▶4options

By increasing or

decreasing pressure

to container

Pressure increase Dispensing amount increase→

Pressure decrease Dispensing amount decrease→

Thickness of Needle Thick Needle Dispensing amount increase→

(Improvement of tendency to

pause)

Thin Needle Dispensing amount decrease→

(Worse of tendency to pause)

Flux Control Knob Long stroke Dispensing amount increase→

Short stroke Dispensing amount decrease→

Dispensing Time Long dispensing time Dispensing amount increase→

Short dispensing time Dispensing amount decrease→

*Choose the way of controlling dispensing time preferentially to get

proper dispensing amount.

5-2. Maintenance

5-2-1) Washing

Wash valve thoroughly after using if dispensed liquid has tendency to①

be stiff or has possibility to damage liquid contacting part.

First of all dispense all liquid entirely from pressure container, liquid②

supply hose and liquid contacting part until sufficient aiir comes out.

Wash liquid inside of valve with a little of proper solvent.③

Then wash thoroughly in order of air solvent air solvent.④→→→

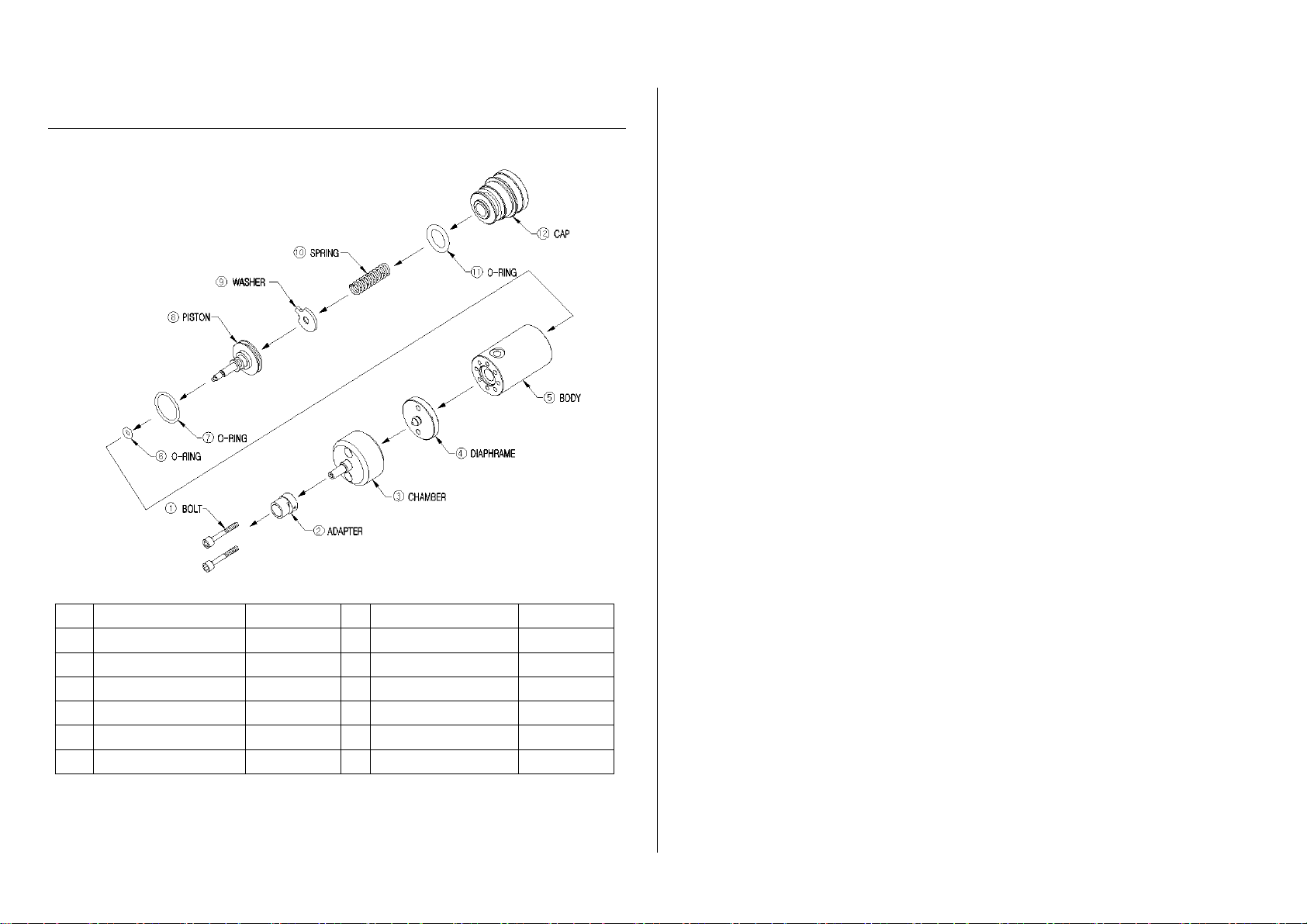

5-2-2) Disassembly

In case of disassembly for washing or replacing part, refer to①

"7.Exploded View & Parts List".

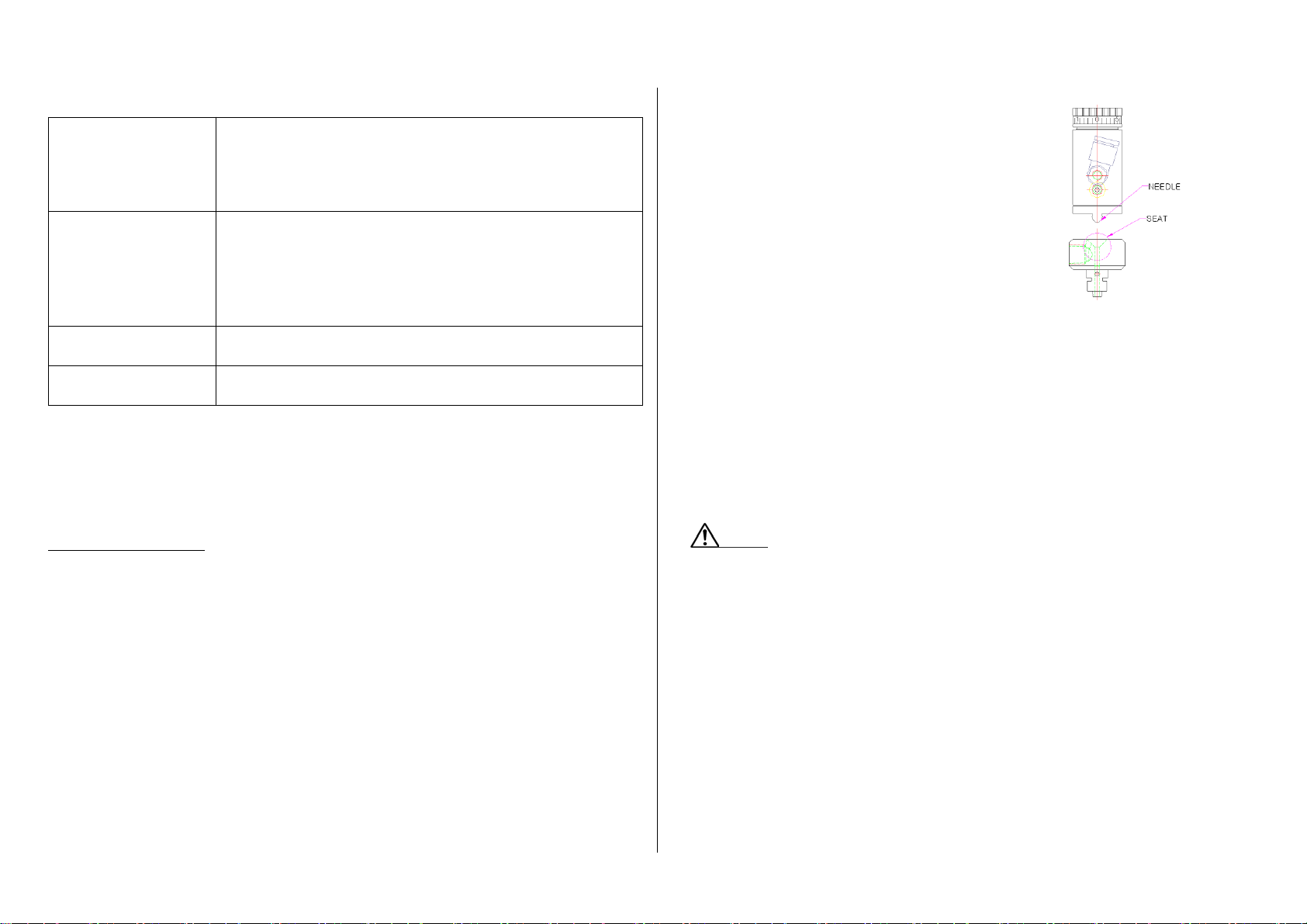

In case of washing valve head with②

sharp pin or others, try not to scratch

needle or seat part. If damaged you

need to replace parts because of

leakage.

5-2-3) Assembly

Diaphragm Assembly①

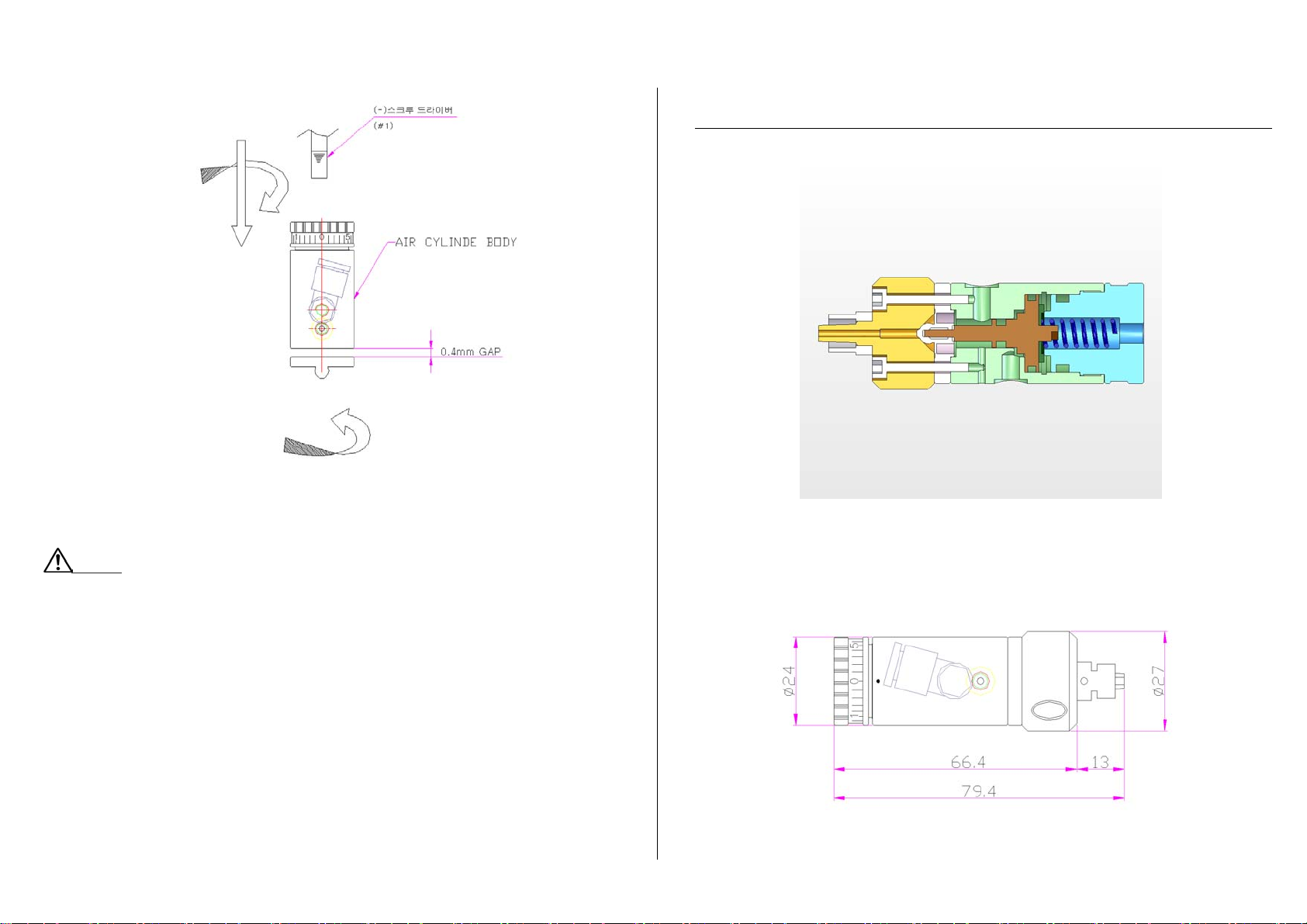

Loosen stroke control knob by turning twice counterclockwise.ⓐ

Separate valve head.ⓑ

Remove diaphragm by turning counterclockwise.ⓒ

Screw new diaphragm carefully to become horizontal toⓓpiston road

screw-thread.

Notice

If it isn't fit thread properly leakage may occur.

After fixing diaphragm at regular intervals(0.4mm) like the picture, forⓔ

matching cylinder body and mount screw, please turn to the

location that you want using a screwdriver like next picture.