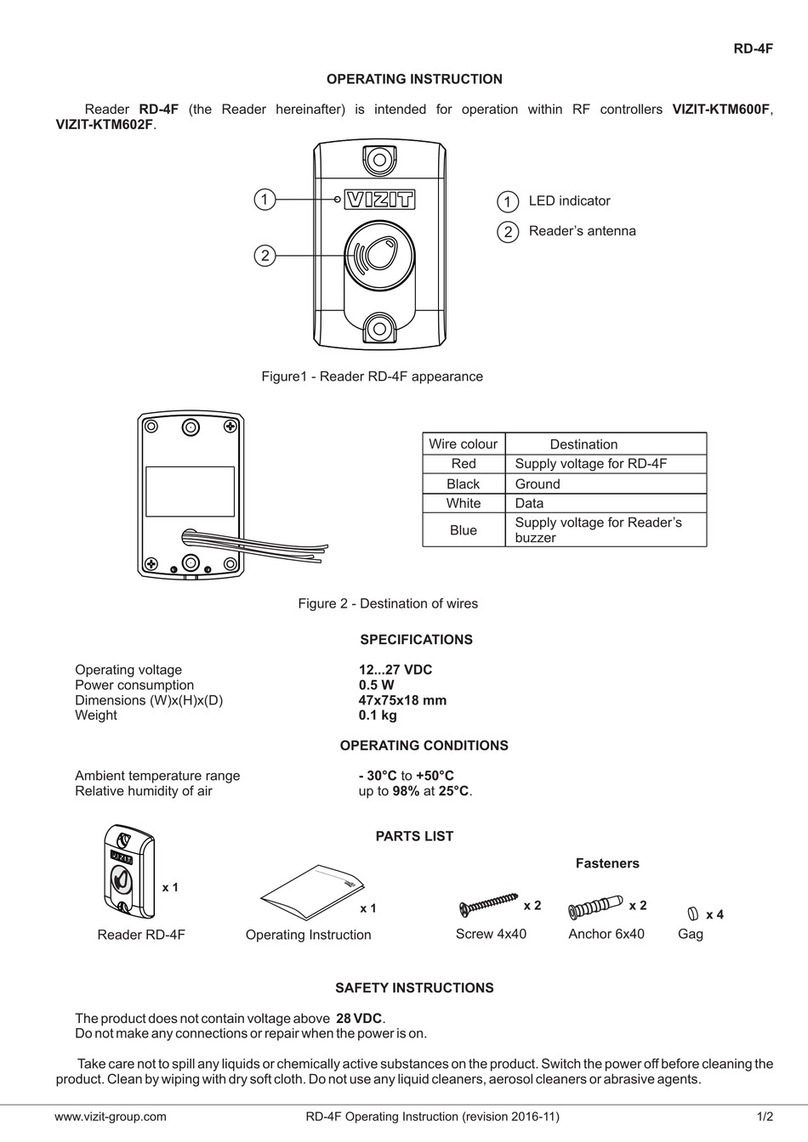

EVICE DESCRIPTION

.......................................................................................................................................... 4

2.2

B

ASIC OPERATION

................................................................................................................................................ 5

2.3

P

OWER

................................................................................................................................................................. 5

3

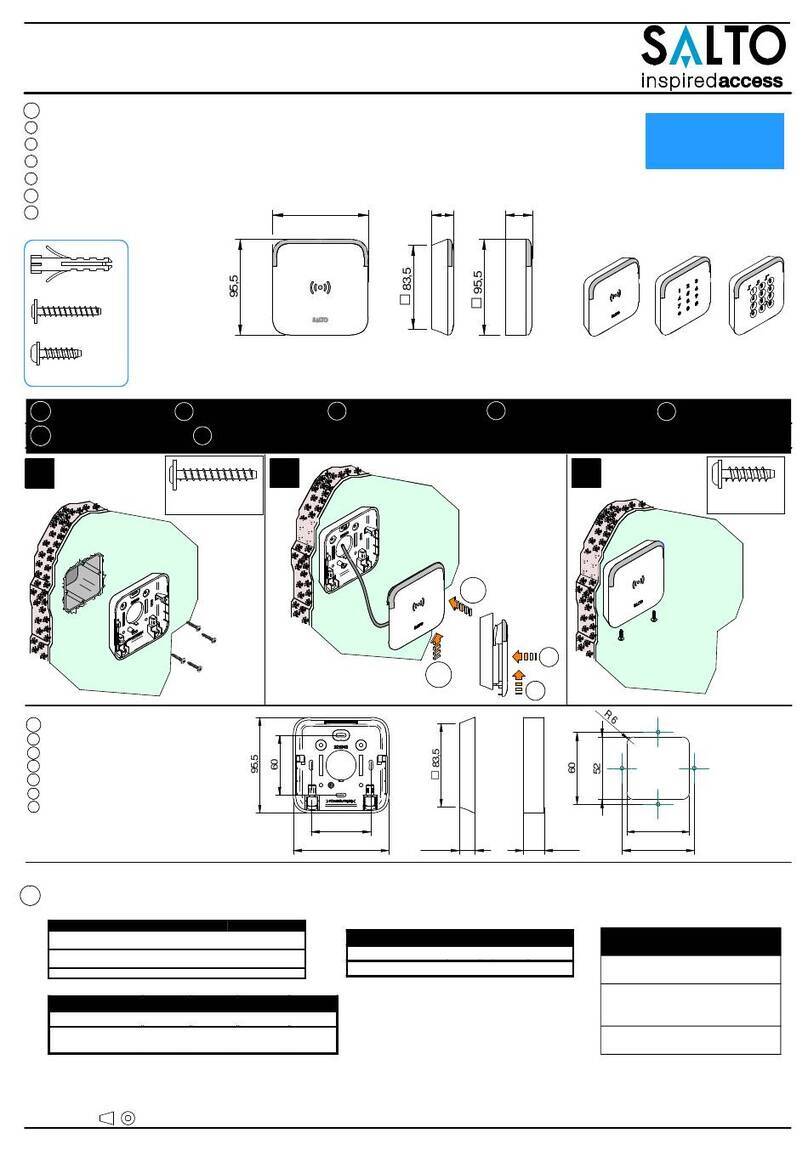

MECHANICAL ASPECTS........................................................................................................................................6

3.1

C

ASE DIMENSIONS

............................................................................................................................................... 6

3.2

D

EVICE ENVIRONMENT

......................................................................................................................................... 6

4

CONFIGURATION.....................................................................................................................................................8

4.1

U

SER SETTINGS

................................................................................................................................................... 8

5

CONNECTION TO HOST .........................................................................................................................................9

5.1

I

NTRODUCTION

..................................................................................................................................................... 9

5.2

T

RANSMISSION CHARACTERISTICS

...................................................................................................................... 9

6

MESSAGES RECEIVED BY READER ................................................................................................................10

6.1

MODBUS

P

ROTOCOL

....................................................................................................................................... 10

6.2

MODBUS

C

OMMANDS

..................................................................................................................................... 11

6.3

C

OMMAND

:

R

EAD LAST TAG CODE

.................................................................................................................... 11

6.4

C

OMMAND

:

125

KH

Z EMITTER CONTROL

.......................................................................................................... 12

6.5

C

OMMAND

:

R

EAD

F

IRMWARE

V

ERSION

............................................................................................................ 12

6.6

C

OMMAND

:

R

EAD

D

EVICE

S

TATUS

................................................................................................................... 13

6.7

C

OMMAND

:

W

RITE PARAMETERS

...................................................................................................................... 14

6.8

C

OMMAND

:

R

ESET

............................................................................................................................................. 14

6.9

C

OMMAND

:

W

RITE DIGITAL OUTPUTS

................................................................................................................ 14

7

DIGITAL OUTPUTS.................................................................................................................................................15

7.1

125

K

H

Z

OK...................................................................................................................................................... 15

7.2

T

AG

P

RESENCE

................................................................................................................................................. 15

8

CONNECTORS.........................................................................................................................................................16

8.1

C

ONNECTOR ON CASE

....................................................................................................................................... 16

8.2

C

ONNECTOR FOR CABLE ASSEMBLY

................................................................................................................. 17

8.3

T

YPE OF CABLE TO USE

..................................................................................................................................... 17

9

MAINTENANCE .......................................................................................................................................................18

9.1

R

EGULAR MAINTENANCE

................................................................................................................................... 18

9.2

D

EVICE REPLACEMENT

...................................................................................................................................... 18

9.3

R

ECYCLING

........................................................................................................................................................ 18

APPENDIX 1 : SPECIFICATION DRAWING................................................................................................................19

APPENDIX 2 : IMPORTANT NOTE ABOUT FCC RULES ........................................................................................20