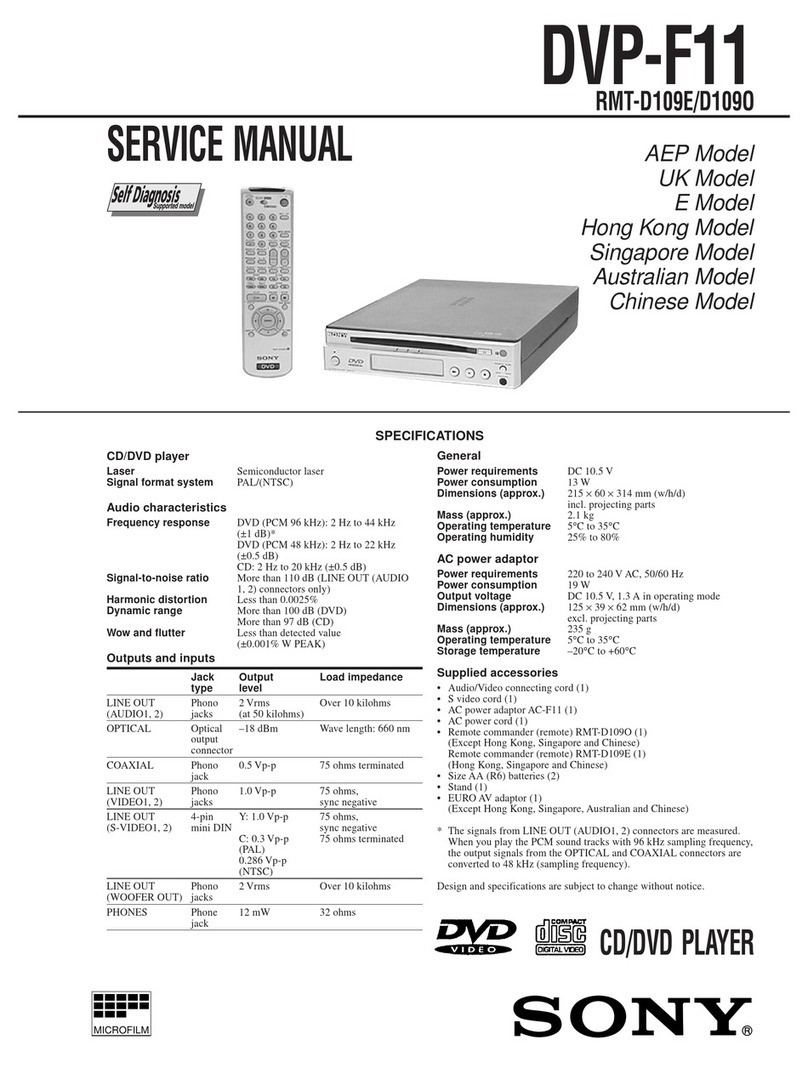

Converting mains voltage supply

The Master Unit has only one variant for all markets.

The Socket Unit has separate type nos. for each market, due to country approvals.

The mains voltage is determined by the type nos. of the Socket Unit, there are

only two internal mains voltage settings (a jumper) on the SMPS, 100/120V and

230/240V AC. (X103, when mounted = 100/120V).

Use the ServiceTool to reprogramme the DVD region code and tuner setup.

The only variant on the Master Unit : 2802

The variants on the Socket Unit :

Type no. Area Region Mains Voltage Market

2825 EU2 DVD region 2 230V Austria, Belgium, Croatia,

Czech Repub., Denmark, Egypt,

Finland, France, Germany, Greece,

Holland, Hungary, Israel, Italy,

Lebanon, Norway, Oman, Poland,

Portugal, Qatar, Saudi Arabia,

Slovak Rep., Slovenia, Spain,

Sweden, Switzerland, Turkey

2826 EU3 DVD region 3 240V Indonesia, Malaysia, Singapore,

Thailand

2827 EU4 DVD region 4 230V Argentina, Chile, Peru, Uruguay

2828 EU5 DVD region 5 230V Morocco, Russia

2829 GB2 DVD region 2 230V Bahrain, Kuwait, South Africa, UK,

United Arab Emirates

2830 GB3 DVD region 3 230V Hong Kong

2831 US1 DVD region 1 120V Canada, USA

2832 US4 DVD region 4 120V Brazil, Mexico

2833 JP2 DVD region 2 100V Japan

2834 AU4 DVD region 4 240V Australia, New Zealand

2835 TW3 DVD region 3 110V Taiwan

2836 KR3 DVD region 3 110V Korea

2837 LA4 DVD region 4 230V Argentina, Chile, Peru, Uruguay

2838 CH6 DVD region 6 230V China

DVD Region setup

First time the Master Unit is connected to the Socket Unit, and powered, the DVD

region code is set, and stored.

How to service 1.3