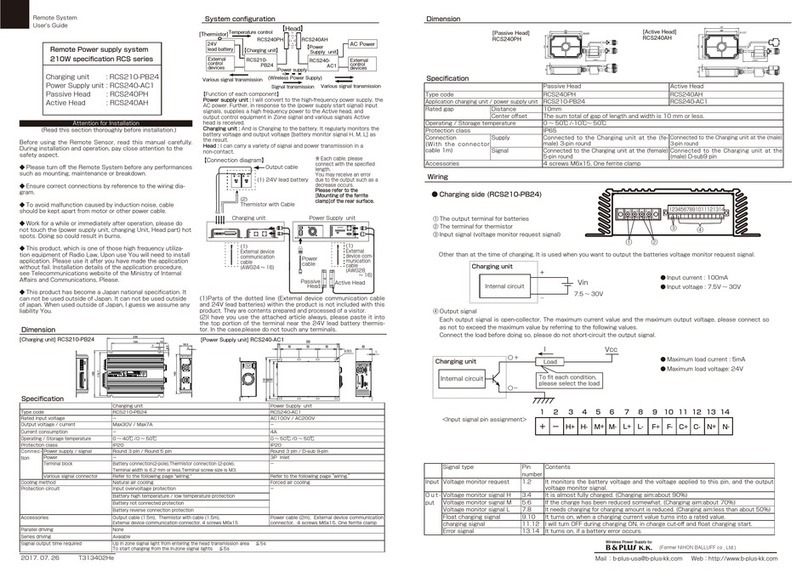

B&PLUS Wireless Power Supply RS24E-424N-PU Series User manual

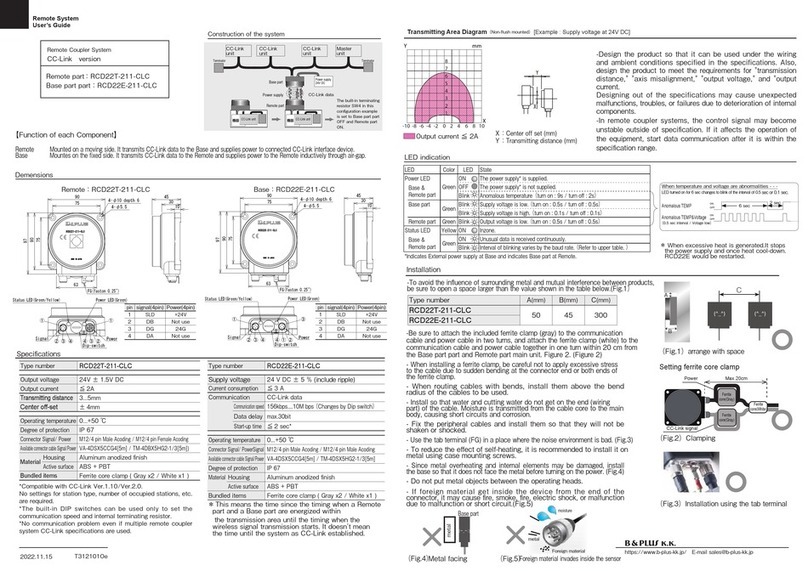

Remote System

User’s Guide

https://www.b-plus-kk.jp/ E-mail seles@b-plus-kk.jp

4.4

Φ

45.0

(3.0)

55.0

55.0

45.0

30.0

Remote sensor sysytem

24 signal transmission / Compact shape

24V1A type

Output sensor:RS24E-424N-PU-_ _ , RS24E-424P-PU-_ _Transmitter : RS24T-424-PU-_ _

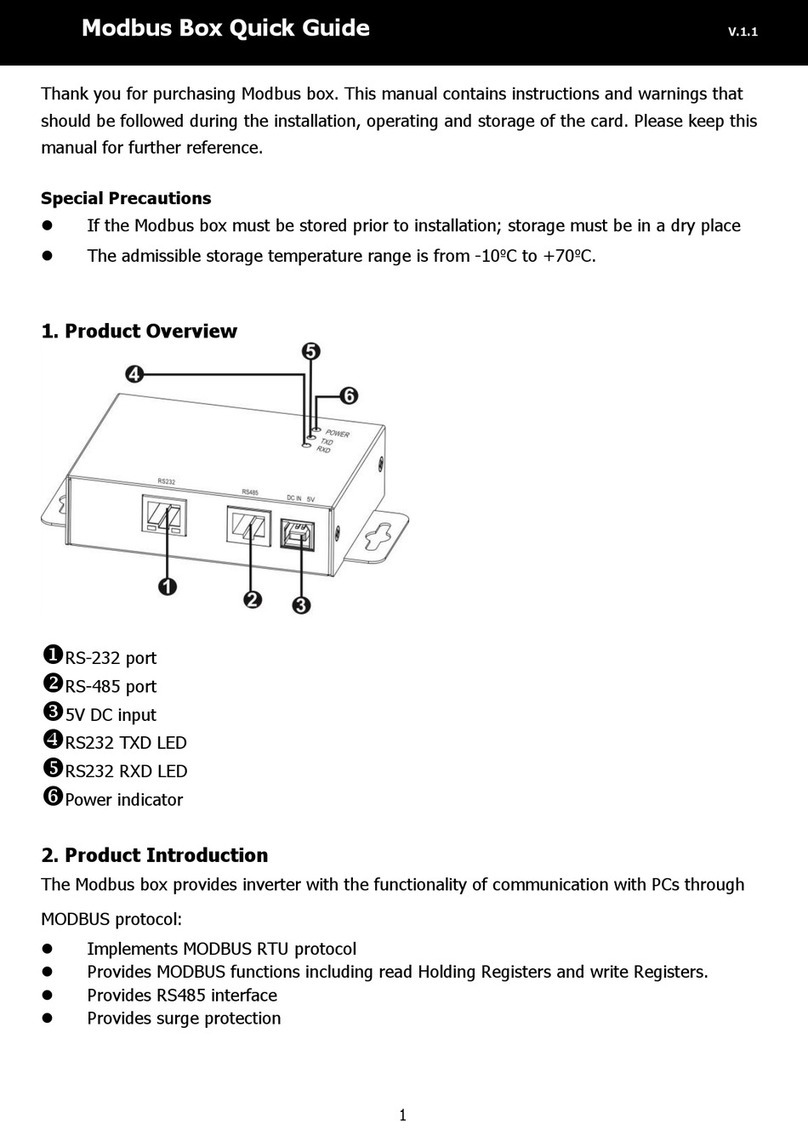

【Function of each component】

Detector : Connects Detector sensor (max.24) and transmits the detected signals to Transmitter.

Transmitter : Provides power for Detector, also passes detected signals from Detector to Output Sensor.

Output Sensor : Puts out detected signal to external controller, also sends power for operating of Detector and Transmitter.

System conguration

Dimension

Specication of the System

Available sensors

LED indication

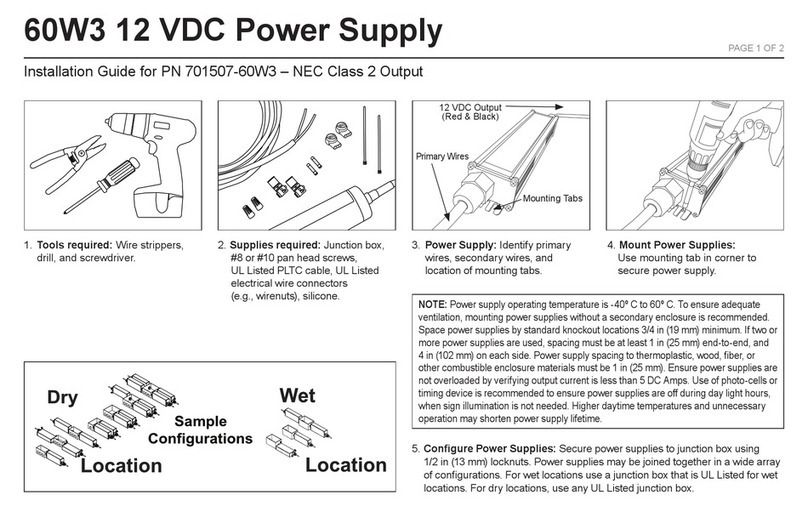

■ Status LED(Green)

■ In zone LED (Orange)

RS24ERS24T Host device

External Power

Unit(24V DC )

DC3-wire,

sensor

The in zone LED lights up when the transmission part and the output part are in a confronting state and communication is possible.

Typical Transmitting Diagram

(Supply voltage at 24V /non-ush mount)

X:Center offset(mm)

Y:Operating distance(mm)

2021.12.21

[ Detector ]

Detected

signal

Detected

signal

max.24 signals

Power

supply

Power

supply

24V DC

[ Transmitter ]

Signal

transmission

[ Output sensor ]

LED

Lighting pattern

Meaning

ON - - The power supply is supplied.

OFF - - The power supply is not supplied.

Blink Slow

(1.5 sec)

O time of the LED is long Anomalous temperature

Blink

Lighting time of the LED is long

Oscillation circuit overcurrent.

Blink

Mid.Speed

(0.6 sec)

O time of the LED is long Supply voltage is high.

Blink

Lighting time of the LED is long

Supply voltage is low.

Blink

High speed

(0.2 sec)

The LED ashes at the

same interval

Short circuit protection.

ON

OFF time of the

LED is long

Lighting time of the

LED is long

ON

OFF

OFF

Operating area Operating area

Drive current ≦ 0.5A

Output sensor:RS24E-424N-PU-_ _(NPN)

Transmitter: RS24T-424-PU-_ _

T319301Fe

Supply voltage 24V DC

Total currenconsumptoion ≦ 1A

Residual voltage ≦ 6.5V

Load current -

*¹【RB】represents robot cable specications.

*² Indicates the time from when the remote and base sections are energized in the transmittable area to when non-contact signal transmission is possible.

*³ Metal protection is a function to prevent metal heat generation when facing metal, and is not guaranteed to work on all metals. Do not intentionally place metal against the communication surface.

RS24E-424P-PU-_ _(PNP)

Type

RS24T-424-PU-_ _

Applicable sensor

DC 3-wire sensor

Drive voltage

(Output voltage)

24V ± 1.5V DC

Drive current tota

l

≦ 1A

Input signals 24

(SI1… 24) and a switching signal(NPN / PNP)

Operating

distance

in the case of 1A

0...4mm

in the case of 0.5A

0...6.5mm

Center oset (1A)

± 6mm :

Transmission distance is within 3mm

± 2.5mm:

Transmission distance 3...4mm

Center oset(0.5A)

± 8mm :

Transmission distance is within 4.5mm

± 3mm :

Transmission distance 4.5...6.5mm

Operating temperature

0...+50℃

Protection class

IP67

Cable

PUR φ 8.6x2(2x0.5mm

2

+13x0.18 mm

2

)+(12x0.18 mm

2

)

【RB】

*¹

Material

Case Polyurethane

Heat sink

Aluminum

Weight Body 165g +Cable 105g/m x2pcs.

Type NPN RS24E-424N-PU-_ _

PNP RS24E-424P-PU-_ _

Supply voltage(Input voltage)

24 V DC ± 5 %

Current

consumption

active Max 1.5 A (with 1A drive)

static Max 0.1 A (when not facing)

Number of output signals

24+1(In zone)

Load current ≦ 50mA/ 1output

Startup time

≦ 0.2sec*²

Frequency of operation

300Hz

LED indication

Status (Green), In zone (Orange)

Operating temperature

0...+50℃

Protection class

IP67

Protection circuit

Reverse connection protection, overheat protection,

short circuit protection,

overcurrent protection Output surge absorption

protection, head metal facing

protection *³

Cable

PUR φ 8.6x2(2x0.5mm2+13x0.18 mm 2)+(12x0.18 mm 2)

Material

Case Polyurethane

Heat sink

Aluminum

Weight

Body 165g+ Cable 105g/m x 2pcs.

Use a sensor that operates correctly within the

conditions in the table below.

In zone LED

Status

LED

(L)

Cable 1

Cable 2

Marking tube

Drive current ≦ 1A

Y

X

(3.0)

55.0

45.0

Φ

4.4

45.0

55.0

30.0

Cable 1

Cable 2

L=Cable length

The notation in meters to

the end of the model

・・・PU-02 ⇒ 2m

max. 5m

(Transmitter,Outputsensor)

(L)

0.5A

X

Ymm

-12 -9 -6 -3 0

10

8

6

4

2

12963

1A

X

Ymm

-8 -6 -4 -2 0

5

4

3

2

1

8642

RS24T-424-PU-_ _

Cable 1 (with marked tube)

Output+24 V WH

Output0V PaleBU

Polarity switching POL

BK Cable 2

Input 1(SI1) BN Input 13(SI13) GN *■ ■

Input 2(SI2) RD Input 14(SI14) BU *■ ■

Input 3(SI3) OG Input 15(SI15) VT *■ ■

Input 4(SI4) YE Input 16(SI16) GY *■ ■

Input 5(SI5) GN Input 17(SI17) BN **

■ ■

Input 6(SI6) BU Input 18(SI18) RD **

■ ■

Input 7(SI7) VT Input 19(SI19) OG **

■ ■

Input 8(SI8) GY Input 20(SI20) YE **

■ ■

Input 9(SI9)

BN

*■ ■ Input 21(SI21) GR **

■ ■

Input 10(SI10)

RD

*■ ■ Input 22(SI22) BU **

■ ■

Input 11(SI11)

OG

*■ ■ Input 23(SI23) VT **

■ ■

Input 12(SI12)

YG

*■ ■ Input 24(SI24) GY **

■ ■

RS24E-424N/P-PU_ _

Cable 1 (with marked tube)

Input+24 V WH

Input 0V PaleBU

In zone Iz BK Cable 2

Output1(SO1) BN Output13(SO13) GN *■ ■

Output2(SO2) RD Output14(SO14) BU *■ ■

Output3(SO3) OG Output15(SO15) VT *■ ■

Output4(SO4) YE Output16(SO16) GY *■ ■

Output5(SO5) GN Output17(SO17) BN **

■ ■

Output6(SO6) BU Output18(SO18) RD **

■ ■

Output7(SO7) VT Output19(SO19) OG **

■ ■

Output8(SO8) GY Output20(SO20) YE **

■ ■

Output9(SO9)

BN

*■ ■ Output21(SO21) GR **

■ ■

Output10(SO10)

RD

*■ ■ Output22(SO22) BU **

■ ■

Output11(SO11)

OG

*■ ■ Output23(SO23) VT **

■ ■

Output12(SO12)

YE

*■ ■ Output24(SO24) GY **

■ ■

Wiring color

■ Polarity switch POL is used to switch the polarity (NPN/PNP) of the sensor connected to the transmission unit.

Check the wiring diagram, and wire it according to the sensor to be connected. If it is not wired, no signal will be detected.

■ When shipped from the factory, the unused core wire of the cable is cut. If the cable is shortened for wiring reasons, the unused

core wire will be exposed. If you shorten the cable for wiring reasons, the unused core wire will be exposed, so please take care

not to short-circuit the cable. Unused wires are as follows: Cable 1: Green*, Blue*, Purple*.

Cable 2: brown*, red*, orange*, yellow*, white, empty. (* indicates a wire with ■ ■ or ** printed on the core wire of each color.)

Wiring Diagram

<When connecting a 3-wire NPN type detection sensor>

Detection sensor

(NPN)

Detection sensor

(DC2W)

(+)

(-)

(出力)

(POL)

(+)

(-)

(SI)

RS24T

Detection sensor

(PNP)

(+)

(-)

(出力)

(POL)

(+)

(-)

(SI)

RS24T

(+)

(-)

(POL)

(+)

(-)

(SI)RS24T

Detection sensor

(DC2W)

(+)

(-)

(POL)

(+)

(-)

(SI)

RS24T

1~2KΩ

PLCRS24E

(+)

(-)

(Iz)

(SO)

<

When connecting a 3-wire PNP type detection sensor

>

<In case of 2-wire detection sensor connection (NPN setting)

>

<In case of 2-wire detection sensor connection (PNP setting)

>

<Connecting to an external PLC, etc.>

1~2KΩ

■When wiring, please check the wiring diagram carefully

to ensure that the wiring is correct.

■When connecting a DC 2-wire sensor, wire a resistance of

about 1 to 2kΩ.

The following is an explanation of the protection functions provided.

Reverse connection protection ... When 24V and 0V are connected in reverse on the power line of the output section, this function turns o the output for a certain

period of time to protect the circuit.

Overheat protection ... is a function that measures the temperature inside the output section and stops the power supply when the temperature exceeds a certain level.

When the temperature drops, it restarts.

Short-circuit protection ... This function turns o the output for a certain period of time to protect the circuit when a current exceeding the specication ows through

the signal output line due to wiring without load.

Overcurrent Protection ... This function detects the current inside the output section and stops transmitting for a certain period of time when the current exceeds a

certain value, thereby protecting the circuit.

Output surge absorption protection...A surge absorption circuit is built in to protect the output circuit.

Head metal confrontation protection ... This function protects the circuit by stopping transmission for a certain period of time when metal is detected.

Protection function

・

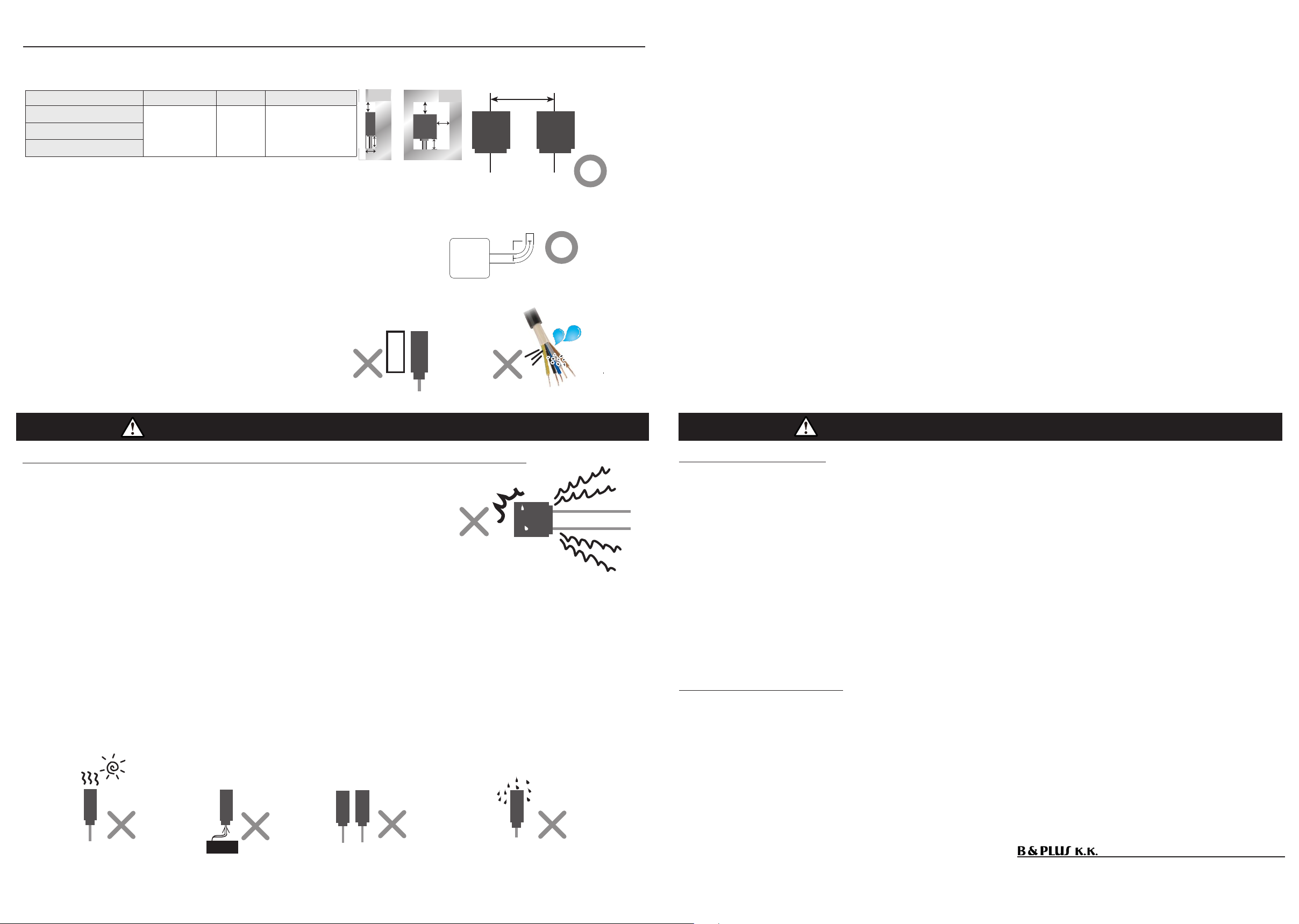

Do not disassemble or modify our products. It may cause a malfunction, re, electric shock, etc., or cause serious damage.

In addition, the warranty will be void if the product is disassembled or modied.

・

If you are in an abnormal condition such as smoke, abnormal noise, or strange odor, discontinue use immediately as there is

a risk of malfunction, re, electric shock, or accident.

・Be sure to use accessories and specied parts. If you do not use it, it may cause malfunction, accident, malfunction, re, etc.

・

If you add or move equipment, please check the installation conditions again.

・

When disposing of this product, dispose of it as industrial waste.

■ About product handling

Other notes Other notes

・The control communication device installed in the product corresponds to a "weak radio station (weak radio wave

device)", so the Minister of Internal Aairs and Communications' radio station permit (diploma) is not required.

However, please be careful when operating it as it may aect electronic devices and medical devices (pacemakers, etc.).

■Standards and regulations

・

A remote sensor system is a system that supplies and transmits power and signals in a non-contact manner. Please do not use it

for any purpose other than this purpose.

・Design with the combination described in the instruction manual or user's guide. Opposition in any other combination may

cause malfunction or damage.

・

Use a constant voltage power supply such as a switching power supply.

(If a power supply with ripples above the rating, such as a full-wave rectied power supply, is used, it may cause malfunction.)

・

If the power supply exceeds the rated voltage, there is a risk of overheating and ignition.

Before supplying power, be sure to check that the power supply is specied in the specications.

・

Design it so that it can be used under the wiring and surrounding environment conditions specied in the specications. Also,

design to satisfy the "transmission distance", "axis deviation", "drive voltage", and "drive current". Designs outside the

specications may cause unexpected malfunctions, troubles, and malfunctions due to deterioration of internal parts.

・

When wiring for installation, maintenance, failure, etc., be sure to check that the main breaker (power panel) is cut before

performing the work. If you work while the line is live, you may get an electric shock or malfunction.

・

As with other electronic devices, inrush current may be generated when the system starts up, so please set the power

supply in consideration of the inrush current.

・

Design the system so that the entire system works safely even if the external power supply is abnormal or the product fails.

・

This product is designed for indoor use. Be sure to use it indoors. Use outdoors may cause an accident, malfunction or re.

Product failures due to mishandling are increasing.

Please be sure to read this manual, and if you have any concerns,

please contact the following before energizing.

https://www.b-plus-kk.jp/ E-mail [email protected]

Precautions for installation and design

・

Please note that the contents and specications of this manual are subject to change without notice.

If you have any questions about the contents of this manual, please contact us.

■

Be sure to check it as there are various dangers such as failure if it is installed incorrectly.

・

To avoid heat generation and ignition due to induction heating, do not put metal

objects between the operating heads.

・

To avoid heat generation and unexpected accidents, remove metal chips and

cutting chips from the transmission surface of the head.

・

To avoid damaging the product due to abnormal heat generation, do not hold the transmission distance

/ axis deviation / overload condition outside the specications for a long time.

・

I

mpact and external noise may cause malfunction or failure. Route the cable away from power lines and high-voltage

equipment without giving a shock. (Fig. 5)

・

Make sure that the total current consumption of the connected devices does not exceed the drive current value.

・In order to consider and reduce the self-heating of this product, take measures so that it can be used below the specied ambient temperature.

・

To reduce the eect of self-heating (heat dissipation), it is recommended to mount it on metal using case mounting screws

.

・

If it is installed in a place where it is exposed to direct sunlight or hot air from a heater, it may cause a re or malfunction. (Fig. 6)

・If you apply power to the transmitter or energize either one with the output sensor facing each other, a failure may occur. (Fig. 7)

・

Please use in an environment where it is not exposed to organic solvents or liquids containing them. (Fig. 8)

impact

Power lines and high-voltage equipment

noise

(+_+) (+_+)

DC24V

( 一 _ 一;)

(;一 _ 一 )

(+_+)

Direct sunlight and hot air Energized by facing each other Liquids such as organic solvents

(Fig. 6) (Fig. 7) (Fig. 8)

(Fig. 5)

(Fig. 2) Cable bending radius

Type code A

(Surroundings)

B(

depth

)C

(Parallel installation)

RS24T-424-PU-_ _

30mm 30mm 165mm

RS24E-424N-PU-_ _

RS24E-424P-PU-_ _

・

When wiring the cable by bending it, use the cable outlet.

Install so that the cable is straight (approximate: about 10 mm)

Install the cable with a bending radius of 50 mm or more. (Figure 2)

・

Excessive force on the cable during installation to avoid excessive

stress Please do not pull with.

・

Fix the cable so that the sensor, the base of the sensor, and the

cable itself are not shaken or shocked.

・

Since metal overheating and internal elements may be damaged,

install the output part so that it does not face metal, and then

turn on the power. (Fig. 3)

・

If water, metal objects, or foreign matter get inside the device from

the end of the cable, it may cause re, smoke, re, electric shock,

or malfunction due to malfunction or short circuit. (Fig. 4)

Installation method

Metal facing output

( 一 _ 一;)

(Fig. 3) (Fig. 4)

(Fig. 1) Arranged with a space

metal

moisture

C

(^_^) (^_^)

Top view

Side view

A

B

金属

A

A

金属

50mm

AA

A

A

金属

A

A

金属

metal metal

((+_+))

metal

Power application

Outputsensor

Transmitter Outputsensor

Foreign material

Foreign material invades inside the sensor

Output sensor

・

To avoid the inuence of surrounding metals and mutual interference between products, be sure to open a space larger

than the value shown in the table below. In addition to the mounting surface, only one surface of A (periphery) can

be in contact with metal. (Fig. 1) The screw tightening torque is 1.5N・m.

This manual suits for next models

2

Other B&PLUS Power Supply manuals