B&PLUS RCD22T-211-CLC User manual

Remote System

User’s Guide

https://www.b-plus-kk.jp/ E-mail [email protected]

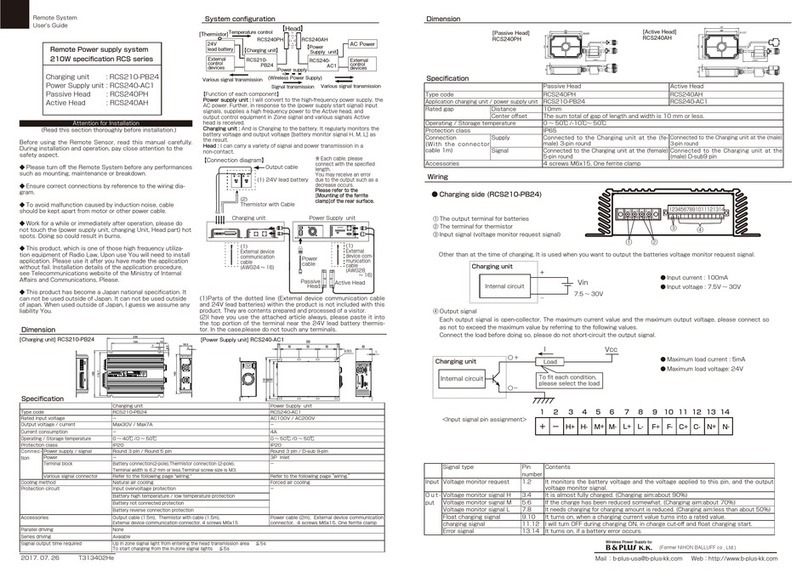

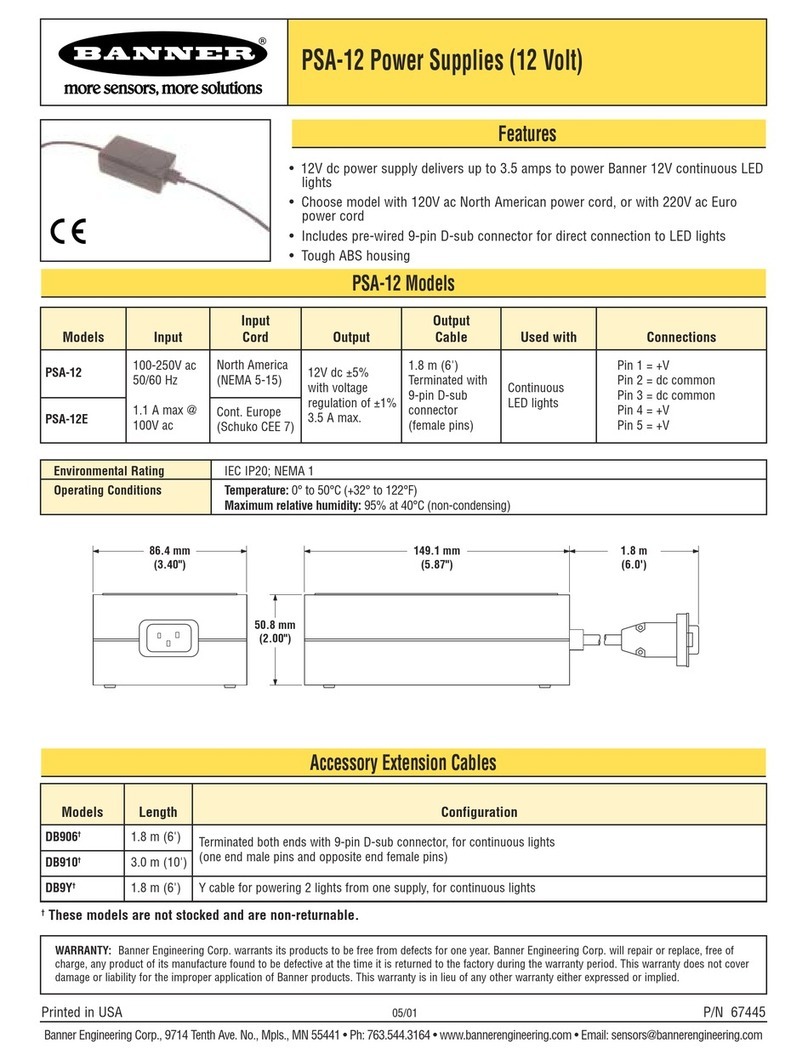

Demensions

Construction of the system

【Function of each Component】

Remote Mounted on a moving side. It transmits CC-Link data to the Base and supplies power to connected CC-Link interface device.

Base Mountes on the fixed side. It transmits CC-Link data to the Remote and supplies power to the Remote inductively through air-gap.

Remote Coupler System

CC-Link version

Remote part :RCD22T-211-CLC

Base part part:RCD22E-211-CLC

*Compatible with CC-Link Ver.1.10/Ver.2.0.

No settings for station type, number of occupied stations, etc.

are required.

*The built-in DIP switches can be used only to set the

communication speed and internal terminating resistor.

*No communication problem even if multiple remote coupler

system CC-Link specifications are used.

0

1

2

3

4

5

6

7

8

-2-4

-6-8-10 2 4 6 8 10

Y

X

mm

Output current ≦ 2A

Type number A(mm) B(mm) C(mm)

RCD22T-211-CLC 50 45 300

RCD22E-211-CLC

T312101Oe

2022.11.15

終端

抵抗

CC-Link

ユ ニ ット

機器

CC-Link

ユ ニ ット

CC-Link

ユ ニ ット

CC-Link

ユ ニ ット

CC-Link

ユ ニ ット

電源

24V DC

終端

抵抗

終端

抵抗

終端

抵抗

CC-Link

ユ ニ ット

機器

Remote part

Base part

The built-in terminating

resistor SW4 in this

conguration example

is set to Base part part

OFF and Remote part

ON.

X:Center off set (mm)

Y:Transmitting distance (mm)

LED indication

Installation

A

B

C

(^_^) (^_^)

Specications

Master

unit

CC-Link

unit

CC-Link

unit

CC-Link

unit

CC-Link data

Terminator

Power supply

24V DC

Terminator

Power supply

-Design the product so that it can be used under the wiring

and ambient conditions specified in the specifications. Also,

design the product to meet the requirements for "transmission

distance," "axis misalignment," "output voltage," and "output

current.

Designing out of the specifications may cause unexpected

malfunctions, troubles, or failures due to deterioration of internal

components.

-In remote coupler systems, the control signal may become

unstable outside of specication. If it aects the operation of

the equipment, start data communication after it is within the

specication range.

-Be sure to attach the included ferrite clamp (gray) to the communication

cable and power cable in two turns, and attach the ferrite clamp (white) to the

communication cable and power cable together in one turn within 20 cm from

the Base part part and Remote part main unit. Figure 2. (Figure 2)

Remote:RCD22T-211-CLC

RCD22T-211-CLC

75

90

90

75

97

63

4-φ5.5

4-φ10 depth 6

FG(faston 0.25")

45

30

10

④②

①

③

①

② ④

Status LED(Green/Yellow) Power LED(Green)

③

Dip-switch

Power

Signal

A66e

RCD22E-211-CLC

75

90

90

75

97

63

4-φ5.5

4-φ10 depth 6

45

30

10

④②

③

①

①

② ④③

A65e

FG(faston 0.25")

Status LED(Green/Yellow) Power LED(Green)

Dip-switch

Power

Signal

Base:RCD22E-211-CLC

pin

signal(4pin) Power(4pin)

1

SLD

+24V

2 DB Not use

3 DG 24G

4

DA

Not use

pin

signal(4pin) Power(4pin)

1

SLD

+24V

2 DB Not use

3 DG 24G

4

DA

Not use

Type number RCD22E-211-CLC

Supply voltage 24 V DC ± 5 % (include ripple)

Current consumption

≦ 3 A

Communication CC-Link data

Communication speed

156kbps....10M bps (Changes by Dip switch)

Data delay

max.30bit

Start-up time

≦ 2 sec*

Operating temperature

0...+50 ℃

Connector Signal/ PowerSignal

M12/4 pin Male Acoding / M12/4 pin Male Acoding

Available connector cable Signal/Power

VA-4DSX5CCG4[5m] / TM-4DSX5HG2-1/3[5m]

Degree of protection

IP 67

Material

Housing Aluminum anodized nish

Active surface

ABS + PBT

Bundled items Ferrite core clamp ( Gray x2 / White x1 )

Type number RCD22T-211-CLC

Output voltage 24V ± 1.5V DC

Output current ≦ 2A

Transmitting distance

3...5mm

Center o-set ± 4mm

Operating temperature

0...+50 ℃

Degree of protection

IP 67

Connector Signal/ Power

M12/4 pin Male Acoding /

M12/4 pin Female Acoding

Available connector cable Signal/Power

VA-4DSX5CCG4[5m] / TM-4DBX5HG2-1/3[5m])

Material

Housing Aluminum anodized nish

Active surface

ABS + PBT

Bundled items Ferrite core clamp ( Gray x2 / White x1 )

* This means the time since the timing when a Remote

part and a Base part are energized within

the transmission area until the timing when the

wireless signal transmission starts. It doesn't mean

the time until the system as CC-Link established.

Transmitting Area Diagram(Non-flush mounted) [Example : Supply voltage at 24V DC]

* When excessive heat is generated.It stops

the power supply and once heat cool-down.

RCD22E would be restarted.

LED Color LED State

Power LED

Green

ON The power supply* is supplied.

Base &

Remote part

OFF The power supply* is not supplied.

Blink Anomalous temperature(turn on : 9s / turn o : 2s)

Base part Green Blink Supply voltage is low. (turn on : 0.5s / turn o : 0.5s)

Blink Supply voltage is high. (turn on : 0.1s / turn o : 0.1s)

Remote part Green Blink Output voltage is low. (turn on : 0.5s / turn o : 0.5s)

Status LED Yellow ON Inzone.

Base &

Remote part Green ON Unusual data is received continuously.

Blink Interval of blinking varies by the baud rate. (Refer to upper table. )

*Indicates External power supply at Base and indicates Base part at Remote.

When temperature and voltage are abnormalities - - -

LED turned on for 6 sec changes to blink of the interval of 0.5

sec or 0.1 sec.

Anomalous TEMP

Anomalous TEMP&Voltage

(0.5 sec interval / Votage low)

6 sec 2 sec

ON

OFF

ON

OFF

-To avoid the inuence of surrounding metal and mutual interference between products,

be sure to open a space larger than the value shown in the table below.(Fig.1)

- When installing a ferrite clamp, be careful not to apply excessive stress

to the cable due to sudden bending at the connector end or both ends of

the ferrite clamp.

- Install so that water and cutting water do not get on the end (wiring

part) of the cable. Moisture is transmitted from the cable core to the main

body, causing short circuits and corrosion.

- When routing cables with bends, install them above the bend

radius of the cables to be used.

Metal facing

( 一 _ 一;)

(Fig.4) (Fig.5)

Foreign material invades inside the sensor

Base part

metal

metal

moisture

Foreign material

- Fix the peripheral cables and install them so that they will not be

shaken or shocked.

- Use the tab terminal (FG) in a place where the noise environment is bad. (Fig.3)

- To reduce the eect of self-heating, it is recommended to install it on

metal using case mounting screws.

- If foreign material get inside the device from the end of the

connector, it may cause re, smoke, re, electric shock, or malfunction

due to malfunction or short circuit.(Fig.5)

- Do not put metal objects between the operating heads.

- Since metal overheating and internal elements may be damaged, install

the base so that it does not face the metal before turning on the power. (Fig.4)

(Fig.2)Clamping

(Fig.3)Installation using the tab terminal

(Fig.1)

arrange with space

CC-Link unit CC-Link unit

Setting ferrite core clamp

CC-Link signal

Max.20cm

Ferrite

core(Gray)

Ferrite

core(Gray)

Ferrite

core(White)

Power

DA

DB

DG

SLD

+24V

24G

FG

DA ④

DB ②

DG ③

SLD①

+24V①

24G③

FG

④ DA

② DB

③ DG

①SLD

①+24V

③24G

FG

DA

DB

DG

SLD

FG

Terminators Terminators

Master unitRCD22ERCD22TRemote unit

External

device

Blue

White

Yellow

SLD

Brown

Blue

FG

Blue

White

Yellow

SLD

Brown

Blue

FG

Please read the CC-Link Installation Manual carefully when wiring.

The following is a wiring example of a T-branch without repeater function.

- The cable color in this wiring diagram shows the cable color when using the recommended connector cable. When

wiring, check the instruction manual of the cable you actually use before wiring.

- Connect "Terminators" between DA-DB of the last unit on the CC-Link network.

- When this unit mounted on the both end of CC-Link network, please set the Dip switch SW4 to ON.(Refer to the

followiing Setting for Switch and Status LED indication (Remote part/Base part part)

・When installing with T-branch wiring, set the communication speed to 625 kbps or less.

- For wiring of external power unit 24V DC to FG, please return to wiring.

Connect "+" of power unit +24V DC to a terminal indicated [+24V] , "-" to [24G].

- Always use a constant voltage power supply such as a switching power supply.

(Use of a power supply with a ripple greater than the rated value, such as a full-wave rectier power supply, may cause

malfunction.)

- Please set the cable length to consider the total length of the entire network according to CC-Link manual.

- When the Remote part and the Base part are not facing each other, no signal is sent from the Remote part, but there is

no problem in communication on the Base part.

Wiring sample

Wiring diagram between master unit and slave

Setting for Switch and Status LED indication (Remote part/Base part part)

Communitation speed is set with S W1~3, when SW4 is turned on, Terminator(110Ω)can be used.

インジケータLED(緑/黄) パワーLED(緑)

ON

OFF

SW4:終端抵抗(110Ω)ON/OFF

SW3~1:ボーレート設定

*Always make changes to the DIP switches

with the power turned off.

If changed while energized, communication

is disabled and the status LED blinks at 0.5

second intervals.

*If the dip switch lid is opened, close it tightly

to prevent water from entering.

Initial value

(default)

SW 1:OFF

SW 2:OFF

SW 3:ON

SW 4:ON

Status LED(Green/Yellow)

SW1 ~ 3:commnunication spped set up

SW4:Terminator(110 Ω )ON/OFF

ONOFF

Pwer LED(Green)

No. = Pin assignment (refer to the dimensional outline drawing)

通常

master

station

Terminator

Terminator

slave

station

slave

station

slave

station

slave

station

slave

station

master

station

支線分断

Terminator

Terminator

SW4 → OFF

SW4 → ON

Terminator

slave

station

slave

station

slave

station

slave

station

slave

station

幹線分断

Terminator

Terminator

SW4 → ON SW4 → ON

master

station

slave

station

slave

station

slave

station

slave

station

slave

station

複数設置

Terminator

Terminator

Terminator

SW4 → ON SW4 → ON

SW4 → OFF

SW4 → ON

SW4 → OFF

SW4 → ON

Terminator

master

station

slave

station

slave

station

slave

station

slave

station

slave

station

Remote part Base part

Terminator

(110 Ω)

Terminator

(110 Ω)

■ for RCD22T(Remote part)

bending radius = 24mm

bending radius = 46mm

bending radius = 24mm

White Gray

bending radius = 46mm

■ for RCD22E(Base part part)

Communication cable VA-4DSX5CCG4 (M12/4 pin female,5m)

Power cable :TM-4DBX5HG2-1/3 (M12/4 pin male,5m) Power cable:TM-4DSX5HG2-1/3 (M12/4 pin male, 5m)

Ferrite clamp(White):DK-Z/RFC-H13

45°

M12 × 1.0

φ 14.5

113

41.7

(5m)

30

45

45°

φ 14.5

M12 × 1.0

9

15.5

42 (5m) 30 45

45°

M12 × 1.0

φ 14.5

115.5

40 (5m) 30 45

1----------------------SLD

2---------------------- White

3----------------------Yellow

4---------------------- Blue

1----------------------Brown

2---------------------- ×

3----------------------Blue

4---------------------- ×

1----------------------Brown

2---------------------- ×

3----------------------Blue

4---------------------- ×

Ferrite clamp(Gray):DK-Z/E04SR401938

Communication cable VA-4DSX5CCG4 (M12/4 pin female、5m)

45°

M12 × 1.0

φ 14.5

113

41.7

(5m)

30

45

1----------------------SLD

2---------------------- White

3----------------------Yellow

4---------------------- Blue

Communication speed

SW3 SW2 SW1 LED status Interval when LED blinks

156kbps OFF OFF OFF

Lighting once every 2 seconds.

625kbps OFF OFF ON

Turning o once every 2 seconds.

2.5Mbps OFF ON OFF

Lighting twice every 2 seconds.

5Mbps OFF ON ON

Turning o twice every 2 seconds.

10Mbps ON OFF OFF

Lighting 3 times every 2 seconds.

--- ON OFF ON LED keeps on when set error

--- ON ON OFF LED keeps on when set error

--- ON ON ON LED keeps on when set error

■Setting for Switch

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

devide

the drop line

multiple

installations

Normal

wiring

devide the

trunk line

Optional parts

【communication cable / power cable】

Recommended connector cable is available as an option. Please use in combination with the remote coupler system.

[Ferrite clamp]

The included Ferrite clamp is available as an option in case it is damaged or lost.

Other note

-The remote coupler system is a system that supplies and transmits power and signals in a non-contact manner. Please

do not use it for any other purpose.

-Design with the combination described in the instruction manual or user's guide. Opposition in any other combination

may cause malfunction or damage.

-If power exceeds the rated voltage, there is a risk of heat generation and ignition. Before supplying power, be sure to

check that the power supply is specied in the specications.

-Design so that it can be used under the wiring and surrounding environment conditions specied in the specications.

Also, design to satisfy the "transmission distance", "center o-set", "output voltage", and "output current". Designs

outside the specications may cause unexpected malfunctions, troubles, and failures due to deterioration of internal parts.

-When wiring for installation, maintenance, failure, etc., be sure to check that the main breaker (power panel) is cut

before performing the work. If you work on a live line, you may get an electric shock or malfunction.

-As with other electronic devices, inrush current may occur when the system starts up, so set the power supply in

consideration of the inrush current.

-

Please be sure in the withstanding voltage test that a capacitor (50VDC 3.3nF) is built in between the each

pouwer supply pin (+24V/24G) and the FG.

-Design the system so that the entire system works safely even if the external power supply is abnormal or the product fails.

-Please be careful about the inuence on the material degradation due to the installation environment and the intrusion

of foreign material. Especially when using it outdoors, please install it with less inuence from ultraviolet rays.

https://www.b-plus-kk.jp/ E-mail [email protected]

Precautions for installation and design

■ Be sure to check it as there are various dangers such as failure if it is installed incorrectly

- Impact and external noise may cause malfunction or failure. Wire the cable away

from power lines and high-voltage equipment without giving a shock. (Fig. 6)

-This product has the CE mark on the exterior of the product. However, we do not

support surges, so if you use the cable with a cable length of more than 10 m,

take measures to prevent excessive surges from being applied.

-Use within the range where the total current consumption of the connected devices does not

exceed the output current value.

-To consider and reduce the self-heating of this product, take measures so that it can be used

below the specied ambient temperature.In order to reduce the eect of self-heating (heat

dissipation), it is recommended to mount it on metal using case mounting screws.

-Installed in a place where it is exposed to direct sunlight or hot air from a heater, it may cause

a re or malfunction. (Fig. 7)

-If you apply power to the remote unit or energize either one with the base units facing each

other, a malfunction may occur. (Fig. 8)

-Please use in an environment where organic solvents and liquids containing them do not come

in contact. (Fig. 9)

((+_+))

impact

Power line and high-voltage equipment

noise

(+_+)

(+_+)

24V DC

(+_+)

(+_+) (+_+)

Direct sunlight

and hot air apply

power

energize facig each other

Base part Base part

Liquies such as

organic solvents

(Fig.7) (Fig.8) (Fig.9)

(Fig.6)

Remote part

Product failures due to mishandling are increasing.

Please be sure to read this manual, and if you have any

concerns, please contact the following before energizing.

-Do not disassemble or modify our products. It may cause a malfunction, fire, electric shock, etc., or cause serious

damage. Also, if it is disassembled or modied, it will not be covered by the warranty.

- If you are in an abnormal condition such as smoke, strange noise, or strange odor, stop using the product immediately

because there is a risk of malfunction, re, electric shock, or accident.

- Be sure to use accessories and specied parts. If you do not use it, it may cause malfunction, accident, malfunction, re, etc.

- If any equipment is added or moved, please check the installation conditions again.

- If any equipment is added or moved, please check the installation conditions again.

■ About product handling

・The control communication device installed in the product corresponds to a "weak radio station

(weak radio wave device)",

so the Minister of Internal Aairs and Communications' radio station permit (diploma) is not required.

However, please be careful when operating it as it may aect electronic devices and medical devices

(pacemakers, etc.).

・ When using the product outside Japan, please check the standards and regulations that the system should comply

with and take appropriate measures.

■ Standards and regulations

・Please note that the contents and specications of this manual are subject to change without notice. If you have any

questions about the contents of this document, please contact us.

This manual suits for next models

1

Other B&PLUS Power Supply manuals