5

4. Installation & Ope ation

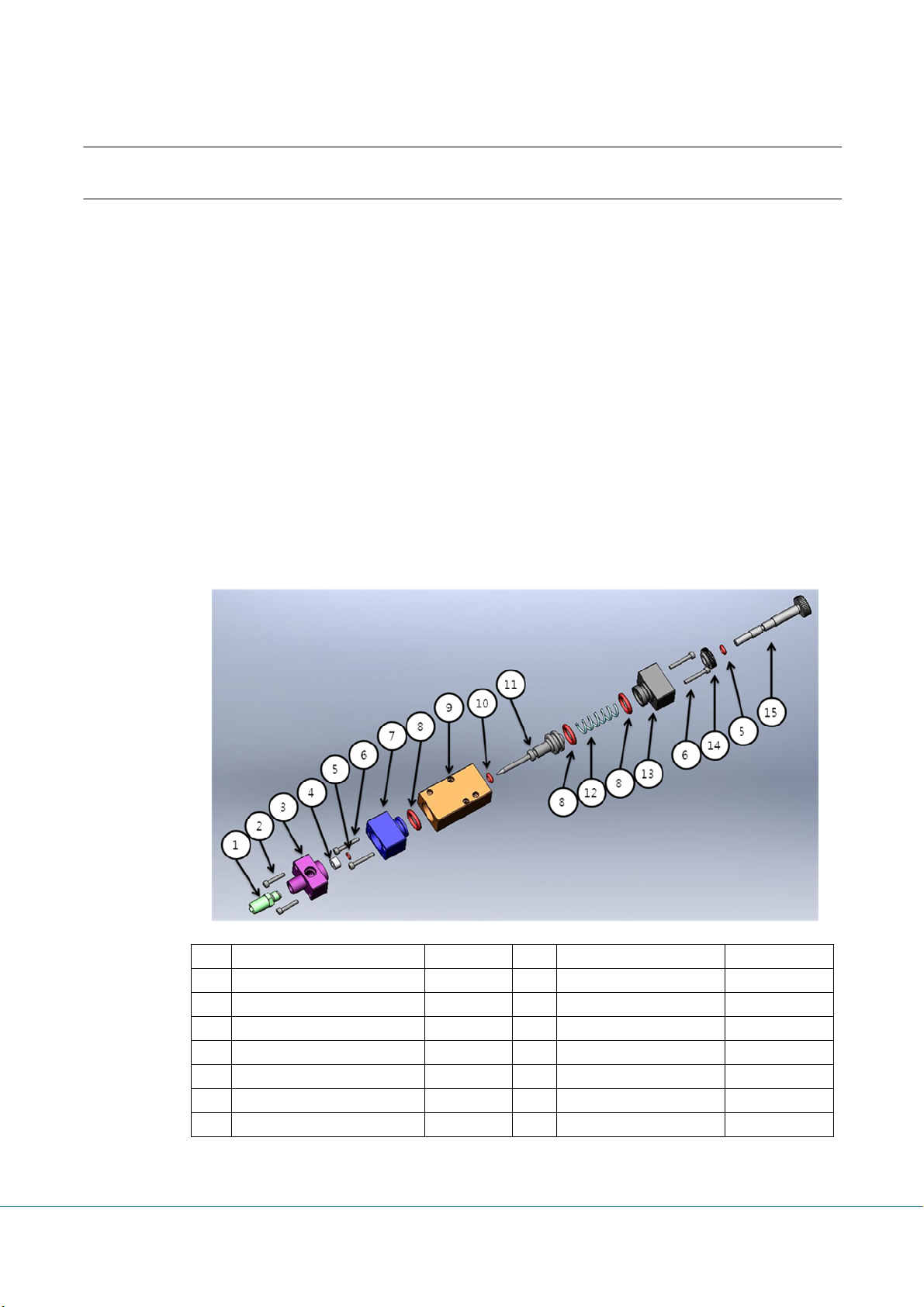

4.1 Connecting Lines

1) Connecting Air-pressure lines

- traightly insert the tube into the air

fitting until it gets installed inside

- Valve open line(A) is connected to the

“open” port on the TAD-200V(controller).

- Valve close line(B) is connected to the

“air out” port on the TAD-

200V(controller).

- Pull the tube gently in order to make

sure that it is safe.

2) Connecting Fluid Line

- The inlet of Fluid line(C) fits in PT 1/8”

line.

3) Caution

- When you cut the tube, make the

severed side a right angled out and the

use of a tube-cutter is recommended.

- Install the fluid line in oblique with the air

line in order to minimize the intervention.

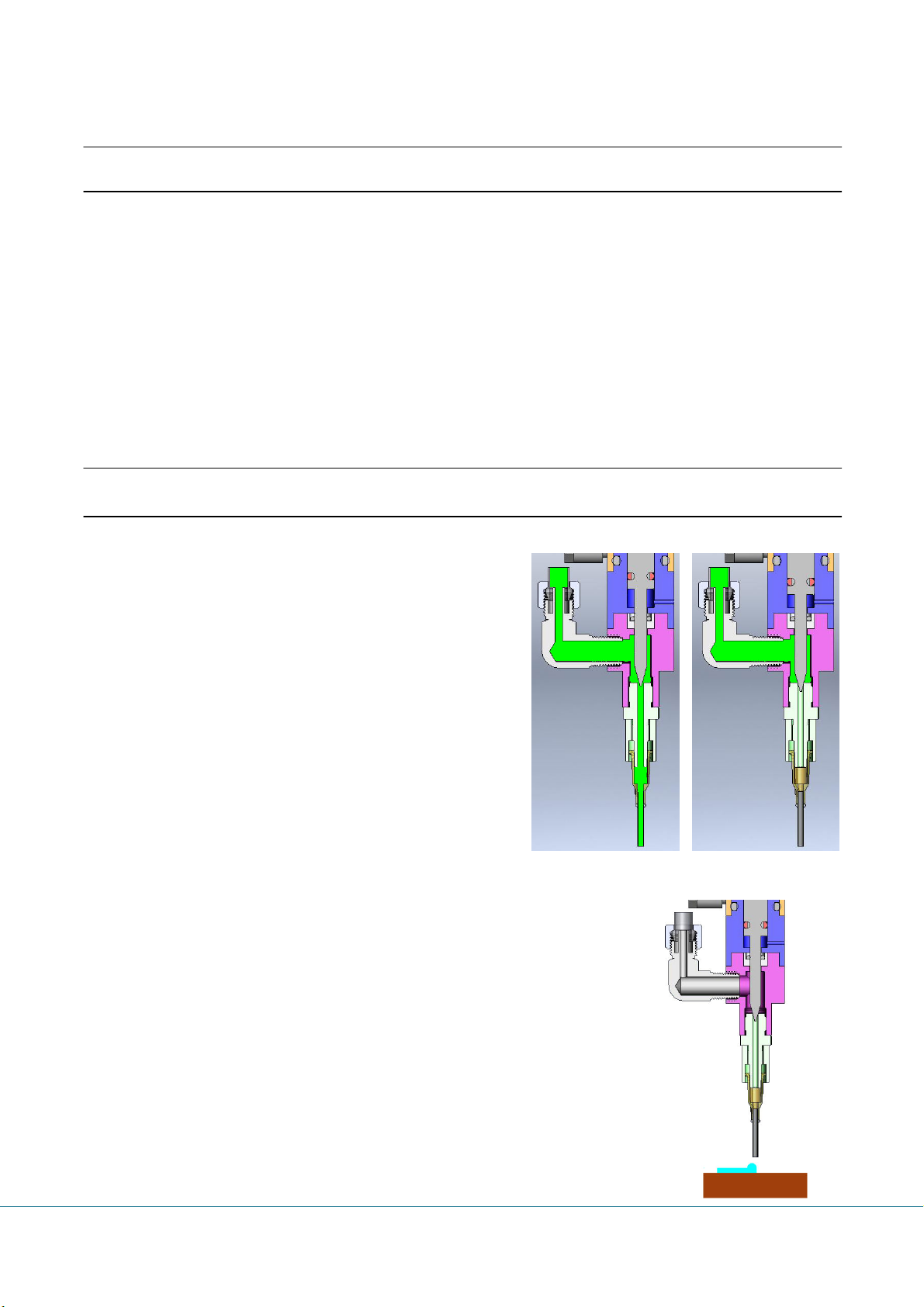

4.2 Ope ation

1) Preparing to use

- Open the fluid line and valve open air

line(A) of the valve.

- Keep dispensing until the consistent

drippings in order to eleminates the air

in the valve.

- And then stop dispensing.

2) Control of the dispensing volume

- Adjust the pressure of fluid inlet.

- Change the nozzle tip(D) to be

compatible to preventing from air

bubbles.

A

B

C

D