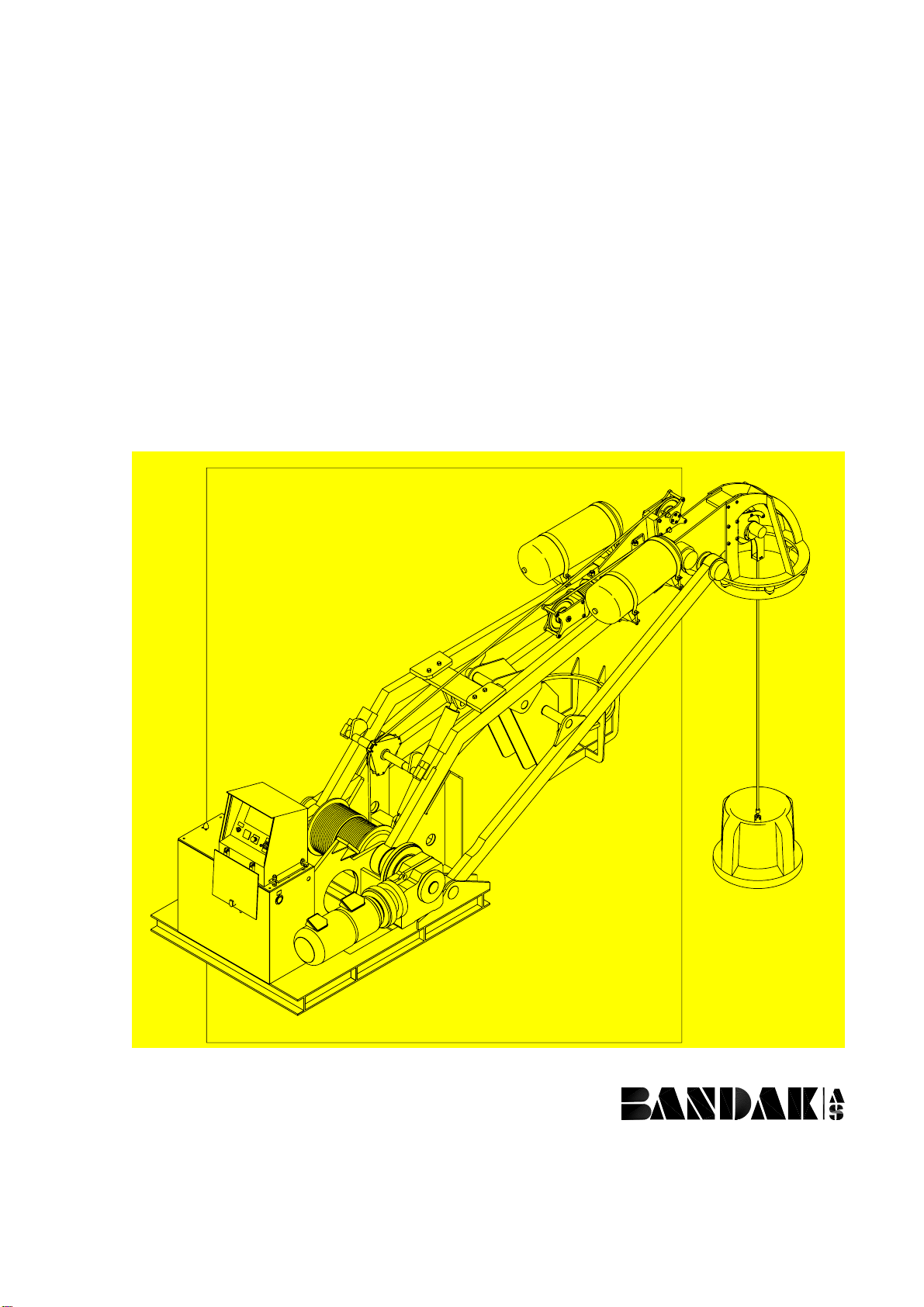

Light Weight Taut Wire Mk 14B Operation Manual

9

4TECHNICAL DESCRIPTION

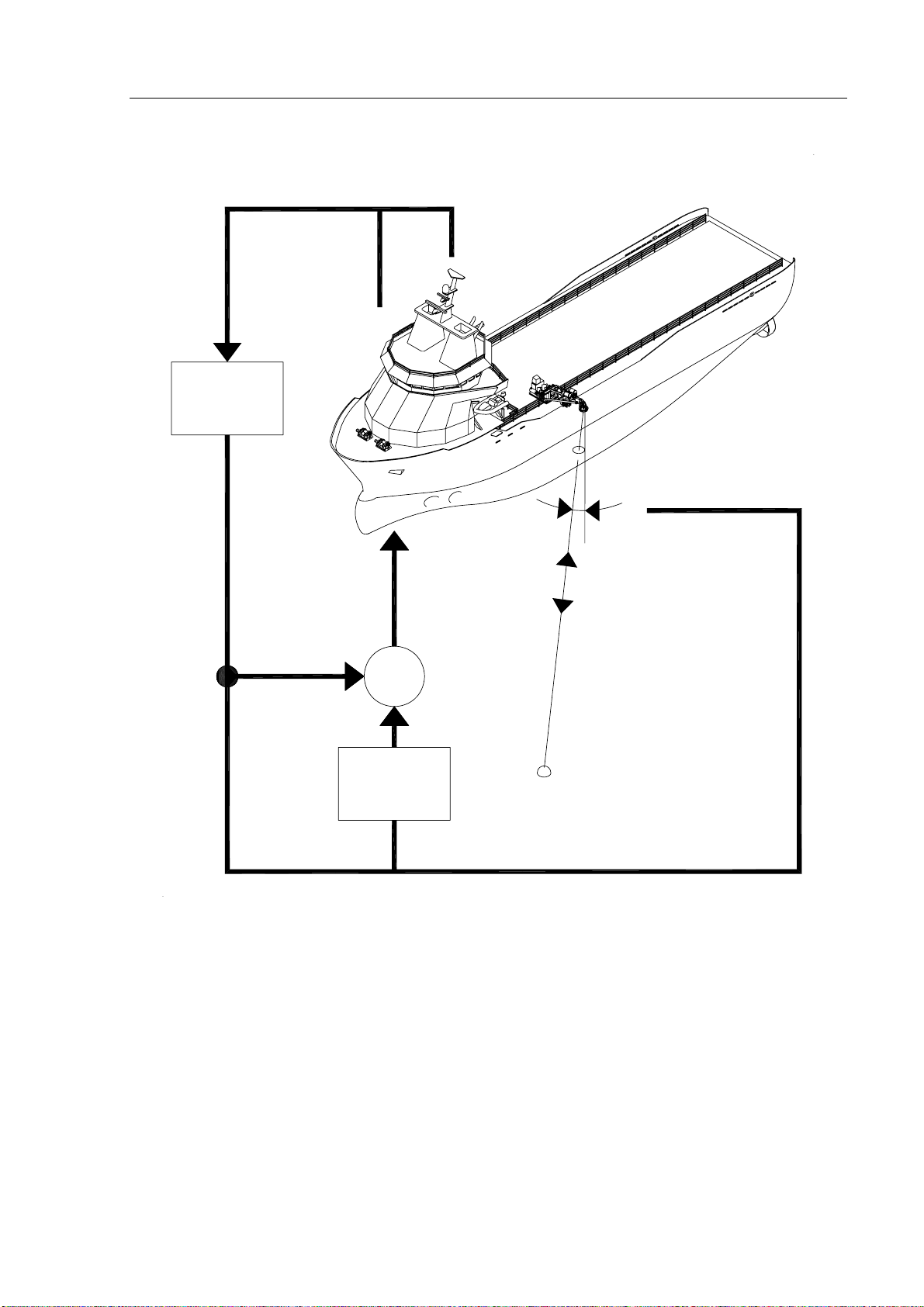

4.1 Principle of Operation

The purpose of the Taut Wire is to give accurate input data, related to

vessel movement, to the vessel data processing system to calculate

vessel position corrections.

The Taut Wire system is fundamentally electro-hydraulic-pneumatic

and requires electrical and air supply from the vessel.

The wire rope, although thin to reduce the "offsets" caused by

underwater current disturbance, is strong enough to heave the weight

with a safety factor of 400 percent. Control of the system is effected

from either of two control panels; main control panel (local) or optional

bridge control panel (remote).

The wire rope is tightened against the depressor weight (on the seabed)

with a constant tension by means of a pneumatically and servo electric

"mooring" control system. Any movement of the vessel in either or

both of the X (alongship) or Y (beam) co-ordinates, will cause a

deviation of the tensioned wire rope from the vertical. This deviation

activates potentiometers mounted in the gimbal (sensor) head and

produce changes of analogue data directly proportional to the X-Y

inclination of the gimbal head.

The analogue wire length measurement is obtained from a measuring

device driven by the moving wire.

The DP system contains an accurate model of the dynamics of the

vessel which simulates the vessel's response to various forces e.g. wind,

wave and current disturbance.

Deviations in the specified position of the vessel (detected by changes

above analogue input parameters) will be processed by the software

model to generate appropriate corrective commands to the vessel's

propeller and rudder system.