B&K 466 User manual

INSTRUCTION

MANUAL BE3'-Model 466

CATHODE RAY TUBE

TESTER/REJUYENATOR

sn

Product of DYNASCAN CORPORATION

1801 West Belle Plaine Avenue, Chicago, Illinois 60613

INSTRUCTION MANUAL

FOR

Model 466

CATHODE RAY TUBE

TESTER/REJUVENATOR

B&K DIVISION OF DYNASCAN CORPORATION

1801 West Belle Plaine Avenue

Chicago, Illinois 60613

TABLE OF CONTENTS

Brief Summary of What the Model 466 Will Do

Why Your Model 466 Is the Most Advanced Tester of Its Type

Safety Precautions

Basic Features of Model 466

Model 466 Control Panel Layout

Preparation for Test

Simplified Test Procedure

Simplified Warmup Test for Color Tubes

Life Test

Removing Shorts

Activate Mode

Restoring Emission

Rejuvenation

Super Rejuvenation

Repairing Open Elements

Setup Charts

466 Field Calibration

Warranty Service Instructions

Page

3

4

p*

o

6

8

9

10

12

13

14

14

15

15

16

17

17

18

19

BRIEF SUMMARY OF

WHAT THE MODEL 466 WILL DO

1. The Model 466 CRT Tester/Rejuvenator will rapidly test acathode ray

tube (using CRT manufacturers1accepted techniques and safeguards) for

all the important factors which determine the quality of atube. The

Model 466 will check for shorts or leakage between the elements in the

tube and will also indicate between which elements the fault exists.

2. The 466 will check the amount of emission from the cathode (s) and will

directly and rapidly indicate relative emission balance between the guns

ofacolor cathode ray tube.

3. The 466 will check the warmup characteristics of atube.

4. It will repair most common faults in cathode ray tubes, such as shorts be-

tween elements, open connections to elements, and inter-element leakage.

5. It will rejuvenate picture tubes having low emission. Other capabilities

of the Model 466 are described in the next section.

3

WHY YOUR NEW MODEL 466 IS THE

MOST ADVANCED TESTER OF ITS TYPE

The Model 466 CRT Tester/Rejuvenator has been designed by B&K to

accurately evaluate virtually any television cathode ray tube.

This professional quality CRT tester retains the proven, valuable capa-

bilities of its predecessors and also incorporates new important advances.

These advances include:

1. Ahuman-engineered control panel which organizes and streamlines the

test by guiding the user rapidly through the correct test sequence.

2. Advances in internal circuitry which provide more directly useful fea-

tures and greater test precision than any comparable tester.

3. Alarge precision meter which is numerically coded to the front-panel

controls to minimize setup time and permit highly accurate, error-free

evaluation of the CRT under test.

4. Color-coded: leakage and emission scales.

5. Gxvoltage and heater voltage (right at the tube pins) are precisely

monitored on meter.

6. Continuously variable heater voltage, which can be precisely set on

meter, effectively protects the instrument from obsolescence by the ap-

pearance of future CRTs having new heater voltages.

7. The voltages to grid 1and grid 2are continuously variable permitting

the tube to be checked under conditions similar to operation of the

tube within the receiver.

8. Improved power supply transformer provides greater safety and up-to-

date comprehensive coverage of all new filament voltages.

9. New color tracking normalize feature which greatly simplifies color tube

evaluation and reduces time for determining proper color gun tracking.

10. New simplified warmup test for color CRTs.

^.

11. Direct metering of relative cathode emission improvement when using

any of the Rejuvenate features. This eliminates need to repetitiously

4

recycle previous test steps, saves time and permits immediately detect-

ing the extent to which rejuvenation should be performed.

%

12. Simplified life test.

13. Activate mode provides precise metered monitoring of activation.

14. Rejuvenation capability is provided in three improved steps, the first

two of which are automatically timed to prevent damage to atube. The

unique Super Rejuvenate feature provides even greater capability for

restoring the emission of an aging and otherwise worthless CRT.

*-.

15. The largest storage spacejjfany CRT tester currently available.

16. New improved, expanded, more versatile adapter set is included and

provides capability to directly test more CRT types than any other cur-

rently available tester. For example, even the new Trinitron, 11SP22

and 11WP22 tubes are accurately tested on the 466 without having to

obtain additional adapters at added cost.

• 9 •

*V

17. Unlike other CRT testers which allow some of the internal elements

of acolor CRT' under test tp “float at random” or to be shorted to-

'a *•••

•,''v•*•

gether (to reduce; cost of the tester), in all test modes the 466 insures

that all key elements of the color CRT are properly connected to ap-

propriate test circuit points. This permits greater precision in test re-

sults and eliminates the real possibility of any uncontrolled, internal

current paths injuring the CRT under test.

***** ^

•<

••••%•V

Safety Precautions

•••—A4‘* •

NOTE: The proper power line supply voltage is indicated in the line

cord storage compartment. Do not attempt to operate this instrument from

apower source other than specified.

When testing any CRT that is installed in achassis, first disconnect the

chassis power plug from the AC line outlet. DO NOT APPLY POWER

TO THE CHASSIS AT ANY TIME DURING THE TEST OF THE

CRT. Remove the receiver female socket assembly from the base of the

CRT. Always perform test steps carefully.

5

Case of weatherproof

heavyweight ABS pla:

resists scarring and v

sharp impacts ^

Storage

Compartment Door

Adapters, power cord,

instruction manual,

setup charts and ^

other optional

items store readily

in hidden compartment

Storage

Door Release

Individual controls adjust G2

Voltage for each electron gun

of CRT under test \

h-nv

mm

Adjusts Gi Voltage to value

specified in Setup Chart

wmm

\

£

1i

V.

li

> >

i

:?

H

n

it

m&m

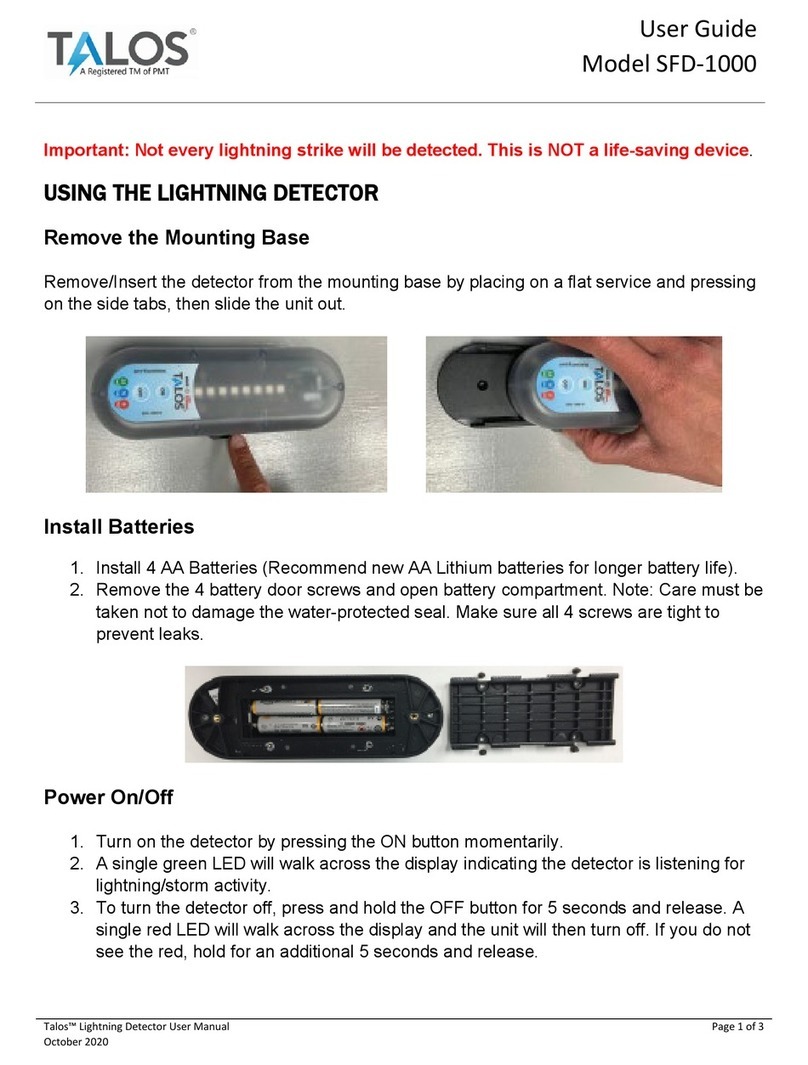

BASIC FEATURES OF MODEL 466

ms

Meter scales are sequentially numbered with

circled numbers which tie in with circled numbers

on step-by-step front panel of 466 tester.

Adjusts Heater

Voltage to

Exact Value

specified in

Setup Chart

Selects Heater

Voltage Range

Color Gun Switch

selects electron

gun to be tested,

activated or

rejuvenated. See

instructions.

Normalize Control

simplifies Color

Tracking test

Power On

Indicator

LARGE CENTRAL

FUNCTION KNOB

CONTROLS STEP-

BY-STEP SEQUENCE

OF TESTING

RED REJUVENATE

PUSHBUTTON (read

instructions before

using).

7

mm

111 msmmm®

mm m*mom

wmmm

mmm mm

iiw|pi! v.;.V ":.v.\

Iv’yVv’*! .'/ •!

V.'m

ft A ft

t'»****

^

t

r^mff »*»*»*»*mVr* •’v.AV.V *.*

••*•%•• •.•v!\\v<

K'!v!v!v«v«' :

,,,, !v’vJv. !»5o“

'*

•! •iSS-vS *. .

.

>••••( ••'•••«*£%

fV v:.;W

w*:m

PREPARATION FOR TEST

Connect line cord of tester to proper power line outlet, rotate NOR-

MALIZE control completely clockwise and all other controls completely

counterclockwise. Find the listing in the test chart for the CRT to be

tested. Note the sequential numbering on the front panel of the 466 which

will guide you rapidly through the test sequence. Circled numbers below

correlate with circled numbers on panel and meter of tester.

The 466 tests both black-and-white and color CRTs in an essentially

identical manner, except that the top switch marked COLOR GUN is al-

RED/B&W

but is switched into each of its three color gun positions for steps (J)3(4)

@, and (7)when testing acolor CRT.

SIMPLIFIED TEST PROCEDURE

®Rotate bottom knob marked ©

indicated

®

guideline

select adapter indicated in chart, connect CRT, adjust heater

voltage as indicated on scale @of meter to value given in chart.

Allow CRT to warmup for at least three minutes. Readjust

heater voltage.

CO

m

x

>

®

Rotate the large function knob to ®H-K LEAKAGE and ob-

serve reading on LEAKAGE scale (?) of meter. (There are two

scales for H-K leakage. One is for color CRTs and the other

for black-and-white CRTs. Re sure to take your reading from

the appropriate scale for the type of CRT under test). The

colored area indicates the range of permissable leakage. Read-

ings outside this area indicate adefective tube. For acolor

CRT repeat this step for all positions of the COLOR GUN

switch.

Rotate the large function knob to ®Gi LEAKAGE. Observe

meter reading on scale ®.For acolor CRT repeat this step

for all positions of the COLOR GUN switch. For both black-

and-white and color tubes, if the reading is outside the colored

area, the tube is defective and should be rejected.

COMMENTS s

(?) and (?)

tube

mittent or short condition. Leakage can be caused by an accu-

mulation of dust at the base pins of the CRT. Cleaning the tube

base with anon-toxic, non-conductive solvent such as methyl

alcohol, will frequently remedy this problem.

m

>

>

o

m

to

O

X)

in

m

m

10

©knob

©©)LTAGE and

®to green !

45 volts. *For tubes marked with an asterisk *, set Gi to 70

volts.

©^.

Set large function knob to position ®and with COLOR GUN

switch in position marked RED/B&W adjust B/W RED

G2voltage control knob until meter pointer reading on meter

©©©or if you can

this step

once for each of the three positions of the COLOR GUN switch,

using the corresponding control.

©Set function switch to ©READ EMISSION and evaluate the

emission on meter scale ©. If meter reads BAD, reject the

tube. If meter reads GOOD, cathode emission is acceptable.

For acolor CRT, perform this step in all three positions of

COLOR GUN switch.

The following step applies only to color CRTs.

®a. Set function switch to ®COLOR TRACKING position.

b. While observing meter pointer, rotate COLOR GUN switch

in all three positions, then set to gun with highest reading

on meter.

c. NORMALIZE eter pointer aligns on

the right edge of the color tracking rectangle (marked

NORMALIZE).

d. Switch the COLOR GUN switch to each of the other two

color guns. If the meter does not read within the bound-

aries of the color tracking rectangle for all three guns,

reject the tube if IN-WARRANTY. If tube is OUT-OF-

WARRANTY, consider using ACTIVATE/REJUVENATE

procedure for the color gun having the lowest emission

reading.

COMMENTS

Azero reading when the Function Switch is in the READ

EMISSION position ©indicates an open G2or Kelement.

The G2voltage control ®should be set carefully so that erro-

neous reading and tube damage are avoided.

EMISSION

TEST

,

r

—

COLOR

TRACKING

SIMPLIFIED WARMUP TEST FOR COLOR TUBES

m* *•

*

To produce satisfactory colors in operation, the emission of each of the

three guns of acolor picture tube must approach its normal operating value

within areasonable time period. One of the unique features of the 466 is

that it provides avery easy, simplified technique for determining the warm-

up characteristics of color tubes as follows.

1. After the standard test steps (l) thru (j) and the Color Tracking eval-

uation step (i) have been completed on acolor tube and the tube has

been evaluated as acceptable, leave all settings of the small knobs un-

changed and rotate the large function knob to the OFF position for 10

minutes or until CRT cools down completely.

2. Leaving all small knobs still undisturbed, rotate large function knob

-back to position marked COLOR TRACKING. Wait 2minutes and

then successively rotate the COLOR GUN switch into all three of its

positions while observing meter position relative to the acceptable track-

ing area indicated on scale (S) of the meter. If the meter needle de-

flects into the acceptable color tracking rectangle of scale ®for all guns

at the two minute point, the warmup characteristic of the CRT is con-

sidered to be acceptable.

3. If any gun failed step ©, above, wait two more minutes and then (leav-

ing all other controls still undisturbed) again rotate the COLOR GUN

••*

switch into all three positions while observing meter. If the meter

needle deflects into the acceptable color tracking rectangle for all three

guns at this time (after atotal of four minutes of warmup), the warmup

characteristic of the CRT is considered to be marginally acceptable.

12

LIFE TEST

1. Set the function switch to position (7)READ EMISSION until GRT

&

is up to operating temperature.

&

2. Rotate bottom right knob (T) SELECT HEATER VOLTAGE to lowest

range. Note the length of time before the meter needle starts to fall

toward zero as the CRT cools down.

%

3. When testing acolor tube, repeat steps (T), and (2)for all three color

*

guns.

%

4. If the meter needle momentarily remains fixed or slightly increases and

then slowly drops to zero, the tube is accepable. If the meter needle

begins to slump toward zero rapidly, then the tube cannot be expected

to last much longer. *

•0*%

• 1

Note: The emission current in “instant on” CRTs (not preheated fila-

ments) can be expected to decrease quite rapidly, since the thermal time

constant of the gun structure is much smaller than for conventional

CRTs.

Comment: In this test, the useful life of apicture tube is approximately

correlated with the “statistical probability” of electrons being emitted

from the cathode surface and passing through the aperture of the elec-

tron gun. This, in turn, depends on whether the small portion of the

cathode surface nearest the aperture can emit electrons efficiently.

If there is excess gas in the tube, positive ions will have been drawn

through the aperture to this crucial portion of the cathode surface.

These ions, on striking the cathode surface, “borrow” electrons from

the cathode and become atoms attached to the cathode surface. These

“contaminating” atoms thus coat the emission surface with abarrier

layer which reduces the “statistical probability” that electrons will be

emitted as desired. The slump in current (if observed in step 2) indi-

cates this surface contamination. Since the contamination will continue

to increase in a“gassy” tube, such atube cannot be expected to last

much longer. Acontinuing degradation of the emission current can

be expected.

13

REMOVING SHORTS

1. Set large function switch to REMOVE SHORTS position.

2. Allow five to ten minutes for the filament to cool. Heater voltage is not

applied to the tube during this function.

3. When repairing acolor tube, set the COLOR GUN switch to the gun

being repaired. For ablack-and-white tube, set the switch to the B/W

position.

red REJUVENATE pushbutton momentarily.

Hefceat the SHORTS test steps (5) and @to determine whether or

p6t the short has been removed. If ashort has been removed, proceed

vith emission test (steps ©thru (?)).

COMMENTS: When the tube in the Shorts test shows acathode to

filament short, do not attempt to repair it. If the tube functions properly

in the set, it is unnecessary to do any more to it. However, if the picture

is bad (due to possible hum in the picture or no control of brightness), the

picture tube can still be used if a1:1 filament isolation tranformer is wired

into the set.

ACTIVATE MODE

*•

The activate mode of the Model 466 comprises amild form of rejuvena-

tion and can be used to increase the emission of some picture tubes when

the emission has decreased below the acceptable level. All tubes with low

emission cannot be activated—it depends on the condition of the cathode

emission surface in the particular tube.

During the activate mode, the heater voltage of the tube is increased,

while the emission current flow is maintained. The relative cathode emis-

sion can be observed on the meter of the 466 as the tube is activated. Note:

Activation of in-warranty color tubes should not be performed.

Activate Procedure

1. After completing normal test steps (T) thru @, note emission reading,

then rotate function knob back to ©and adjust heater voltage to a

value 40% above value specified in setup chart. (Example: If setup

chart specified 6.3 v., adjust heater to 1.4 x6.3 v. =8.8 v.).

14

2. Rotate function knob to position (?) and note emission reading on

meter. Allow the CRT to activate for 5minutes, while noting the meter

deflection. If the pointer moves upward and stabilizes at ahigher read-

ing, it is probable that the tube has been activated to the extent possible.

3. Rotate function knob to OFF and wait one minute. Repeat normal

steps (§), ®and 0.

NOTE: Picture tube leakage reading may change after the tube is ac-

tivated. Allow tube to cool afew minutes until original leakage reading

is restored, then perform steps ©, @and ®and note emission reading.

If emission is still too low and CRT is out-of-waranty, consider performing

Rejuvenation Procedure outlined below.

RESTORING EMISSION

NOTE: Any attempt to bring back the emission by rejuvenating atube

should be done very cautiously, AND ONLY AFTER IT HAS BEEN DEF-

INITELY DETERMINED THAT THE TUBE IS NO LONGER USE-

FUL IN ITS PRESENT CONDITION. When rejuvenating aColor tube,

make sure you attempt rejuvenation of the defective gun only. Always fol-

low carefully the procedure outlined below.

It is not generally advisable that you attempt rejuvenation of an “in-

warranty*' tube.

REJUVENATION

1. Set the large function switch to the REJUVENATE 1position.

2. When repairing acolor tube, set the COLOR GUN switch to the gun

that is to be rejuvenated. For ablack-and-white tube, set the COLOR

GUN switch in the “B/W” position. Note precisely the meter pointer

position.

3. Press the red REJUVENATE button momentarily. Observe new meter

needle position. Repeat step until needle deflects into GOOD area of

scale ®or until pointer deflection fails to increase from the previous

reading.

4. If meter pointer fails to indicate in GOOD area after Step 3, rotate large

function knob to REJUVENATE 2position, wait 15 seconds for heater

15

r

to come up to its new operating temperature, note new meter reacting,

then momentarily press red REJUVENATE pushbutton. Repeat step

until meter reading fails to increase. Do not continue the REJUVE-

NATE process beyond the point where the meter needle ceases to indi-

cate increased relative emission after each release of the REJUVENATE

pushbutton.

_*•*

5. If Steps 3and 4(which provide an automatically timed rejuvenate cycle)

did not bring the cathode emission to the acceptable level, you have the

option of proceeding to the SUPER REJUVENATE step. This last step

is manually controlled in duration by the red REJUVENATE push-

button, when you rotate the large function knob into the SUPER

REJUVENATE position.

SUPER REJUVENATION

With function switch in SUPER REJUVENATE position note meter

needle position, then press red REJUVENATE button for 14 to i

/2second

and release immediately. Observe new meter reading. If emission is still

inadequate, wait at least 5seconds and repeat step until emission fails to in-

crease. Increase time of rejuvenation to 1or 2seconds until some improve-

ment in emission is obtained. This SUPER REJUVENATE is not an auto-

matically timed position, so the longer you hold down the red REJUVE-

NATE button, the longer the SUPER REJUVENATE cycle will continue.

DO NOT CONTINUE CYCLING IN ANY REJUVENATE STEP IF

THE METER READING DECREASED SLIGHTLY AFTER THE LAST

DEPRESSION OF THE RED REJUVENATE PUSHBUTTON.

SHORTED CRT NEVER USE SUPER REJUVENATE MODE.

••* • •

NOTE: To avoid accidental application of REJUVENTE voltages to

anormal CRT, NEVER LEAVE FUNCTION KNOB IN ANY REJUVE-

NATE POSITION MARKED IN GOLD unless you intend to immediately

perform that specific rejuvenation step.

For a

16

REPAIRING OPEN ELEMENTS

»»•

if the tube has an open G1or G2element, the probable cause is abad

solder connection at the base pins of the picture tube. For an open ele-

ment, the first step is to try resoldering the base pins. If the tube has an

open cathode, it may actually be abreak in the weld between the cathode

and its connecting tab or very weak emission from the cathode. First, try

restoring emission as discussed in “Restoring Emission”. If rejuvenation

does not help, an attempt can be made to weld the cathode tab as follows:

*•*,_ •

Turn function switch to Rejuvenate 2position. With the non-metallic

handle of ascrewdriver, tap the neck of the tube lightly. Carefully watch

as you press the red REJUVENATE button. If the weld takes you will see

abright flash. If the weld does not take, set function knob in SUPER

REJUVENATE position and press red REJUVENATE button while lightly

tapping neck of CRT. If the weld takes, you will see abright flash. IM-

MEDIATELY RELEASE RED PUSHBUTTON. Retest the tube to be

sure it will function satisfactorily.

NOTE: When not actively using the 466, rotate the large function knob

^•

to the POWER OFF position. Do not pinch line cord between mating

aluminum edge extrusions of case when closing cover.

SETUP CHARTS

An up-to-date test chart is included with your Model 466. In order to

keep your setup chart up-to-date, it is recommended that you subscribe to

the B8cK Chart mailing service. These mailings will occur in May and No-

vember of each year and will include all the tubes presently listed on your

chart plus all new types of CRTs that have come out since the last mailing.

If you wish to take advantage of this service, remit cash, check, or money

order (no COD’s please) to:

B8cK Division of Dynascan Corporation

1801 West Belle Plaine Avenue

Chicago, Illinois 60613

and you will be placed on the subscription list.

17

466 FIELD CALIBRATION

The Model 466 CRT Tester/Rejuvenator can be recalibrated as follows:

A. HEATER VOLTAGE CALIBRATION

Equipment Needed: An accurate A.C. VOM or VTVM.

Set meter for the AC scale that gives closest full scale reading to 6.3

VAC. Connect meter leads to pins 1and 12 of socket #1. Plug the

466 line cord into a117 VAC outlet. Turn the large function switch

to the ADJUST HEATER position. Turn the heater selector switch

to 5-8 position. Turn the heater adjust pot until the VOM/VTVM

reads 6.3 VAC. Adjust R1( the heater cal trim pot until the 466 meter

reads 6.3 VAC on scale ©.

B. EMISSION CALIBRATION

Equipment Needed: Amilliammeter and a100K resistor.

Turn the 466 large function switch to the READ EMISSION position.

Turn the color gun switch to the RED-B/W position. Turn the G„

pots (RED-GREEN-BLUE) to full counterclockwise positions. Set the

milliammeter to arange capable of reading 300 microamperes. Con-

nect the negative lead to pin 11 of socket #1. Connect the positive

lead to one end of the 100K resistor. Connect the other end of the

resistor to pin 10 of socket #1. Slowly turn the red G2pot until the

milliammeter reads 300^a. Adjust R9, the emission cal trim pot, until

the 466 meter reads 50 on scale ©.

C. COMPRESSION CALIBRATION

Equipment Needed: Amilliammeter and a100K. resistor.

Turn the 466 large function switch to the READ EMISSION position.

Turn the color gun switch to the RED-B/W position. Turn the G..

pots (RED-GREEN-BLUE) to full counterclockwise positions. Set the

milliammeter to arange capable of reading 3milliamperes. Connect

the negative lead to pin 11 of socket #1. Connect the positive lead

to one end of the 100K resistor. Connect the other end of the resistor

to pin 10 of socket #1. Slowly turn the red G2pot until the milliam-

meter reads 3ma. Adjust R4, the compression adjust trim pot, until

the 466 meter reads 100 on scale ©.

18

Table of contents

Other B&K Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Seetru

Seetru Quickmount Installation, operating and maintenance instructions

LaserLine

LaserLine GL3000PM owner's manual

Endress+Hauser

Endress+Hauser Proline Promass 80H technical information

PHYWE

PHYWE Cobra SMARTsense 12903-00 operating instructions

Keysight Technologies

Keysight Technologies 16089A Operation and service manual

TALOS

TALOS SFD-1000 user guide